All mechanisms of the car have certain controls. The clutch of the machine is controlled by the driver using a pedal, which exerts pressure on the mechanism for transmitting force to parts that directly separate the engine and transmission. One of the methods of transmitting such force is a hydraulic drive, the main part of which is the clutch master cylinder.

Purpose and principle of operation

The clutch mechanism in cars is used for short-term disconnection from the engine. The disengagement process is carried out using a pedal, which the driver depresses, transmitting the force directly to the parts of the mechanism that are disengaging. The force from the pedal must be sufficient to move the clutch fork and trigger the release mechanism.

The transfer of force can occur in two ways: mechanical - using rods, levers or cables, and hydraulic - using fluid pressure created in the clutch master cylinder and transmitted through the pipeline to the working cylinder. The clutch is squeezed out after a force is applied to the pedal acting on the pusher of the master cylinder, which, in turn, on the piston, which creates pressure in the system, which is transmitted through the pipeline to the working cylinder.

General product design

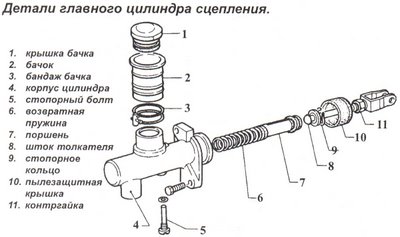

In most cases, the clutch master cylinder is made of cast iron by casting, inside which there is a piston and a pusher, which are the main working elements of the cylinder. Its pusher is connected to the pedal on one side and abuts against the piston on the other. The main parts of the master cylinder are as follows:

- Cylinder body.

- A pusher that connects the pedal to the mechanism.

- Piston.

- Recoil spring and plugs.

The cylinder itself is divided by a partition into two parts: the upper one is used to fill the cavity with liquid from the tank, and the lower one is used as a working area.

Consequences of using cheap products

The wide range of clutch master cylinders on the market has a wide range of prices for similar products. As practice shows, a low price is achieved due to reduced quality indicators of the finished product. Cheap clutch master cylinders fail due to poor-quality piston seals, fluid leaks due to low precision in manufacturing parts and poor build quality. It makes sense to repair such products, a poor-quality cylinder changes completely.

Installation and replacement

Removal of the clutch master cylinder is carried out in the following order:

- Pumping out the working fluid reservoir with a pear or other device.

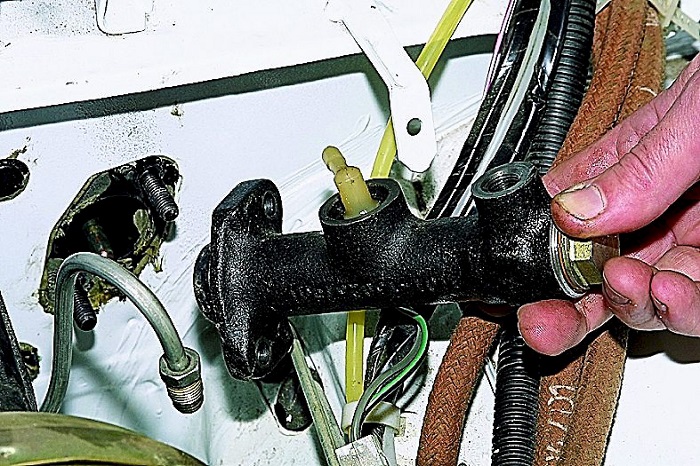

- Loosen the hydraulic hose clamp and disconnect it from the drive connection.

- Unscrewing the union of the hydraulic drive.

- Unscrewing the nuts of the studs securing the drive to the car body.

- Removing the cylinder.

The product is installed in the reverse order. After installation, to bring the cylinder and the entire system into working condition, the process fluid is poured into the tank and pumped.

When installing the clutch master cylinder, special attention is paid to ensuring the tightness of the connection of the hoses and the tube that supplies pressure to the slave cylinder.

If the tightness of the connections is insufficient, fluid leaks and air enters the system, which leads to incomplete disengagement of the clutch or complete cessation of its operation.

Faults in the clutch master cylinder

Despite the simplicity of the device, the following breakdowns may occur in the clutch master cylinder, which make it difficult or impossible for its normal operation:

- Lack of process fluid. The liquid level in the reservoir must be periodically monitored and, if necessary, topped up to the set level. It manifests itself when the cuff on the cylinder is damaged or broken or the system connections are not tight. It is eliminated by identifying the place of leakage and ensuring its tightness.

- Air entering the system, leading to a failure of work, which is manifested by the "under-release" of the clutch with a characteristic crunch or vibration of the lever when shifting gears. The cause of the malfunction is cracks in the tubes, wear of moving parts or leakage of the system at the connections. Efficiency is eliminated by detecting and eliminating such areas, and pumping the entire system to remove the air located there.

- Pumping liquid through yourself. A malfunction manifests itself when the cuffs fail or the piston itself is worn out. Eliminated by replacing damaged parts.

The first signs of a malfunction should serve as a reason for diagnosing the clutch master cylinder and the entire system as a whole. Timely measures taken will avoid replacing the entire unit, eliminating the malfunction by replacing worn parts.

Partial renovation

Repair of the clutch master cylinder using a repair kit

The first signs of a malfunction should serve as a reason for diagnosing the clutch master cylinder and the entire system as a whole. Timely measures taken will avoid replacing the entire unit, eliminating the malfunction by replacing worn parts. Repair of the clutch master cylinder is carried out using a repair kit, which includes the following parts:

- Protective cap.

- Retaining ring.

- Piston.

- Recoil spring.

- Piston seals.

Repair work on the cylinder with the installation of a repair kit is carried out in the following order:

- Removal and disassembly of the cylinder.

- Flushing with brake fluid (do not use other solvents).

- Inspection of the cylinder for seizures, the condition of the mirror and the rod. Minor corrosion and galling can be removed with fine-grained emery paper. Although damage of this type indicates a violation of the clearance between the cylinder and the piston.

- Replacement of worn out parts provided by the repair kit.

- Before assembling the cylinder, all parts are lubricated with brake fluid, and grease is applied to the spherical surface of the piston in contact with the pusher.

- Assembly and installation of the clutch master cylinder.

- Bleeding the system.

Popular manufacturers

All major car manufacturers equip them with their own clutch master cylinders, which are fully compatible with a particular car model and are of excellent quality. But on the market there are products from third-party manufacturers that are not original spare parts. Among such companies that produce clutch master cylinders for various car models of all kinds of manufacturers, the following are the most popular:

- Sachs. A German company that manufactures products that fully comply with the quality certificates of the following manufacturers: VW, Audi, Volvo, BMW, most domestic cars, and supplies them to Formula 1 cars.

- TRW. World leader in quality clutch cylinders for dozens of different car manufacturers. All products have a quality certificate ISO 9002, MIRA, RBA, TUV.

- Metelli. An Italian company that manufactures products with the participation of an automated computer control system, and ensures that all parameters of its products comply with the ISO 9002 quality system.

- Febi. Manufacturer of quality products with ISO 9002 certification.

- Herzog. A German manufacturer that produces clutch cylinders for both passenger cars and trucks, including models of domestic production.

- Valeo. A French company specializing in the production of high-quality components, including clutch cylinders for BMW, Ford, General Motors, as well as other manufacturers, including domestic ones.