Nominal diameter of the reinforcement. This value indicates the clear diameter of the reinforcement and is called the nominal diameter. One of the main parameters of control valves. The kvs value of the reinforcement directly depends on this parameter. Most often, the nominal diameter is less than the diameter of the pipeline, which makes it possible to save money, however, when calculating the control valve, remember about the losses on the confuser and diffuser, which occur before and after the valve, respectively. In the Russian Federation, as well as in the countries of the former USSR, at present, you can also find the designation of the nominal diameter as Du (nominal diameter). The nominal diameter is designated by the letters DN or DN with the addition of the nominal size in millimeters: for example, the nominal diameter of 150 mm is designated DN 150 (DN150).

Regulatory attitude is the ratio between the highest flow rate and the lowest flow rate. In practice, this is the ratio between the highest and the lowest regulated flow rates (otherwise, under the same conditions).

Maximum leakage closed also refers to the characteristic parameters of the valve. For control valves, this value is often expressed as a percentage of the maximum flow rate (Kvs, Avs, Cvs), and the test conditions are clearly defined in the IEC 534-4-1982 standard. If the leakage value is indicated, for example, as 0.01% Kvs, this means that a maximum of one hundredth of a percent of the Kvs (i.e. 0.01 Kvs) of the test fluid will flow through this valve when closed under test conditions. If this value plays an important role in the operation of the equipment, contact the manufacturer for information on its test conditions or request a higher density if technical capabilities allow. of this type fittings.

After choosing the control method and the type of control valve: two-way or three-way, it must be correctly calculated and selected. The calculation and selection of the control valve depends on the selected control method. With two-position control (with an electrothermal drive), a control valve with a minimum diameter at a given water flow rate is selected so that the pressure drop across it does not exceed the maximum losses of 25 kPa during cooling and 15 kPa during heating. These values \u200b\u200bcan be specified by the manufacturer. The selection is carried out according to the nomogram for the corresponding thermostatic valve according to the manufacturer's data, an example of such a nomogram for a three-way control valve from Cazzaniga is shown in Fig. 4.16. Dotted lines are also plotted in the diagram to indicate the pressure loss in the bypass line. Calculation example: Given: Water flow through the fan coil heat exchanger (7 \u003d 0.47 m 3 / h. The pressure loss on the heat exchanger is 14.4 kPa. We accept a valve with a diameter of 15 mm (1/2 ") with K v \u003d 2 m 3 / h. Pressure loss on direct course AR \u003d 4.7 kPa, on the bypass - AR \u003d 8.0 kPa. For control valves with modulating control (using a remote control and a thermostat or with a servo drive), the quality of regulation depends on a correctly selected valve, which is determined by the correspondence of the gate travel of the control valve to a certain required water flow through the valve. When selecting a modulating control valve, use general principles no matter where the valve is installed: on the fan coil heat exchanger, on the air cooler or air heater of the central air conditioner.

The operation of the control valve is characterized by the value of the throughput K v, m 3 / hour, and the throughput characteristic. The coefficient of conditional throughput is equal to the flow rate of liquid through the valve in m 3 / h with a density of 1000 kg / m 3, with a pressure drop across it of 0.1 MPa (1 bar). Conditional coefficient of throughput is determined by the formula:

(3) where q is the volumetric flow rate of the liquid through the valve, m 3 / hour; Ψ is a coefficient taking into account the effect of fluid viscosity, determined depending on the Reynolds number:

![]()

(4) according to schedule 4.17;

p is the density of the liquid, kg / m 3;

v is the kinematic viscosity of the liquid, which changes depending on the temperature and concentration of the solute for aqueous solutions, cm 2 / s; d - nominal diameter of the valve, mm; AP is the pressure loss across the control valve at the maximum liquid flow through it, MPa.

Throughput characteristic is the dependence of the relative throughput on the relative displacement of the valve gate, where K v, K vy are the actual and conditional throughput coefficients, m 3 / hour, S, S y are the actual and conditional gate travel, mm. It is sometimes referred to as the ideal control valve characteristic. Most often, control valves are produced with a linear flow characteristic: (5)

Less often equal percentage:

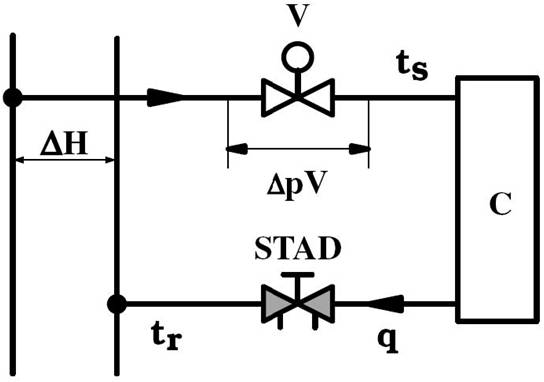

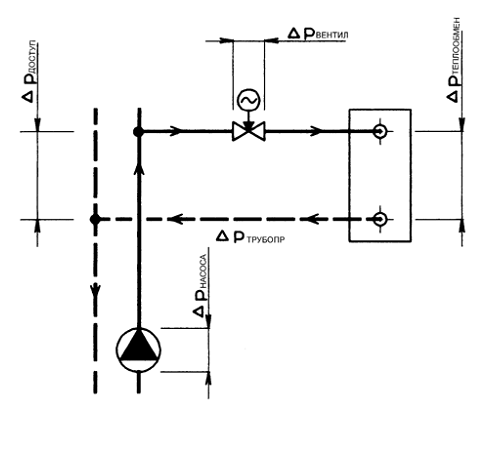

The real picture of the change in fluid flow through the valve differs from the ideal and is characterized by working characteristic valve, which expresses the dependence of the relative fluid flow rate on the valve travel. It is influenced by the parameters of the regulated area. A controlled section is a network section that includes a technological control element (fan coil heat exchanger, air cooler, air heater), pipelines, fittings, a control valve, the pressure drop at which remains constant during the regulation process or fluctuates within relatively small limits / 10%. The pressure drop in the regulated section is the sum of the pressure drop across the control valve and the pressure drop across the rest of the technological network. The diagram of the regulated section and the pressure distribution when installing a two-way valve is shown in Fig. 4.12, when installing a three-way valve in Fig. 4.11. The ratio of the pressure drop across the valve and the pressure drop in the controlled section has a significant effect on the type of flow characteristic, this value is called differently in foreign and domestic literature: control coefficient, relative valve resistance.

AR Let us denote the ratio - \u003d n You can build several operating characteristics of the network depending on the ratio n, an example of such a construction is shown in Fig. 4.18 a for a control valve with a linear flow characteristic, in fig. 4.18 b for a control valve with an equal percentage (logarithmic) flow characteristic. When the control valve is closed, the actual liquid flow through the valve turns out to be greater than the theoretical one, and this deviation is the greater, the greater the value of the relative resistance of the valve.The ideal characteristic corresponds to n \u003d 1, when the pressure drop in the network is infinitesimal, in this case the flow rate and ideal characteristic match. The operating flow characteristics have the smallest deviation from the ideal form at n\u003e 0.5. Thus, the pressure drop across the control valve must be greater than or equal to half of the total pressure drop in the controlled section, or more or equal to the pressure drop across the technological network elements:

A valve that is fully open at the maximum volume of flowing water and for which these ratios are satisfied is considered to be correctly selected. The water control valve, supplied without calculation, can be identified visually on the system after installation. The cross-section of such a valve usually coincides with the cross-section of the pipeline in the regulated section (control valve on the air cooler or air heater of the central air conditioner). A properly selected valve has a smaller cross-section than the pipeline.

Figure: 4.18. Graphs of operating flow characteristics of control valves with linear (a) and equal percentage (b) flow characteristics

The selection of the control valve is carried out according to the coefficient of flow using the nomogram for the control valve of the corresponding manufacturer. An example of such a nomogram for a Danfoss VRG3 three-way seated control valve is shown in Fig. 4.19.

Calculation example. Given: Fan coil cold load Q x \u003d 0.85 kW. Mass water flow through the fan coil heat exchanger

![]() where Qx is the cold load, kW. Δt - temperature difference of the coolant at the inlet and outlet of the fan coil unit is taken as 5 ° C.

where Qx is the cold load, kW. Δt - temperature difference of the coolant at the inlet and outlet of the fan coil unit is taken as 5 ° C.

Volumetric water flow q \u003d G / p \u003d 146.2 / 1000 \u003d 0.146 m 3 / h The pressure drop in the heat exchanger is determined according to the table for Delonghi FC10 fan coil unit

![]()

We select a three-way control valve according to the nomogram so that the pressure drop across the control valve is greater than the pressure drop in the heat exchanger, taking into account the margin for losses in pipelines, shut-off valves: at G \u003d 146.2 kg / h according to the nomogram in Figure 4.19. we determine Kvs \u003d 0.4 m3 / h of a control valve with a diameter of R 1/2 "(15 mm) and the pressure loss across the valve A p \u003d 15 kPa. At Kvs \u003d 0.63 m 3 / hour, the pressure loss across the valve A \u003d 5, 8 kPa and the pressure ratio will be less than 1. Therefore, we take a valve with K vs \u003d 0.4.

Figure: 4.19. Nomogram for the selection of the Danfoss VRG3 three-way control valve (modulating control)

![]()

Capacity of the control valve Kvs - the value of the Kvs coefficient is numerically equal to the water flow through the valve in m³ / h with a temperature of 20 ° C at which the pressure drop across the valve is 1 bar. You can calculate the throughput of the control valve for specific parameters of the system in the Calculations section of the website.

DN of the control valve - nominal diameter of the hole in the connecting pipes. The DN value is used to unify the standard sizes of pipeline valves. The actual hole diameter may slightly differ from the nominal one up or down. An alternative designation for the nominal diameter DN, common in the post-Soviet countries, was the nominal diameter DN of the control valve. A number of nominal diameters DN of pipeline valves are regulated by GOST 28338-89 "Nominal passages (nominal sizes)".

PN control valve - nominal pressure - the highest overpressure of the working medium with a temperature of 20 ° C, which ensures long-term and safe operation. An alternative designation for the nominal pressure PN, common in the post-Soviet countries, was the nominal pressure PN of the valve. A number of nominal pressures PN of pipeline valves is regulated by GOST 26349-84 "Nominal (conditional) pressures".

Dynamic range of regulation, it is the ratio of the highest flow rate of the control valve at fully open gate (Kvs) to the lowest flow rate (Kv) at which the stated flow characteristic is maintained. The dynamic control range is also called the control ratio.

So, for example, the dynamic control range of the valve equal to 50: 1 at Kvs 100, means that the valve can control the flow rate of 2m³ / h, keeping the dependencies inherent in its flow characteristic.

Most control valves have dynamic ranges of 30: 1 and 50: 1, but there are also valves with very good control properties with a control range of 100: 1.

Control valve authority - characterizes the regulating ability of the valve. Numerically, the authority value is equal to the ratio of the pressure loss at the fully open valve plug to the pressure loss at the regulated section.

The lower the authority of the control valve, the more its flow characteristic deviates from the ideal and the less smooth the flow rate change will be when the stem moves. So, for example, in a system controlled by a valve with a linear flow characteristic and low authority - closing the flow area by 50% can reduce the flow rate by only 10%, with high authority, closing by 50% should reduce the flow through the valve by 40-50%.

Displays the dependence of the change in the relative flow through the valve on the change in the relative stroke of the control valve at constant drop pressure on it.

Linear flow characteristic - the same increments in the relative stroke of the stem cause the same increments in the relative flow rate. Control valves with linear flow characteristics are used in systems where there is a direct relationship between the controlled variable and the flow rate of the medium. Control valves with linear flow characteristics are ideal for maintaining the temperature of the heating medium mixture in substations with dependent connection to the heating network.

Equal percentage flow characteristic (logarithmic) - the dependence of the relative increase in flow rate on the relative increase in the stroke of the rod - logarithmic. Control valves with a logarithmic flow characteristic are used in systems where the controlled variable is non-linear with the flow through the control valve. For example, control valves with an equal percentage flow rate characteristic are recommended to be used in heating systems to control heat transfer from heating devices, which nonlinearly depends on the heat carrier flow rate. Control valves with a logarithmic flow characteristic perfectly regulate the heat transfer of high-speed heat exchangers with a low temperature drop of the coolant. It is recommended to use valves with equal percentage flow characteristics in systems where regulation according to a linear flow characteristic is required, and it is not possible to maintain a high authority on the control valve. In this case, the reduced authority distorts the equal percentage valve characteristic, bringing it closer to linear. This feature is observed when the authority of the control valves is not lower than 0.3.

Parabolic flow characteristic - the dependence of the relative increase in flow rate on the relative stroke of the rod obeys a quadratic law (runs along a parabola). Parabolic control valves are used as a compromise between linear and equal percentage valves.

Kv value.

The control valve creates an additional pressure loss in the network to limit the water flow to the required limits. The water flow depends on the differential pressure across the valve:

kv is the flow rate on the valve, ρ is the density (for water ρ \u003d 1,000 kg / m 3 at a temperature of 4 ° С, and at 80 ° С ρ \u003d 970 kg / m 3), q is the liquid flow rate, m 3 / h , ∆р - differential pressure, bar.

The maximum k v (k vs) value is reached with the valve fully open. This value corresponds to the flow rate, expressed in m 3 / h, for a differential pressure of 1 bar. The control valve is selected so that the value of k vs provides the design flow for a given available differential pressure when the valve is operating under specified conditions.

It is not easy to determine the value of k vs required for a control valve, since the available differential pressure across the valve depends on many factors:

- The actual head of the pump.

- Pressure losses in pipes and fittings.

- Pressure loss at terminals.

The pressure loss in turn depends on the accuracy of balancing.

When designing boiler plants, the theoretically correct values \u200b\u200bof pressure loss and flow rate for various elements of the system are calculated. However, in practice, it is rare for the various elements to have precisely defined characteristics. Installation typically selects pumps, control valves and terminals for standard performance.

Regulating valves, for example, are produced with k vs values \u200b\u200bincreasing in geometric proportion, called Reynard series:

k vs: 1.0 1.6 2.5 4.0 6.3 10 16 ......

Each value is approximately 60% larger than the previous one.

It is not typical for a control valve to provide an accurately calculated pressure loss for a given flow rate. If, for example, a control valve is to create a pressure loss of 10 kPa at a given flow rate, then in practice it may turn out that a valve with a slightly higher k vs value will create a pressure loss of only 4 kPa, and a valve with a slightly lower k vs value will provide a pressure loss at 26 kPa for the estimated flow rate.

|

∆р (bar), q (m 3 / h) |

∆р (kPa), q (l / s) |

∆р (mm ВС), q (l / h) |

∆р (kPa), q (l / h) |

|

q \u003d 10 k v √∆p |

q \u003d 100 k v √∆p |

||

|

∆p \u003d (36 q / k v) 2 |

∆p \u003d (0.1 q / k v) 2 |

∆p \u003d (0.01 q / k v) 2 |

|

|

kv \u003d 36 q / √∆p |

k v \u003d 0.1 q / √∆p |

kv \u003d 0.01 q / √∆p |

Some formulas contain flow rate, k v and ∆р (ρ \u003d 1,000 kg / m 3)

In addition, pumps and terminals are often oversized for the same reason. This means that the control valves are almost closed and the regulation cannot be stable as a result. It is also possible that periodically these valves open as much as possible, at startup it is necessary, which leads to excessive flow in this system and insufficient flow in others. As a result, the question should be asked:

What if the control valve is oversized?

It will be understood that it is generally not possible to find the exact control valve required.

Consider the case with a 2000 W heater, designed for a temperature drop of 20 K. The pressure loss is 6 kPa for a design flow rate of 2000x0.86 / 20 \u003d 86 l / h. If the available differential pressure is 32 kPa and the pressure loss in the pipes and fittings is 4 kPa, there must be a difference of 32 - 6 - 4 \u003d 22 kPa across the control valve.

The required value of k vs is 0.183.

If the minimum available k vs value is 0.25, for example, the flow rate instead of the desired 86 l / h will be 104 l / h, an excess of 21%.

In systems with variable flow, the differential pressure at the terminals is variable because the pressure loss in the pipes is dependent on the flow. Control valves are selected for design conditions. At low loads, the maximum potential flow in all plants is increased and there is no danger of an excessively low flow in one single terminal. If the design conditions require maximum load, it is very important to avoid overflow.

A... Flow limitation with balancing valve in series.

If, under design conditions, the flow at the open control valve is higher than the required value, a balancing valve can be installed in series to limit this flow. This will not change the actual gain of the control valve, it will even improve its performance (see illustration on page 51). The balancing valve is also a diagnostic tool and a shut-off valve.

B... Decrease in maximum valve lift.

To compensate for the oversized control valve, the valve opening can be limited. This solution can be considered for valves with equal percentages, since the k v value can be significantly reduced, correspondingly decreasing the valve's maximum opening. If the valve opening is reduced by 20%, the maximum kv value will decrease by 50%.

In practice, balancing is done with balancing valves in series with the control valve fully open. The balancing valves are adjusted in each circuit so that at the design flow rate the pressure loss is 3 kPa.

The lift of the control valve is limited when the balancing valve is obtained at 3 kPa. Since the plant is balanced and remains balanced, the required flow is actually obtained under design conditions.

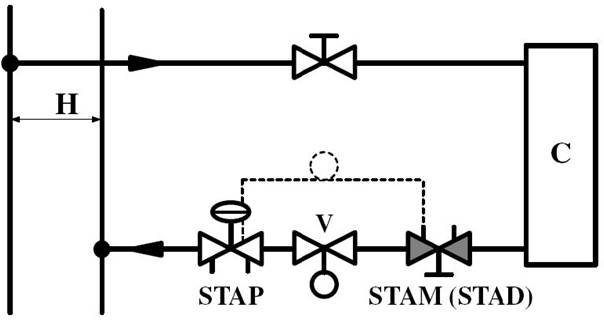

C... Reduction of flow by means of a ∆p regulating valve in a group.

The differential pressure across the control valve can be stabilized as shown in the figure below.

The STAP differential pressure valve is set to the desired flow rate for a fully open control valve. In this case, the control valve must be exactly sized and its control factor close to unity.

A few rules of thumb

If two-way control valves are used on terminals, most of the control valves will close or nearly close at low loads. Since the water consumption is low, the pressure loss in pipes and fittings will be negligible. The entire head of the pump falls on the control valve, which must be able to withstand it. Such an increase in differential pressure makes it difficult to control at low flow rates, since in fact the control coefficient β "decreases significantly.

Suppose the control valve is designed for a pressure loss of 4% of the pump head. If the system works with low consumption, the differential pressure is then multiplied by 25. For the same valve opening, the flow rate is then multiplied by 5 (√25 \u003d 5). The valve is forced to operate in an almost closed position. This can lead to noise and fluctuations in the control value (in these new operating conditions, the valve is oversized by a factor of five).

That is why some authors recommend to design the system so that the calculated pressure drop across the control valves is not less than 25% of the pump head. In this case, at low loads, the excess of the flow rate at the control valves will not exceed a factor of 2.

It is always very difficult to find a control valve that can handle this high differential pressure without generating noise. It is also difficult to find sufficiently small valves that meet the above criteria when using low power terminals. In addition, it is necessary to limit changes in the differential pressure in the system, for example using secondary pumps.

Considering this additional concept, the calibration of a two-way control valve must satisfy the following conditions:

- When the system is operating under normal conditions, the flow across the fully open valve should be rated. If the flow rate is higher than the specified, a balancing valve in series must limit the flow. Then, for a PI controller, a control factor of 0.30 would be acceptable. If the control parameters are lower, the control valve should be replaced with a smaller valve.

- The pump head must be such that the pressure loss across the two-way control valves is at least 25% of the pump head.

For on-off controllers, the concept of control parameters is irrelevant since the control valve is either open or closed. Therefore, its characteristics are not very important. In this case, the flow is slightly limited by the balancing valve installed in series.

The specifics of calculating a two-way valve

Given:

wednesday - water, 115C,

∆paccess \u003d 40 kPa (0.4 bar), ∆ppipe \u003d 7 kPa (0.07 bar),

∆pheat exchange \u003d 15 kPa (0.15 bar), nominal flow Qnom \u003d 3.5 m3 / h,

minimum flow rate Qmin \u003d 0.4 m3 / h

Payment:

∆p access \u003d ∆p valve + ∆p pipe + ∆p heat exchange \u003d

∆pvalve \u003d ∆paccess - ∆p pipe - ∆pheat exchange \u003d 40-7-15 \u003d 18 kPa (0.18 bar)

Safety oversize for working tolerance (provided that the flow rate Q has not been overestimated):

Kvs \u003d (1.1 to 1.3). Kv \u003d (1.1 to 1.3) x 8.25 \u003d 9.1 to 10.7 m3 / h

From the serially produced series of Kv values, we select the closest Kvs value, i.e. Kvs \u003d 10 m3 / h. This value corresponds to the clear diameter DN 25. If we choose a valve with a PN 16 threaded connection made of gray cast iron, we will receive the type number (article of the order):

RV 111 R 2331 16 / 150-25 / T

and the corresponding drive.

Determination of the hydraulic loss of a selected and calculated control valve at full opening and a given flow rate.

The calculated actual hydraulic loss of the control valve must be reflected in the hydraulic calculation of the network.

![]()

and a must be at least 0.3. The check established: the selection of the valve corresponds to the conditions.

Warning: The authority of a two-way control valve is calculated in relation to the differential pressure across the valve when closed, i.e. available branch pressure ∆p is accessible at zero flow rate, and never relative to the pump pressure ∆p of the pump, since due to the influence of pressure losses in the network pipeline to the point of connection of the regulated branch. In this case, for convenience, we assume

Control of the regulatory relationship

Let's carry out the same calculation for the minimum flow rate Qmin \u003d 0.4 m3 / h. The minimum flow rate corresponds to pressure drops,,.

Required regulatory attitude ![]()

must be less than the preset control ratio of the valve r \u003d 50. The calculation satisfies these conditions.

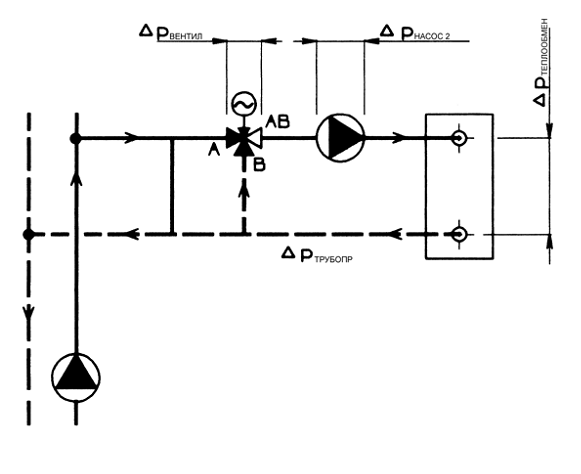

Typical control loop layout using a 2-way control valve.

The specifics of calculating three-way mixing valve

Given:

medium - water, 90C,

static pressure at the point of connection 600 kPa (6 bar),

∆ppump2 \u003d 35 kPa (0.35 bar), ∆ppipe \u003d 10 kPa (0.1 bar),

∆pheat exchange \u003d 20 kPa (0.2), nominal flow rate Qnom \u003d 12 m3 / h

Payment:

Safety oversize for working tolerance (provided that the flow rate Q was not overstated):

Kvs \u003d (1.1-1.3) xKv \u003d (1.1-1.3) x53.67 \u003d 59.1 to 69.8 m3 / h

From the serially produced series of Kv values, we select the closest Kvs value, i.e. Kvs \u003d 63 m3 / h. The clear diameter DN65 corresponds to this value. If we choose a nodular cast iron flanged valve, we get type No.

RV 113 M 6331 -16 / 150-65

We then select the appropriate actuator according to the requirements.

Determination of the actual hydraulic loss of the selected valve at full open

Thus, the calculated actual hydraulic loss of the control valve must be reflected in the hydraulic calculation of the network.

Warning: With three-way valves, the most important precondition for error-free operation is the observance of the minimum differential pressure.

on ports A and B. Three-way valves are able to cope with significant differential pressure between ports A and B, but at the expense of deformation of the control characteristic, and thus a deterioration in the control capacity. Therefore, at the slightest doubt about the pressure difference between both fittings (for example, if three-way valve without a pressure compartment directly connected to the primary network), we recommend using a two-way valve in connection with a rigid connection for quality control.

Typical control line layout using a 3-way mixing valve.