Due to the fact that the VAZ 2106 car is equipped with a clutch, which has hydraulics in its design, from time to time it is required to carry out not only routine maintenance and repairs, but also pumping the clutch hydraulic drive. This is due to the fact that air can enter the system during operation. Air, of course, depressurizes the entire system, which leads to adverse consequences, whether it be an accident or even an accident.

Among other things, air can enter the system during repair work, after replacing the brake fluid, etc. That is why it is imperative to take measures to eliminate defects. After all, not eliminated defects of this system can contribute to the breakdown of mates, nodes and transmission parts.

Workplace tooling

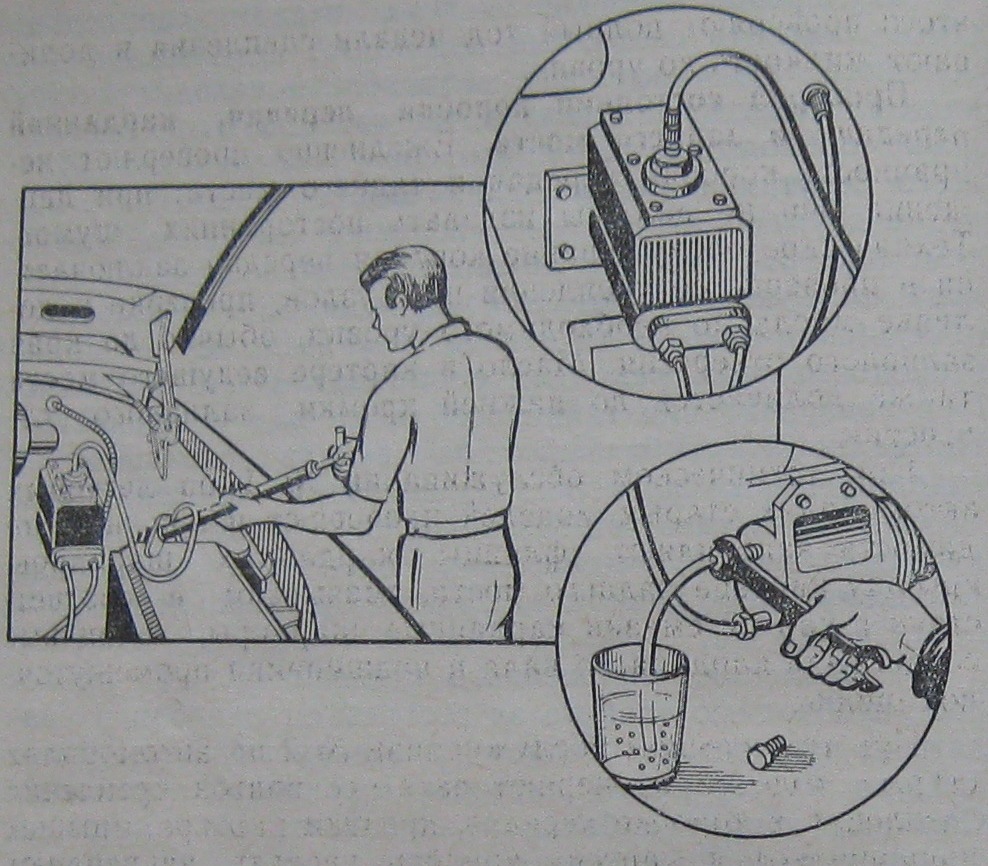

Don't know how to properly pump the clutch on a VAZ 2106 with your own hands? Fortunately, there is a way out! To do this, you just need to use a practical guide, taking into account some recommendations. Naturally, to perform this operation, you will also need to have the necessary set of locksmith tools, hollow clean containers, an auxiliary hose, and rags.

If it is necessary to bleed the clutch hydraulic drive after replacing the spent brake fluid with a new one, then, alas, it is impossible to do without cleaning the drain fitting of the GCC. Therefore, you will definitely need a special brush with a steel working surface in the form of a wire.

Algorithm for the clutch bleeding operation on the VAZ 2106

The first step is to put a rubber hose of the appropriate diameter on the fitting inlet. Before performing this operation, it is recommended to clean the entrance from dust and dirt deposits. The second end of the hose is directed to the tank for receiving the brake fluid (spent). It should be remembered that the connecting hose should be put on the fitting with some interference.

Unfortunately, outside help is indispensable for bleeding the hydraulic clutch. Why is this the case? The answer lies on the surface! Assistance will be required during subsequent operations directly in the passenger compartment. The partner will have to depress the clutch pedal about five times. In this case, the interval between rolls should not be less than 3 ... 5 seconds. If the pedal does not return to its original position, it should be returned to this position by yourself.

After the clutch pedal is once again recessed, the person who works with the hydraulic drive must unscrew the drain nipple with an open-end wrench. Remember, however, that the union must not be completely screwed out. This operation is necessary in order for the air to leave the system (when unscrewing the union, the user will hear the movement of air masses coming out of the hose). Immediately after the flow stops and the air leaves the hydraulic system, the assistant will need to give the command to release the pedal so that it takes its original position. At that time, the person working with the hydraulic system must tighten the union. Professionals working in service centers note that the clutch pedal must acquire elasticity with each operation of unscrewing-twisting the fitting. As soon as the effort becomes required, you can stop the operation.

As a rule, the brake fluid level, when performing the above steps, does not decrease too much in the standard clutch reservoir. However, in spite of this, close supervision of the brake fluid level should be carried out. A decrease of up to 10 mm from the lower cut of the drive capacity must not be allowed.

The next step will be to bring the tightening torque of the fitting to the maximum and dismantle the auxiliary rubber hose. Many motorists who are pumping the VAZ 2106 clutch for the first time do not take into account the fact that liquid remains inside the auxiliary hose, after dismantling it. That is why it is most advisable to drain this liquid back into the tank.

Several ways to bleed the clutch. Video:

So, after performing all the previous operations, you will need to add brake fluid to the standard tank by tightening the cap with a little effort. Then - we use the previously prepared rags and remove all smudges. Many experienced people advise you to visually inspect the entire system before starting the engine. If no problems are found, then you can start checking the system directly with the engine running (with mandatory gear shifting).

The final step will be to check the quality of the work. The check will consist in measuring the stroke of the piston pusher when squeezing the clutch. With correct bleeding of the clutch, the stroke should be about 26 ... 28 mm. What if the actual parameters do not meet the requirements? Don't make unreasonable decisions. It is enough just to carry out an additional adjustment operation.

Remember that clutch bleeding must be timely and of high quality, since the safety of absolutely all road users will depend on it!