Often, car owners are faced with the fact that when ignited, the starter only clicks, but does not twist and, as a result, the car does not start. But it happens that the starter turns regularly, which is audible by the characteristic sound, but the car still does not start. What to do in a similar situation?

Reasons why the car won't start

Any modern car is essentially a kind of symbiosis of numerous units, systems and mechanisms, due to which not only its characteristics improve, but also there are more chances to face a situation where the car simply does not start. The localization of such problems can be different and, as a result, the reasons are different. Among these are:

- Lack of gasoline, oil and other automotive fluids;

- Discharge of the battery and / or the formation of rust (oxide) on its marks, which interfere with the transfer of charge;

- Problems with candles, injector (carburetor);

- Malfunctions in the electronics system;

- Problems in the operation of the fuel pump;

- Clogged fuel and / or air filters;

- Clogged throttle valve.

INTERESTING! Some car companies are committed to providing full service over a specified period of time. So, in the event of any breakdown, the owner only needs to call the warranty service center and specialists will immediately come to perform repairs.

The starter motor cranks, but the engine will not start. How do you find the reason?

Cause of situations in which the engine turns, but does not start, there may be several factors, however, in the event of such problems, first of all, it is necessary to pay attention to correct operation of the ignition system and the power supply system, that is, the fuel supply.

IMPORTANT! It is advisable to carry out diagnostics of these systems only in those cases when the operation of the starter proceeds without jerks and unnecessary sounds. In this case, the problem usually lies in the starter itself.

Diagnostics of the ignition system

First of all, you need to unscrew the candle and check for spark. To do this, a high-voltage wire is put on the switched off candle, and the metal part of the engine is touched with its skirt. If a spark appears when the engine rotates, then the spark plug is working and does not require replacement - that is, the problem lies elsewhere.

INTERESTING! Depending on the type of engine, the absence of a spark indicates problems of different locations. So, problems in an injection car indicate a malfunction of the ignition module, in a carburetor car - a malfunction of the ignition coil.

The ignition module, due to the design and performance features, is almost impossible to check independently, which cannot be said about the coil.

To diagnose the ignition coil, you need to remove the central wire of the distributor cover and bring it to a distance of about 5 mm to the metal part of the engine, excluding any contact. If there is no spark after cranking the engine with the starter, the coil is out of order.

If the coil is OK, a final check of the ignition system must be performed - remove the distributor cover and check it for defects and damage. If the diagnostics of the ignition system did not give the expected result, and the starter still works, but the car does not start, you need to proceed to the next stage - diagnostics of the fuel system.

If the coil is OK, a final check of the ignition system must be performed - remove the distributor cover and check it for defects and damage. If the diagnostics of the ignition system did not give the expected result, and the starter still works, but the car does not start, you need to proceed to the next stage - diagnostics of the fuel system.

NOTE! In most cases, problems of this nature lie precisely in the ignition system, therefore, all stages of diagnosis should be carried out as carefully as possible.

Fuel system diagnostics

Checking this unit should be performed sequentially, starting from the fuel pump and ending with the injector (carburetor).

In vehicles with an injector when the ignition is switched on, the sound of the electric fuel pump operating in the passenger compartment should be heard. If this sound is absent, the reason is in the pump motor - either it burned out or does not receive voltage. Therefore, first of all, you need to check the pump itself and its safety system.

Cars with a carburetor are more difficult to diagnose because the pump is driven by a camshaft. In view of this, to check it will be necessary to disconnect the end of the hose from the inlet fitting. So, if after that you swing the pump priming lever several times, then fuel should flow from the fitting or hose.

When the starter turns, but the car does not start, the problem may also lie in the injector ramp, or rather, in the presence of gasoline in it. To check, it is enough to press on the valve of the union connecting the pump - gasoline should come from it.

An obligatory part of the diagnosis is checking the fuel filter for blockages. This is not surprising, because situations often arise when, due to lack of fuel, the car does not start, the starter turns, the relay clicks.

An obligatory part of the diagnosis is checking the fuel filter for blockages. This is not surprising, because situations often arise when, due to lack of fuel, the car does not start, the starter turns, the relay clicks.

Also follows check the throttle, which, when clogged, can cause the starter to idle.

What to do when the engine won't start but the starter clicks

Often, car owners are faced with a problem such as "drowned out the car and will not start, although the starter turns." The implementation of the measures and recommendations indicated above, in the majority of cases, can solve the existing problems. However, sometimes the relay may be faulty. To eliminate and eliminate problems of this kind, you should also diagnose the relay, after which you may have to repair or replace it.

Starter relay diagnostics

"The car does not start, the starter is spinning" - the cause of such problems can often be identified and eliminated on their own at an early stage, but for this you need to responsibly and thoroughly diagnose the starter relay.

To check the condition of the retraction relay, first of all, it must be carefully removed from under the hood. After that, the starter must be cleaned of dust, dirt, mechanical debris. Oxidized contacts are processed with fine sandpaper.

To check the condition of the retraction relay, first of all, it must be carefully removed from under the hood. After that, the starter must be cleaned of dust, dirt, mechanical debris. Oxidized contacts are processed with fine sandpaper.

The next step is to place the starter in close proximity to the battery and prepare two wires of the required length. It is advisable to use wires with crocodiles. Then, with one electric drive, you need to connect the positive terminal of the battery with a similar output on the solenoid relay. After that, do the same with the second wire, connecting the minus contacts. If, when connecting the wire to the relay, a characteristic click of the charge sounds, then it is serviceable and can be installed back. Otherwise, it should be repaired or replaced.

Repair or replacement of relays

Repair and replacement is a fairly straightforward process:

Summing up, we can conclude that situations when the car does not start, and the starter turns, although they cause some inconvenience, but, often, are not critical, since they can almost always be independently resolved.

But do not forget that it is better to prevent the situation than to courageously solve problems, therefore the first rule of the car owner is to regularly check the correct operation of all systems and mechanisms of personal transport.

What to do if the car's injection engine does not start? What to do when, when turning the key in the ignition lock, the starter turns, but the engine does not start. If the engine was carbureted, then the situation with the determination of breakdowns is a little easier. How are things going with injection engines?

In an area where there are a sufficient number of auto repair shops, and calling a tow truck is not a problem, it is not so difficult to solve the problem. But what if this is not possible? After all, there are times when you have to do everything yourself. In fact, many breakdowns that prevent the engine from starting can be corrected by yourself.

Self-diagnostic tools

- Light bulb. You can make such a test lamp yourself by connecting wires from the instrument panel to the lamp. To do this, you need to use light bulbs up to 3 watts.

- Discharger. It is used to determine if a spark is being supplied to the spark plugs. There are many recommendations for self-collecting such a device.

- Multimeter. It's not very possible to assemble it yourself. But such "testers" are widely available in the trade network.

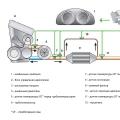

Possible reasons why the injection engine does not start

![]()

Fuel system

It is necessary to diagnose the fuel supply system. In domestic injection vehicles, when starting the engine, you can hear a specific buzz from the rear of the car. This sound indicates the operation of the fuel pump. Accordingly, if no such buzzing is observed, most likely the problem lies in the pump.

It is necessary to check the fuses that are responsible for the fuel pump, the main engine control relay and the fuel pump relay. In some cars of the VAZ family, the fuses are hidden under the glove compartment, in others behind the cover of the heating panel on the passenger side. If the fuses are OK, check the relay.

You can touch it, and a specific click should sound. If the relay is also working properly, you need to check the pressure in the fuel system. This is best done with a pressure gauge. If this is not possible, you will have to find a spool, which should be under the protective cap.

When you press on it, you should feel pressure. Some models do not have a spool. Then you need to disconnect the fuel supply pipe. If the pump is working, then pressure should also be felt under the finger.

Clogged fuel filters or fuel lines can also be a possible cause. There may also be such a banal reason as the lack of fuel in the tank.

![]()

If it turns out that all the elements of the fuel system are in order, then the next thing to pay attention to is the ignition system.

Ignition system

The main thing to be sure of is the presence of a good spark, that is, a discharge between the two contacts of the spark plug. If the starter turns, and the engine does not start, then there is a high probability of a malfunction of the ignition system. Here we need our spark gap. If you check the spark plug without it, for example, by attaching it to the engine, then the resistance will be too great.

Therefore, we will not be able to accurately check our candles and, in addition, the controller can be disabled. After checking the fuel system, the ignition system and not finding the causes of the malfunctions, it will be necessary to check the engine. Most likely, the reason is in it.

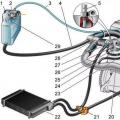

Starter malfunction

This can be a very common reason why a car engine will not start. In order to establish the possible cause of the breakdown of the starter, it is very good if the motorist has at least a rough idea of \u200b\u200bthe structure of this mechanism, and how you can check whether he is working.

![]()

It is important for owners of foreign cars to know that imported starters can stop turning even from a lack of lubrication or contamination. In this case, the solution is very simple: remove the starter from the engine, carefully clean it from dirt and thoroughly lubricate the necessary mechanical components. Moreover, the used grease must be removed. In principle, this is not difficult, but if it does not work out, then it is better to contact the master.

Some starter malfunctions are audible. If you turn the key in the ignition lock, there is a click in the starter, but it does not start, then the relay is most likely faulty. If possible, then you need to repair it. If the relay cannot be repaired, then it is worth replacing it. Only demountable relay types can be repaired.

Accumulator battery

The battery must be intact, and the terminals must be clean without oxide, otherwise there will be no good contact between the battery and the car's electrical wiring. The battery must be sufficiently charged and “hold” it.

If the battery has been used for some time in undercharged mode, then there is a very high probability of deep discharge, in which it will no longer be able to recover.

![]()

Wiring

Corrosion can form on wiring or connections, which prevents the normal flow of current. All contact pairs must be clean and the connections insulated.

Nozzles

Injectors in a car rarely fail all at the same time. Therefore, if there is a malfunction of any of the injectors, then the engine will still be able to start and work, albeit intermittently.

Crankshaft sensor

If this sensor is defective, the engine will not be able to start. In this case, the starter turns, but the engine still does not start. Failure of other sensors will not be able to affect so much that the engine does not start. To test the sensors, you should use a multimeter.

What to do if the starter turns, but does not turn the engine, does not turn it There are few reasons for this behavior, they should be studied in more detail, and also methods for elimination should be considered. It is possible that you will immediately start to panic, but this is not worth doing. Repair will cost a maximum of 300 rubles. The only thing that this breakdown will take away from you is time. But it all depends on what kind of malfunction is hidden in the starter. First you need to diagnose.

Breakdown diagnosis

So, the symptoms are obvious - the starter turns, but does not turn the engine. Of course, you can start a car from a tug, but it is reasonable to do this only if you need to get to the place of repair. You will not constantly start the engine in this way. First of all, pay attention to whether extraneous metal sounds are heard from the side of the starter. If they are present, then the cause of the breakage can be immediately determined - the teeth on the flywheel rim are worn out, so the bendix gear cannot mesh with them.

But there may be other malfunctions. For example, the breakage of the bendix itself. Its main part is the overrunning clutch. With its help, the gear can only rotate in one direction. If it rotates freely in both directions, then the freewheel is damaged. You just have to replace the bendix, and this procedure will take half an hour at most. It is very rare that metal plates or a plastic plug are destroyed. If such a breakdown occurs, the starter turns, but the engine does not start, as it closes the contacts, but does not engage the gears.

How to remove the starter

To work, you need a small set of tools - keys for 10 and 13. And regardless of the car on which this mechanism is removed. Repair of starters on various brands and models of cars is carried out using the same technology. The reason for this is the identical design of the electric drive. They can differ in size, type (with or without a gearbox), as well as the type of plug (plastic, metal plate). Otherwise, there are practically no differences.

True, on some you have to dodge not weakly to remove the starter. For example, on domestic classics, in order to unscrew the lower fastening nut, you need to crawl under the car to release the engine starter. And then, using a 13-point head, a pair of cardan shafts and an extension cord, unscrew this unfortunate nut. True, most drivers simply ignore it, during assembly they carry out fasteners for two nuts. In the other models of domestic VAZ cars, there are no problems with dismantling the starter.

How to replace the bendix

You can replace the bendix in just 10-15 minutes. With the condition that the starter has already been removed from the vehicle and prepared for repairs. First, unscrew the rear cover fasteners, then remove the retaining ring from the rotor. Unscrew the two nuts that tighten the starter parts. But it is possible to disconnect only after the stator windings are disconnected from the brush assembly. When repairing starters, try to pay attention to every detail, even the smallest.

First, clean the louvres and housing. Second, assess the wear on the bushings and brushes. When all parts of the starter are disconnected, the rotor will remain in the front cover. Closer to its edge is a retaining ring. A clip is put on top of it, which can be shifted towards the rotor winding by inflicting a few light blows. Then use a screwdriver to remove the ring. That's all, now the bendix can be easily dismantled, and a new one is installed in its place. It is recommended to coat the spiral splines on the rotor surface with lithol or graphite grease.

How to remove the gearbox

But everything is much worse if the starter turns, but does not turn the engine, and metal sounds are also heard. This suggests that it will be necessary to remove the gearbox and change the flywheel crown. Since you are going to climb here, then remember how long ago you changed the clutch. If you do not remember when, then purchase a kit - a disc, basket, bearing and six bolts. The procedure for removing the gearbox is not easy, so it is unnecessary to carry it out once again. First of all, disconnect all wires going to the gearbox and the speedometer drive cable. Now drain the oil while controlling its appearance.

After that, disconnect the drives - remove the inner CV joints from the gearbox. Please note that both hinges cannot be removed at the same time! First dismantle the first one, then put a plug in its place. After that, just take out the second one. Otherwise, the differential will collapse, you will have to disassemble the box to eliminate the damage. Then you hang up the engine and gearbox, dismantle the pillows. However, this is the end of the preparation. Now just unscrew the bolts or nuts that secure the box to the engine. And you can do undocking.

Flywheel ring replacement

Please note that if the starter turns, but does not turn the engine, and the reason is in the crown, then not all of its teeth will be destroyed. Most will be in perfect condition, but a small sector will be spoiled. The thing is that the crankshaft stops in one position relative to the starter. And it is in it that the engagement begins - the impact of the bendix gear on the crown.

Repairing the crown can be completely free. It will be quite reasonable to remove and install it on the reverse side. This element is completely symmetrical, so no problems will arise. The new one has a cost of about 200-250 rubles, which also will not hit your pocket. First, it must be knocked off the flywheel. Then the crown (new or the same) is warmed up. Red-hot is not necessary. And just applied to the flywheel. That's all, now the metal is cooling and the crown grips the flywheel tightly. This completes the repair and starts assembling the car.

Conclusion

Now you know how easy it is to change the starter. The price of a new one is relatively small. For example, for VAZ cars the minimum is 2300 rubles. Of course, the more expensive the car, the more money will be spent on buying a starter. But changing it completely is not always wise. If the fault is in the bendix, then its cost is ten times lower. Therefore, it is easier to replace only this unit.

Surely every driver knows what an unpleasant problem it is when the engine completely refuses to start. Yesterday the car started up, but today it completely failed. This trouble can happen anywhere and absolutely suddenly, but before troubleshooting, you need to know the reasons why the car will not start. In this article, we will analyze why the car does not start, the causes and remedies.

First of all, you need to immediately drop the panic. It doesn't matter where it happened, but if you are on the roadway, then the first step is to turn on the hazard warning lights, and also try to remove the car from the road by all available means. Now you can search with peace of mind for what reasons the engine of your car will not start.

If the engine does not start even without a filter, then the ignition system is faulty. To evaluate the operation of this system, you can unscrew one of the candles, and then examine its condition. The spark plug electrodes must not touch each other and must be clean. If they show any deposits or blackness, then such a plug must be replaced and try to start the car again. If it is not possible to change the candle, then it can be heated over the fire for a while and wiped with sandpaper. Alternatively, you can use the rubbing part of the matchbox. As a rule, after that, the engine of the car starts up easily and can safely get to the place of high-quality diagnostics.

In most cases, a black plug not only implies plug failure, but also an increased fuel content in the mixture, which most often indicates an incorrect carburetor adjustment.

But if you are sure that the candle is not the cause of the problem, then you need to check for a spark.... It is worth warning right away that this can not be done on every car, since the ignition coils of some cars do not withstand such a load. To do this, grasp the high-voltage cable with one hand and slightly lean its contact against the cylinder block so that there is a distance of at least 5 millimeters between it and the latter.

Ask your partner to turn on the starter for a short time, if you see a spark, then the ignition system is in perfect order, or the plug still needs to be replaced. If there is no spark, then check the condition of the cable, wipe it and the distributor from moisture, and open the distributor cover. In a contact ignition system, it is enough to simply clean the contacts, which usually always solves the problem. In BSZ, it makes no sense to do this and diagnostics must begin with checking all contact connections, and then start changing one element after another one by one.

Otherwise, if the candle is black and wet, then you simply "flooded" it. This is a very urgent problem for those drivers who are used to starting the engine simultaneously with pressing the accelerator pedal. Because of this, their car firmly ceases to "grasp" and then the case ends with a planted battery.

To avoid this, it is necessary to dry the candles. To do this, they are twisted and heated on a gas stove. Then they are thoroughly wiped, after which they are installed on the car. If you are in a hurry, you can use a technique that involves quick drying and blowing out the cylinders. To do this, press the gas pedal to the floor and turn on the starter. After 2-3 engine revolutions, gradually release the pedal, it is at this moment that the motor, as a rule, grabs.

If you are the owner of a car with an injection system and it won't start, then pay attention to the dashboard. The corresponding “Check Engine” icon may light up on it, which indicates specific reasons. You can find out the exact location of the breakdown using a diagnostic computer.

Starter malfunction

More serious problem when the starter motor does not crank the engine at all... Here really

there may be room for panic, however, many reasons are completely removable.

So, you turned the key, but instead of the usual turning on of the starter, nothing happened, then check the reliability of the battery terminals. Most likely, they just came off, which means that they need to be tightened, in some situations even cleaned if they have oxidized.

Among the reasons for the failure of the starter may be that the battery is simply discharged.... In this case, it will sluggishly spin the engine, or even at all, only the retractor will work. If you are confident in charging it, check that all contact connections are secure.... Many vehicles are equipped with a special starter relay, which reduces current and reduces stress on conductors. It is this that can have poor contact if it was established on its own.

You can find out about this by the fact that even the retractor with a characteristic click did not work. If the retractor is triggered, but the starter does not turn, then try again. Many cars, due to their age and "cleanliness" of contacts, are not always able to start the first time. Otherwise, the starter must be cleaned, and maybe even replaced..

Sometimes the car will not start due to the fact that the starter turns, but does not turn the engine. This means that a special ring fell off the flywheel, which caused the bendix to slip. Only replacing the faulty unit will help here.

If your car still won't start even after the above measures, then the reasons lie elsewhere. Only service station employees will help you find out about this. To get to the station, just ask a friend to take you in tow, and then head to the nearest repair site.

You turn the ignition key, but the car does not start - the starter turns, but does not grasp, as usual. And what is the reason is not clear, at first glance everything is working properly and works flawlessly. But the problems are lurking somewhere, they need to be identified. The reasons for this behavior are mostly different for carburetor and injection engines, but there are also similar ones. And the fact is that there are significant differences in the design of the ignition and the fuel system. In fact, it turns out that carburetor motors are much more complicated. So, big and about the reasons for the appearance of such a breakdown.

A breakdown can cover almost anywhere, so after several failed attempts, check if gasoline is entering the combustion chambers. Unscrew the candle and look at its electrode, it should be wet. If not, then the gasoline does not enter the combustion chambers. Now remember if the gasoline has run out? If this is the case, then refueling will save, but if not, you will have to continue looking for a malfunction.

One of the vulnerabilities is the fuel pump. It is driven by a camshaft rod and is installed next to the ignition distributor. It may have such breakdowns:

- Reducing the length of the stem leads to the fact that the membrane stops moving and pumping gasoline.

- Failure of valves. In this case, the membrane moves, and the car does not start, since gasoline is still not pumped over. There are two valves inside the fuel pump - for inlet and outlet. The problem can be solved only by replacing these elements.

- The destruction of the membrane, springs, metal elements leads to the fact that the fuel does not enter the carburetor.

On sale you can find pump repair kits. As practice shows, the probability of qualitatively repairing this unit is one in ten, therefore it will be much cheaper and easier to purchase a gas pump assembly.

A filter is installed in front of the pump, which should preferably be changed at least once every 10 thousand km. The quality of gasoline and the condition of the tank make themselves felt, the filter becomes clogged. There is also a small filter at the inlet to the carburetor, the size of it is like a thimble. To remove it, you need to use the keys to "12" or "13", depending on the specific model of the carburetor. Cleaning is most convenient with a toothbrush.

But there is another small breakdown that can infuriate any car owner. The motor works normally, without interruptions, but suddenly, for no apparent reason, it simply stalls, it does not work to start. And after a while he can grab and continue to work without problems. These are the “mood swings” that occur when the spring between the float and the needle comes off. This also happens, as practice shows, but only very rarely. As long as the needle moves by itself, the fuel enters the chamber without any problems. But as soon as she gets a little jammed, gas stops flowing into the carburetor.

On cars of the classic VAZ 2101-2107 series, similar symptoms occur if the valve adjustment is violated. In this case, the starter turns, and the engine does not start, or it catches and instantly stalls. Usually, starting the engine to a cold one occurs without problems, but as soon as it warms up to operating temperature, problems begin. The reason is that the valves are completely closed by the valves, so gasoline is not supplied to the combustion chambers. The problem is solved by adjusting the valves.

- There is no power. In this case, the valve does not open, the engine stalls. If you're on the road and don't have time to look for a breakdown, connect the valve lead to the positive battery lead.

- Valve nozzle clogged. To clean it, you must remove the air filter housing and unscrew the device. Blow out the holes with compressed air.

- Failure is not treated, only the valve can be replaced. The temporary solution is to trim the protruding edge of the needle.

Note that the engine needs air to function properly. If the air filter is clogged and does not allow air to pass through, this will cause the starter to turn, but the engine will not start. If none of the above helped, then one thing remained - clogging of the jets in the carburetor. We'll have to completely disassemble it and clean all channels, getting rid of foreign objects.

Injection power system

Here you need to look for breakdowns in such nodes:

- Fuel pump installed in the tank. When the ignition is turned on, it starts to work, pumping gasoline under pressure into the rail. If it does not turn on, then the pump is faulty or there is an open in the power circuit. If the pump pumps gasoline without stopping, then the reason lies in another element.

- If the pump pumps gasoline without stopping, then the reason lies in the pressure sensor. It is installed on the ramp and is designed to monitor the operating mode.

- The car still does not start (the starter turns) due to the failure of the electromagnetic injectors installed in the ramp. Breakage of all at once is almost impossible, rather there is a destruction of the wiring or clogging of the nozzles.

- Failure of the fuel system sensors leads most often to unstable engine operation, but in some cases, to the inability to start it. If the crankshaft position sensor fails, the engine will not start.

It is quite difficult to distinguish between the power supply system and the electrical equipment in injection motors. The reason is that these two systems are intertwined with each other, interconnected. Most of the sensors are electrical equipment, but are primarily involved in mixture formation and fuel injection. In fairness, it should be noted that with their help the ignition timing is also controlled.

As is the case with carburetor engines, it is necessary to monitor the condition of the fuel and air filters. The fuel line has two filters - fine and coarse filters. The first is located under the bottom of the car, the second directly on the gas pump. If gasoline enters the rail, then there are no problems with filters. There were cases when there was a break in the power wire of the injectors, coils, sensors, directly at the terminal "30" of the generator.

Ignition system

Everything that has been said above about injection motors can be safely transferred to breakdowns in the ignition system. The reason is that most of the same sensors are responsible for the operation of ignition and fuel supply. Even the electronic control unit is responsible for the operation of all components and assemblies of the car. If it fails, there is no way to start the engine. But why does the starter turn the crankshaft, but the engine still does not start? One of the reasons is the failure of the ignition coils (all, if there are 4 of them) or the ignition module. This happens extremely rarely, so the engine will rather triple.

A contact or contactless ignition system is installed in carburetor engines. The following elements can fail in the BSZ:

- Ignition relay.

- Switch.

- Hall Sensor.

- Runner or distributor cover.

- Low and high voltage wires.

- Ignition coil.

In contact ignition systems, there is no switch and Hall sensor, instead of the latter, a contact group is installed. She has a limited resource, she can fail at any time.

There is no ignition distributor on injection engines. The moment of voltage supply to the electrodes of the spark plugs is regulated by a system of sensors and control. And if the starter turns, the car will not start, there is no spark, the reason may be:

- Ignition module or coils.

- Electrical wiring.

- Electronic control unit.

- Crankshaft or camshaft position sensors.

To identify a breakdown, it is necessary to diagnose all vehicle components. Most often, the crankshaft position sensor breaks down, you can check it with a multimeter. The resistance of the winding fluctuates in the range of 550-750 Ohm. But this is a "rough" check, the most accurate picture of the device's performance can be obtained by analyzing the graphs on an oscilloscope. If this device is not there, then you can make the simplest one from a personal computer.

Above, cases were considered when the starter turns, but the engine does not start. But it may be that when the ignition key is turned, the starter does not show signs of life at all. Then the breakdown must be looked for in the electric drive, and specifically in the retractor relay. Very often the contacts burn, collapse, breaks occur in the winding. Because of this, the starter does not turn the engine at all, you cannot even hear the click of the retractor relay.

Toyota LiteAce V 1996 - 2007

The pump can be heard running. The candles are black and dry. On the 1st and 2nd cylinders it is absolutely dry. On the 3rd, a little bit you can catch a pair of benzos. On the 4th, a little more. As if there is no gasoline.

I tried to measure the voltage on the forces, with a tester, it seems, I don't have it (but I read somewhere that it is impossible to measure the impulse voltage with a tester). The temperature in the garage is 5-10 C. There is gas equipment that does not work now, the fuse is pulled out.

After repairs (I changed the force for new ones, changed the generator, the hydraulic booster, the wiring, rewound the harness with electrical tape), the car immediately started up, worked for 5 minutes and stalled. Another 5 minutes and another 4 minutes.

And now I'm twisting, grabbing, for a few seconds, but won't start. The gasoline gauge shows half a tank, I refilled another 5 liters from the canister. Explain the search technology. Fuel filter? A pump that buzzes but doesn't work?

5 answers

You can buy with an adapter, you can borrow from the service by leaving a deposit, you can do it yourself. A pressure gauge with a scale of up to 7-10 kg (it is possible from a compressor for inflating tires) and a hose with clamps, even oxygen, nothing will happen to it during the measurement.

Relieve pressure from the ramp and unscrew the spool, pull on the hose (no longer needed, the main thing is to make it easy to look at), tighten the clamps. We turn the key and see what the pressure gauge shows.

It will not be possible to measure with a digital tester, during the operation of the injector, they can measure the presence of voltage relative to the mass when the ignition is on.

You can measure it with a dial gauge, the readings will not be very accurate, but this is not necessary, the device will show whether the opening pulses are coming or not.

Alternatively, an LED with a resistance per injector chip, it will also show the signal flow.

I think we need to observe what happens to the pressure during work. If you have nowhere to connect a pressure gauge, you still need to somehow introduce a tee into the line (for example, from a classic carb), perhaps when the car stalls, the pump stops pressing. If the old nozzles are not thrown away, try putting them back. As I understand it, everything worked before the replacement.

Renovated. It seized, but did not start because there was poor contact on one coil. That is, on the chip, I measured the voltages of 12V and 5V and at 0.65 (apparently logical 1). Diagnostics by closing Te1 and E1 gave code 15 which, after erasing, appeared again. The fact is that I altered and lengthened the chips for the reels. And I selected the contacts of the chip by color and did not take into account that they are of different standard sizes. That is, the chip was inserted with a click. And sometimes voltage was applied to the coil, but more often not. But here's what's interesting. Before, when I didn't have a spark, the candles were always wet, but now they were dry. Everything else was coincidence. Thanks for the advice.

And the possible reasons. It is no secret that difficulties of this kind are always an unpleasant and unexpected surprise for any driver. Surely each of us had to witness a situation when the car does not start, the starter turns but does not grasp. Let's try to figure out why this is happening in order to have an idea of \u200b\u200bhow to behave in such a situation. The fact that the starter is spinning well already means your battery is healthy. Read how to check the condition of the battery.

Not a single car engine is insured against such a situation. And it doesn't matter what the temperature is outside the cabin. Let us analyze sequentially what to do for different types of power units.

In the case of a carbureted engine, it is a little easier to determine the reasons for the difficult start. First, let's try to pull out the choke (air damper control) handle. If that doesn't help, then move on to finding the spark. Poor contact, oxidized or burnt terminals can make it difficult to start the motor. The same goes for poor coil ground contact. If everything is in order with the spark and there is fuel in the gas tank, then there are problems in adjusting the starting device.

The procedure will be as follows:

The injector has its own peculiarities, which appear in the event of problems with starting. With these symptoms, you need to start by checking the fuel pump. This may be due to oxidation of the power terminals. After that, it is necessary to check the level of fuel pressure in the fuel rail. Find the side where the fuel supply is connected. On the side opposite to it, a valve is located under the cap. Click on it and expect fuel to run from there. If this does not happen, we begin to check the performance of the fuel pump pressure reducing valve and the condition of the fuel filter.

What could be the reason that I twist the starter, but the injection engine does not start - blog readers often ask me? One of the possible troubles is associated with the flooded. This often happens in frosty weather. It is required to wait until they are dry enough. The engine can be cranked with the starter by first removing the injector connectors.

Diesel

The most difficult to start a diesel engine. The fuel in it ignites according to a slightly different principle. The chambers in which the diesel fuel burns up are heated to very high temperatures, after which the diesel fuel is fed into them together with air, which is ignited by compression. In cold weather, it is advisable to heat the air in the cylinders with glow plugs. If this is not done, then the car may start, but it immediately stalls or works unstably until warming up.

Even the slightest frost or freezing temperature can be enough for starting problems. In a diesel engine, start by checking the condition of the glow plugs. We start by checking the glow plug control unit. For this we need a control lamp. We connect it to the mass and power of the candles, and then turn the key in the ignition lock. In the case of a working unit, the indicator lamp will light up.

Other diesel engine starting problems

Another reason why the starter spins for a long time, but the engine fails to start, may be due to the airing of the high pressure pump. First you need to check if there is power to the kill valve. We turn on the ignition and use the already familiar control lamp for this. When connected, the valve should emit clicks, and their absence may just signal its malfunction.

It remains to check the fuel line - we unscrew either the return line of the injectors, or the plug. If there is an option of manual pumping, it should be carried out until diesel fuel flows and the air stops flowing. If it is not possible to bleed, then it makes sense to check the fuel filter, which is often clogged with paraffin from the fuel or ordinary dirt.

Friends, these are the main reasons why the engine may not start even with prolonged rotation of the starter. If you have not yet joined the blog subscriber base, I recommend doing so right now. In the coming days, we are expecting new useful materials from a variety of areas related to the car and its maintenance. For today we will say goodbye!

The most annoying malfunction for any motorist is the inability to start the power unit of the vehicle. Every driver, at least once, had to witness an unpleasant situation when the starter turns, but the engine does not start. Note that it can appear at any time, regardless of the state of the car, its mileage and the type of installed power plant. This phenomenon is especially common in winter, when for a long time the starting device turns the crankshaft in jerks, and at the same time does not grab it from the auto start.

However, in most cases, the starter continues to turn normally, while starting the engine is still impossible. We will deal with the causes of this phenomenon, and describe the effective ways to eliminate them.

Why does the starter turn, the car won't start?

Among the features of this phenomenon, it is necessary to note the very complexity of searching for a possible malfunction, since it is easier to find a breakdown if the starting device cracks and cannot turn the crankshaft, or the fuel pump has stopped functioning after the voltage appears in the vehicle's on-board network. Naturally, the problem cannot be solved by itself, and in any case, it is necessary to carry out diagnostic measures, during which the cause of this phenomenon will be revealed. To begin with, consider a situation in which a normally functioning starter cannot start a car engine.

Reasons why it is impossible to start the power unit

Troubleshooting must begin with diagnosing the performance of the engine starting system, in particular the starter and its traction relay. A properly functioning element should not emit extraneous noises (metal crackling, hum) at the moment the voltage is applied to it, and during operation should emit a characteristic buzzing sound. This indicates that his electric motor rotates normally, without hesitation and malfunction. When the described symptoms are observed when starting the vehicle engine, the starter needs a diagnosis.

If the starter device is working properly, and the engine still does not start, it is necessary to start diagnosing the vehicle systems that are involved in the process of starting the power unit. First of all, it is necessary to check the fuel supply system and the correctness of the ignition. In addition, attention should be paid to the control elements of the operation of various units and systems of the vehicle, to test the sensors. Simply put, if the starter turns and the car does not start in frost or warm season, this is evidence that there is not enough fuel mixture in the cylinders of the power unit, or there is a malfunction of the ignition system and various elements (candles, sensors), which leads to the impossibility of starting from the pusher.

Fuel supply system diagnostics

Troubleshooting in it must be carried out in several stages, at each of which damage should be excluded in the following parts and parts:

- injector or carburetor;

- fuel mixture supply lines;

- fuel purification elements (filters);

- gasoline pump.

As an option, it is also necessary to consider airing the fuel supply system. If a diesel engine is installed on the car, then in winter the diesel fuel can simply freeze in the main hoses of the fuel system and paralyze its operation. On an injection engine, immediately after turning on the ignition, the electric gasoline pump begins to pump fuel, this is indicated by a buzzing in the engine compartment. If no sounds occur in the area of \u200b\u200bthe engine compartment before turning the starter, therefore, the fuel pump has a problem, or no voltage is supplied to the terminals of its electric drive. Having noticed this, it is necessary to check the condition of the fuel pump, its relay and fuse.

You should not ignore the performance check of the fuel pump on vehicles with a power unit, the design of which includes a carburetor. This element of the fuel supply system functions by the camshaft. To determine its performance, it is enough to disconnect the main hoses from the outlet of the fuel pump and the carburetor inlet pipe. Then you need to manually pump the system using a special handle located on the gas pump. If the device is functioning properly, fuel should start flowing from the hose.

Advice! On cars with an injector, it is most convenient to control the amount of fuel by pressing a special control valve, which is located on the fuel rail (rail). The serviceability of the unit is evidenced by the presence of fuel, which indicates that gasoline is supplied under pressure through the ramp to spray it into the cylinders. At the same time, it is necessary to check the filter element, since it often becomes clogged, interfering with the passage of fuel in the system. In addition, the throttle valve needs to be checked and cleaned.

Ignition check

Another reason due to which the car stalled and does not start, the starter turns idle, the ignition system may not work correctly. It is quite simple to check its functioning and establish the cause of the problem; it is enough to check any of the spark plugs for arcing. To do this, it is necessary to remove the candle from the cylinder of the power unit, put a high-voltage wire on its head, and place the skirt 10-15 mm from the engine block. Next, you should ask the assistant to crank the starter. The presence of a spark indicates the health of the ignition system.

Another reason due to which the car stalled and does not start, the starter turns idle, the ignition system may not work correctly. It is quite simple to check its functioning and establish the cause of the problem; it is enough to check any of the spark plugs for arcing. To do this, it is necessary to remove the candle from the cylinder of the power unit, put a high-voltage wire on its head, and place the skirt 10-15 mm from the engine block. Next, you should ask the assistant to crank the starter. The presence of a spark indicates the health of the ignition system.

If the engine is carbureted, it is worth checking the operation of the ignition coil. It is tested by analogy with candles: its central wire is disconnected, the contact end of which is located a few millimeters from the car body. When cranking the starter, the wire should spark. If this is not observed, the coil is faulty, or it is necessary to diagnose the operability of the distributor.

A few more reasons for the inability to start the motor

If the fuel supply and ignition systems in the cylinders of the power unit function properly, and the starter cannot start the engine, it is necessary to check the on-board electrical network and its elements. A malfunction can be caused by trivial breakdowns, such as oxide film, corrosion, fuse failure, etc. It is possible that there are malfunctions in the control system of the injection power unit.

Note that it often happens when the starter cannot start the power unit after heavy rainfall, overcoming a deep puddle or visiting a car wash. This causes moisture build-up on the equipment in the engine compartment, which makes it impossible for most electronic modules to function.

As you can see, the starter turns, but at the same time it cannot start the vehicle's engine due to many reasons, half of which are painfully commonplace and it will take only a few minutes to eliminate them. The main thing is to correctly perform the whole range of diagnostic measures.