Many drivers know how to drive an Audi A4 automatic transmission. But for some, our article will serve as a small introductory lesson on the topic of studying automatic transmissions of this well-known automaker.

A bit of history of the Audi brand.

The father and inspirer of the Audi car brand is Ferdinand Pich, who in 1974 took over as head of the company's advanced development department. Being not only a talented designer, but also a competent, discerning marketer, Pich managed to convince the company's management of the need to radically change the company's position in the market.

He began the development of an all-wheel-drive passenger car, experimenting with aluminum, and in 1980, Audi surprised motorists around the world with the introduction of an all-wheel drive sports coupe at the Geneva Motor Show. Audi quattro... This model became truly revolutionary, since before that all-wheel drive was the privilege of trucks and SUVs. For Pih, it was a kind of experiment that fully met his expectations. Continuing to develop the concept of four-wheel drive in passenger cars, he launched in 1984 the Audi 90, which was developed only for US sales, and its European counterpart, the Audi 80.

Audi Quattro 1980

The Audi 100, which was released in 1990, became the most expensive model of the automaker. This is the first car that Audi has used in the premium segment. Wealthy customers could purchase a model with a new six-cylinder V-type engine, which was the lightest and most compact among its counterparts of similar power.

Audi 100

Audi 100 Thanks to the new fuel injection system and other innovative solutions, Audi engineers managed to remove 174 horsepower from the 2.8-liter unit. At the same time, the new engine retained great power even at high revs.

New representative in the lineup

Continuing to conquer the elite segment of the car market, the automaker releases the Audi A8 sedan in 1994. The heavy and powerful executive car was popular due to the increased stability (and therefore safety), which was provided by the same four-wheel drive.

In 1996, the company presented the world with a compact Golf class car - the Audi A3.

Audi A8

Audi A8 The development costs of the model were minimal, since the production of this car was based on the already finished VW Golf platform. However, thanks to the sporty style and high quality of the interior, the class of the car was one step higher, which brought it closer to competitors from Mercedes and BMW.

For a long time, Audi did not offer anything worthy of SUV enthusiasts, while the company's competitors offered their customers several models of cars of this class. The Q7 SUV, which appeared in 2005, made up for this delay, instantly gaining popularity among fans of giant cars.

Model A4.

The successor of the Audi 80, which was produced from 1986 to 1994, is the A4 model, which entered the series since November 1994. The car has acquired a more impetuous outline of the body, and the magnificent interior of the cabin conquers with its comfort. Along with this, the new model has implemented a number of improvements related to passive safety: the car is better able to withstand a blow to the side pillars, two side airbags are added to the basic configuration (in addition to the two front ones)

1994 Audi A4

1994 Audi A4 Motorists can order this model in one of several variations:

- 1.6 or 1.8-liter petrol engine with 4 cylinders (with 101 and 125 hp respectively),

- 2.6 and 2.8 liter V-shaped six-cylinder engines (174 hp),

- and a 1.9-liter turbodiesel (110 hp).

The car body is made of galvanized steel, thanks to which it is completely protected from corrosion. The proof of reliability and quality is the 10-year body warranty provided by the manufacturer.

Models with a gasoline engine were equipped with Tiptronic, which allowed shifting gears in manual mode. This option enables an experienced driver to show their skills.

Automatic transmission for Audi A4.

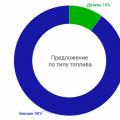

There are now two models of automatic transmission used in the Audi A4:

- "AG-4" for a naturally aspirated four-cylinder engine developed by VW;

- "5 HP 18" for a six-cylinder engine (developed by ZF).

New Audi A4 with automatic transmission

New Audi A4 with automatic transmission Both models are controlled electronically and hydraulically. The inclusion of gears depends on the following parameters:

- engine speed;

In addition to the input parameters, the control takes into account:

- the driver's driving style (recognizing it, the automatic machine independently sets the gear shift points);

- terrain (the shift mode on a mountain road will differ from the mode on a flat road).

How to operate this automatic box.

- Driving off the car. As soon as you start the engine, put the car on the brake, and only then move the selector lever from position P or N to the desired range of motion. Otherwise, your car will start moving at a low speed.

- Do not, under any circumstances, press the brake and accelerator pedals at the same time. Under normal conditions, the automatic transmission should be in the "D4" position constantly.

- Operate the accelerator pedal smoothly, without jerking. In this case, switching of the automatic transmission to higher gears will occur quickly, thereby ensuring low fuel consumption. Use the ranges "2" "1" only in those cases when you need to perform quick engine braking or exclude unnecessary switching of the machine to higher gears.

- Kick-down mode. At low speeds, you can go down to a lower gear by pressing the accelerator pedal all the way down. This will allow you to use the full power of the engine to accelerate the vehicle.

- Stopping the car. When the car stops, the selector lever can remain in one of the driving ranges. The engine will idle.

Gearbox selector lever Audi A4

Gearbox selector lever Audi A4 - At the moment of stopping on a slope, if one of the driving ranges is switched on on the automatic transmission, and the car is held by the brake, do not increase the crankshaft speed. Turn off the engine during a long stop.

- Maneuvering. When maneuvering in small areas (garages, parking lots, etc.), use the mode with the accelerator pedal fully depressed. Adjust the speed by lightly pressing the brake pedal. Never press the brake and accelerator pedals at the same time.

Automatic transmission diagnostics.

There are many diagnostic methods for an automatic transmission. Consider the main ones that allow you to assess the condition of the automatic transmission.

- Oil condition and level.

- The level is checked with a dipstick with risks marked on it. The oil should be pure red, with no burning smell. If the oil is drained into a separate container, then whitish streaks should not remain when it is stirred.

Engine compartment of Audi A4 with V6 engine

Engine compartment of Audi A4 with V6 engine Ready time. Warm up the vehicle to normal idle speed. Standing on the brake, switch N—\u003e D and N—\u003e Dh and note the time before the jolt (the moment the machine is turned on). It should not exceed 1 second. Now switch N -\u003e R and time again. You should have less than 1.2 seconds. If the time intervals are higher than indicated, then this means wear of the clutches.

Diagnostics on the road

- Select a straight section of road.

- Check the position of the accelerator and its indication on the instrument panel.

- With the selector in D, alternately accelerate and decelerate the vehicle at half and full throttle. Make sure you switch 1—\u003e 2, 2—\u003e 3, 3—\u003e 4 and 4—\u003e 3, 3—\u003e 2, 2—\u003e 1.

- While driving in fourth gear, switch the selector to position 5 and make sure that the shift from 4 to 3 occurs immediately.

- Enter Dh mode. See if there is any inclusion 1 and 4, and how the switching is going on 2-\u003e 3 and 3-\u003e 2.

- While the car is moving in gears 2, 3, 4, listen, perhaps the automatic transmission is humming.

Diagnostics by codes... There is a diagnostic connector located under the hood of your vehicle. Connect a jumper between the TAT and GND contacts and turn on the ignition. The HOLD light should light up once for a few seconds and then go out. If after that it continues to flash with impulses (short or long), the automatic transmission of your car needs to be repaired.

Audi A4 Routine Maintenance

Audi A4 Routine Maintenance Diagnostics of the mechanical part of the automatic transmission. It is carried out without disassembly by checking the pressure (linear) in all modes. But this procedure cannot be carried out without special equipment.

Repair of the automatic transmission Audi A4

Automatic transmission repair always begins with diagnostics (often computer). Sometimes it happens that, as a result of diagnostics, a reason is revealed that is not related to mechanics, but to the electrics of the machine. About how much it costs to repair an automatic gearbox, you can only talk after the volume and complexity of the work has been determined.

The most common reason for the failure of the machine is banal negligence in relation to timely maintenance. For example, if the oil and oil filter were not changed in time, and the box was allowed to overheat (slipped, towed a trailer, your car has a clogged radiator, etc.), then the following will happen:

- There is a shortage of oil on the torque converter slip bushing;

- The bushing turns, the rest of the oil flows out of the box;

- Clutches burn out without oil.

For example, the cost of repairs in this case (oil and filter replacement) will be about 3000 rubles.

Cars with CVT transmissions have recently become more popular among our compatriots. This type of gearbox is relatively new, so not every motorist knows about the device and the advantages of using such a unit. What is the Audi A4 variator, what are its design features and disadvantages, we will tell you in this article.

[Hide]

What kind of variator is used on Audi?

The first manufacturers to equip their vehicles with variable speed transmissions (CVTs) were Volkswagen and Audi. The company equips the Audi A4 and A6 models with Multitronic transmissions. This type of gearbox belongs to continuously variable transmissions. The consumer characteristics of the Multitronic are quite high. The model of the check point "01J" is installed in A4 and A6 cars.

Gearbox CVT Multitronics 01J

CVT design features

If we talk about the design, then the main components of CVTs on Audi are:

- Two wet multi-plate clutches. They are used to disconnect the power unit from the transmission. According to the clutch device - forward and reverse friction clutches. By design, these elements look similar to devices used in conventional automatic transmissions. But CVT clutches have certain advantages when compared to a torque converter. For example, there are all fewer of them, they are compact in themselves and easier to manage.

- Planetary reductor. This component is only used for reversing. When the vehicle is traveling forward, the mechanism is blocked by the forward clutch. And when the driver engages the reverse gear, the corresponding clutch locks the ring gear of the mechanism to the transmission case. As a result, the gearbox starts moving in the opposite direction. The transmission control system limits the reverse travel speed.

- CVT transmission. This device is designed to smoothly change the transfer parameter. Its main structural components are driven and driving pulleys, they are connected by a chain. Each pulley consists of two shafts with a tapered surface. The drive element is connected to the vehicle's internal combustion engine crankshaft through an intermediate gear. And from the driven shaft, the torque is supplied to the main gear. When the transmission is running, one of the shafts on the pulley will move so that the control system can measure its diameter.

- Metal chain. Audi was pioneering by being the first to use chain in transmissions. Its use made it possible to increase the range of gear ratios due to a decrease in the contact surface of the chain with the shaft, when compared with wedge-shaped belts. To make the metal chain less noisy, the engineers used links of different sizes in it.

- Pressure and adjusting hydraulic cylinders are installed on each shaft. The adjusting mechanism allows you to adjust the gear ratio, that is, changes the shaft diameter. The clamping device performs the function of pressing the chain against the shaft discs. A torque controller is used to ensure optimum downforce. This sensor is mounted on the drive shaft.

- Differential and main gear.

- A control system is used to ensure the correct operation of the unit. It contains input controllers, a control unit and a hydraulic mechanism that acts as an executive device. Input controllers are used to assess the position of the gear lever, the number of revolutions at the input of the gearbox, as well as at its output. The sensors monitor the temperature and pressure level of the transmission oil. The control device is designed to select the optimal gear ratio, taking into account the driving conditions and the driver's wishes. In accordance with the data received from the controllers, the control unit determines the oil pressure level in the system and implements it by acting on the solenoid valves. The device itself is mounted at the checkpoint. The actuator controls and cools the cylinders, forward and reverse clutches, changes the oil pressure in the transmission.

- Oil pump. Used to circulate transmission oil.

- Ejection pump. This device is used directly to cool the clutches. Its principle of operation is based on the supply of transmission oil through a vacuum. The cooling process is carried out in a heat exchanger, which is part of the motor cooling system.

- According to Audi engineers, the use of "Multitronic" CVTs made it possible to ensure optimal dynamics when moving the vehicle. Fuel economy is also achieved during normal operation of the box.

What is the service life?

Before buying a car with CVT, many motorists are interested in the question of how much the CVT travels on average. The service life in vehicles Audi 2012 or other model year may be different. It happens that the box serves 40 thousand km, and sometimes it fulfills 200 thousand kilometers without any complaints. It all depends on the conditions of use and maintenance of the machine. Precisely because CVTs are very sensitive to misuse, many potential car owners bypass cars with a CVT side.

You can repair the CVT transmission from an authorized dealer or service station. Service at the "officials" is relevant if the vehicle is still under warranty. The cost of repairs at a dealer is higher than at specialized service stations.

List of errors

A common type of CVT breakdown is failure of the electronic unit. You can try to fix the problem by flashing the device, but the dealer usually changes the ECU. Car owners are faced with the problem of breaking a metal chain. "Officials" in such cases change the entire gearbox assembly.

Carrying out computer diagnostics of the CVT transmission, you can get error codes that indicate the following problems:

- 17105 P0721 or 17106 P0722 - the output speed sensor has broken down, this leads to the absence or supply of an incorrect signal from the control device;

- 17114 P0730 - diagnostics show an incorrect ECU gear ratio;

- 17134 P0750 - the ABS / EDS unit is broken or does not work correctly;

- 17137 P0753 - problems in the operation of the transmission electrical circuit;

- 18201 P1793 or 18206 P1798 - the sensor for the number of output revolutions has broken down or is not functioning correctly, with such a problem the signal from the controller will be either incorrect or completely absent;

- 17090 P0706 - the transmission selector position sensor is out of order or not adjusted.

Emergency mode

Why the emergency mode of the variator turns on and how to solve the problem - find out from the car owner's review on the video (the material was filmed and published by the Cars and Upgrade channel).

In emergency mode, the variator gearbox works when there are problems in the operation of the control unit, electrical circuit failure. If this mode is activated, the PRND scale on the dashboard will immediately light up. Other signs of malfunction:

- the driver presses the gas pedal, the car starts jerking;

- when switching speeds, the car jerks;

- in some cases, it is not possible to activate the reverse speed;

- when the gearbox goes into emergency mode, the car cannot be removed from the parking mode.

Mechanical breakdown

Mechanical faults include:

- damage to electrical wiring, open circuit;

- oxidation or damage to contacts on sensors or control unit;

- open metal circuit CVT;

- mechanical damage to controllers;

- failure of the control unit as a result of mechanical impact on it, in this case, flashing the device will not help.

An example of what failures can occur in the operation of a CVT transmission is shown in the video (the material was filmed and published by the user Ilya Filyaev).

How do I change the oil?

Replacing consumables begins with the purchase of an original oil.

For use in Audi CVT gearboxes, General Motors has released a special grease, which is called ATF AUDI G052180A2.

If you are having difficulty finding an original oil, then you can replace it with Mobil1 LT71141. This liquid is no worse in quality, but its cost is on average 50% less. The oil should be changed every 60 thousand km. With this run, the liquid usually loses its properties. In principle, you can use any other oil, the main thing is that it meets API or SAE standards. When buying a lubricant, purchase:

- filtering device;

- sealant;

- rubber gasket for the pallet.

The volume of the purchased oil canister should be 5 liters.

As for the filters, there are two of them in CVT transmissions. One of them is mounted directly in the unit itself, therefore, to replace it, you will need to disassemble the unit. The second filter is the part of the tube connected to the radiator. This tube is only replaced if it becomes clogged or foreign particles are found in the lubricant.

In addition to the filter and the liquid itself, prepare:

- socket wrench -3357;

- hexagon;

- construction or medical syringe for filling with a special tube;

- clean rags.

Below is a detailed video instruction on self-changing the working fluid in a CVT gearbox (video filmed and published by Artur Prokurov).

It is necessary to change the lubricant in a garage with a pit or on an overpass, if possible, use a lift. The vehicle must be positioned horizontally and secured. The replacement process is performed like this:

- Place a bowl or an old bucket under the drain hole of the variator box, into which the "mining" will be collected. If you drove the car onto a lift, then you can additionally flush the checkpoint. To do this, start the car engine, set the gearshift lever to the "Tiptronic" position, that is, to the manual gearshift mode. From the first gear, in turn, go to the highest gear, letting on the gas when the selector is shifted to each subsequent mode. In this case, the speed should be no more than 50 km / h. Then apply the brake, set the clutch lever to R and accelerate to 20 km / h. Press the brake again and set the selector to mode D. This procedure should be repeated five times, and then set the lever to position P and turn off the engine.

- When the motor has cooled down a little, you can start replacing. Climb under the bottom of the car. There you will see two plugs on the transmission. These are the drain and filler holes, which are also used to control the lubricant level. The drain plug is usually made of aluminum, and when unscrewing it, be careful not to damage the threads. After unscrewing the cover, the process of draining the oil from the variator will go. In total, about five liters should come out of the system. Be careful not to get the grease on your skin.

- After draining the consumable from the transmission, remove the bolts that secure the pallet. After dismantling, remove metal particles from the magnet. After removing the wear debris, degrease the bottom of the sump with solvent, remove the old gasket and clean the place for a new one.

- Remove the filter element and seal from the transmission. Then put the pallet in place. Install the drain plug with a new O-ring.

- Then unscrew the screw or plug from the inspection hole.

- First, pour new oil into a syringe and connect a previously prepared tube to it. Pour consumables in small doses through the inspection hole into the transmission. Pour the oil until it flows over the edge. On average, an Audi CVT transmission contains about 4.5 liters of fluid.

- Install the filler plug and start the engine. It should run for a few minutes, after which its speed should be increased to 2500.

- Please note that the level of consumables in the box depends on the temperature of the gearbox. Therefore, if possible, connect a computer with specialized software to the diagnostic connector and check the temperature level. The checked parameter should be no more than 30-40 degrees. At a lower temperature, you can pour the liquid, and at a high temperature, you can underfill. Both are dangerous for the transmission. Therefore, after the gulf, it is imperative to check the lubricant level in the gearbox with your own hands. If necessary, add oil to the system without shutting down the engine. As you remember, oil is poured until it pours out of the control hole. Screw on the cover.

- Step on the brake pedal and shift all gears one by one. Linger on each of them for a few seconds. Check the level again.

- Good car dynamics. A vehicle can accelerate an order of magnitude faster than a car with an automatic transmission.

- Driving a vehicle with a CVT is generally softer. Due to the lack of gears, there are no jerks when shifting them.

- Profitability. CVT cars generally use less fuel than automatic cars.

- Possibility to control the vehicle both in automatic mode and in manual mode. If the driver gets tired of the automatic transmission, he can switch to manual control and independently change gears in accordance with his needs.

Main disadvantages:

- The reliability of the CVT is poor. If you are wondering if the CVT is reliable, then as we said, this type of gearbox often fails. Moreover, it can break even after 40 thousand kilometers. The weak point of variator gearboxes is the control unit.

- A sophisticated and expensive service. CVT transmissions are not as widely used as automatic transmissions. Accordingly, they are not yet as well studied by specialists at service stations. Therefore, only authorized dealers are usually engaged in the repair of such transmissions.

- One of the weak points of the variator is the chain. As a rule, its resource is about 100-150 thousand kilometers. But it happens that it wears out earlier. And its replacement is not a cheap pleasure.

- CVT gearboxes require special lubrication. Moreover, for each car model with CVT, a specific oil must be used. The cost of consumables is rather big, and you can't use unsuitable fluids.

When purchasing an A4, you can choose between a five-speed manual transmission, a new type of continuously variable automatic transmission (Multitronic) and an automated transmission with manual shifting (Tiptronic).

All forward gears in the five-speed gearbox are fully synchronized, with the individual gear ratios matched to the respective engine power.

Gears last a very long time. If, despite this, a malfunction occurs in the gearbox, then it should be repaired in a workshop. Dismantling shafts and gears requires special tools and appropriate knowledge. Even workshops, as a rule, send gearboxes requiring repair to special enterprises.

Engine power is transmitted through the clutch to the primary (input) shaft of the gearbox. There are five gears on this shaft (and another gear for reverse gear). These gears constantly mesh with the corresponding pinions on the output shaft. The gears of both shafts are supported on needle rollers, that is, there is no rigid connection between the shaft and the gear.

Gears and shafts

The gears rotate freely until one of them, due to the inclusion of a gear, meshes with the corresponding gear on the other shaft. To do this, on each shaft, first a rigid connection is made between the gear and the shaft with the help of the synchronizer blocking ring, after which the gear sits rigidly on the shaft and can interlock with the mating gear to transmit force. In order for the gears to mesh with each other, the shaft speeds must match. For this purpose, part of one shaft, by means of friction elements, slides over part of the other shaft. Due to friction, the shaft, which rotates faster, is braked until both shafts rotate in sync.

Forward and reverse gears

The first three gears are crawler gears. The fourth gear is direct, the engine speed is transmitted approximately in a 1: 1 ratio. When fifth gear is engaged, the transmission output shaft rotates faster than the engine crankshaft. Naturally, the car must also have a reverse gear. For this, an additional gear is located on each drive shaft, which reverses the direction of rotation of the drive wheels. When a gear is selected using the gear lever, the movements of the lever are transmitted through the gear shift bar to the shift segment located on the gearbox.

Continuously variable Multitronic transmission

The newly designed Multitronic transmission accelerates faster and uses less fuel. In addition, the Multitronic transmission offers more comfort than a five-speed manual gearbox. Audi Multitronic has undergone a number of changes, improvements and enhancements, so it differs from the previous CVTs. Thanks to the optimally designed hydraulics, the shifting processes are very dynamic and without coasting. Thus, the disadvantage of the old CVTs ("rubber band effect" or "slip clutch syndrome") is a thing of the past. The disadvantages of the previous CVTs are also eliminated thanks to the regulation modes, which have been partially revised. The aforementioned “rubber band effect” is eliminated by the electronic speed tracking system, which provides dynamic driving performance while maintaining the same noise pattern.

In addition, the electronics take part in a dynamic driving ratio control program 8 (DRP). This program, based on how the driver presses the accelerator pedal, determines the driver's desire - he wants to get maximum power from the engine, or, conversely, to save fuel. In the latter case, on the basis of the multidimensional characteristic of the engine speed, which is stored in the memory, the switch to a low gear ratio occurs already at a speed of 60 km / h (acceleration gear). If the driver goes full throttle (presses the accelerator pedal sharply all the way), the electronic circuit immediately switches to sporty driving characteristics and engages such a gear ratio (downshift) that the high revs required for maximum power are achieved even at low speeds. During normal driving, the electronics selects the most suitable gear ratio in the range between two extreme values, and, in contrast to the shifting processes in a manual transmission, here all gear ratio changes occur completely imperceptibly and without jerks. In addition, the electronics detect uphill and downhill movements and help the driver by compensating for power or, conversely, increasing the braking torque when braking the engine. The highlight of this program is the so-called "manual mode", in this mode, six fixed steps are switched in an additional rocker or using a lever on the steering wheel, and in this case the switching occurs smoothly, without jerks.

The principle of the variator

In the process of designing the Multitronic gearbox, Audi engineers were able to create a continuously variable variator with a new transmission element (the so-called lamellar chain), which allows high forces and torques to be transmitted over a long period of time.

Moreover, this variator, in which the ratio between the maximum and minimum gear ratios is 6, surpasses all previous types of automatic transmissions in relation to the largest and smallest gear ratios. Thanks to its high maximum gear ratio, the variator, for example, facilitates starting off and eliminates the need for a hydraulic torque converter.

Instead, Audi uses an oil-cooled multi-plate clutch, which not only eliminates the transmission losses typical of a converter, but also allows different starting algorithms. These algorithms are selected by the electronics in accordance with the driver's intentions, which again are determined by the way in which he presses the accelerator pedal.

In addition, the hydraulics have been designed in a special way. The variator uses a two-plunger principle, due to the separation of the oil flow between the high-pressure circuit and the cooling circuit, a much smaller pump is required compared to the conventional design. This allows you to increase the efficiency. transmission and improve the car's driving performance.

Magnesium crankcase transmission

In addition to the aluminum crankcase gearboxes, the Audi A4 is also equipped with a magnesium crankcase.

To avoid contact corrosion, use only genuine Audi parts (bolts and attachments). Damage resulting from contact corrosion is not covered by the warranty. A gearbox with a magnesium housing can be recognized by the lettering "Mg AI 9 Zn 1" located on the left side of the gearbox.