Should I choose a manual transmission or an automatic one? And if automatic, then an ordinary automatic machine, "robot", or a variator? Such questions are very popular among motorists when choosing a new or a used car. The Internet is filled with gearboxes, both useful information and information "junk". Only a professional in the subject can distinguish useful from rubbish. Such is his, the Internet, a defect. Therefore, I decided to write a few lines about all these mechanics, automatic machines, robots and variators, moreover, without plunging into the nuts, so that any reader, regardless of the level of technical literacy, could understand what is at stake, and that he, PERSONALLY , will be better.

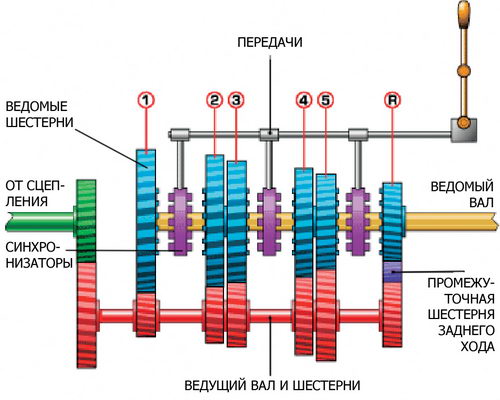

Manual Transmission

Let's start with the "mechanics". In the case of a manual transmission, under the hood we have an engine, a "black box" of a transmission, with all its shafts, gears, synchronizers and engaging couplings. And between the engine and the box there is a clutch unit. The clutch pedal was pressed - the engine and the gearbox were completely separated. As long as you keep the clutch pedal depressed, the power unit and gearbox are unconnected and you can shift into any gear based on driving conditions. This is the main advantage of the "mechanics", especially for the "advanced" driver, who knows and is able to apply the techniques of active driving. For example, in the case of a front-wheel drive car, "push" the engine against the wheels of the front axle before the maneuver. And in the case of rear-wheel drive, turn the car into a bend, switch to a steeper trajectory. But, as often happens, the disadvantages are an extension of the merits. Actively "drive", of course, is pleasant, but wielding the clutch pedal and the shift lever in the endless traffic jams of megacities is not the most pleasant experience. This is the minus.

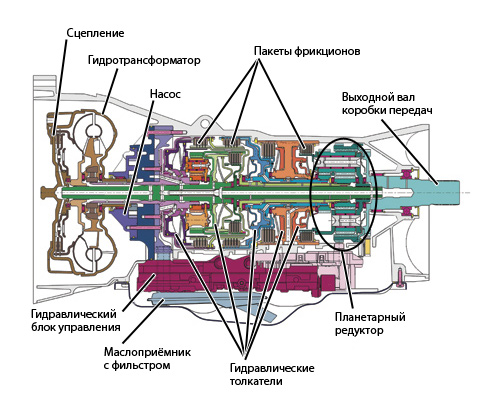

Hydromechanical automatic transmission, or "conventional automatic"

In order not to control the gearbox "hand-to-hand", and not to strain too much with the handles-legs in the dense city traffic, an automatic transmission was invented. First, a hydromechanical automatic transmission (automatic transmission) appeared. In order to understand how it works, you need ... a fan (ordinary, household) and some kind of children's spinner-toy with a propeller-propeller similar to a fan. Turn on the fan and bring this toy to it. What will happen? The propeller on the toy will spin too! Now imagine that the propeller does not drive the fan motor, but the car engine. And the second screw is on the shaft, which goes into the "black box" with gears, couplings, and everything else. Both of these screws are housed in a sealed housing filled with a special transmission fluid called a torque converter.

What are these passions for? And in order to move smoothly, shift gears as smoothly as possible without any clutch "from the driver's foot", as in the "mechanics" between the engine and the "black box" with gears. After all, in order to get under way, you need to smoothly connect the motor and the "black box" of the box. Here is the torque converter, without losing any effort from the engine, and it does it. And the liquid is needed in order to transmit rotational movement through it. And then the air, it will not cope. The density of the air is low for the transfer of energy at these rotational speeds. As for the gear changes, they are performed at the command of the control unit, automatically, depending on the driving conditions. Previously, these units were hydraulic, now they are electronic.

In general, everything in the hydromechanical automatic transmission seems to be good. It goes by itself, it switches itself. The driver can only press the accelerator and brake pedals, and click the automatic selector between “Parking”, “Drive” and “Back”. Moreover, this thing works quite reliably. If you do not pretend to be Schumacher on the automatic transmission, and follow the Maintenance Regulations, then it will not break.

But there are drawbacks. The main ones among them are the tangible moments of automatic switching of the automatic transmission ranges in the "black box" with gears, and higher fuel consumption, in comparison with the "mechanics" with the same power units. The need for more comfort, rising fuel prices and environmental concerns have encouraged engineers to think about automation again.

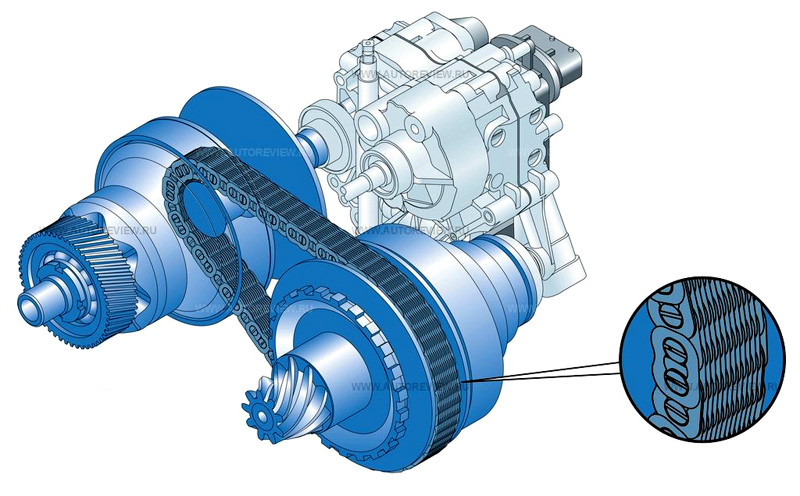

"Variable speed drive". CVT automatic transmission

To understand what the engineers have thought of, imagine ... a bicycle. Pedals, two sprockets, with a chain between them. Slightly more advanced models have a few sprockets on the rear wheel for gear shifting. I switched it to a big sprocket - pedaling is easier and you can go up a steep hill, only you have to pedal more often. At the same time, the speed of the bike drops, but this is a price for high traction. And if you ride on flat terrain, or from a mountain, then I turned on a smaller sprocket at the back - you pedal less often, and the speed of the bike increases. Now imagine that the bike has a belt instead of a chain drive. That is, instead of a chain - a belt, instead of sprockets - pulleys, only instead of a bunch of sprockets on the rear wheel - ONE pulley, but its diameter can ... smoothly change.

Have you presented? Here, in front of you, a CVT automatic transmission! One pulley is of constant size, the second is of variable size and its diameter changes at the command of the control unit, adjusting to the driving conditions. And between them - the strongest "belt", which is either a multi-link chain, or composite, of metal plates. A smooth change in the diameter of one of these pulleys leads to the fact that the switching points of the automatic transmission are not felt at all. After all, they simply do not exist, these switching moments. J Amazingly comfortable piece of work, this variator! But it was not without flaws, significant and smaller.

"Variators" are not cheap. They also strongly dislike slipping. Due to the fact that between the "black box" with pulleys and the belt you have to put the same torque converter (you need to get under way!), And also because of mechanical friction in the "black box", energy losses are quite large, fuel consumption, in comparison with the "conventional" automatic transmission, a little less. And maybe more. And you also have to "conjure" the engine programs so that it does not hum like a trolleybus at constant speed during acceleration. After all, there is no stepped gear change. Therefore, the space for research again opened up for engineers.

"Robots". Robotic transmissions

To overcome the shortcomings of hydromechanical and variable speed automatic transmissions, several design schools turned their attention to ... a conventional mechanical gearbox. But what if we replace the foot clutch actuator with an electric actuator, the gear change lever and traction lever to the "black box" with gears with electric actuators, and control the clutch and shifting using an electronic unit, based on the driving conditions? Of course, only a fairy tale tells itself easily and quickly. The engineers had to tinker a lot with the control programs for this unit and the reliability of the electric drive, but automated manual transmissions, which journalists dubbed "robotic" or "robots", went into mass production for small cars. They represent precisely the classic "mechanics" in which the clutch and gear changes are controlled by an electronic unit.

The main advantage of the majority of "robots" is their high fuel efficiency, for which they, first of all, were created. After all, a computer with a perfect control program never makes mistakes, never gets angry, does not get depressed and never gets tired, unlike drivers with different experience, skill and resistance to physical and mental stress. Therefore, a car with a "robot" consumes less fuel than the same car with any other gearbox, including "mechanics". And such a "robot" is cheaper than any other automatic transmission in the purchase, when ordering a new car. Like this.

But even here it does not do without flaws. No matter how hard the engineers tried to optimize the moments of switching, the "pecking" of the car with its nose during violent acceleration is very noticeable. Such "robots" are for economical and quiet driving, and not for "Schumacher". They also dislike slipping in clutch assemblies. The engineers had to tighten up again.

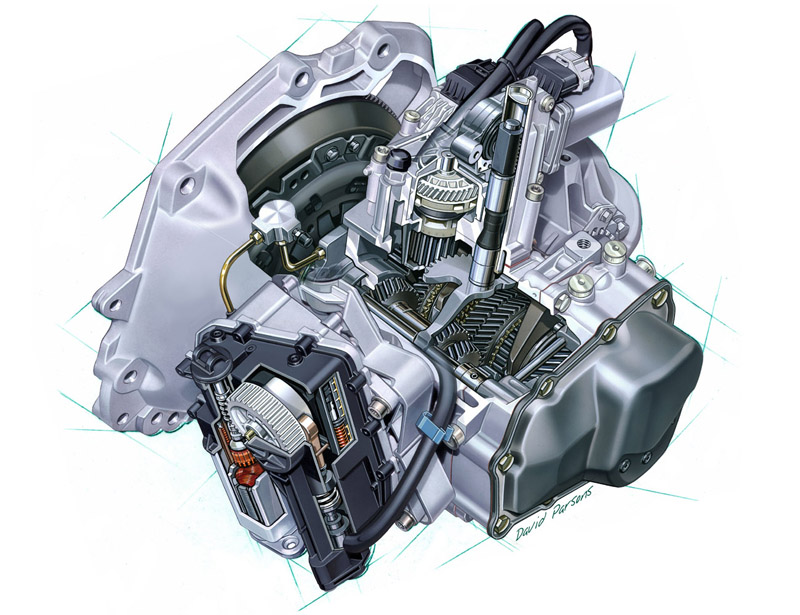

"Robots" classDSGfrom Volkswagen

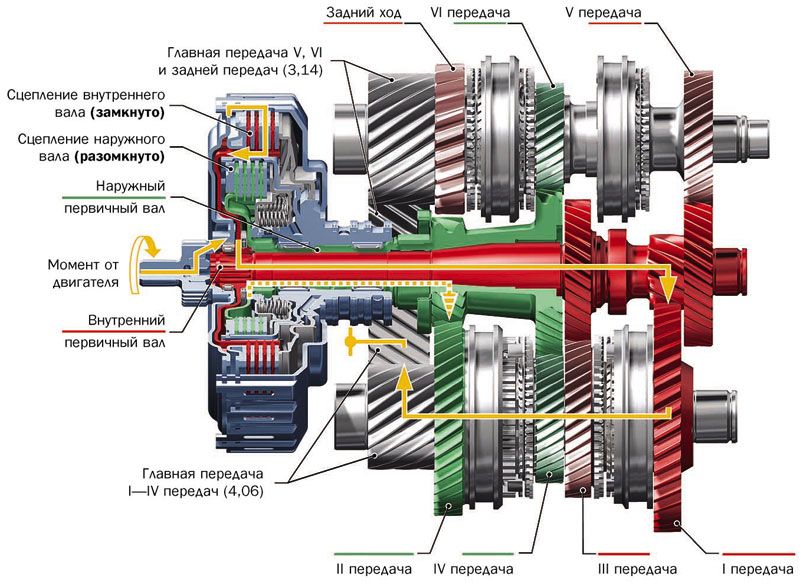

Imagine a car with a six-speed manual transmission. Have you presented? Only this box is not quite ordinary. More precisely, it is not at all usual. It seems to consist of TWO units, with the 1st, 3rd and 5th gears connected to the engine through one clutch module, and the 2nd, 4th and 6th through the other. It turns out something like "two in one". Now imagine that all controls are fully automatic, electronic and electrical. Moreover, when you accelerate, for example, in 2nd gear, the control unit has ALREADY turned on the 3rd, and is only waiting for the best moment to make an instant "click-click" by independent clutches in order to "release" the second gear and "cut in" a previously prepared 3rd. Switching to such an automatic gearbox takes not just a split second, but milliseconds! The driver and passengers simply do not notice these changes, and acceleration is smooth and very fast. For example, in DSG, which was the first in the world to be put on the conveyor by VOLKSWAGEN, the switching times take 7 milliseconds. It's much faster than blinking your eyes. Therefore, there are no jerks and jerks, like those of the "robots" described above.

The DSG 7 SPEED WARRANTY has been extended to 5 years or 150,000 km:

Concern VOLKSWAGEN AG, meeting the wishes of customers, in order to maintain customer confidence in the cars of the concern, at the expense of the manufacturer carries out free repair or replacement of gearbox assemblies DSG 7 DQ 200 for up to 5 years or until 150,000 km of run from the date of transfer car to the first buyer. When the owner of the car contacts the authorized dealers with a complaint about the work of DSG 7 DQ 200, diagnostics and, if necessary, free repairs will be carried out in accordance with the current technical recommendations of the concern.

In the same way, such "robotic" boxes switch not only "up" but also down. The transmission control unit closely monitors the driver's actions using sensors on the pedals and steering gear, and prepares in advance the best gear for the driver's goals.

If I say that such "robots" of the VW DSG class work brilliantly, then this will not be an exaggeration, and not only in terms of gear changes. Their control units also do not “get tired” or “make mistakes”, so the fuel consumption of a car with DSG, especially in the urban cycle, is less than with any other gearbox, including the “mechanics”.

As for the shortcomings, there are few of them, but, alas, they are: The high cost and unacceptability of slippage in clutch units (however, what kind of clutch does it like?).

These are the options.

Sincerely,

Denis Kozlov (DOK)

Your expert in vehicle selection and maintenance