Attachments on MTZ 82 provide the machine with versatility. The tractor can be aggregated with various types of attachments and trailed equipment. It should be noted that it is easy to install and dismantle. Rear linkage is responsible for the ease of use of machines and units. In this article we will consider the rear linkage mechanism, its structure and equipment with which the MTZ-82 tractor can be operated.

The rear linkage mechanism is designed for installation of trailed, mounted and semi-mounted equipment. In addition, the rear linkage is responsible for bringing the equipment to the transport or working position.

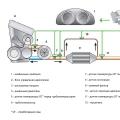

The MTZ-82 tractor is equipped with a three-point hydraulic hitch, separate-aggregate type. The effort required for work is transmitted from the main diesel engine through the power take-off shaft.

Agricultural attachments for MTZ-82

The tractor is mainly used in agriculture, therefore, manufacturers have focused on various mechanisms and units designed for all stages of field work. The entire range of such machines can be roughly divided into three categories.

Hinged device

Such equipment includes units, the entire weight of which fully rests on the tractor. Basically, such a device is attached to the rear attachment system, this includes plows, cultivators and seeders.

But sometimes the front attachment also performs a supporting function, for example, for a dozer blade or equipment for planting seeds. Attachments that the MTZ-82 tractor can work with include:

- mowers of segment-finger type - B-4 or KS-F-2;

- two-rotor mowers;

- disk seeders of class SPU-4 and SPU-4D, SPU-6 and SPU-6D;

- three-body plows PLN-3-35 P and L-108;

- aggregate for tillage of combined type APN-2;

- cultivator designed for continuous soil cultivation - KNS-4.0;

- four-row device for planting potatoes - L-202.

Semi-mounted device

One part of the weight of such a device falls on the MTZ-82 tractor, the other on its own axis of the unit. This attachment is attached to the hitch cross member or drawbar pivots.

This type of fastening is typical mainly for potato harvesters and mechanisms. Semi-mounted mowers are attached to the tractor half frame. A special hook is provided for fertilizer spreaders. The semi-mounted equipment with which the MTZ-82 tractor works include:

- ridge-forming cultivator for root crops - KGO-3.0;

- chisel-type hiller - OCH-2.8;

- cultivator for processing row spacings - KON-2.8.

Tow hitch

This is a self-supporting equipment, in other words, the weight of the unit falls on its own wheel axles. The tractor only acts as a tractor. Such equipment includes:

- two-axle semi-trailers for cargo transportation;

- block-modular cultivator - KPM-4.0;

- equipment for liquid and solid fertilizers (organic) - PRT-7A and MZHT-F-6;

- device for continuous soil cultivation - KPS-4.0.

Mounted excavator

This device is used for road and construction works... The bucket operates through a PTO shaft and is equipped with an independent hydraulic system. The rear hitch is used for the equipment operation.

An offset working axis is provided. Thanks to this feature, the bucket can pick the soil almost close to the walls of the excavation. The length of the frame along which the bucket moves is 2 meters. This approach provides the ability to excavate close to building walls and sidewalks.

The digging depth is 3.1 meters. This attachment belongs to the category of quick-change devices. It will take no more than 30 minutes to complete the installation. The work is carried out by one tractor driver.

Specifications:

The attachments are controlled from the tractor cab. If necessary, the bucket can be replaced with a hydraulic hammer or pit drill.

Front loader

Attached equipment can be aggregated on the MTZ-82 tractor to carry out loading and unloading operations. These units can be used for agricultural work or for the needs of utilities. Of the most popular, the following models can be noted:

PF-09

This is perhaps the most common model used in public utilities. It can be supplemented with a bulldozer blade or a bucket with a volume of 0.8 cubic meters. The equipment is driven by a hydraulic system, controlled from the tractor driver's cab.

PF-08-1 (PF-1)

Improved version of the previous model. Of the features, we can note the even distribution of the load on the tractor frame. This minimizes the possibility of the machine tipping over when working with heavy weights.

This effect is achieved due to the rods that are connected to the rear axle of the tractor. This approach made it possible to increase the carrying capacity of the attachments to 1000 kilograms. The unit is controlled hydraulically from the cab. Can be equipped with a hay fork.

PKU-08

A universal model that can be aggregated with a dozer blade. The universal mounting scheme allows the installation of devices for removing snow or leaves. Work with sand, gravel or mineral fertilizers.

PBM-800

This is a variant of a forklift truck, which is mainly used for work in warehouses.

For road works can be used:

- Hydraulic hammer - GPM-120.

- Cold milling machine - ФД-567.

With the help of these devices, the MTZ-82 tractor can loosen or crush hard ground, dismantle concrete or asphalt surfaces.

To clean the streets, the tractor is installed:

- UMDU plow and brush equipment. The brush speed is 540 rpm. Brush coverage - 2,000 millimeters.

- Grader blade. Designed for planning construction sites or clearing streets from snow. Attachment weight is 450 kilograms. The blade can be rotated at an angle of 90 degrees, the hydraulic system is responsible for the operation of the unit.

- Brushes for wet cleaning of streets. The width of the equipment coverage is 2 meters. The device is supplemented with a 500 liter water tank.

Advantages and disadvantages of attachments

As can be seen from the list of equipment used, the MTZ-82 tractor is a universal machine for multi-purpose use. The machine is used for road and agricultural work, logging, street cleaning and transportation of goods.

The hydraulic system, rear and front hinges are responsible for the operation of the equipment. According to the mechanics, the equipment works quite tolerably, provided that hydraulic fluid is regularly topped up, maintenance is carried out, and rubbing parts are lubricated.

Three-body plows cause complaints. The power of the tractor diesel engine is clearly not enough to work with this equipment. On hard ground or large areas, plowing is uneven.

Incorrect operation of the front loader has been noticed, especially at the maximum load capacity.

Any person always strives for convenience and comfort. Therefore, after 2-3 years of processing your site with a walk-behind tractor, which you have to follow, the owner has the idea of \u200b\u200bcreating a mini-tractor. On it, you can already not only plow and sow, but also carry loads, sitting in the cab and simply operating the levers.

From the walk-behind tractor

This device is very easy to use due to its small size and high maneuverability. In addition to large fields, it is used in small areas of the garden, as well as between buildings and trees, where an ordinary tractor cannot turn around.

This device is very easy to use due to its small size and high maneuverability. In addition to large fields, it is used in small areas of the garden, as well as between buildings and trees, where an ordinary tractor cannot turn around.

A reliable and long-tested option for creating a device is from a walk-behind tractor. And there are two ways: buy a ready-made adapter for the walk-behind tractor or make it yourself. It should be borne in mind that not every adaptive node is suitable for an existing walk-behind tractor. That is why most often they make it by hand. This requires:

- Corner, pipe, channel and metal sheet 1.5-2 mm thick for the frame.

- Two wheels of the desired size with an axle.

- The seat, which is taken from the "Zhiguli" and redesigned.

- Drill, welding machine and locksmith tools.

Usually used in the household. This unit is relatively inexpensive, has 4 speeds forward and 2 backward, engine power 6.5 hp. The assembled motoblock weight is about 90 kg. To him, they easily make the necessary adapter together with a homemade plow. Its assembly is broken down into several stages:

- A frame is made from a corner, a channel and, if necessary, pipes are also used.

- They put the steering column, taken from unusable "Zhiguli" and converted to the desired size.

- The seat is installed and secured with bolts, selecting the optimal distance to the steering wheel.

- Place control levers: clutch, throttle, brakes.

- Finally, finish and paint.

- The finished product is tested and the assembled assemblies are slightly adjusted.

It is desirable that the rear wheels are larger in diameter relative to the front. This increases the cross-country ability and gives some seriousness to the home-made unit.

In the case when the walk-behind tractor itself with the engine is behind the seat, the grip of the driving rear wheels with the soil is better. This allows you to attach a double-body plow to the unit, which greatly increases productivity.

Manufacturing from scrap parts

There are times when the owner does not have a walk-behind tractor. But in the garage there are various spare parts and wheels from automobiles and other equipment. Perhaps there will be a working engine, for example, from “Oka”. Then the creation of a mini-tractor starts practically from scratch. And the craftsmen who are engaged in homemade products know perfectly well where to get the necessary missing components and assemblies. This is an auto-analysis of foreign cars and domestic cars, which is available in every city and village.

There are times when the owner does not have a walk-behind tractor. But in the garage there are various spare parts and wheels from automobiles and other equipment. Perhaps there will be a working engine, for example, from “Oka”. Then the creation of a mini-tractor starts practically from scratch. And the craftsmen who are engaged in homemade products know perfectly well where to get the necessary missing components and assemblies. This is an auto-analysis of foreign cars and domestic cars, which is available in every city and village.

To begin with, they make a schematic drawing, on which they estimate the approximate location of the main nodes. Then the frame is made from the channel and the corners are reinforced with sheet metal. Its width is determined by the size of the existing drive axle of the car. The length of the frame depends on the engine to be installed, handlebar position, seat and attachment.

Wheels, axles and steering are completely taken from the Oka car or another. Bridges do not need to be shortened. There is only one caveat when installing the engine. It is necessary to raise the motor so that the wheel clearance is greater. This will allow the tractor to work even in deep furrows.

Wheels, axles and steering are completely taken from the Oka car or another. Bridges do not need to be shortened. There is only one caveat when installing the engine. It is necessary to raise the motor so that the wheel clearance is greater. This will allow the tractor to work even in deep furrows.

An engine from a Ural or Dnepr motorcycle with a gearbox that has a reverse speed is sometimes adapted to such a unit. But their motors are multi-turn, so it is necessary to install an additional one to reduce the speed of the mini-tractor. After all, it is made to cultivate the land, and not to compete in Formula 1 races. The lower the speed of the machine, the greater the pulling force. Any schoolchild knows this.

Homemade attachments

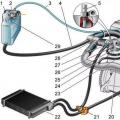

When the finished mini-tractor has passed all the tests, acquired the status of significance and earned the love of the whole family, the task of manufacturing attachments for it comes to the fore. And it depends on the intended crops and tillage. If a walk-behind tractor was used to create a tractor, then there is a ready-made assembly for coupling with agricultural equipment. In another case, you will have to make a hitch with your own hands, the photo of which is presented.

When the finished mini-tractor has passed all the tests, acquired the status of significance and earned the love of the whole family, the task of manufacturing attachments for it comes to the fore. And it depends on the intended crops and tillage. If a walk-behind tractor was used to create a tractor, then there is a ready-made assembly for coupling with agricultural equipment. In another case, you will have to make a hitch with your own hands, the photo of which is presented.

It shows that the design of the hitch is three-point. It should be movable both vertically and horizontally. It is made from steel profiles using a welding machine. Needed to connect units.

Of course, it is possible to make a single-point hitch assembly, but this will greatly reduce the number of mounted agricultural processing machines, and, consequently, reduce the versatility of the tractor.

There are several types of agricultural units for cultivating the land.

Types of plows

For home-made tractors, these types of plows are most often used: single-body and double-body. The first cling to light and medium motoblocks, and the second to more impressive equipment. For a mini-tractor, if it has a powerful engine and a decent weight, multi-hulls are prepared, which cling to a homemade hitch.

For home-made tractors, these types of plows are most often used: single-body and double-body. The first cling to light and medium motoblocks, and the second to more impressive equipment. For a mini-tractor, if it has a powerful engine and a decent weight, multi-hulls are prepared, which cling to a homemade hitch.

The plow is often made from the skimmer of the factory plow, which is usually used by the MTZ tractor. It is only necessary to slightly modify the share and the correct curvature of the blade. The use of a horse plow is possible.

For plowing heavy and hard lands, as well as soils with roots of trees and shrubs, self-made disc plows are used. They are a frame with sharp discs up to 40 cm in diameter, which cut into the soil at a slight angle to the direction of travel. This allows them not only to cut the roots, but also to loosen the ground.

Hillers and harrows

Any homemade hiller consists of a frame and two discs located at an angle to each other. This unit is used for hilling rows of potatoes and strawberries.

Harrows are designed for breaking up clods and loosening plowed land. They represent a lattice frame with a size of 100 × 50 cm, welded from corners of 50 × 50 mm, and sharp fingers up to 15 cm long, located evenly over the area of \u200b\u200bthe frame. The harrows cling to the back of the plow and work with it.

Potato planters and diggers

This attachment is used for a specific crop - potatoes. Powered by its own wheels, it distributes seeds evenly along the furrow, and does not depend on slipping.

The potato digger is a sharp knife 20-30 cm wide, which horizontally enters the soil to a depth of 20-25 cm. It pulls the potatoes to the surface using an inclined grate. At the same time, the tubers are cleaned from soil and grass.

Other equipment

Other attachments can be used depending on the purpose:

- Mowing machines are mounted. Used for making hay for pets and removing weeds in the garden.

- Rake for raking cut grass. They are mounted and trailed. Trailed ones have two wheels. They cling directly to the tractor.

- Mounted cultivators. They usually consist of a frame and 6-8 cultivator tines. The principle of work is the same as that of a flat-cut plow. They have two wheels with which the depth of cultivation is regulated.

- Garden sprayers. This is the right unit. They are sprayed on cultivated crops to protect them from pests, and also protect grain from weeds using special chemical compositions. It is mainly used in farm fields.

- Bulldozer dumps. They are attached in front of or behind the tractor. They represent a shovel up to 1.5 m wide. They are made of steel with a thickness of 3-5 mm. Attached with a hinged device. Designed for cleaning the area from snow and debris, as well as for leveling the surface of the site.

- Coons. This special attachment is for material handling only. Manufactured for the specific type of activity of the mini-tractor.

- Rotary brushes and snow blowers. They are especially needed in the winter on city streets. A tractor with such equipment is able to clear all the narrow spaces between houses and shops, where it is difficult for a conventional tractor to drive up.

Assembling a simple unit, as well as homemade attachments for a mini-tractor, does not present any particular problems. It only takes time, desire, the necessary tools and materials.

1. Main types

2. Tips for choosing

3. Disadvantages of homemade hitch

With additional equipment, a standard mini tractor becomes a multifunctional machine. Reasonably selected hitch allows:

- increase the number of operations performed;

- use the technique all year round, and not only in the summer at the height of the season;

- more likely to recoup the investment.

In the article we will talk about the types of attachments for a mini-tractor and their purpose.

A mini-tractor is a good solution for farms, utilities, construction teams. Using a hinge:

- work in the field: work the land, water, plant, sow;

- making hay: mow, collect rolls, transport to storage;

- watching the site: remove snow, foliage, clean roads from ice;

- carry out preparatory work: building materials are brought up, rubble is poured, etc.

Main types

For tillage

Plow... With the help of a plow, the primary cultivation of the land is carried out with a seam turnover in the spring. In autumn, the plow loosens the soil, mixing the fertile and infertile layers. Suitable for both developed plots, virgin lands.

For compact tractors, one-, two- and four-furrow plows are available. The processing width and overall productivity depend on the number of bodies.

Tillage cutter. It is used for finishing, as well as:

- loosening the soil,

- cutting beds,

- leveling the soil,

- fertilizer embedding, etc.

The cutters differ in working width, working depth.

Hiller... Serves not only for direct hilling of row crops (primarily potatoes), but also for the formation of ridges. Hillers differ in the number of working sections and are equipped with a row spacing adjustment.

Cultivator... The attachment loosens the soil, cuts weeds, processes row spacings, etc. The devices differ in the working width (up to 1.8 m), the depth of processing.

For planting and harvesting

Harrow... Designed for surface treatment: leveling an already plowed area and breaking the crust, clods of earth before planting. For minitractors, tooth, rotary, disc harrows are produced, which differ in the type of working body.

Potato planter... Depending on the model, the equipment is aggregated with equipment with a one-point or standard three-point linkage system. Performs all necessary operations: prepares furrows, lays tubers, forms a ridge.

Potato digger... Conducts mechanized harvesting of potatoes and other root crops. Vibrating and conveyor diggers cut the soil layer together with tubers, after which the crop falls on special grates or belts, where it is cleared of the soil with the help of vibration. In the process, the tubers are practically not damaged.

For mowing grass

Mower... According to the type of aggregation, there are front and rear mowers. By the type of cutterbar, they are segmental and rotary. Segmental are designed to work with sown grasses. They act on the principle of scissors: one part remains stationary, and the other performs reciprocating movements. These mowers are ideal for utilities for mowing roadsides and for farmers for making hay.

More powerful rotary mowers are used for fine mowing of high-yielding field grasses. When hitting obstacles in the form of small stones and roots, the cutting blades fold in, protecting the unit from damage.

Rake-tedders... They are used for raking hay into swaths, tedding, turning over the grass in the mowing when drying. Models are available for tractors with three-point and one-point linkage systems.

For watering, spraying and fertilizing

Mounted sprayer... Suitable for simple irrigation of crops, liquid fertilizing, herbicides. It is completed with tanks of various sizes, from 50 to 400 liters. With the help of the pump, the liquid is supplied to the spray nozzles located on the boom. The models are available with different boom lengths (6-10 m). An automatic control system installed on the sprayer allows you to adjust the flow rate of the working fluid, mix the contents of the fertilizer tank, turn on and off the booms.

Fertilizer spreader... It is used for surface application of granular and powder fertilizers. Allows you to normalize the dosage of the mixtures used, distribute them evenly over the site.

For cargo transportation

Front loader... Designed to work both in warehouses and outdoors. Front-mounted allows the unit to be used simultaneously with other factory attachments. It is applied for:

- loading and unloading works;

- snow drift cleaning;

- transportation of bulk building materials;

- loading of trucks, trailers, etc.

The lifting capacity of the mini tractor loader is 400-500 kg, so a counterweight is used to work with them. On some models (FP-02, FP-04), it is possible to replace the bucket with a bulldozer shovel or pitchfork. With the simultaneous aggregation of the tractor with the forks and the mower, the hay harvesting process is noticeably simplified. There are also jaw tips.

For cleaning the territory

Communal brush... The unit installed on the mini-tractor cleans not only debris and rotten foliage, but also fresh snow of a small cover, therefore it can be used all year round. The cleaning brush is a reliable assistant for public utilities, owners of private cottages, parking lots and gas stations. The unit is used not only on the street, but also for cleaning premises. By adjusting the pneumatic wheels, the brush is set to the desired working height.

Bulldozer equipment... Cleans snow and debris from roadways, covers pits and trenches with soil, levels the site, is suitable for working with bulk building materials (crushed stone, sand, asphalt chips). Depending on the model, the bucket is lowered, raised and rotated hydraulically or manually.

Correctly selected equipment increases labor productivity, which means it helps to quickly return the money invested in the business. Here are some tips to consider when choosing a tractor attachment:

- Scope of planned work... In small areas and operations of the same type, the cost of a large set of attachments is not economically justified.

- Mini tractor power... On each hitch produced, the manufacturer indicates the recommended power, which must be observed. The higher the performance of the unit, the more horsepower it requires. For tractors 25-30 HP the range of attachments is higher than for less powerful ones.

- Rotation frequency... This indicator on the power take-off shaft must correspond to the speed of the gearbox on the equipment (540 rpm, 720 rpm, 1000 rpm or 2000 rpm).

- Weight... The working mass of the equipped hitch should not exceed 1/3 of the mass of the mini-tractor itself.

- Hydraulic system... The technical characteristics of the machine must match the capabilities of the tractor hydraulic system.

- Suspension system... For tractors with a three-point hitch, select the appropriate units. Pay attention to the hitch category.

Even having a very small summer cottage or vegetable garden, sometimes it is simply impossible to do without mechanical assistance in the form of a walk-behind tractor or a mini tractor. This unit will be able to optimize many processes for maintaining the site, and attachments, which are widely available on the modern market, can significantly expand the scope of its application. This article is devoted to an overview and principles for choosing attachments that will help you mechanize many agricultural jobs.

Types and purpose

There are several types of attachments for mini tractors, which, for greater convenience, can be grouped according to their areas of application in various aspects of human life. There are also universal devices necessary for almost every owner of such a unit, to which, first of all, a trailer and a loader should be attributed.

In agriculture

Agriculture is a field in which various mechanical units are often used and, accordingly, attachments are most often used here.

Did you know? Land-processing equipment has long been treated with great respect. In the Middle Ages, theft of a plow was punished with the wheel.

Such devices include plows, harrows, various automatic devices for sowing soil and planting plants, units for harvesting, irrigation and spraying, as well as various trailers, loaders and dumps. Below we will consider in more detail the use of all these units in this area of \u200b\u200blife.

In construction

Attachments such as blades, excavator buckets, augers, trenching attachments and rippers make mini tractors very useful for digging trenches and holes for building foundations, as well as for digging cesspools, cattle graves and other depressions in the ground, which are large should exceed their depth.

Loaders, winches, buckets with loading platforms, cargo tractor carts, fork pallets allow builders to easily and quickly move various loads around the construction site - both small and rather large and heavy. In addition, some of the above devices also allow you to lift loads to low heights.

Communal sphere

For the utility sector, the most important attachments are shovels, blades, sprayers, asphalt brushes, chemical and sand spreaders, snow cutters, buckets, snow throwers, snow plows and front loaders.

With the help of such an arsenal, utility workers can resist snow drifts on roads and sidewalks, fight against ice, clean streets from dust and settled small particles, clean paving slabs and the roadway, and also remove a variety of garbage - like household, accumulated in small quantities, and large consignments of construction waste.

Did you know? The smallest tractor that can be driven is the size of a pinhead and is housed in the Yerevan Folk Art Museum.

Livestock

In the livestock sector, it is very difficult to find a worthy application for attachments of mini tractors, since all work involves interaction with living organisms, which it is desirable not to physically injure during its implementation. Therefore, the most commonly used machines in this area are buckets, trailers, loaders and dumps.

With the help of these devices in animal husbandry, a rather narrow and specific list of works is performed, for example, cleaning livestock buildings from feces, transporting feed, animals or their meat, digging gutters and cesspools, and in very rare cases (this requires a rather serious qualification of a mini tractor operator) feeding animals.

Agricultural use

As already noted, agriculture is the area where attachments are most widely used, therefore, in this article we pay attention to the attachments designed for it. Below you will find an overview of the most popular and useful machines used for agricultural soil and plant cultivation.

Soil preparation and cultivation

For the purpose of preparing and cultivating the soil, several units that are fundamentally different in their functionality are used:

The plow is used exclusively for the purpose of plowing the land and due to the fact that it plunges quite deeply with the blades into the soil, for its comfortable and effective use it is necessary to have a mini tractor with a capacity of at least 24 horsepower, for example, the Xingtai 244.

Important! In order to save time spent on plowing and / or loosening, it is recommended to work towards the longest section of your plot. This way you will waste less time on inefficient turns of the mini tractor and equipment.

Harrows, cultivators and rotary tillers are used to loosen the soil, and sometimes also to remove weeds and level the forthcoming planting site of cultivated plants.

By default, any mini-tractor should cope with these units, however, the harrows are very often very wide, sometimes they can reach up to 400 centimeters. To use such large attachments, you must have a machine with a power of at least 14-15 horsepower, for example, DW 150RXi, Forte 151 EL-HT Lux or Claus LX 155.  Mowers are most often used on the soil, which they are just planning to turn into a field, to clear it of a variety of tall weeds, as well as small bushes. Absolutely any mini-tractor is suitable for working with the mower, the only condition for its adequate operation is the mandatory connection to the machine's battery.

Mowers are most often used on the soil, which they are just planning to turn into a field, to clear it of a variety of tall weeds, as well as small bushes. Absolutely any mini-tractor is suitable for working with the mower, the only condition for its adequate operation is the mandatory connection to the machine's battery.

Planting equipment

Most often, when they talk about planting crops with the help of such units, they mean planting vegetable crops, but it should be noted right away that with the help of attachments it is possible to plant cereals, legumes, as well as corn.

Here is a list of the most popular equipment:

The principle of planting vegetable crops is that vegetables are fed from a common reservoir with a huge amount of planting material to different furrows through special tubes, which, after they enter the soil, are immediately sprinkled with earth. To work with such equipment, it is advisable to have a tractor that would be equipped with an engine with a capacity of 15 horsepower.

Seeders, in general, work on the same principle as machines for planting vegetables, only their tanks are much smaller, and instead of pipes through which vegetables are supplied, they are equipped with special nets moving in different directions along the direction of the mini tractor.

When there is a coincidence of cells located on different grids, a portion of grain falls out of the tank, which is sprinkled with earth. Adequate operation of such a seeder can be provided by a mini tractor with a capacity of 15 horsepower.

Video: seeder for grain in operation

Planting maintenance

In order to maintain plantings in agricultural technology, the following attachments are used:

The weeding cultivator serves to loosen the soil, giving oxygen access to the roots of plants, destroy weeds and increase the beneficial effect of fertilizers that are applied under the plants using the second type of attachment from this list - the fertilizer hopper.

Some types of mini tractors allow you to use both of these attachments together, for example, the Zubr 150 or the Garden Scout T-15.

Watering and spraying

Alas, a mini tractor is not able to provide decent watering for numerous plantings, so it is better to establish, for example, a drip irrigation system on your site.

However, such a technique is quite capable of coping with spraying plants, for this purpose there are the following attachments:

The principle of operation of both of these devices is generally the same, they differ only in the materials from which they are made. A sprayer for chemicals is capable of carrying and spraying various substances with which it is highly undesirable to treat plants at the same time as water, due to a possible chemical burn.

This is why it is advisable to keep two separate sprayers, or at least thoroughly clean the tank after the chemicals and before spraying with water. You can use this device with absolutely any mini tractor.

Harvest

After the completion of all the main work, the time comes for harvesting, and here the following units will be extremely useful on the farm:

Equipment for different types of vegetables works on the same principles, which can be mechanical, vibratory or conveyor. The main difference between them is the size of the cutter for digging, and the depth to which the digging takes place. Any mini tractor is equally well suited for the use of such equipment.

Loader

In the basic configuration of absolutely any mini-tractor there is such attachments. It can be used to load and unload a variety of materials (feed, building materials, etc.).  Its initial configuration includes a bucket (the average volume is 0.5-5 cubic meters) and an arrow (allows you to raise and lower the load horizontally). Instead of a bucket, a wide variety of other devices can be installed on the boom, for example, blades, crane lifts, forks, rippers and more.

Its initial configuration includes a bucket (the average volume is 0.5-5 cubic meters) and an arrow (allows you to raise and lower the load horizontally). Instead of a bucket, a wide variety of other devices can be installed on the boom, for example, blades, crane lifts, forks, rippers and more.

This will greatly enhance the functionality and usefulness of your engine. The maximum weight that an average mini-tractor with a capacity of 15 horsepower can lift on a loader is 1500 kilograms.

Trailer

Trailers, which are usually attached to the tailgate of your car, may differ slightly in their functionality. For example, there are tipper trailers and flatbed trailers, single-axle and multi-axle, etc.

A dump-type trailer hitch is best suited for transporting any bulk cargo, and an onboard one is more profitable for transporting packed cargo. The number of axles on a trailer is also extremely important, as it is proportional to the weight of the load that you can transport with it.  It is also important to understand that single-axle trailers have less weight and much more mobility and maneuverability than two- and three-axle trailers, which, in turn, are more stable and have a more pronounced passability. The maximum weight that an average mini-tractor on a trailer can carry is about 2000 kilograms.

It is also important to understand that single-axle trailers have less weight and much more mobility and maneuverability than two- and three-axle trailers, which, in turn, are more stable and have a more pronounced passability. The maximum weight that an average mini-tractor on a trailer can carry is about 2000 kilograms.

How to choose attachments

When buying attachments, first of all, make sure that the material from which it is made corresponds to that declared by the seller. Carefully inspect the structure for mechanical damage and / or manufacturing defects, pay special attention to the part of the equipment that is in direct contact with the ground.

Important! It is best not to do business with individuals and non-certified sellers, especially those selling Chinese models of attachments. It often happens that after the purchase (especially for Chinese equipment) it turns out that this unit is designed to work only with one specific model of a minitractor.

Video: Attachments for Mini TractorsWhen purchasing attachments, you must clearly understand what it will be used by you for, is there a need for such an acquisition, think about whether you can do without it, estimate the benefits that you will be able to derive from owning this unit.

As for advice on choosing any specific types of attachments, first of all try to get extensions for a loader, a shovel and a trailer - these three units are responsible for most of all the work that can be done on a mini tractor. Moving on to choosing more highly specialized equipment, do not hesitate to ask the opinions of more experienced farmers.

Pros and cons of homemade attachments

Of course, many owners of mini tractors are quite skillful and technically competent people, which in some cases allows them to make attachments for their machines on their own, but this method of providing themselves with such units will not always be beneficial to you.

First, here are the arguments that make the production of homemade attachments feasible:

- often the cost of production is cheaper than buying a ready-made device;

- you will not be limited by the factory operating parameters of the unit and the features of its basic settings;

- if the need arises, you can change the mount on your equipment and hang it on another mini tractor;

- you can always repair a broken part in the unit yourself.

Now for the negative aspects of using homemade equipment:

- during its operation, damage to the mountings and other parts of the minitractor is possible;

- purchased attachments can sometimes be replaced under warranty, but self-made ones cannot;

- usually the efficiency of purchased equipment is much higher than that of home-made;

- homemade equipment often breaks down more often than purchased equipment.

So, we hope that this article has answered some of your questions about additional units that can expand the functionality of mini tractors.

Mechanization is the most important and most useful process that has replaced manual labor in all civilized countries for a long time, so do not be afraid of innovations and if you have the opportunity, join the ranks of people who have optimized their work processes as soon as possible!

Was this helpful?

Thank you for your opinion!

Write in the comments which questions you did not receive an answer to, we will definitely respond!

6

times already

helped