Like gasoline engines, diesel engines are equipped with an exhaust gas filter. But, since the principle of fuel ignition in these two types of engines is different, then the exhaust gas filters for diesel and gasoline engines differ significantly from each other.

It should be noted that if catalytic converters of exhaust gases have been installed in the exhaust system of gasoline engines for a long time, particulate filters began to be installed without fail on diesel engines much later - after the introduction of environmental standards Euro-5.

From the name of the device itself, it is clear that its main task is to filter the engine exhaust from the contained soot particles. The diesel particulate filter of modern diesel traps up to 90% of the amount of soot contained in the exhaust. Externally, the particulate filter is a small metal cylinder filled with a special heat-resistant ceramic material. Thanks to the cellular structure of the ceramic filler, the filter retains the smallest particles resulting from combustion. In fact, the diesel particulate filter is the part of the muffler designed to clean the exhaust.

How the particulate filter works

The work of particulate filters is usually divided into two stages: direct exhaust gas filtration (soot capture) and filter regeneration. At the stage of soot capture inside the filter, in contrast to the catalytic converter of a gasoline engine, no complex chemical or physical processes take place. The special fine-mesh ceramic structure of the inner part of the filter sifts exhaust gases, trapping soot particles on its walls. At the same time, even the most efficient filters are not able to completely exclude the ingress of soot into the atmosphere, allowing microparticles from 0.1 to 0.5 microns in size to pass through. However, the content of particles of this size in the exhaust of a diesel engine does not exceed 5-10%.

Naturally, over time, the amount of soot trapped in the filter reaches a critical indicator - the filter becomes more and more clogged, and after a certain moment this begins to affect the performance of the power unit as a whole: engine power decreases, fuel consumption increases. The second stage of the device is aimed at cleaning or regenerating the particulate filter. Unlike the filtration process, the filter regeneration step is a very complex process. The regeneration of particulate filters is implemented differently by different car manufacturers. True, the essence of all these solutions is the same - cleaning the filter cells from clogged soot.

Naturally, over time, the amount of soot trapped in the filter reaches a critical indicator - the filter becomes more and more clogged, and after a certain moment this begins to affect the performance of the power unit as a whole: engine power decreases, fuel consumption increases. The second stage of the device is aimed at cleaning or regenerating the particulate filter. Unlike the filtration process, the filter regeneration step is a very complex process. The regeneration of particulate filters is implemented differently by different car manufacturers. True, the essence of all these solutions is the same - cleaning the filter cells from clogged soot.

In most cases, a particulate filter is a combined device that combines a particulate filter element and a catalytic converter of harmful exhaust gases. A typical example is the diesel particulate filters used on their vehicles by Volkswagen. Thus, the developers not only fulfill the requirements for exhaust cleaning, but also provide a cleaning process for the particulate filter element. The structure of the combined filter is as follows: inside the filter housing there are heat-resistant cells made of silicon carbide with channels of a minimum cross-section. These cells are the soot-fighting filter element. The inner sides of the filter housing are made of a special catalytic material (usually titanium), which promotes the oxidation and combustion of carbon monoxide and carbon dioxide. An additional function of the neutralizer in this case is its ability to heat the particulate filter to a temperature of about 500 ° C. As a rule, this temperature is quite enough for the accumulated soot particles to simply burn out by themselves, thereby cleaning the filter cells. This process is called passive regeneration of the particulate filter.

However, the effectiveness of passive regeneration of the particulate filter on a diesel engine is achieved only with a relatively long engine operation under load, for example, during a long trip on a country road at high speeds. After all, only then a high temperature is reached in the filter, sufficient to burn out the accumulated soot. If the soot filling has reached a critical level, and it is not possible to warm up the filter due to insufficient engine load (driving short distances or infrequent movement in the city), but at the same time the sensors record filter clogging in excess of the permissible norm, the process of active cleaning of the particulate filter starts. This process involves the supply of an additional portion of fuel to the engine cylinders after the main part of the diesel fuel. Then the EGR valve is closed, and if necessary, the electronics temporarily changes the algorithm of the standard turbine geometry control. The unburned fuel mixture enters the catalyst through the intake manifold, after which the mixture is afterburned, which significantly increases the temperature of the exhaust gases. The exhaust gases entering the particulate filter reach 500-700 ° C and instantly burn out soot from clogged filter cells.

However, the effectiveness of passive regeneration of the particulate filter on a diesel engine is achieved only with a relatively long engine operation under load, for example, during a long trip on a country road at high speeds. After all, only then a high temperature is reached in the filter, sufficient to burn out the accumulated soot. If the soot filling has reached a critical level, and it is not possible to warm up the filter due to insufficient engine load (driving short distances or infrequent movement in the city), but at the same time the sensors record filter clogging in excess of the permissible norm, the process of active cleaning of the particulate filter starts. This process involves the supply of an additional portion of fuel to the engine cylinders after the main part of the diesel fuel. Then the EGR valve is closed, and if necessary, the electronics temporarily changes the algorithm of the standard turbine geometry control. The unburned fuel mixture enters the catalyst through the intake manifold, after which the mixture is afterburned, which significantly increases the temperature of the exhaust gases. The exhaust gases entering the particulate filter reach 500-700 ° C and instantly burn out soot from clogged filter cells.

Unexpected short bursts of black smoke will be obvious evidence that active filter regeneration has started. In this case, the instruments will show an instant and short increase in engine idle speed with a simultaneous surge in fuel consumption. It should be noted that the entire forced cleaning procedure is fully automated and does not require the intervention of the machine owner. The electronics reads data from the sensors installed before and after the filter, when the required pressure level is restored, the active regeneration process ends, and the engine returns to normal mode.

Some manufacturers that do not use a combined diesel engine exhaust aftertreatment filter use a separate catalyst. Here, the filter is cleaned by automatic injection of a special additive into the fuel. When the particulate filter is full and the engine power drops, the injection system injects the additive into the fuel. After the combustion of such a mixture, an extremely high temperature of over 600 ° C is reached in the exhaust system. In addition, the active substance of the additive does not disintegrate during combustion with diesel fuel, but enters the red-hot particulate filter, where, when burned, it raises the temperature to 900 ° C, providing instant soot burning and quick filter cleaning. Considering the short duration of exposure to ultra-high temperatures and the strength of the materials from which the filters are made, the exhaust system is not destroyed.

Removing a particulate filter - methods and consequences

Unfortunately, frequent regeneration has a negative effect on the car engine. During regeneration, the rich fuel mixture does not burn completely and enters the engine oil. As a result, the oil liquefies, increasing in volume. The protective and lubricating properties of the oil are reduced, in addition, the liquid oil easily overcomes the seals, causing the risk of entering the intercooler and cylinders.

The service life of particulate filters reaches 110-120 thousand km of vehicle mileage. However, given the low quality of domestic diesel fuel, it is not uncommon for the replacement of the filter on a new car to be required after 25-30 thousand kilometers. Depending on the model of the car, the cost of a filter for the exhaust system of a diesel engine ranges from 900 to 3000 euros.

Removing the particulate filter is an effective alternative to replacing it. By removing the filter, the owner of the machine will save himself from the problems associated with regular blockages and the need to clean the device. The traction characteristics of such a car increase markedly, and the fuel consumption decreases. In addition, there is no need to use special engine oils required for vehicles with particulate filters. As for the possible negative consequences of removing the filter, then with the correct dismantling of the device, in addition to the increase in harmful emissions of fuel combustion products to the level of the Euro-3 requirement, nothing terrible will happen to the car.

Many car repair shops today offer a particulate filter removal service. However, trusting "garage" specialists is quite dangerous. This option is fraught with damage to the sensors of the exhaust system, which leads to the inclusion of an emergency mode of the car and subsequent repairs. In order to properly remove the particulate filter, several steps must be taken, including preliminary computer diagnostics, reprogramming of the ECU and subsequent technical dismantling of the device.

The advent of the diesel engine on the mass consumer market forced the developers of such engines to bring them to world environmental standards. Diesel engines must effectively fight exhaust gases by trapping emissions hazardous to the atmosphere. During the modernization of the exhaust gas system of diesel engines, DPFs have been installed everywhere, which effectively clean the exhaust. During operation of a diesel engine, the particulate filter becomes dirty and needs to be cleaned or replaced.

Table of contents:What is a DPF particulate filter: task and principle of operation

As the name suggests, the DPF's job is to trap soot particles as they appear in the exhaust. Soot accumulates in it, which is then afterburned, thereby achieving less harmful to the environment exhaust.

The DPF works as follows:

- Soot accumulates in the filter up to a critical moment, which depends on the pressure difference before and after the filter element;

- When this pressure deviates from the norm, that is, the throughput of the filter decreases, the electronic engine control unit receives information about this and activates the afterburning mode of the accumulated soot;

Please note: Depending on the engine manufacturer, the afterburning process can be activated under different conditions. - The afterburning process takes place at an increased crankshaft speed and enhanced fuel injection, the command to which is given by the control unit;

- This increases the temperature of the exhaust gases to values \u200b\u200bat which the soot burns out.

Despite the presence of the soot afterburning mode, nevertheless, it can accumulate in the DPF and not burn. This is especially true for drivers who rarely operate a car at high speeds, moving mainly in urban areas.

Since the cost of a DPF particulate filter is quite high, drivers need to monitor this element and clean it in a timely manner so as not to face the need to replace it.

Reasons for a clogged diesel particulate filter

Soot is a byproduct of running diesel fuel in engine cylinders. In the exhaust gas, it is present in the consistency of a fine powder, which is almost completely retained by the particulate filter mesh.

Soot is a byproduct of running diesel fuel in engine cylinders. In the exhaust gas, it is present in the consistency of a fine powder, which is almost completely retained by the particulate filter mesh.

During the working cycle, hydrocarbon particles do not burn in the chamber, which go into the exhaust. Because of them, resinous deposits begin to form. This resin sticks together fine soot particles, which leads to the formation of carbon deposits. In a place with soot in this soot, other elements of diesel fuel combustion are present, as well as metal sulfates arising in the exhaust due to the combustion of oil that has entered the cylinder.

Please note: Metal sulphates are combustion products of fuel additives containing metal elements. Especially a lot of metal-containing additives are found in universal oils that can be used for diesel and gasoline engines. This is one of the reasons why such oils are not recommended for diesel engines on a regular basis.

The result of the processes described above is the formation of soot soot with particles of other elements, which settle on the filter and do not burn in the soot afterburning mode.

What determines the service life of the particulate filter

The service life of the element is directly correlated depending on how attentively the car owner approaches the particulate filter clogging issue. The service life is also affected by the number of activation of the soot afterburning modes. The more often the car engine activates the soot afterburning mode, the less the particulate filter will last.

Experts recommend that in order to increase the service life of the particulate filter, especially if a car with a diesel engine is operated within a city, clean this element at every service center. This is especially important if there are engine malfunctions that can lead to the formation of massive carbon deposits on the filter element.

Please note: A clean particulate filter is also economically efficient. If the filter is dirty, the engine power decreases, which increases the consumption of the engine to move the car with the same dynamics.

It is possible to increase the life of the particulate filter by using special additives for diesel fuel.Additives can be found in automotive stores that are aimed at reducing the amount of carbon build-up from the engine. This is achieved by maximizing the combustion of fuel in the engine cylinders, which leads to a decrease in the amount of soot in the exhaust gases. It is recommended to use such an additive at least once every 3000 kilometers of vehicle run.

It is possible to increase the life of the particulate filter by using special additives for diesel fuel.Additives can be found in automotive stores that are aimed at reducing the amount of carbon build-up from the engine. This is achieved by maximizing the combustion of fuel in the engine cylinders, which leads to a decrease in the amount of soot in the exhaust gases. It is recommended to use such an additive at least once every 3000 kilometers of vehicle run.

Also, the quality of the fuel used greatly affects the formation of carbon deposits on the particulate filter, so you need to refuel with a high-quality diesel engine in order to maximize the life of this element.

How to clean the DPF particulate filter

There are two main ways to clean the DPF from carbon deposits. The first implies the need to remove the filter element from the car, and the second involves performing actions directly on the car. Both methods have their advantages and disadvantages, so we will consider them separately.

Cleaning the particulate filter with removal

The complexity of this method lies in the need to dismantle the diesel particulate filter, as well as in the duration of the procedure. On average, it will take about 8 hours to clean the filter.

The complexity of this method lies in the need to dismantle the diesel particulate filter, as well as in the duration of the procedure. On average, it will take about 8 hours to clean the filter.

For cleaning, special fluids for washing the particulate filter are used, which can be purchased at car stores. It is better to choose formulations of proven brands such as Luffe, Pro-tec, Liqui Moly and the like. These fluids are compositions of petroleum components and various additives that are capable of dissolving soot soot. Liquids are supplied in 5 liter canisters, on average, one flush will require the entire canister. The canisters on top may have a place for attaching a hose, some of them have a hose included. The hose makes it easier to fill the DPF with flushing fluid.

The housing of the removed particulate filter must be completely filled with flushing fluid and left for the time specified in the instructions for use of the composition (about 8 hours). After that, it is enough to rinse the filter with a jet of water to rinse out the remaining dirt, as well as the remaining cleaning agent.

Please note: Washing with water must be taken seriously as the cleaner is flammable and can ignite when exposed to exhaust gases.

After rinsing the particulate filter with water, it remains to dry and reinstall it.

Cleaning the particulate filter without removing

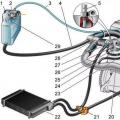

The method of flushing the particulate filter without removing it is faster, since the work is carried out directly on the car. The design features of the filter allow you to supply liquid for cleaning through the hole for installing a pressure or temperature sensor, having previously removed them.

The method of flushing the particulate filter without removing it is faster, since the work is carried out directly on the car. The design features of the filter allow you to supply liquid for cleaning through the hole for installing a pressure or temperature sensor, having previously removed them.

It is important to note that a different composition is used to clean the particulate filter without removing it. This is due to the fact that work is being carried out directly on the car, and there is no way to make sure that oil products will be completely removed from the particulate filter. Therefore, for cleaning, a water-alkaline composition is used. with flushing liquid. The liquid will allow, after cleaning, to neutralize the remaining alkali.

To flush the particulate filter without removing it, you will need to get a spray gun.

Note: You can also find flushing fluids initially in aerosol cans. For effective use of the liquid in the can, be sure to read the instructions for it.

Before flushing the particulate filter, the car engine must be warmed up, after which it is necessary to wait until a temperature of about 40 degrees Celsius is established in the filter element. This must be done to improve the efficiency of the alkaline composition.

The composition is sprayed onto the particulate filter at a pressure of about 8 bar. In this case, the spraying process should be interval: 10 seconds the liquid is injected, then 10 seconds you need to wait before injecting a new dose. Thus, you will need to introduce about 1 liter of cleaning fluid. It is also important to rotate and move the spray probe in order to clean the entire particulate filter. After rinsing with an alkaline composition, clean water is sprayed in the same way.

After performing work on cleaning the particulate filter with liquid means, it is recommended to carry out the procedure for the afterburning of soot residues by operating the car at high speeds for 20-30 minutes.

The requirements for the cleanliness of the exhaust of automobile engines are becoming more stringent every year. Car manufacturers are constantly creating new systems to protect the environment. One of the devices of this plan was a particulate filter. So it was named for the fact that it completely removes soot and soot from the exhaust of a car.

What is the particulate filter used for?

The particulate filter is designed to clean the car exhaust from unburned fuel residues, and most importantly, to reduce the carbon monoxide content in it. Its correct name is a catalytic converter, or simply a catalyst. Its task is, using a chemical process - catalysis, to convert toxic (poisonous) engine exhaust into components that are safer for nature and people. Many have noticed that drops of water drip from the exhaust pipe like from an air conditioner. It can be argued that most looking at this thought to themselves, and sometimes even stated aloud, about the quality of our fuel. They say it gets a lot of water. However, it is not. The appearance of a liquid indicates the high-quality operation of the particulate filter - catalyst.

The basic principle of the particulate filter

As already mentioned, the diesel particulate filter processes the exhaust gases using catalysis reactions. Simply put, it converts harmful substances into steam, which, when condensed, turns into that very water and an almost harmless exhaust. In a particulate filter, this transformation process is provided by three elements of the periodic table:

These rare and expensive components contribute to the high cost of the DPF. It is these substances that, when reacting, convert unburned hydrocarbons from the CH series into ordinary H2O vapor, and the dangerous carbon monoxide CO makes useful carbon dioxide. Platinum and palladium work as oxidizing agents and rhodium as a reducing agent. In terms of the amount of active ingredients, this particulate filter is called a three-part filter. A working particulate filter reduces emissions by up to 85%.

How the particulate filter works

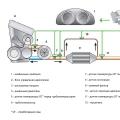

The purpose of the catalyst indicates where the diesel particulate filter is located. It is located in the exhaust system. Usually car manufacturers try to install it just behind the exhaust manifold, as high temperatures improve the conversion processes. However, there is also a minus here. The proximity to the engine and the temperature conditions lead to faster wear of the particulate filter. The neutralizer consists of three parts:

The particulate filter is based on the catalytic converter unit. It is performed in the form of a cylindrical (sometimes oval) block of the finest tubes. They resemble in their appearance from the end part, a honeycomb. From the inside, these cells are covered with catalytic components, thanks to which the exhaust is purified in them. The top of the block is covered with a special layer that retains heat. Naturally, except for the inlet and outlet of the working tubes. All this is enclosed in a metal case with increased strength and heat resistance.

Attention! When the engine is running, the particulate filter in the process of catalysis heats up to 150-200 degrees. Therefore, you should be extremely careful when working with it, and allow it to cool properly.

Sometimes the catalyst is placed directly in front of the exhaust resonator muffler. This arrangement extends the life of the particulate filter, but reduces its effectiveness.

Electronic support of the particulate filter

Normal operation of the catalytic converter is possible only under the condition of high-quality fuel combustion in the combustion chambers. Combustion of this level can only be provided by the fuel system of the engine, equipped with an ECM (Electronic Engine Control System), in which all processes are controlled by an electronic unit operating on data received from various sensors. Included in this scheme and the catalyst. Directly upstream of the catalytic converter, a special sensor is integrated in the particulate filter housing. Its name is oxygen sensor. The common nickname is the Lambda probe. The essence of its work is that, having a zirconium-platinum coating, when heated, it changes the resistance potential of the outer shell, depending on the degree of carbon monoxide content in the exhaust. If this content begins to go beyond the specified limits, the ECU shortens the opening time of the injectors and thereby reduces the fuel supply. And when this indicator decreases, it normalizes the process in the reverse order.

Systems Euro-2 and Euro-3 and 4

The first vehicles with particulate filters received the Euro classification. For the purity of exhaust gases according to European standards. However, after some time, the above-described exhaust control system through an oxygen sensor was developed and implemented. The cleaning efficiency has become even higher. The service life of the particulate filter has increased. This system has already received the Euro-2 classification. As a serial number.

But the disadvantage of the system was the possibility that the ECU did not react at all when the particulate filter failed or was removed. Then the Euro-3 system was developed. The essence of the idea is this: another oxygen sensor was inserted into the system, after the neutralizer unit. It turned out that while the filter is working and everything is in order, the ECU sees the following picture: the resistance readings of the first sensor go in waves. CO levels change all the time. At the same time, the readings of the second sensor are a flat line with small fluctuations, that is, the filter performs its task. If the readings become the same, then the catalyst has crumbled or burned out and the ECU sharply reduces the injection. If the particulate filter is clogged, then the line of readings of the second sensor will become absolutely flat. But, however, when this happens, the driver will feel the change without any sensors. A plugged, in fact, exhaust pipe, this is a drop in power by more than 50%. Well, in recent years, the automotive industry has adopted the Euro 4 standard as a basis. But the main condition for the transition to this standard is not the design changes of the car, but the transition of all filling stations to the new fuel standard. Many articles on the Internet argue that an operation to install a special catalyst is needed to switch a car to the Euro-4 standard. This statement sounds strange to say the least. The fact is that all Russian cars manufactured since 2005 are already equipped with a particulate filter, which is the catalytic converter. Another question is that many owners have deleted it. But the issue of removing this device from the exhaust system is a topic for a separate article and is not considered here.

Attention! Work on removing or replacing the filter should be carried out only after consulting a specialist.

The possibility of failure of the particulate filter

The tubes for the neutralizer unit are made of two types of material. There are ceramic honeycombs and metal ones. Ceramic honeycombs are more durable in operation, since their surface cannot interact with active substances during reactions. In addition, ceramic, unlike metal, tolerates high temperatures better. But at the same time, a particulate filter with a ceramic base is afraid of strong shocks and impacts, because this material is more fragile. So the main reason for the breakdown is the destruction of the neutralizing unit.

In the ceramic version, it can crumble, and in the metal version it can burn out. For systems with a block located directly behind the exhaust manifold, this is a very frustrating moment. Either fragments of ceramic fall down and block the exhaust gas outlet, or the metal block also falls and blocks the exhaust. The second option is the clogging of the working cells when using low quality fuel. And the last one is the development of all active elements on the inner surface of the honeycomb. The rarest case, the destruction of the metal case. In all cases, a set of work is required to replace or remove the particulate filter. But this issue is also worth considering as a separate topic.

Diesel Particulate Filter

Diesel fuel is fundamentally different in composition from gasoline and the principle of operation of diesel engines differs from the operation of conventional gasoline internal combustion engines. Accordingly, the particulate filter, the catalytic converter of these engines, has a structure different from the gasoline one.

The diesel particulate filter is made of silicon carbide and titanium. The main task of the neutralizer here is not catalysis, but simple capture and afterburning of accumulated soot particles by high temperatures. Such filters began to be installed on diesel engines relatively recently, after the adoption of environmental standards Euro-4 and Euro-5. The features of this system are the self-cleaning properties of these neutralizers. The electronics provide for a system of forced afterburning of particles. When soot accumulates in the honeycomb, a special valve is turned on, asynchronously supplying a small amount of additional fuel to the cylinders. Once in the honeycomb, this mixture heats up the particulate filter to a temperature of 500-700 degrees Celsius, forcibly burning out the soot deposits cleanly. On some models, an additional system for injecting a nitrogen mixture into the particulate filter is also installed. According to experts, converters for diesel engines according to Euro-5 standards retain up to 95% of the emitted soot. But the topic of diesel engines should also be considered as a topic for a separate article, or even a series of articles.

Below you can watch an interesting video of the particulate filter:

Particulate filter Features of the use of a particulate filter in urban environments.

If the car does not accelerate to the required temperatures, depending on the brand, someone has 30 km / h, someone has 50 km / h, there is no stable speed above a certain threshold, the particulate filter does not go into regeneration mode. This is due to trivial safety: since there is a certain amount of carbon in the filter, which, when oxidized to carbon dioxide, will release temperature.

In this situation, there is a risk that the diesel particulate filter housing will heat up to a critical temperature and damage the anti-corrosion coating of the body, etc. In the future, the anticorrosive under the bottom will start to smoke.

Therefore, most brands have a limitation that the filter is burned out only at certain operating modes of the engine in motion.

How to ensure cooling of the particulate filter

When we are in city traffic jams, especially in winter, the particulate filter does not go into burn-through mode. The control unit reads the signals from the ABS sensors, sees that the speed is not sufficient, and the particulate filter accumulates soot. Small soot particles accumulate in the pockets, as shown in the figure below.

Read more about the particulate filter device.

With a certain frequency, a certain amount of them accumulates, the resistance of the filter at the exhaust rises, and at the inlet and at the outlet reaches a certain value, in this situation it is necessary to put a back pressure sensor in front of the filter and a modern engine will give access to the regeneration mode.

In this case, the injectors give an additional injection of one more portion of fuel at the moment of the working stroke. As a result, the fuel ignites when the exhaust stroke begins. That is, when the piston throws all combustion substances into the exhaust. In fact, a burning torch flies into the particulate filter from the cylinder. It raises the temperature inside the particulate filter, the soot under the influence of platinum begins to oxidize to carbon dioxide, and in the gaseous form, the substances seep through the porous ceramic, as shown in the picture, and the particulate filter is operational again.

The resistance is reduced to the desired threshold, the regeneration mode is turned off, the car continues on.

How the particulate filter clogs up in traffic jams. No regeneration occurs

There are certain restrictions in traffic jams, and it is in this situation that the following happens: the accumulation is in progress, but the mode is not activated, over time, the accumulation of soot will occur above a certain threshold, after which the car's control unit will inform the owner that it is time for the owner to go to the car service. Namely, he will show that the particulate filter is clogged, above a certain limit, regeneration is no longer possible, and all that remains is to go to the service.

Replacing the particulate filter and its cost

There are several solutions to this problem. If the clogging of the particulate filter has reached this level and the owner immediately reacts to the sensor and arrives at the service, then with a special. the dealer's appliance can activate the regeneration mode. In this case, there will be a characteristic, smoky carbon dioxide exhaust, under the supervision of specialists, the engine will work in the required mode so as not to overheat the bottom of the car.

If you start this problem, and do not go right away, but with a delay, then the degree of contamination of the particulate filter can cross the second critical border, where even from the dealer's scan there will be a ban on burn-through. And then any official dealer will say that you only need to replace the particulate filter.

Recall that the main element of this filter is platinum, so the cost of the device is very high. Well, for example, if you take the filter of a passenger car, then the cost can reach from 1000 euros.

What to do in such a situation if you don't want to buy a new soot, or simply, as they say, there is nothing.

Let's consider several options:

1. Removing the particulate filter. But at the same time, not for all cars, the control unit can be made to work in the case of a particulate filter replaced by a flame arrester. Because they catch both the pressure drop and the difference in the content of certain substances, with these components, the control unit will not allow the car to move. Basically, the older generation models manage to deceive the system. Newer and more modern ones will fail.

Those who cannot cheat will have to live with him throughout the entire operation of the car. And sooner or later it will have to be changed. At the very least, do not stay in traffic jams for long, especially in winter. After each standing, let the system regenerate, drive a certain number of kilometers along the track at a certain speed, so as not to let it completely clog.

2. There is a second decent and quite economical option, in addition to replacing it. The option will be interesting for both the car owner and the car service. This is the maintenance and cleaning of the particulate filter.

Diesel particulate filter diagnostics and problem solving

Let's look at an example and a possible way out of the situation. If during the diagnosis such an inscription appears as in the figure: "Particulate filter is full" - this situation is taken from VAG.

It is necessary to work on this problem. There is a choice before you.

As you can see in the picture, the difference in cost is up to 10 times. Cleaning the filter is less costly for both the owner and the service. When servicing the particulate filter, it will retain its performance, nothing will be damaged, and the owner will not have to worry about replacing and overpaying money.

How to clean and what, we will talk in the next article. And consider products such as diesel particulate filter cleaner, cleaning fluids, and preventative additives to reduce clogging during vehicle operation.

Read an interesting article

A device such as a particulate filter is available in all diesel cars produced since 2011 (as well as on a number of models produced after 2000 - then it was not yet a mandatory element, but was already used by some car manufacturers) in the territories of countries belonging to WTO (Euro-5 standard, adopted by the Customs Union).

New particulate filter  Particulate filter after use

Particulate filter after use

The main task of such an element is to maximally clean the exhaust gases from impurities harmful to the environment.

The use of particulate filters has reduced the content of soot particles in the exhaust of diesel vehicles by almost 100% - more precisely, by 99.9%.

What is the purpose and how does the particulate filter of a car work?

There are currently two types of soot cleaners used in cars:

Diesel Particulate Filter DPF (an abbreviation for Diesel Particulate Filte) for diesel cars traps soot particles up to 1 micron in size, which are formed as a result of fuel combustion. Such a filter is distinguished by the simplicity of the device, but at the same time it requires regular cleaning (regeneration) actions.

A filter type FAP (short for the French expression Filtre A Particules) is a more complex device that does not require regular intervention. Regeneration (purification) takes place here in automatic mode.

The location of the particulate filter (see Fig. 1) is in the exhaust system, behind the catalytic converter. In some cases, it can also be combined with a catalytic converter, and then its location is right behind the exhaust manifold.

This is the place where the flue gases have their highest temperature. In this embodiment, the device is called a "catalytic coated particulate filter".

The average service life of particulate filters is designed for a mileage of 150 thousand km. But this is the European standard. On Russian fuel, according to the reviews of the owners and workers of car services, this figure is reduced by almost three times.

At the moment when the on-board computer generates an error indicating that the particulate filter is clogged, the car owner will need to make one of the following decisions:

- Full replacing the particulate filter... A very expensive undertaking. Of course, the price very much depends on the make and model of the car, but in any case, this action is much more expensive than all of the items listed below. For example, at a BMW it will cost you around 1,500 euros to replace a particulate filter.

- Physical removal of the particulate filter. The procedure is also not cheap, and has several disadvantages. It is not enough to simply take and cut out the filter, replacing it with a pipe section. A number of on-board computer procedures are tied to the data received from the particulate filter sensors, which means that it will be necessary to replace its firmware. Replacing the firmware does not always go smoothly, in some cases errors occur (false alarms of indication, other problems with the on-board computer).

- Deception of the DPF sensor. It consists in installing a separate device that emulates the normal operation of sensors (falsifies signals) or software removal of the particulate filter from the electronic control unit system. This procedure does not relieve the car owner from cleaning the filter itself. However, it significantly extends its life or allows you to easily remove the particulate filter with the least errors in the operation of the on-board computer.

- Regeneration. The most correct procedure, because removing the filter increases the emissions of harmful substances into the atmosphere, despite the fact that even without this element, European cars successfully pass technical inspection according to Russian standards. At the same time, the cost of regenerating filters remains acceptable in comparison with the same removal or replacement, although they require periodic repetition.

VIDEO INSTRUCTION

Regeneration types - cleaning methods

In essence, a particulate filter is a container filled with a substance with a porous structure (most often ceramic is used). When the exhaust gases pass through these "honeycombs", soot and fumes are deposited on the pores of the filler.

Over time, the pores become clogged and the passage of exhaust gases becomes difficult, which leads to an increase in fuel consumption and a decrease in engine power, and the risk of various problems increases.

To restore the filter properties, a regeneration procedure is performed, which can be of two types:

- Active. The pores are cleaned by increasing the temperature inside the filter to 600-1000 degrees Celsius. At this temperature, the soot completely burns out.

- Passive. Here, the removal of soot also occurs due to its combustion, but combustion proceeds at a temperature of about 350 ° C (this is the normal temperature of diesel exhaust gases). To oxidize soot, a special catalyst is needed to lower the reaction temperature - for example, platinum in Volkswagen filters (the same catalytic coated particulate filters that were mentioned earlier).

Active regeneration requires special procedures on the part of the car owner, while passive regeneration takes place without any involvement of the car driver.

If regeneration does not have the desired effect, you can always simply rinse the filter. Flushing the particulate filter is performed after removing it from the vehicle. The unit is placed in a special chemical composition for a while, and then the same composition is passed through a filter under pressure.

How to start regeneration of the particulate filter

You can increase the temperature inside the particulate filter for complete combustion of soot in one of the following ways (active regeneration):

- The introduction of special additives (most often based on cerium) into the fuel mixture, which, when passing along with the exhaust gases, continue to burn. In this case, the removal of the vehicle assembly itself is not required. The disadvantage of this method is its low efficiency - the method can give a positive effect only at the initial stage of pollution (no more than 2000 - 3000 kilometers from the moment the error indicator on the on-board computer panel is triggered).

- Starting a special procedure for the engine operation through the electronic control unit of the car. In this case, the air supply is reduced, the fuel is injected at the exhaust stroke (that is, it enters the exhaust system unburned). In some car models, original technologies are used, for example, an additive is additionally introduced, or the outflow of burnt gases is reduced, etc.

If regeneration does not help, it is necessary diesel particulate filter repair.

It will be removed, disassembled and cleaned by hand, or completely replaced in the workshop. Of course, this can be done with your own hands, but it is better to trust the specialists.

The regeneration procedure is launched most often without user intervention:

- The soot filter sensor is triggered.

- During the movement, the control unit will independently increase the speed, reduce the air flow and clean the particulate filter.

But, if the cleaning attempts are unsuccessful, or the soot level is critical, the control unit will refuse cleaning attempts and display an error.

In this case, you can try to start the procedure yourself through the service menu of the electronic control unit (EBP) and follow the instructions of the system (if the automatic speed control mode is not supported).

It all depends on the car model and the EBP firmware. In some cases, knowledge of service codes or connection of external diagnostic devices may be required.

What liquid will help to regenerate the diesel particulate filter

If you have not become the owner of a car with a diesel particulate filter with a catalytic coating or an integrated automatic regeneration procedure, then you can always resort to using special additives.

You can try to restore the particulate filter, for example, using universal means:

- Regeneration catalysts from ARDINA - Diesel Particulate Filter Regeneration Aid (poured into the fuel tank as an additive).

- Liqui Moly Pro-Line Diesel Partikelfilter Reiniger is a cleaner that requires forced injection, after application it must be neutralized with another solution (Pro-Line Diesel Partikelfilter Spulung).

- Liqui Moly Diesel Partikelfilter Schutz is another additive that acts as a catalyst.

VIDEO DESCRIPTION

If an original additive is used in the car (for automatic feeding from a special tank in the diesel particulate filter regeneration mode), then it should be ordered from authorized dealers.