As a rule, the main and working cylinders are fairly reliable parts that fail very rarely. In most cases, they cannot be repaired. The good news is that these parts are inexpensive and can be easily replaced by yourself. In the event of minor faults, it is recommended to carry out repairs, which is not a complicated undertaking. Below is how to replace both clutch cylinders.

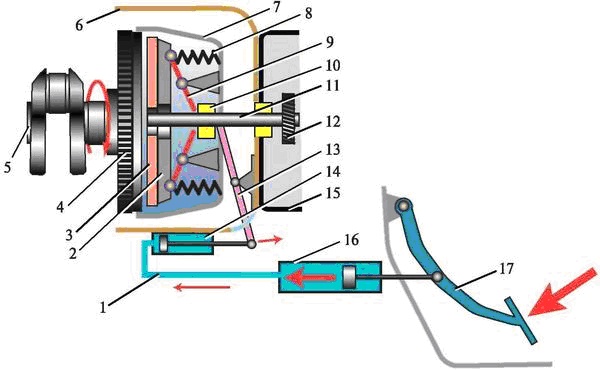

The hydraulic clutch drive on domestic cars practically does not differ from the systems installed on foreign cars. Thanks to this, the information described below can be used as a guide not only for cars of the VAZ brand. To carry out self-repair, dismantling and installation of cylinders, you need to know the entire structure of this unit, which includes the following elements:

Clutch pedal located in the passenger compartment. It is the main governing body.

The master cylinder is located just behind the pedal. It implements the function of transferring forces from the pedal to the slave cylinder.

Working cylinder. This mechanism is used to move the fork and thrust bearing.

Clutch fork.

Thrust bearing.

The system of pipelines through which the brake fluid moves.

Diagnostics of the main or working cylinder

Car diagnostics is gaining more and more popularity today. The need for this procedure cannot be overestimated, since it allows you to monitor the condition of the machine throughout the entire operating period. With its help, it is possible to prevent any breakdown and eliminate the flaw at the initial stage of development, which in turn has a positive effect on the cost of repair work. In this section, we will figure out how to check the master and working cylinders yourself without using special equipment.

- Visual inspection of cylinders... Carefully check the surface of the cylinders and tubes for leaks. The problem may lie in the depressurization of the joints of the parts or damage to the case.

- Check for fluid... If you find a significant decrease in the level of the working mixture, this indicates a leak. As a rule, the cause of such a problem is a failure of the cuff or a malfunction of the piston.

- Air Testing... The presence of air inside the system may indicate a failure of the clutch pedal. To fix the problem, bleed the clutch. If the procedure does not help, replace or repair the clutch cylinders.

- The presence of extraneous sounds... When you press the clutch pedal and change gears, you hear extraneous sounds or feel vibration on the gear lever. Check the entire system first. The problem may lie in the failure of one or more elements.

It should be understood that if there are any signs of a malfunction, it is necessary to urgently diagnose and fix the breakdown. Otherwise, such a small problem can lead to a more complex one, the elimination of which, at best, will require significant financial costs.

How to replace the clutch slave cylinder

To perform all the operations described below, you will need: a set of wrenches, screwdrivers and pliers. Disconnect the negative wire from the battery beforehand and drain the fluid from the hydraulic drive system.

First, it is necessary to disconnect the cotter element, which is connected to the pusher of the clutch slave cylinder. Use pliers to do this. Using the same tool, remove the retraction spring from the fork.

Unscrew the fitting hose slightly. The easiest way to do this is using an open-end wrench.

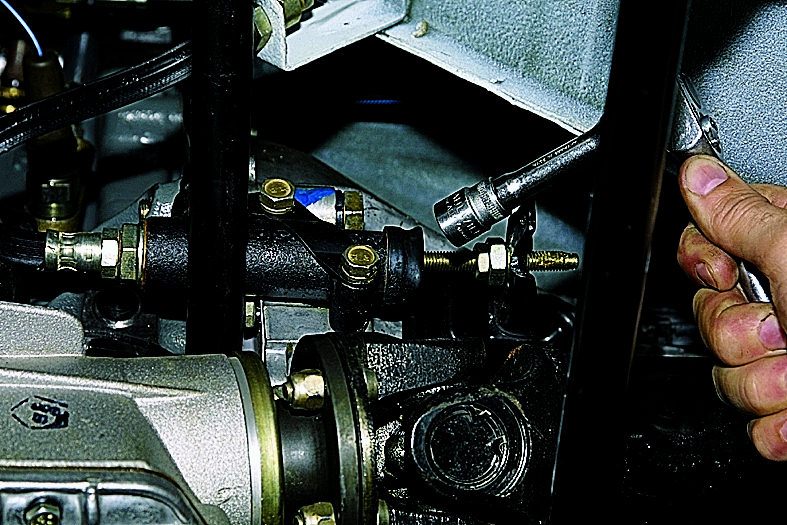

The slave cylinder is attached by 2 bolts to the crankcase, which are easiest to unscrew with a socket wrench 13. After this operation, remove the pusher from the fork. This will allow you to easily dismantle the desired cylinder.

Following this, you need to remove the bolts located on the holes of the working cylinder. Using a 17 wrench, fix the brake hose tip, unscrew the part by hand. There is a special O-ring in the connection between the cylinder and the hose, it must not be lost. As a rule, such a ring is not provided in new kits.

Replacing the clutch slave cylinder with a new analogue is performed in the reverse order. During work, make sure that the hose of the hydraulic drive is not kinked. To do this, you first need to loosen the fitting at the point where it joins the pipeline. At the end, the system must be filled with working fluid, check the integrity of the connections and all segments. Then adjust the system if necessary.

How to remove the clutch master cylinder

![]()

Preparatory work for this operation is identical to the previous one. Before starting, you need to disconnect the negative contact from the battery, drain the drums of the hydraulic drive. Before starting the dismantling, it is necessary to remove the fastening elastic clamp from the expansion tank in order to move it to the side.

It is necessary to displace the pipeline with the union. To perform this operation, you need an open-end wrench 13. First, you need to loosen the fastening clamp, which will allow you to displace the hose with the fitting located on the master cylinder.

Use a 13 socket wrench and an extension to complete the next step. Using this tool, unscrew both nuts, which are the main fasteners of the master cylinder. After that, the part can be removed from the studs.

Replacing the clutch master cylinder by repair is not recommended, due to the cheapness of the part and the painstaking process. Install in reverse order. After installation, fill the system with hydraulic fluid and check all connections for leaks.