The continuous tightening of environmental requirements for cars with internal combustion engines is forcing automakers to implement various devices on their products. One of these units is the start-stop system, which controls the operation of the power unit during downtime in traffic jams and at traffic lights. Thanks to it, the restart of the motor is carried out without the participation of the driver.

[Hide]

The purpose of the invention of the Start-Stop system

The conducted studies of the modes of movement of vehicles showed that up to a third of the operating time, the engine is at idle speed. This is due to traffic in dense city traffic with frequent downtime at traffic lights. To reduce harmful emissions, it was proposed to introduce automatic jamming and starting of the power unit.

Toyota began using forced engine shutdowns on a number of models as early as the mid-70s. But the massive introduction of start-stops dates back to the post-2005 period.

The system allows:

- reduce fuel consumption;

- reduce the number of emissions into the atmosphere;

- reduce the noise of the car during stops.

How the start-stop system works

The start-stop system works on the principle of forced termination of the engine after stopping the car and restarting automatically. The stopping of the vehicle movement is recorded by the speed sensor, which transmits a signal to the control unit. At the same time, information about the engine speed is received. On machines with a manual transmission, it is required to put the lever in neutral, and release the clutch pedal. Cars with automatic transmission activate the system when the brake pedal is held down.

Based on these parameters, the motor stops. The operation of the air conditioner or audio system continues from the battery. In this case, an indicator on the instrument cluster turns on, informing the driver about the operation of the system.

To complete the startup cycle, you need:

- on vehicles with manual transmission - press the clutch pedal;

- on a car with an automatic transmission - release the brake pedal.

A special sensor is installed on the batteries of cars with a start-stop system, which determines the charge level and the possibility of restarting the engine. When the voltage at the battery terminals drops, the system automatically turns off.

An overview of the principles of the Start / Stop function on the seventh generation VW Passat is demonstrated in the video from the Dmitry Force channel.

System design

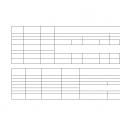

The system uses a large number of sensors and control units. The listing and diagram refer to Volkswagen vehicles, since they are the most common start-stop vehicles. The products of other vehicle manufacturers have minor design differences.

Schematic diagram of the start-stop system components

The system includes the following components:

| Designation on the diagram | Name |

| AND | Accumulator battery |

| FROM | Generator on engine |

| C1 | On-board voltage regulator |

| B | Starter |

| F | Limit switch for brake signals |

| F36 | Clutch pedal switch |

| F416 | Start-stop system control button |

| G62 | Coolant temperature sensor |

| G79 | Throttle Pedal Position Sensor |

| G701 | Non-contact sensor for neutral position of the gear lever (on the mechanics), installed on the top of the crankcase |

| J104 | Anti-lock brake system controller |

| J255 | Climate or air conditioning controller |

| J285 | Instrument cluster |

| J367 | Battery charge level monitoring |

| J393 | Comfort controller |

| J500 | Electric power steering with controller |

| J519 | On-board network parameters control unit |

| J532 | Voltage stabilization system (necessary for the correct operation of the electronics) |

| J533 | Diagnostic channel |

| J623 | Power unit operation control unit |

| J791 | Parking assistant |

In addition, the system uses:

- 1 - power steering;

- 2 - speed sensor;

- 3 - various sensors on the engine;

- 4 - sensor of the fastened driver's seat belt;

- 5 - climatic installation;

- 6 - terminal 50R;

- 7 - terminal 30;

- 8 - onboard multimedia system.

Fiberglass-filled batteries (EFB) are used to provide an increased number of engine starts. The electrolyte in such devices is located inside the pores of a fiberglass cloth sandwiched between the battery plates. The batteries are maintenance-free and provide increased starting amperage.

EFB battery design diagram

EFB battery design diagram Another difference between machines with a start-stop system is the generator and voltage regulator, connected via a digital data bus. Such a connection allows you to control the parameters of the nodes and use this data during the operation of the system. The starter has increased strength and durability. The windings are adapted to repeated repeated starts at short intervals.

The electronics include a special voltage regulator with an output power of 180-300 W. An electric energy storage unit is installed inside, which is transmitted to the on-board network through an electronic rectifier. The device smooths the voltage ripple at the moments of the starter operation. Due to this, during start-stop operation, the multimedia system, instrument cluster and external lighting lamps are not turned off.

On a number of cars (for example, Honda or Mercedes-Benz) there is a start-stop system based on a reversible generator. The device is equipped with a reinforced drive belt and a specially designed tensioner. The switchable tensioner allows the electric machine to operate in alternator or starter mode. The advantage of the design is quiet operation and quick response (2 times faster than with a conventional starter).

Reversible generator system

Reversible generator system The Japanese company Mazda offers an original system based on the principle of injection and ignition of the fuel mixture in the cylinders. The engine is stopped by a signal from the sensors, while the pistons are stopped in a certain position. After giving a start signal, the position of the pistons is interrogated. Based on the data received, the control unit injects fuel into the cylinders and ignites in a given sequence. An additional impulse to the crankshaft is given by a starter that is connected for a short time.

Start-stop system from Mazda

Start-stop system from Mazda Conditions for system activation

After turning on the ignition, the on-board network is interrogated to ensure the conditions for activating the system:

- the car is stationary;

- the engine is idling;

- the cooling system is warmed up to a certain temperature (15-25 ° C, depending on the car manufacturer);

- the brake system is operational (on a number of cars the pressure is measured in the vacuum brake booster);

- the car battery is sufficiently charged and warmed up;

- the microclimate system is correctly configured (the difference between the external and internal temperatures is not more than a certain value, usually the threshold is 5-6 ° C);

- it is checked on a diesel engine (during the start-stop procedure, it is disabled);

- the driver is wearing a seat belt;

- closed external body panels (doors, hood);

- the clutch pedal is depressed and the gearbox lever is in neutral (for manual transmission);

- the brake pedal is fully released (for automatic transmissions).

Failure to comply with at least one of the listed conditions leads to the shutdown of the start-stop system. Reinitialization is only possible after switching the ignition system back on.

Advantages and disadvantages of the start-stop system

According to the owners' reviews, the following advantages from using the system can be distinguished:

- reduction of fuel consumption and, as a result, emissions of harmful substances into the atmosphere;

- the use of an improved battery and a powerful starter makes it easier to start the engine at low temperatures.

There are many more disadvantages:

- The system provides good economy parameters only when driving from traffic light to traffic light. When driving in lingering traffic jams, when the car drives several meters and stops, start-stop is less effective. In addition, from frequent starter activation, the battery charge level drops, which does not have time to be replenished. As a result, the system automatically turns off. The tests carried out have shown that the effectiveness of the start-stop in these situations differs by 2 times.

- Increased load on the battery, which leads to its rapid deterioration. The cost of an EFB battery is 50-60% higher than that of conventional batteries.

- Installing a reinforced starter capable of frequent starts. The device is expensive.

System names by different manufacturers

Almost all automobile concerns use the phrase "start-stop" in the name of the system:

- the version from BMW has the designation Auto Start Stop, and from Mercedes-Benz - ECO start / stop;

- mazda designates the device as i-STOP or i-ELOOP;

- south Korean KIA uses the term Intelligent Stop and GO system;

- for Porsche vehicles, the Auto Start-Stop-Funktion designation is used.

Disable start-stop system

Despite the advantages that the system provides, sometimes you need to turn it off:

- Car manufacturers have provided a special button by pressing which the driver disables the start-stop system. However, this function only works within one ignition cycle. When restarting the motor, the button must be pressed again.

- It is possible to bypass the system startup by disconnecting the signal wire from the battery level sensor. In this case, icons will appear on the instrument cluster, indicating attempts to operate the start-stop. There will be an error in the memory of the control unit, but it will not affect the characteristics of the car. The negative point will be the lack of communication between the electronics and the battery, which will not allow the car to automatically control the charge level. On a number of Volkswagen vehicles, it is possible to disable the icons on the instrument cluster via the diagnostic interface. However, this option depends on the version of the instrument cluster installed on the vehicle.

- It is possible to disconnect the start-stop by removing the plug from the function control button. The control unit detects an open circuit and shuts down the system.

- Soldering the capacitor into the button control circuit. Additional capacity emulates the situation when the motor is started by pressing a button. The control unit, receiving such a signal, deactivates the system. The solution is not suitable for all vehicles.

- On some Volkswagen vehicles, it is possible to completely disable the system using the VASYa-diagnostician diagnostic program. The operation is carried out in specialized centers or independently, if the owner has the equipment and can use it.

Photo gallery

Video

Methods for disabling the Start / Stop function on BMW cars are shown in the video filmed for the BimmerDoc channel.

The Stop & Start system (in another interpretation - the Start & Stop system) is designed to save fuel, reduce harmful emissions and noise by reducing the engine idling time. As the practice of car operation shows, the idle mode is up to 30% of the total engine operation time. This is facilitated by frequent stops at traffic lights, being in traffic jams, which are attributes of a large city.

Until recently, the Stop & Start system was used primarily in hybrid vehicles. Today the situation is changing radically. Almost all leading car manufacturers have vehicles equipped with this system in their model range.

The principle of operation of the Stop-Start system is to turn off the engine when the vehicle is stopped and start it quickly by pressing the clutch pedal (manual transmission) or releasing the brake pedal (automatic transmission).

Structurally, the Stop-Start system combines a device that provides multiple engine start-ups and an electronic control system.

There are several approaches to implementing the multiple engine start function:

- reinforced starter;

- reversible generator (starter-generator);

- fuel injection into the cylinders and ignition of the mixture.

The simplest and most reliable in terms of design is the system Stop & Start from Bosch. Thanks to this system, the name "stop-start" has become a common name for the rest of the systems. The system is installed on Audi, BMW, Volkswagen cars and provides a reduction in fuel consumption and harmful emissions by up to 8%.

The system is based on a special starter designed for a large number of engine starts and with an extended service life. The starter is equipped with a reinforced low-noise drive mechanism, which guarantees quick, reliable and quiet engine starting.

The control system stops and starts the engine, as well as controls the battery charge. Like all modern electronic systems, it includes input sensors, a control unit and actuators.

The system does not have its own electronic unit, but uses the power of the engine control unit, in which the corresponding software is installed. The actuators of the system are injectors of the injection system, ignition coils, and a starter.

The operation of the Stop & Start system is cyclical (shutdown-start). Engine shutdown occurs under the following conditions:

- full stop of the car;

- shifting the gear lever to neutral and releasing the clutch pedal - for a car with a manual gearbox;

- brake pedal depressed - for vehicles with automatic transmission.

In addition, when deciding to turn off the engine, the system evaluates the engine speed, coolant temperature, battery charge level, and the operating mode of the air conditioner.

When the engine is not running, electrical energy consumers (air conditioners, audio systems, etc.) are powered from the storage battery.

When the clutch pedal is depressed (releasing the brake pedal on a vehicle with an automatic transmission), the system activates the starter and starts the engine. In the future, the cycle of the system is repeated.

If the value of the battery charge falls below a predetermined value, the system is turned off based on the signal of the corresponding sensor and the command from the control unit. The system is switched on after charging the battery. The system can be forcibly disabled using a dedicated button on the instrument panel.

Start-stop system next generation turns off the engine already in the process of stopping the car (until it comes to a complete stop), thereby achieving even greater fuel economy The process of stopping the car is recognized by the control unit according to certain driving parameters: the speed before braking, the speed at the current time, the absence of a road slope, the lack of maneuvering. If the driving parameters do not correspond to the preset values, the system is triggered after a complete stop of the vehicle.

The system has a similar design ISG (Idle Stop & Go) from Kia Motors. The main difference of this system is the control of the car generator. So, at a high load on the engine to reduce fuel consumption, the generator is turned off, when braking, the generator is turned on and the battery is recharged. When the battery power drops below 75% of the nominal, the system turns off. The system also turns off when using the air conditioner.

System STARS (Starter Alternator Reversible System), manufactured by Valeo, uses a reversible generator in its work. The system is installed on Citroen, Mercedes cars and allows to reduce fuel consumption by up to 10%.

Reversible generator is an AC electric machine, which, depending on conditions, can act as a generator and a starter. The operation of the reversible generator is provided by a special drive belt and a reversible tensioner, which allows the transfer of force in two directions. The reversible alternator runs quietly and has a shorter start-up time (0.4s versus 0.8s for a conventional starter).

The STARS system is controlled using a separate electronic control unit that interacts with the engine control unit. The composition of the input sensors is similar to that of other Stop-Start systems.

A further development of this system is the use of regenerative braking to create additional energy and reduce fuel consumption.

Mazda has developed a system SISS (Smart Idle Stop System), which is an alternative to other Stop & Start systems. Another name for the system i-Stop... It uses fuel injection into the cylinders and ignites the fuel-air mixture to repeatedly start the engine. The system is installed on gasoline engines equipped with direct fuel injection.

To ensure the operation of the SISS system, the pistons in the cylinders are stopped at certain positions that are optimal for further engine start. When the vehicle starts moving (when the brake pedal is released), fuel is injected into the cylinders and the fuel-air mixture is ignited, thus starting the engine. When starting the engine, in addition to the energy of combustion of the fuel, the energy of the starter is used, which is switched on for a short time.

Reducing fuel consumption when using this system reaches 9%. SISS only works with automatic transmissions.

The start-stop system saves fuel, reduces noise and emissions by reducing engine idle time. The practice of operating a car shows that in idle mode, the engine runs up to 30% of the time. This is facilitated by traffic with frequent stops at traffic lights and traffic jams - the attributes of a large city.

Until recently, start-stop technology was perceived exclusively as an element of hybrid vehicles. Today the situation has changed significantly, as most of the leading car manufacturers have expanded their range of vehicles equipped with such a system. The start-stop function, according to experts, will appear on half of the produced passenger cars by 2015.

How the start-stop system works very simple: when the vehicle is stopped, the engine is turned off, and when the clutch pedal is pressed (if a manual transmission is installed) or the brake pedal is released (if an automatic transmission is installed), the engine starts quickly.

The design of the start-stop system should include the following elements:

- device for multiple engine start;

- control system.

The function of repeated engine start can be realized with:

- reinforced starter;

- reversible generator (starter-generator);

- injection of fuel into cylinders and ignition of the mixture;

- hydrostarter.

Start-stop system with reinforced generator

The simplest and most reliable solution from a technical point of view is the Start & Stop system from Bosch. Thanks to this system, the name "start-stop" has become a household name for all systems of this kind. The "Start & Stop" system is installed on VW, BMW, Audi, etc. cars, providing a 4% reduction in fuel consumption of a passenger car and its CO 2 emissions in the "New European Driving Cycle" (NEDC) and up to 8% in the urban cycle.

The "Start & Stop" system is based on a reinforced starter, which has an increased service life (designed for a large number of engine starts). The starter is also equipped with a special low-noise drive mechanism, which guarantees fast, reliable and repeated engine starting.

The "Start & Stop" system performs the functions of stopping and starting the engine, monitoring the battery charge level. The system does not have its own electronic control unit, but uses the capabilities of the engine control unit, where the corresponding software is installed.

Due to the fact that the components of the Start & Stop system are no larger than conventional components, the Bosch system can be easily integrated into almost any vehicle. However, some units and systems required additional adaptation to operate in start-stop mode. They are listed in the table below (a variant of the system with a reinforced generator is considered using the example of the start-stop system included in the BlueMotion package for Volkswagen vehicles).

| Node / system | Adaptation measures implemented |

|---|---|

| Control units (in general) | Extension of the program codes of control units by one information bit for the start-stop system (applies to control units that affect or depend on the start-stop system) |

| Generator | Connected via LIN to the data bus diagnostic interface |

| Battery | Glass fiber filled battery for increased cycle times |

| Starter | Increased wear resistance |

| Onboard network | A special sensor on the negative pole for monitoring the state of the glass fiber battery. New wiring to the battery. The control unit for monitoring the battery status via the LIN bus is connected to the data bus diagnostic interface. |

| ITUC | Gear recognition sensor (sensor with analog output or sensor with pulse width modulated output signal) |

The device of the star-stop system with the reinforced generator "VW BlueMotion"

Below is a diagram of the start-stop system with an enhanced VW BlueMotion generator. The design of systems from other manufacturers does not differ significantly.

|

|||

| The image can be enlarged. Symbols of system elements using the example of a mechanical gearbox: | |||

| A | Battery | J623 | Engine control unit |

| C | Generator | J791 | Parking aid control unit |

| C1 | Voltage regulator | 1 | Electromechanical power steering |

| B | Starter | 2 | Speed \u200b\u200bsignal, distance sensor |

| F | Brake light switch | 3 | Engine control systems (e.g. ignition, power supply, mixture formation, exhaust gas recirculation, secondary air charging, exhaust gas cleaning, etc.) |

| F36 | Clutch pedal switch | 4 | Seat belt recognition |

| F416 | Start-stop system power button | 5 | Heating, ventilation, air conditioning |

| G62 | Coolant temperature sensor | 6 | Terminal 50R |

| G79 | Accelerator Pedal Position Sensor | 7 | Terminal 30 |

| G701 | Gearbox neutral position sensor (only for manual gearbox) | 8 | Radio tape recorder, radio navigation system |

| J104 | ABS control unit | ||

| J255 | Climatronic control unit | ||

| J285 | Instrument cluster control unit | ||

| J367 | Battery monitoring control unit with battery sensor | ||

| J393 | Convenience system central control unit | ||

| J500 | Power steering control unit | ||

| J519 | Onboard supply control unit | ||

| J532 | Voltage regulator | ||

| J533 | Data bus diagnostic interface | ||

How the Bosch Star-Stop System Works

The operation of the "Start & Stop" system is as follows. When the machine stops in front of a traffic light or in a traffic jam, the system, based on the signal from the crankshaft speed sensor, turns off the engine. Electricity consumers (air conditioners, audio systems, etc.) are powered by a storage battery. When the clutch pedal is depressed (releasing the brake pedal on a vehicle with an automatic transmission), the system activates the starter and starts the engine. This cycle of stopping and starting the engine is repeated as many times as necessary.

Many drivers worry about the fact that using the star-stop system they will be left with a discharged battery (for example, in severe frost). However, these fears are unfounded, since if the value of the battery charge falls below a predetermined value, the system is turned off based on the signal of the corresponding sensor. The start-stop function is activated only after the battery has been charged. Also, the "Start & Stop" function can be forcibly disabled with a special button on the dashboard.

Start-stop system with reversible generator

Valeo's STARS (Starter Alternator Reversible System) uses a reversible generator in its operation. The system is installed on cars "Citroen", "Mercedes" and allows to reduce fuel consumption by up to 10%.

Reversible alternator An alternating current electric machine, which, depending on conditions, can perform the functions of both a generator and a starter.

The operation of the reversible generator is provided by a special drive belt and a reversible tensioner, which allows the transfer of force in two directions. The reversible alternator is quiet and has a shorter start-up time (0.4 seconds versus 0.8 seconds for a conventional starter).

Start-stop system with fuel injection

Mazda has developed the SISS (Smart Idle Stop System) as an alternative to other start-stop systems. This system uses fuel injection into the cylinders and ignites the fuel-air mixture to repeatedly start the engine. The system is installed on gasoline engines equipped with direct fuel injection.

For this system to work, the pistons must stop in a strictly defined position, so that each cylinder has the necessary air volume for optimal engine start in the future. The Smart Idle Stop System monitors the position of the pistons during engine shutdown. "SISS" numbers the cylinders, and as soon as the movement starts (when the brake pedal is released), fuel is injected into the cylinders and the fuel-air mixture ignites, that is, the engine starts. When starting the engine, in addition to the energy of combustion of the fuel, the energy of the starter is used, which is switched on for a short time.

For vehicles with automatic transmission, the starting process takes 0.35 seconds, which is almost twice as fast as conventional systems. In addition, Mazda SISS guarantees a quick start of the engine in each individual case. The driver should not feel a delay when he wants to move from a place.

When using this system, it reaches 9%. The SISS start-stop system works only with automatic transmission.

Hydraulic alternative

For the segment of heavy commercial vehicles, which accounts for about 30% of harmful emissions, the development of the company "Poclain Hydraulics" - the hydraulic system "CleanStart" is intended. The main component of the CleanStart is a lightweight and compact hydraulic starter motor that can be mounted directly on the crankshaft to minimize mechanical losses. The properties inherent in a hydrostatic drive (the moment in this case reaches 800 N ∙ m) allow starting heavy engines with a volume of up to 16 liters almost instantly (starting time is 0.4 seconds) without noise and vibration. Therefore, this development was especially interested in the manufacturers of buses, the power unit of which can be turned off not only in anticipation of the permitting signal of the traffic light, but also during the embarkation and disembarkation of passengers at the bus stop. Here, the start-stop system offers even more advantages than in the passenger car segment.

In addition to a 15 kW hydraulic motor, the “CleanStart” system circuit includes several more elements: a pump (an existing hydraulic pump supplying various types of auxiliary equipment can be used), a control valve, a hydraulic accumulator and a tank. While the pump is running, the solenoid valve directs part of the working fluid flow to the accumulator, where the nitrogen gas is compressed by the oil through the separating diaphragm. The energy stored in this way is saved without losses for various transformations for a subsequent start. The discharge is controlled by a proportional valve, and the power is not enough for one, but for several starts, the total resource of the system is about 4 million cycles. It is also important that the accumulator allows for fast charge and discharge cycles, does not require maintenance and has a higher specific power compared to chemical energy sources. But if we talk about the "CleanStart" system as a whole, then it is still inferior to its competitors in terms of weight and size characteristics - the curb weight of the vehicle when equipped with a hydraulic starter increases by about 40 kg, but for a bus or truck this is not too much weight increase.

According to the developer, a bus equipped with the CleanStart system reduces fuel consumption by more than 10% in the urban cycle (12 stops lasting 15 seconds at a distance of 7 km). Considering that the equipment can be mounted not only on new, but also on vehicles in operation, this system can be considered a serious reserve for improving the environment.

Motorcycle start-stop system

Honda has developed a start-stop system for motorcycles and scooters called the Idling Stop System. The system operates in automatic mode and provides a short-term engine shutdown after reaching zero speed, which saves up to 7% fuel. When you turn the throttle handle, it turns on the engine again for further travel.

The introduction of the Idling Stop System required significant changes to the design of the starter, which was integrated into the flywheel.

Also, the motorcycle start-stop system must be activated only after sitting in the driver's seat. Since there is no relevant information from the manufacturer, we assume that a weight sensor is installed in the seat, which turns off the system every time the driver leaves his seat.

Intelligent start-stop system with recuperation

The next step in the development of start-stop systems is the use of energy recovery during braking.

The ISG (Idle Stop & Go) system from Kia Motors has a design similar to the Bosch system, but there is an important difference in the control of the car generator: at high engine load to reduce fuel consumption, the generator is turned off, when braking, the generator turns on and the battery is being recharged - energy is recovered. If the battery charge falls below 75% of the nominal, the ISG system is automatically shut off. When using the air conditioner, the system also turns off. Such a system can be called intellectual.

Probably, in the near future, ISG's competitors will also become systems with recuperation.

Operating the start-stop system

If the car's engine is not yet warmed up, or the temperature outside is very low, then the start-stop system will not work. It will also turn off when there is a very high power consumption (for example, when using an air conditioner), insufficient charge and after repeated depressions of the brake pedal. Russia has a long winter, during which the system will not fully justify itself, but in summer, autumn and spring it will save a little fuel.

How will the start-stop system affect battery or starter wear? No way, because the cars are equipped with reinforced units. For example, the places of the starter support, which are subjected to very heavy loads, have a large margin of safety, therefore they should not break during the entire period of operation.

Bosch has been supplying start-stop systems to car manufacturers since 2007. During this time, experience has been accumulated that allows the company to occupy a leading position in the development, production and diagnosis of malfunctions of such systems and components, their maintenance and repair. Using the example of the company's products, we will try to find the "pitfalls" of the new system.

The number of passenger cars equipped with a system that reduces fuel consumption and CO2 emissions by 5–8% is constantly growing. According to forecasts, in 2013, every second new car from the compact urban to the executive or high-tech sports car will be equipped with a start-stop system.

Like all other components and assemblies of a car, this system will require high-quality repair and maintenance. To assess its technical condition and troubleshoot, you need at least an appropriate diagnostic tester, such as the KTS from Bosch. It is also used to register a new battery in the battery monitoring and management system. Registration is required to ensure optimal start-stop performance. These conditions alone are enough to understand that even a simple battery replacement should be done in a workshop. An auto mechanic can also "break wood". In order to avoid mistakes, it is important for him to have the necessary information. The Bosch ESI software contains data on all vehicles with start-stop systems and provides repair and maintenance instructions, system information and a parts catalog. It is advisable that the employee has at hand special equipment such as the BAT 131 tester for checking the status of the batteries and the Bosch FSA diagnostic system that determines the status of the sensors.

Start-stop batteries practically do not differ from traditional ones. Photo: Bosch

Power sources of increased power and reliability can be called the core of the system. Starting the engine is the most intense mode of battery operation, requiring a quick return of a huge amount of electrical energy. And if in a car of traditional design the battery undergoes such a shock only a few times a day, in the presence of a start-stop system, such overloads can occur hourly, if not every minute. To conserve fuel, experts advise turning off the engine whenever a stop of more than 30 seconds is expected. Think for yourself how many times you will have to start the engine when "driving" in a traffic jam. And the battery should not only ensure frequent reliable engine starts, but also maintain the operability of all electricity consumers during a stop - from lighting lamps to air conditioning and "music". The rechargeable battery must provide high performance, be resistant to high cyclic loads and be able to quickly take charge. It must provide energy when the engine is started frequently, as well as power the necessary electrical appliances during the stop phase. A normal battery will not last long under these conditions. Bosch, for example, has two dedicated battery lines - the Bosch S5 EFB (with liquid electrolyte) and S6 AGM (with absorbent glass fiber). By the way, it is important to remember that the EFB battery can be replaced with another one of the same or with an AGM battery. If an AGM battery was originally installed, it can only be replaced with a battery of the same type. The correct battery selection can be made using the ESI software from Bosch, which also provides instructions on how to replace the battery.

In the new conditions, it is not only the batteries that fall. The starters specially developed by Bosch for start-stop systems are designed for significantly more engine starts and have reinforced bearings, improved planetary gears and an optimized commutator. Indeed, much more often involved in work, they must withstand not only mechanical, but also thermal loads. Many of our motorists remember the complete (albeit temporary) failures of the overheated starter, who "improved" their "Zhiguli" by removing the heat shield under the exhaust pipe.

Start-stop system. Photo: Bosch

Generators are also subject to special requirements. Not only do they have to have increased power to compensate for the increased power consumption from batteries caused by frequent starts and work of consumers at stops, but also start generating electricity already at idle speed. Batteries must be recharged quickly and in all conditions.

The "start-stop" function was "simply" added to the already familiar electronic engine control unit, adding the necessary sensors (such as battery status or wheel speed sensors). We also needed additional DC / DC converters (DC to DC again). They stabilize the voltage in the system when the car starts to move and keep the radio, navigation system and hands-free headset running smoothly. For those who are finally convinced that "start-stop" is very simple, we put a thick point in our story. And to those who have doubts from among the specialists, we will tell you that the Bosch group of companies has organized training in the safe handling of start-stop systems ”in 43 Bosch training centers around the world. A Bosch technical hotline is available for service station employees who face problems.

Once a colleague at the electronic research institute took up a hack. He came across the ideal client from the ministry: with money, but no brains. With a simple foreign car radio and a request to "train" it to receive domestic radio broadcasts in stereo. The client was upset that the yellow Stereo LED stubbornly refused to light up. Want to know what the start / stop system has to do with it?

My colleague did not invent a stereo decoder. He did it easier: he took and soldered the harmful LED directly to the Mono / Stereo switch. The customer immediately calmed down: if you press the button, the light will flash yellow, here's your stereo. Press again - here's a mono.

Exactly the same “care” for a person has been demonstrated by the world auto industry for some time now. Only instead of the stereo mode, which was once inaccessible to the average man in the street, he slips him another linden.

The first example is the Euro-6 and more standards. Honestly fulfilling them, without bringing the cost of a passenger car closer to the price of a rover, is not yet possible. Whoever got caught is a fool himself.

The second example is hybrids with a declared consumption of a liter per hundred. In principle, you can declare zero liters per hundred - and it will work! After all, it is not at all necessary to inform the buyer that the first hundred kilometers will be carried by the battery, which will then be discharged.

Third example - cars with start / stop mode. I drove up to a traffic light, stopped at a red one - the motor immediately turns off, saving personal gasoline and public air. The green light turns on - you release the brake (or you press on the gas - sometimes it happens), the motor quickly wakes up and carries you on. The win is obvious!

But - only on paper. And the point is not even that the extra hundreds and thousands of starts will necessarily affect the resource of the machine's units. And not even that, especially for such machines, it was necessary to invent batteries, which are one and a half times, or even two times more expensive than conventional ones.

So what's the deal? And in what turned out in practice: start-stop cars frankly "sleep" at intersections, and with the economy of gasoline, too, there was trouble. And it turned out not today or yesterday.

So that no one says that the Russians have mixed everything up, and the author is a brake on progress (however, they will say so anyway), let us turn to our Western colleagues. The journalists of the German AutoBild took 15 cars with the start / stop system for a test and set up a simple experiment: it was decided to measure the start delay from a traffic light. In other words, the time taken to accelerate the car to 20 km / h with the system turned on and off was taken into account. In the first case, the motor at the traffic light was de-energized by the automatics, and in the second, it threshed at minimum idle, as usual.

What did you intend? For example, the Mazda CX-3 Skyactiv-D accelerates to the test kilometers per hour with stupid automatic gear in 3.15 seconds, although without it it did the same thing in just 1.54 seconds! The mediocre system doubled overclocking, eating 1.61 s!

The Volkswagen Polo 1.4 TDI (1.48 s additional delay) and the Hyundai i30 blue 1.4 (1.12 s) were doing a little better. How many beeps in the back will get their drivers at each intersection, estimate for yourself.

Against this background, a loss of only 20% looks already gorgeous. This is exactly how the Audi A4 3.0 TDI quattro and the Porsche 911 Carrera showed themselves. And the Mercedes-Benz GLC 250 4Matic is generally in chocolate: it lasted only 0.08 s.

And now about the main thing. Why did you introduce "start-stop"? Thinking to save fuel? Blessed is he who believes. For example, in Volkswagen Passat 2.0 TDI the difference was as much as… 0.1 l / 100 km! Those who do not believe, I invite you to follow the link. Compare this "economy" with the conditions of a sluggishly creeping city - you will count less than a percent.

By the way, no one warns the future owner of the car about such a deterioration in the dynamics of the car. Say, pay money for innovation and save nature! And don't think about how much natural resources were additionally ditched in the production of all these bells and whistles.

Calculation error? Nothing like this! The same test was carried out back in 2012! Here are some of the numbers at that time: BMW 116d worsened its performance by 84%, Audi A6 TDI - by 63%, Volkswagen Passat TDI - by 59%, Porsche Cayenne - by 47%. Only a car with a three-pointed star on the radiator grille managed to keep up appearances.

How else to make a person constantly fork out for a new product, if he is quite satisfied with the old one? Only to outlaw the old product: to constantly hammer into the head that, they say, this Neanderthal burns the air, devours oil, poison brothers in reason. Moreover, this is declared at the highest level - in words, all managers stand up for the environment.

Against this background, boring reasoning about the dangers of frequent starts, the cost of flimsy bells and whistles, the high cost of AGM batteries look unprofitable and outdated. By the way, as far as batteries are concerned, we are unambiguously hinted that there will be no others at all soon. Why produce them if AGM batteries can replace old ladies in any situation?

In general, you push a button, light the right light bulb - and everyone is happy.