What is an ignition coil? It is a part of a car that falls into the electrical category, its main function being to supply high voltage to the spark plugs. This process takes place through high voltage wires. The ignition coil itself converts a low current into a higher one.

Video with diagnostics and replacement of the ignition coil on Renault Logan below.

The process of replacing the ignition coil on Renault Logan

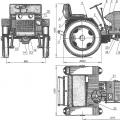

The process of replacing the ignition coil with Renault Logan is quite simple and requires a minimum of tools and skills. Consider both engine versions:.

8 valve engine

Let's first look at how to change the coil on an 8-valve engine:

Due to a constructive miscalculation of Renault Logan engineers, a breakdown of the ignition coil on a Renault Logan is a disease of this car. When installing a new coil, it is recommended to lift it higher away from the engine to avoid contact and vibration on it.

16 valve engine

Now, consider how the ignition coil changes on a Renault Logan with a 16-valve engine:

- Everything is much simpler here, since each candle has its own coil. Disconnect the plug from the coil.

- Use the 8 key to unscrew it and remove it. We do this with all the coils.

- We carry out the assembly in the reverse order.

The choice of the ignition coil for 8 and 16-valve motors

Since Renault Logan has two types of engines, there will be two articles, respectively. Consider the catalog numbers of the original spare part and analogs that can be installed on this car.

8 valve engine

So, for an 8-valve engine:

The original ignition coil in Exist

224336134R Is the original catalog number of the Renault Logan ignition coil. The average cost in the Russian Federation is 4500 rubles. Easily assembled and installed on standard seats.

Consider the analogs of the ignition coil that can be installed on Renault Logan:

| Manufacturer's name | vendor code | Average price in rubles in Russia |

|---|---|---|

| Master-sport | 7700274008-PCS-MS | 1800 |

| Dello | 30770002740008 | 2000 |

| Fenox | IC16017 | 2100 |

| Asam | 30179 | 2200 |

| Amd | AMD.RENEL111 | 2500 |

| Delphi | CE20048-12B1 | 3000 |

| Tesla | CL 116 | 3350 |

| Bosch | 0 986 221 060 | 3700 |

| Hitachi | 138764 | 4500 |

| Valeo | 245 105 | 4500 |

| Febi | 21524 | 6100 |

| SWAG | 60 92 1524 | 7500 |

Analogue Quartz is one of the cheapest and most reliable substitutes

Thus, it can be seen that there are a lot of analogues and they are affordable for pricing.

16 valve engine

Consider the article and analogues of the Renault Logan ignition coil for a 16-valve engine:

Original catalog number - 82 00 765 882 ... The average cost, which is 2200 rubles.

Analogues:

| Manufacturer's name | vendor code | Average price in rubles in Russia |

|---|---|---|

| Dello | 30820005680671 | 1200 |

| Asam | 30472 | 1400 |

| Tesla | CL 100 | 1500 |

| Profit | 1810-9009 | 1600 |

| Fenox | IC16100 | 1650 |

| Amd | AMD.EL439 | 1750 |

| Valeo | 245 328 | 1800 |

| Jp Group | 1291601000 | 2000 |

| Cargo | 150505 | 2100 |

| Febi | 21666 | 2400 |

| Bosch | 0 986 221 045 | 2450 |

| SWAG | 60 92 1666 | 2500 |

The main causes of the malfunction

There are quite a few reasons for the failure of the ignition coil on Renault Logan. Let's consider the main ones:

findings

Replacing the Renault Logan ignition coil is considered one of the simplest repair operations. Dismantling does not require special knowledge and skills, and the process itself is quick and easy. The main thing is to know how many valves the engine has and choose the right ignition coil.

For Renault Logan and Renault Sandero with 8-valve K7J and K7M engines, produced before 2012, a very common problem is the appearance of engine triplets. It is especially pronounced after a long stay or in damp weather.

The main and most likely cause is usually cracks in the bottom of the ignition coil. They appear over time, due to sudden changes in temperature.

The fact is that the ignition coils on Logan and Sandero until 2012 are installed in such a way that, due to their design, the lower part is in contact with the cylinder head cover. Over time, the plastic of the coil body bursts and cracks form, into which moisture gets. This leads to malfunctions. It is worth noting, though, that on many machines, coil cracks do not affect engine performance over the years.

There are several ways to solve the problem.

The most common option is to install a Bosch coil. Its fundamental difference is the brackets with which it is attached to the cylinder head cover. Due to them, a gap is provided between the coil and the cylinder head cover. The only drawback of the design is that when installing this coil, due to its higher position, there is not enough length of the standard high-voltage wire of the 2nd cylinder. Therefore, you will either have to find a replacement for this wire, or purchase a set of longer high-voltage wires. A Bosch wire kit is considered ideal. An alternative to it can be a set of high-voltage wires NGK.

The most common option is to install a Bosch coil. Its fundamental difference is the brackets with which it is attached to the cylinder head cover. Due to them, a gap is provided between the coil and the cylinder head cover. The only drawback of the design is that when installing this coil, due to its higher position, there is not enough length of the standard high-voltage wire of the 2nd cylinder. Therefore, you will either have to find a replacement for this wire, or purchase a set of longer high-voltage wires. A Bosch wire kit is considered ideal. An alternative to it can be a set of high-voltage wires NGK.

The most affordable way to solve the problem is to purchase a similar ignition coil of the old design. In this case, it is recommended to select slightly longer bolts, similar to those that attach the coil and nuts to them. The nuts are used as spacers, lifting the ignition coil housing slightly.

Complexity

LiftNot indicated

We check the ignition coil and its electrical circuits when a malfunction is detected in the ignition system - there is no spark formation on the spark plugs.

The supply voltage is supplied to the ignition coil and the fuel pump from the storage battery through fuse F03 (25 A) and then through the relay K5 (power circuit) installed in the engine compartment mounting block (see "Electrical equipment").

The voltage to the relay coil (control circuit) K5 is supplied from the ignition switch through fuse F02 (5 A), located in the mounting block in the passenger compartment.

To check the power circuit of the ignition coil, disconnect (with the ignition off) from the coil the block of the wiring harness of the engine control system (see "Removing the ignition coil"). We connect the tester probes to the "C" terminal of the wiring harness block and the engine "ground". Immediately after turning on the ignition (while the fuel pump is running) ...

… The instrument should register a voltage approximately equal to the battery voltage.

If there is no voltage at terminal "C" of the wiring harness block, then the following may be defective: fuses, contact group of the ignition switch, relay K5 or their electrical circuits.

With the ignition off, remove the K5 relay from the mounting block in the engine compartment. We connect the tester probes to the sockets of the power circuits of the relay: "positive" - \u200b\u200bto socket "3", and "negative" - \u200b\u200bto socket "5" (the number of the socket corresponds to the number of the relay output). With the ignition on ...

… The tester should show the battery voltage.

If so, then the relay or its control circuit is faulty.

If there is no voltage, we check whether the socket "5" of the relay is connected to the "mass" and whether "+12 V" is supplied to the socket "3". We check the connection of the relay socket to the "ground" with a tester in ohmmeter mode - the resistance should be zero.

To check the voltage supply "+12 V" to socket "3" of the relay ...

… We connect the "positive" tester probe to the relay socket, and the "negative" one to the "-" terminal of the battery.

If there is no voltage, check the fuse F03 (25 A). If the fuse is working, we check the circuit from the fuse socket to the relay socket.

To do this, remove the fuse ...

... and connect the tester probes (in ohmmeter mode) to the fuse socket (shown in the photo) and to socket "3" of the relay.

If the tester shows "infinity" - the circuit is open. If the circuit is working properly, we check if "+12 V" is supplied from the battery to another fuse socket.

For this…

… We connect the "positive" tester probe to another socket (shown in the photo) of the fuse, and the "negative" one to the negative terminal of the battery.

The tester should show the battery voltage. Otherwise, the circuit (open or short to ground) from the battery to the fuse socket is faulty.

To check the control circuits of the K5 relay, disconnect (with the ignition off) the engine control system wiring harness block from the ECU.

We connect the tester probes (in ohmmeter mode) to socket "2" of the relay and terminal "69" of the ECU wiring harness block. If the tester shows "infinity", it means an open in the control "minus" relay circuit.

If the "minus" control circuit of the relay is in good working order, we check whether "+12 V" is supplied to socket "1" of the relay.

For this…

… We connect the "positive" tester probe to socket "1" of the relay, and the "negative" one to the "negative" terminal of the battery.

The tester should show the battery voltage. If there is no voltage, we check the fuse F02 installed in the mounting block in the passenger compartment. If the fuse is intact, check the circuit from the fuse socket to the relay socket "1" and the circuit from the other fuse socket to the terminal "3" of the ignition switch harness block.

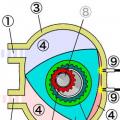

Numbering of the terminals of the ECU wiring harness block

A 1–2 W lamp probe can be used to test the ignition coil control circuits.

Relieve the pressure in the engine power supply system and do not connect the engine control system wiring harness block to the fuel module cover. Disconnect the wiring harness block from the ignition coil and connect the probe probes to the "C" and "A" terminals of the wiring harness block. If the probes of the probe do not fit into the socket of the terminals of the block, we insert pieces of uninsulated wires into the sockets (you can use pins).

If the coil power supply circuit and the control circuit are working properly while cranking the crankshaft by the starter ...

... the light on the probe should flash rapidly.

Otherwise, we check for an open and short circuit "to ground" the wire connecting the terminal "A" of the coil wiring harness block with the terminal "32" of the ECU wiring harness block.

Similarly, by connecting the probe probes to the terminals "C" and "B" of the ignition coil harness block, and then to the "B" terminal of the coil harness block and to the "1" terminal of the ECU wiring harness block, we check another ignition coil control circuit.

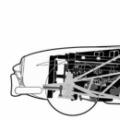

You can check the health of the ignition coil itself on the engine by disconnecting the wiring harness block and high-voltage wires from it.

To check one of the primary windings of the ignition coil, connect the tester probes to the terminals "C" and "A" of the coil.

In ohmmeter mode, check the winding for an open circuit.

If the tester shows infinity, there is an open circuit in the winding. Similarly, having connected the tester probes to the terminals "C" and "B" of the coil, we check the other primary winding of the coil for an open.

To check for a break in the secondary winding of the ignition coil, we connect the tester probes to the paired high-voltage terminals of the coil (terminals 1–4 or 2–3 cylinders).

With a working ignition coil, the tester should register a resistance of about 7.0 kOhm.

If the secondary winding is broken, the tester will show "infinity".

Similarly, we check the other secondary winding of the ignition coil.

We check the secondary windings of the ignition coil for breakdown on the engine. We release the pressure in the engine power supply system and do not connect the wiring harness block to the fuel module cover. Testing requires two known good spark plugs.

We connect the bodies of the candles with a piece of uninsulated wire ("massaging").

We connect the paired leads of the ignition coil with candles with serviceable high-voltage wires and place the candles on the cylinder head cover. We turn the crankshaft with the starter.

To avoid electrical shock, do not touch spark plugs or high voltage wire lugs.

With a working ignition coil, sparks should regularly slip between the spark plug electrodes. Similarly, having connected the high-voltage wires to the other two paired terminals of the coil, we check another secondary winding for breakdown.

Checking the ignition coils of the 1.6 (16V) engine and their circuits Renault Logan, Sandero

To check the operation of the ignition coil, release the pressure in the engine power system (see) and do not connect the engine control system wiring harness block to the fuel module cover connector.

Remove the ignition coil and insert a known good spark plug into it.

We press the threaded part of the spark plug to the metal part of the engine.

To avoid electric shock when cranking the crankshaft with the starter motor, do not touch the spark plug with your hands.

The assistant, turning the key in the ignition switch to position "D", turns the crankshaft with the starter.

With a working spark plug, ignition coil and its circuit between the electrodes, sparks should regularly slip. If this is not the case, it is necessary to check the supply and control circuit of the coil.

To check the power supply circuit of the coils, disconnect the wiring harness block of the engine control system from the coil 1 or 2 of the cylinder ...

… And connect one tester probe to engine ground and the other to pin 1 of the wiring harness block.

With the ignition on, the device should record the battery voltage.

If there is no voltage, then the following may be faulty: fuses, contact group of the ignition switch, relay K5 or their electrical circuits.

Checking the circuits of relay K5 and fuses F3 and F02 see "Checking the engine ignition coil 1.4-1.6 (8V) and its circuits".

To test the control circuit of the ignition coils, we use a probe with a 1.2 W lamp. We relieve the pressure in the engine power system (see. "Removing and disassembling the fuel module") and do not connect the engine control system wiring harness block to the fuel module connector. Disconnect the wiring harness pads from the ignition coils 1 and 4 cylinders. We connect the probes of the probe to the terminal "1" of the wire block of the coil 1 of the cylinder and the output "2" of the block of wires of the coil of the 4 cylinder.

If the control and power supply circuits of the ignition coil are in good condition, the probe lamp should flash rapidly while the crankshaft is cranked by the starter. Otherwise, we check for an open and a short to ground on the wire connecting the terminal "2" of the harness block of the coil 4 of the cylinder with the output "32" of the ECU harness block.

Similarly, we check the circuits of the coils of cylinders 2 and 3 by connecting the tester probes to terminal "2" of the wire block of the coil 3 of the cylinder and to terminal "1" of the ECU block.

If the power supply and control circuits of the ignition coil are in good working order, but there is no spark on the spark plug when checking (see above), then the coil itself should be checked.

To check the ignition coil, measure the resistance of the primary and secondary windings of the coil.

To check the primary winding ...

… We connect the tester probes (in ohmmeter mode) to the terminals "1" and "2" of the ignition coil.

In a working coil, the resistance of the primary winding should be 0.5 ± 0.02 Ohm.

To check the secondary winding ...

… We connect the tester probes (in ohmmeter mode) to terminal "2" and the high-voltage terminal of the ignition coil.

For a working coil, the resistance of the secondary winding should be equal to 7.5 ± 1.1 kΩ.

If the coils are working properly, we check the connection circuit between the wire pads of the coils 1 and 4 of the cylinders. To do this, disconnect the pads of wires from the ignition coils of 1 and 4 cylinders and connect the tester probes (in ohmmeter mode) to terminal "2" of the wiring block of the coil 1 of the cylinder and terminal "1" of the wiring block of the coil 4 of the cylinder. If the tester shows "infinity" - the circuit is open.

Similarly, we check the connection circuit of the coils of 2 and 3 cylinders by connecting the tester probes to terminal "2" of the wire block of the coil of cylinder 2 and to terminal "1" of the wire block of the coil of cylinder 3.

3.1.2. Renault Logan. Checking the ignition coil of its circuits, high-voltage wires

INSPECT IGNITION COIL AND ITS CIRCUITS

We check the ignition coil and its electrical circuits when a malfunction is detected in the ignition system - there is no spark formation on the spark plugs.

The supply voltage is supplied to the ignition coil and the fuel pump from the storage battery through fuse F03 (25 A) and then through the relay K5 (power circuit) installed in the engine compartment mounting block (see "Electrical equipment").

The voltage to the relay coil (control circuit) K5 is supplied from the ignition switch through fuse F02 (5 A), located in the mounting block in the passenger compartment.

To check the power supply circuit of the ignition coil, disconnect (with the ignition off) from the coil the block of the wiring harness of the engine control system. We connect the tester probes to the "C" terminal of the wiring harness block and the engine "ground". Immediately after turning on the ignition (while the fuel pump is running) ...

… The instrument should register a voltage approximately equal to the battery voltage.

If there is no voltage at terminal "C" of the wiring harness block, then the following may be defective: fuses, contact group of the ignition switch, relay K5 or their electrical circuits.

With the ignition off, remove the K5 relay from the mounting block in the engine compartment. We connect the tester probes to the sockets of the power circuits of the relay: "positive" - \u200b\u200bto socket "3", and "negative" - \u200b\u200bto socket "5" (the number of the socket corresponds to the number of the relay output). With the ignition on ...

… The tester should show the battery voltage.

If so, then the relay or its control circuit is faulty.

If there is no voltage, we check if the socket "5" of the relay is connected to the "ground" and if "+12 V" is supplied to the socket "3". We check the connection of the relay socket to the "ground" with a tester in ohmmeter mode - the resistance should be zero.

To check the voltage supply "+12 V" to socket "3" of the relay ...

… We connect the "positive" tester probe to the relay socket, and the "negative" one to the "-" terminal of the battery.

If there is no voltage, check the fuse F03 (25 A). If the fuse is working, we check the circuit from the fuse socket to the relay socket.

To do this, remove the fuse ...

... and connect the tester probes (in ohmmeter mode) to the socket (shown in the photo) of the fuse and to socket "3" of the relay.

If the tester shows "infinity" - the circuit is open. If the circuit is working properly, we check if "+12 V" is supplied from the battery to another fuse socket.

For this…

… We connect the "positive" tester probe to another socket (shown in the photo) of the fuse, and the "negative" one to the negative terminal of the battery.

The tester should show the battery voltage. Otherwise, the circuit (open or short to ground) from the battery to the fuse socket is faulty.

To check the control circuits of the K5 relay, disconnect (with the ignition off) the engine control system wiring harness block from the ECU.

We connect the tester probes (in ohmmeter mode) to socket "2" of the relay and terminal "69" of the ECU wiring harness block. If the tester shows "infinity", it means an open in the control "minus" relay circuit.

If the "minus" control circuit of the relay is in good working order, we check whether "+12 V" is supplied to socket "1" of the relay.

For this…

… We connect the "positive" tester probe to the "1" socket of the relay, and the "negative" one to the "negative" terminal of the battery.

The tester should show the battery voltage. If there is no voltage, we check the fuse F02 installed in the mounting block in the passenger compartment. If the fuse is intact, check the circuit from the fuse socket to the relay socket "1" and the circuit from the other fuse socket to the terminal "3" of the ignition switch harness block.

Numbering of the terminals of the ECU wiring harness block

A 1-2 W lamp probe can be used to test the ignition coil control circuits.

Relieve the pressure in the engine power supply system and do not connect the engine control system wiring harness block to the fuel module cover. Disconnect the wiring harness block from the ignition coil and connect the probe probes to the "C" and "A" terminals of the wiring harness block. If the probes of the probe do not fit into the socket of the terminals of the block, we insert pieces of uninsulated wires into the sockets (you can use pins).

If the coil power supply circuit and the control circuit are working properly while cranking the crankshaft by the starter ...

... the light on the probe should flash rapidly.

Otherwise, we check for an open and short circuit "to ground" the wire connecting the terminal "A" of the coil wiring harness block with the terminal "32" of the ECU wiring harness block.

Similarly, by connecting the probe probes to the terminals "C" and "B" of the ignition coil harness block, and then to the "B" terminal of the coil harness block and to the "1" terminal of the ECU wiring harness block, we check another ignition coil control circuit.

You can check the health of the ignition coil itself on the engine by disconnecting the wiring harness block and high-voltage wires from it.

To check one of the primary windings of the ignition coil, connect the tester probes to the terminals "C" and "A" of the coil.

In ohmmeter mode, we check the winding for an open.

If the tester shows infinity, there is an open circuit in the winding. Similarly, having connected the tester probes to the terminals "C" and "B" of the coil, we check the other primary winding of the coil for open circuit.

To check for a break in the secondary winding of the ignition coil, we connect the tester probes to the paired high-voltage terminals of the coil (terminals 1-4 or 2-3 cylinders).

With a working ignition coil, the tester should register a resistance of about 7.0 kOhm.

If the secondary winding is broken, the tester will show "infinity".

Similarly, we check the other secondary winding of the ignition coil.

We check the secondary windings of the ignition coil for breakdown on the engine. We release the pressure in the engine power supply system and do not connect the wiring harness block to the fuel module cover. Testing requires two known good spark plugs.

We connect the bodies of the candles with a piece of uninsulated wire ("massaging").

We connect the paired leads of the ignition coil with candles with serviceable high-voltage wires and place the candles on the cylinder head cover. We turn the crankshaft with the starter.

To avoid electrical shock, do not touch spark plugs or high voltage wire lugs.

With a working ignition coil, sparks should regularly slip between the electrodes of the spark plugs. Similarly, having connected the high-voltage wires to the other two paired terminals of the coil, we check another secondary winding for breakdown.

CHECKING HIGH VOLTAGE WIRES

We check high-voltage wires in case of violation of sparking on the spark plugs.

To check, remove the high-voltage wire from the output of the ignition coil ...

... and from a candle.

We connect the tester probes to the terminals of the high-voltage wire.

The resistance of a good wire should be within 1-5 kOhm.

Similarly, we check the high-voltage wires of the spark plugs of other cylinders.