The main requirement of modern life, characterized primarily by an accelerated pace, is to ensure human mobility. And, probably, the main way to solve the problem of movement in space, for most people, has become a car. However, the process of acquiring a "steel horse" is accompanied by the emergence of a large number of questions, one of which is the choice of the type of transmission.

Manufacturers of modern cars equip their products with gearboxes of several types that differ significantly from each other: mechanical, automatic, robots, etc. How to make your choice optimal? What is the difference between an automatic box and a robot? We will try to answer some of the questions regarding the checkpoint in this article. We will focus on gearboxes installed on later car models, and therefore less known to the domestic car enthusiast - variators, robots and automatic machines.

What is the difference between a variator and a robot?

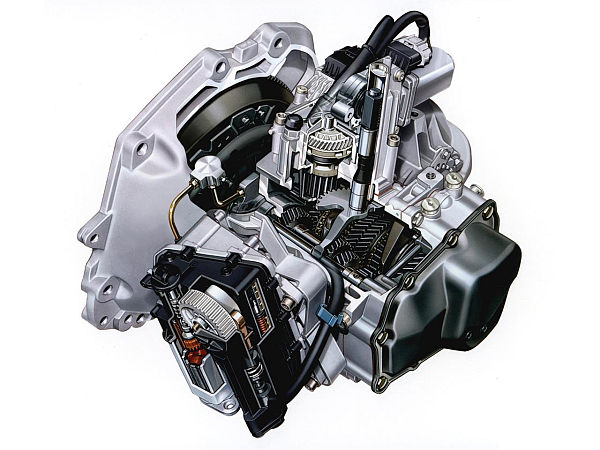

First of all, a variator is a continuously variable transmission, the principle of operation of which is based on the transmission of torque from moving conical disks, which act as pulleys, by means of a stacked steel belt or a steel chain consisting of a large number of links. As the driving discs move apart and the driven ones move, the output torque increases. Otherwise, its value decreases. This design predetermines the main disadvantage of the variator - the absence of a neutral position and reverse gear. However, manufacturers solve this problem, however, each in its own way.

To answer the question: "What is the difference between a variator and a robot?" So, the advantages of the variator:

Fuel efficiency comparable to mechanical transmission.

Minimal acceleration time combined with a dynamic set of speed and no jerks.

Achievement of high revs of the power plant exclusively at high speeds, which leads to a minimum risk of engine failure.

Easy to learn, even for a novice driver.

However, along with the advantages, the variator also has disadvantages:

The complexity of the design of the accompanying equipment, which also implies its expensive repair.

The complexity of repair and restoration work.

The gear oil used in the variator has specific properties, which makes it not only rare, but also expensive.

Now, in the same vein, we will consider a robotic gearbox, or a robot, which is, in fact, a mechanical transmission, supplemented by a control unit that controls the clutch and the gear shift process.

Advantages:

Simple design and low consumption of gear oil.

Lower cost of repair.

Possibility of functioning in manual transmission mode.

Low fuel consumption.

The disadvantages of a robotic gearbox are as follows: