Car tires are an important part of a car. Tire pressures should be monitored regularly to ensure the safety of the driver and passengers. To accomplish this task, a tire pressure monitoring sensor is intended. The device of the sensor, the principle of its operation and possible malfunctions are described in this article. Photo and video materials are attached.

Description of tire pressure sensor

A tire pressure sensor (TPS) is a device that monitors the air pressure in tires. They are sold with a 5-piece repair kit. The DSH differs in the type of attachment. They can be external and internal.

External ones are cheaper, but unreliable, as they are put on the rubber air duct. The second type is mounted instead of an air duct inside the disc. Tires are inflated through them. These are reliable devices, protected from external influences and aerobic stress. There are both mechanical and electrical sensors of both types, which differ in design and principle of operation.

Working principle and functions

The simplest pressure control sensors are mechanical. They are external caps that are installed instead of the standard ones. They contain a valve that measures the air pressure in the wheels. Depending on this value, the indicator is either in the green zone - pressure of 2 bar, or in the yellow zone - up to 1.7 bar, or in the red zone - up to 1.3 bar.

Electronic sensors are more sophisticated. They have built-in electronic chips that need to be registered. With the help of chips, information about the pressure is transmitted to the display. The simplest electrical pressure control sensors are equipped with an indicator that lights up green if the reading is normal, and lights up red if there is an abnormality.

Modern cars are equipped with universal TMPS - wheel pressure monitoring system. According to European regulations, each machine must be equipped with a TMPS system, which is operated by sensors. Pressure control sensors are installed on each disc, so the repair kit consists of 4 instruments. An example of a repair kit in the photo.

Information is transmitted using a radio signal at intervals of 15 minutes in a calm state and after 5 minutes in motion. The TMPS system processes signals and displays information on the display. In the event of a malfunction, a warning light on the instrument panel is illuminated. Batteries are used to power the LDS. The disadvantage of TMPS is that it cannot be disabled. Therefore, if the batteries run out, the control lamp is on. In this case, the batteries must be replaced.

In the TPMS system, external electronic sensors are used in the form of caps, which are included in the repair kit. They are installed instead of the standard ones. They do not require balancing, they are easy to install, which is both a plus and a minus, since it is easy for a thief to unscrew them. Tightness is provided only by the cap, which reduces their reliability.

There are longitudinal strikes built into the wheel rims. The device is installed after disassembling the tire on the rim of the disc near the nipple hole, which can be seen in the photo.

The tire is installed in place, balanced taking into account the LDS. During operation, the adaptation of the devices takes place. The disadvantage of such devices is the complexity of installation: they must be prescribed, plus - protection from thieves, high tightness of the system.

Another variant of the LDS is microchips, which are mounted inside the tire during its manufacture. The memory of the chip contains all the information about the tire (recommended pressure, dimension, date of manufacture, etc.). TPMS monitors changes in tire pressure. If pumping or tire fitting was performed, they need to be calibrated. The disadvantage is the inaccuracy of the readings in some driving modes and the one-time use, which leads to a rise in price.

Uncontrolled tire pressure can lead to increased fuel consumption, premature tread wear and road accidents.

Possible malfunctions and their symptoms

The main reason why automatic long-life spreaders fail is due to dead batteries. To fix this problem, you need to change the batteries. Incorrect operation of devices is possible after a puncture of a tire and its repair. For example, they can display pressure requirements on the screen.

To solve this problem, you should reset the pressure control devices, that is, reset the readings, and re-register after repair. If this does not help, then you need to contact the dealership.

The second common cause is mechanical damage, for example, a nipple breaks off. Bad road surface is the most common cause of nipple breakage. The nipple may be damaged by the owner of the car: if the indicator cap is carelessly unscrewed. In this case, repair is impossible; replacement with serviceable parts is required. These malfunctions can be detected after visual inspection.

If the indicator is on, and the pressure is normal, then you need to reset the readings by zeroing the device or re-register. To do this, with the engine off, turn on the ignition and, without starting the engine, press the SET button until a sound signal appears. Thus, you can reset the readings, after which the device will give the correct readings. To register the device, you can contact the service center.

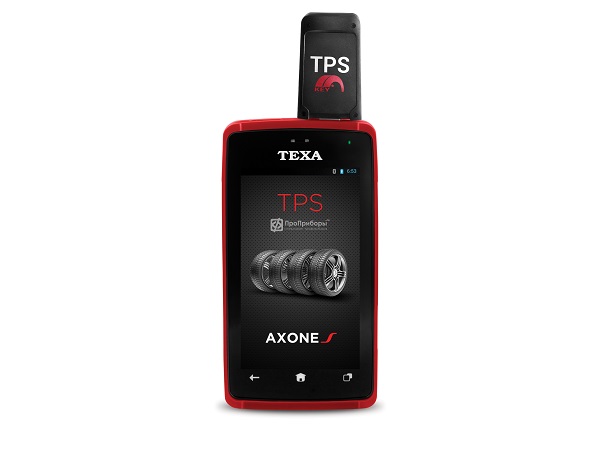

If mechanical damage to the LDS is found, repair will not help them, but a replacement is needed. A TPMS repair consists of replacing faulty sensors. The TPS TEXA instrument can detect defective longitudinal ramps by testing, the display of which shows all the information about each tire. Defective sensors detected by TPS must be replaced with serviceable devices.

How to install and configure the sensor?

The installation of control sensors depends on the type of their placement. The easiest way to install sensors is in the form of caps. To do this, you need to purchase a repair kit, remove the standard caps and install with sensors. To install the LDS on the disks, it is necessary to remove the tires, and install the devices on the rims of the disks in the area of the nipples.

The sensors can be programmed using the TPS TEXA instrument. To do this, enter the ID code of the programmable LHP on the TPS screen and check if it is correct. The TPS has an exclusive feature that allows you to scan universal LHPs and identify the sensor for programming. Checking the corresponding wheel shows that the TPS programming was successful.

The TPS can be used to check the nut tightening torque when mounting the sensor to the disc and the TPMS insertion procedure. Then, using TPS, you need to turn off the error light if it is on (the author of the video is the RusTechnika channel).

How do I disconnect the device?

With a seasonal tire change, a situation arises that an error is generated when the TPMS is installed. The question arises how to disable sensor control. The TPMS cannot be completely disabled. You can try to turn off the warning light.

There are several ways to disable the indicator:

- Physical removal of the indicator light from the dashboard.

- Physically disable the TPMS.

- Installation of trickery for TPMS in the form of a pipe with sensors placed in it and air pumped to the required pressure.

- Stick a black tape on the bulb.

All the suggested methods are not able to disable the TPMS system, they just make it useless. In order for it to work normally again, you need to either buy an additional repair kit, or re-register, etc. You can install a cheap version of the Chinese-made TPMS system, however, it may not be suitable for this car model. The TPMS system allows you to constantly monitor the air pressure in the tires of the vehicle.

Correct tire pressure enables better driving, improves safety, saves gas mileage and reduces tire wear.