The UAZ Patriot 3163 and UAZ Hunter are equipped with a five-speed manual South Korean gearbox Daimos (DYMOS). The gearbox is highly reliable and has a long service life. The service life of the Daimos checkpoint with proper maintenance is about 300,000 km. The gearbox housing is "sharpened" for fastening to engines ZMZ-405, ZMZ-406, ZMZ-409 and ZMZ-514 diesel. As for the gearbox repair, it is quite difficult to make it due to the lack of spare parts. The positive aspects of the operation of the DYMOS gearbox include a clear stroke of the gear shift knob, a classic algorithm, minimal physical effort to change gear and high selectivity.

The gear ratios are fairly well balanced. The first gear of the gearbox is the most "traction". DYMOS copes with its main direct tasks perfectly. The noise of the gearbox is significantly reduced compared to the Arzamasovskaya one. Due to the presence of 5th gear, comfort when driving on the highway has increased. Different oils are used in the gearbox and transfer case. Do not use oils in the transmission that are not recommended by the manufacturer.

Gear ratios gearbox Dymos

| I Transfer | II Transfer | III Transfer | VI Transfer | V Transfer | R Transfer |

|---|---|---|---|---|---|

| 4,155 | 2,265 | 1,428 | 1,00 | 0,88 | 3,827 |

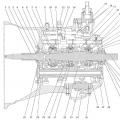

Gearbox device Daimos

1 - front gearbox housing; 2 - primary shaft bearing cover; 3 - primary shaft; 4 - mounting bolt; 5 - the rear bearing of the input shaft; 6 - toothed crown; 7 - double cone synchronizer for 3rd and 4th gears; 8 - hub and synchronizer coupling for 3rd and 4th gears; 9 - clamp; 10 - ball bearing; 11 - gear wheel 3 transfers; 12 - neutral position indicator switch; 13 - bolt of the head of the control mechanism; 14 - the head of the rod of the control mechanism; 15 - control lever assembly; 16 - control shaft assembly; 17 - reversing switch fuse bracket, assy; 18 - gear wheel of a reverse gear of a secondary shaft; 19 - double cone reverse synchronizer; 20 - sealing cover; 21 - 5th gear synchronizer ring; 22 - clutch and hub of 5th gear and reverse synchronizer; 23 - gear wheel 5 of the secondary shaft transfer; 24 - rear transmission case; 25 - retaining ring of the secondary shaft rear bearing; 26 - adjusting ring of the primary shaft bearing cover; 27 - adjusting ring of the intermediate shaft bearing; 28 - front tapered roller bearing of the intermediate shaft; 29 - pinion gear 2 of the secondary shaft; 30 - triple cone synchronizer for 1st and 2nd gears; 31 - hub and synchronizer clutch for 1st and 2nd gears; 32 - pinion gear 1 of the secondary shaft transfer; 33 - intermediate reverse gear shaft; 34 - intermediate reverse gear; 35 - flange bolt for fastening the intermediate gear axis of the reverse gear; 36 - intermediate shaft; 37 - rear tapered roller bearing of the intermediate shaft; 38 - double angular contact ball bearing of the secondary shaft; 39 - bearing oil seal; 40 - protective ring; 41 - retaining half-ring; 42 - retaining ring; 43 - secondary shaft

1 - primary shaft; 2 - toothed rim of the input shaft; 3 - the front needle bearing of the output shaft; 4 - the inner ring of the 4th gear synchronizer; 5 - blocking ring of the double-cone synchronizer of the 4th gear; 6 - retaining ring of the synchronizer hub for 3rd and 4th gears; 7 - external synchronizer ring 4 transfers; 8 - clutch for switching 3 and 4 gears; 9 - hub of synchronizer for 3rd and 4th gears; 10 - dry synchronizer; 11 - synchronizer spring; 12 - a ball of a biscuit of a synchronizer; 13 - outer ring of the 3rd gear synchronizer; 14 - double-cone blocking ring of the 3rd gear synchronizer; 15 - the inner ring of the 3rd gear synchronizer; 16 - toothed rim of gear wheel 3 transfers; 17 - gear wheel 3 transfers; 18-needle bearing of gear wheel 3 transfers; 19 - bearing bush of gear wheel 3 transfers; 20 - needle bearing of gear wheel of 2nd gear; 21 - gear 2 transfers; 22 - gear ring 2 gears; 23 - the inner ring of the 2nd gear synchronizer; 24 - locking ring of a three-cone synchronizer 2nd gear; 25 - outer ring of synchronizer 2 transfers; 26 - retaining ring of the synchronizer hub for 1st and 2nd gears; 27 - clutch for switching 1st and 2nd gears; 28 - hub of synchronizer for 1st and 2nd gears; 29 - outer ring of the 1st gear synchronizer; 30 - blocking ring of a three-cone synchronizer of 1st gear; 31 - the inner ring of the 1st gear synchronizer; 32 - gear wheel of 1 transfer; 33 - needle bearing of gear wheel of 1st gear; 34 - secondary shaft; 35-needle bearing of reverse gear; 36 - reverse gear; 37 - the inner ring of the reverse synchronizer; 38 - double cone blocking ring of the reverse synchronizer; 39 - an outer ring of the reverse synchronizer; 40 - hub of reverse gear and 5th gear; 41 - synchronizer dry (5 gears / reverse); 42 - a ball of crackers; 43 - reverse gear synchronizer clutch and 5th gear; 44 - retaining ring of the reverse gear and 5th gear synchronizer hub; 45 - 5th gear synchronizer outer ring; 46 - toothed ring of the gear wheel of the 5th transfer; 47 - gear wheel of 5 transfers; 48-needle bearing of gear wheel of 5th transfer; 49 - persistent washer; 50 - rear double ball bearing; 51 - retaining ring; 52 - retaining half-ring; 53 - protective ring; 54 - retaining ring

READ ALSO ON THE SITEWeak valve springs in an engine can cause a variety of reliability and performance problems. Each valve in the cylinder head has at least one spring. The valve spring applies pressure to the valve holder to stop the valve. If any devices on a VAZ 2112 car stopped working for you, fuses or relays may be to blame. At least, first of all, you need to check them, and then draw some conclusions regarding the malfunctions. Correct diagnosis ... Tramblerless ignition systems have been around for nearly a decade and have eliminated much of the maintenance that used to be associated with the ignition system. The absence of a distributor means that there is no cover or rotor to replace, and also no ... |

Problem: When driving, if you quickly stick in the 3rd gear, you can hear (and feel on the handle) a tangible crunch. If you stick it slowly and carefully, then without a crunch. And the more often you push the lever, the stronger the crunch. And the slower, the greater the likelihood of perfect transmission.

Diagnosis: the synchronizer is erased. For replacement, you need to throw off both boxes and disassemble.

(For one replacement, the noisy bearing of the shaft)

for support we use a wide rope and hoist

it turned out to be not at all difficult to remove the distributor even without a hole, we unscrew the bolts and pull it down,

it is necessary to put something soft on the floor because 40 kg in a twisted state under the car cannot be kept

the box is even easier to remove because it hangs on chains, it can be carefully lowered

box dymos

Handout UAZ

i will underestimate the distribution box to 3.3, but later, so I took it apart to see the number of splines on the shaft, since there are options for 12 and 18 splines, the lowering kit is made for the option with 18 splines

To pull off the bearing of the shaft is a test for the nerves. In the beginning I tried to weld that

then to the bearing and pull it off but the welding broke. My recipe is as follows: we take two long bolts, we saw off the caps with a grinder, on the sides to make an oval, we break the separator in the bearing, put the bots in the bearing and wedge it. then press out with a puller

.jpg)

In the box itself on the shaft, I have not yet removed the stars, only today I bought a three-legged puller, so to be continued, criticism and advice are very welcome, since I myself am the first to repair the box. no repair experience yet.

We continue to repair, to press out the gears, I used a three-legged puller (bought for 600r). I disassembled everything in about half an hour, everything turned out to be simple

4th gear synchronizer, 3mm thickness evenly

3rd gear synchronizer, apparently worn 2.85 mm

perhaps this 0.15 is enough for a poor inclusion

Replacement of the 2nd and 3rd gear synchronizer is required. To my surprise, this detail was not in our city. I got into the Internet, I know only 3 spare parts stores that 100% do not throw uazobaza.ru, bazashop.ru and 3160.ru They do not have these details! I looked in Yandex, (I can do that) those shops that it shows did not inspire confidence, elementary phone number and address are not indicated, I'm afraid of scammers. For example: www.uazlyuks.ru/index.php...t/product&product_id\u003d1630 the site is generally made in the ukoza constructor, and I myself can do it myself in a day.

In short, the question is simple: Who ordered spare parts via the Internet and in which store? Give me a link, and I'll look for synchronization there myself. And then there have already been incidents. Thanks in advance.

1. Remove the fork 5 of the clutch release bearing and the bearing

2. Remove the shift cover / lever assembly.

3. Remove the reversing lamp switch.

4. Remove the stem head pin using a fine barrel bit.

Remove the bolt 1 of the idler reverse gear axle on the gearbox housing.

5. Unscrew the flange bolts and magnetically remove the springs and plungers.

6. Remove the mounting bolts and remove the input shaft bearing cover.

7. Remove the bearing 1 of the input shaft, having previously removed the circlip 2.

8. Remove the front gearbox housing by unscrewing the mounting bolts (shown by arrows)

9. Remove the circlip 4 of the output shaft bearing, the circlip 1, the protective ring 2, and two retaining half rings 3

10. Remove the bolt 1 of the idler reverse gear axle on the rear gearbox housing and remove the axle.

11. Using a fine cylindrical end bit, press out the gear shift lock pins.

Remove the gear shift rods.

Attention! Do not reuse the locking pins.

12. To remove the output shaft assembly, intermediate shaft assembly and rods from the rear case of the gearbox, heat the rear wall of the crankcase in the area of \u200b\u200bthe double bearing using an electric heater.

Note:

For easy dismantling, secure the output shaft, intermediate shaft and gear shift shaft with a rope or strap and hang;

Heat the rear wall of the crankcase at a temperature of 400 ° C for about 4 minutes.

Attention! To avoid damage to the bearing, do not use a press or hammer to remove it.

13. After heating, dismantle the shafts by lightly hitting the rear casing with a rubber hammer.

The all-wheel drive system of the UAZ Patriot SUV has such an important unit as the transfer case. This mechanism is necessary to redistribute the torque between the drive shafts.

Until 2013, the Ulyanovsk manufacturer equipped its new UAZ Patriot with a mechanical dispensing unit. Then the developers decided to update the drive. Among the main updates was the replacement of the standard handout box with a more advanced Korean Dymos movement. But only the company is Korean here, and the production of the unit itself is carried out in the PRC.

Our article will tell you about what a Daimos handout for UAZ-3163 is, where the design features of the unit and the main advantages over the classic mechanical design will be considered. Let's talk about when repairs are required, during which the circuit will come in handy.

Transfer case features

The Daimos distribution box, which UAZ Patriot is currently equipped with, is a two-stage gearbox, where the gear system is placed in an aluminum case. The main transmission link in the unit is a chain, through which the moment is directed to the front axle. The transfer unit is controlled by a special electromechanical mechanism that allows you to select different driving modes.

For example, in a traditional manual transmission, a lever acts as a switch, which is operated by the driver through manual force. Today, this lever has been replaced by a control washer, which is located between the seats. This regulator has increased the comfort of driving an SUV.

One of the main advantages of the new Daimos distribution box is its ability to withstand increased loads. In addition, the new unit has grown in size compared to its predecessor. This entailed a change in the design of the propeller shaft of the rear axle of the UAZ Patriot, after which it began to be produced in one piece. Previously, this transfer element was a pair of hollow pipes with an intermediate connection segment. Now this link (bearing) is absent, which favorably helps to reduce the level of vibration and increases the resource of the entire mechanism.

Also, the design of the transfer case made it possible to abandon many of the gears and shafts that were present in the old box. Now in the Dymos unit, the chain is the transmitter of the moment, which significantly reduces the noise of the mechanism as a whole.

Note that in order to increase the clearance, the manufacturer lifted the new razdatka and fixed it as high as possible. The clearance is now 320 mm.

To ensure the possibility of installing the Korean box in the UAZ Patriot drive system, the designers had to change the transmission tunnel. Its dimensions are larger. Due to the larger dimensions of the new dispensing unit, the developers had to abandon the hand brake mechanism. Previously, the handbrake blocked the rear universal joint, and the mechanism itself was located near the transfer case. Now special mechanisms located in close proximity to the discs are responsible for blocking the wheels.

- Providing better cross-country ability, since now the gear ratio of the main stage of the unit is 2.56 instead of 1.94, as it was on the old transfer case. The SUV has become able to confidently overcome obstacles when there is a Daimos handout on it.

- The new box is easy to operate. This was made possible thanks to the presence of a progressive regulator, which the manufacturer placed in the central tunnel.

- Absence of third-party noises that could previously be produced by a mechanical dispensing unit.

For the updated UAZ Patriot, an upgraded gearbox has become available. It was kindly presented by the same company - Dymos.

Gearbox from Dymos on UAZ Patriot

The unit is equipped with a five-stage gear selection mechanism, which has proven itself on the positive side in terms of reliability. The box requires a minimum of maintenance and is famous for its excellent resource. Despite the fact that the Daimos transmission and razdatka are combined units, the manufacturer has provided lubricants for them with different consistencies.

To remove the dispensing unit for repair, you will need to resort to the simultaneous dismantling of the transmission unit. The scheme is suitable for this purpose. Only after such a procedure will it be possible to disconnect the mechanisms. Units are connected by means of nuts. There is a layer of sealant between the housings.

In the photo we see the Dymos transmission combined with the transfer unit.

If there is interest in the technology of dismantling and disassembling the box, then you can familiarize yourself with it here on the website.

Now let's talk about the types of malfunctions that are typical for the UAZ Patriot dispensing unit, and the reasons for them. Your car will probably need repairs after diagnosis, and a diagram will come in handy for this purpose.

Breakdowns and causes of the transfer case

Despite the fact that, in general, the Korean Daimos handout box is a fairly reliable unit, it is still possible that the impact of various factors causing malfunctions is possible. What is this breakdown?

- The low gear in the box began to turn off spontaneously.

- There is a grease leak from the unit housing.

- The noise of the mechanism, accompanied by vibration, appeared.

- Presence of traces of crumbling teeth and backlash in bearings.

- The chain tension level has decreased.

What causes these faults to appear? The reasons may lie among the following factors:

- The component components of both the transfer case itself and the transmission unit were worn out.

- The owner is inclined to drive for a long time with the front axle activated, having her needs for that.

- Systematic impact of increased loads caused by improper operation of the dispensing unit.

- Use of a lubricant that does not fall under the manufacturer's regulations.

- The mount of the motor mountings is loose or these components have become unusable, which will be indicated by vibration at start.

- Prolonged exposure to vibrations, which can be caused by improper tire pressure or other factors, including wear of the driveline.

- Incorrect modifications to the units in the UAZ Patriot drive system.

When the indicated signs appear, the owner of the UAZ Patriot is recommended not to postpone for a long time with the diagnosis of the drive, but to take measures to identify faults as soon as possible and eliminate them. And if repairs are required, the scheme will help in this matter.

Let's sum up

Here's some important information! Some owners set themselves the goal of replacing the old transfer case with a new unit. Can you do this? Installation of a Korean unit on a UAZ Patriot is possible, but some work will need to be done. Repair can be done independently, the scheme will help with this. Here it is necessary to replace the tunnel casing, cardan drives, transmission unit frame cross members, handbrake actuator, electrical wiring and fuel lines.

The gearbox is considered to be a mechanism designed to change the frequencies and torques of the driving wheels within increased limits. A gearbox with a mechanical transmission is most often gear.

The manual transmission of modern domestic cars is a convenient and reliable unit that cannot avoid the prospect of wear or the impact of negative factors. Most often, motorists have to deal with the following gearbox malfunctions:

⦁ spontaneous shutdown of the lower gear of the box - the device uncontrollably returns to neutral mode;

⦁ occurrence of an oil leak;

⦁ the appearance of extraneous sum, hum, grinding or vibration;

⦁ crumbling of bearing teeth;

⦁ bearing malfunctions or spring deformation;

⦁ relaxation of chain tension.

All of the above negative factors are a direct result of long-term vehicle operation without proper maintenance. Aggressive driving style, which involves jerky gear changes and rough handling of the lever, can significantly accelerate the process of responsible wear of gearbox mechanisms. A reliable car service will allow not only to quickly identify the cause of the breakdown, but also to comprehensively fight to overcome it. Sale of a gearbox allows the motorist to radically get rid of problems - to buy a manual transmission and install a new mechanism.

Transmission faults usually develop as a result of:

⦁Significant wear of parts due to oil starvation of the gearbox.

⦁Long trips with the first axle engaged unnecessarily.

⦁ Abrupt and aggressive operation of the gearbox - jerky shifting or abrupt transition to neutral mode.

⦁ The use of lubricants that are incompatible with a particular manual transmission or are not intended at all for this mechanism.

⦁Unqualified maintenance - unauthorized gearbox bulkhead can cause poor-quality twisting of mechanisms.

⦁ prolonged exposure to vibrations or loads resulting from inaccurate use of the gearbox.

⦁Settings of parts that are not compatible with a specific gearbox modification.

⦁Installation of used or non-original parts.

⦁Lack of regular gearbox diagnostics - it is worth checking the condition of the gearbox after overcoming the first 50,000 km.

⦁ Unprofessional vehicle maintenance.

Despite the fact that the gearbox is not considered a fragile mechanism, it needs careful and careful use and timely technical inspection. Early diagnosis of malfunctions and identification of their causes will allow the entire mechanism to continue its life due to the local replacement of worn parts.

Top 5 malfunctions of the UAZ manual transmission

In the process of active operation of a hardy modern car, its systems sooner or later wear out. The motorist will have to say goodbye to bearings, synchronizers, oil seals, couplings, pumps, transfer cases, center differentials, gear forks, rods and other components. At the same time, the choice remains with the owner himself: to buy the gearbox again or to replace worn-out mechanisms locally to continue the service of the original gearbox.

The manual gearbox of a UAZ car usually encounters the following faults:

⦁ Poor attachment of the gearbox to the crankcase - this negligence is fraught with spontaneous disengagement of the forward gear, which is especially dangerous under heavy shock loads. Loosening usually occurs during clutch replacement or oil refilling.

⦁ Sharpened synchronizer teeth that can cause jerky or difficult gear changes.

⦁Worn bearings and faulty rod retainers - these can cause spontaneous disengagement or gear shifting.

⦁Worn gear teeth, which can lead to problem shifting and the appearance of knocking or grinding noise during the mode changeover. This defect requires a comprehensive solution, the implementation of which is facilitated by the sale of manual transmissions. Installing a new gearbox will provide gear teeth with uniform abrasion as a result of the planned load.

⦁Oil problems - this general group of faults is caused by the use of poor-quality lubricant, insufficient amount of oil or its non-compliance with a certain gearbox modification.

Despite the fact that most of the listed malfunctions can be quickly eliminated by a local method, qualified specialists from proven service stations still advise motorists not to crowd together and carry out a comprehensive replacement of worn-out parts or even install a new gearbox.

A quality service station is characterized by:

⦁the presence of its own store with original spare parts and mechanisms - the sale of the checkpoint allows the motorist to immediately abandon local repairs in favor of a new mechanism;

⦁use of high-tech equipment;

⦁specialists with many years of practical experience;

⦁high quality diagnostic equipment;

⦁possibilities for prompt and high-quality exchange, sale and installation of all modifications of gearboxes and other UAZ mechanisms.

Modern auto centers are a whole complex of maintenance, which provides disassembly, defecting, replacement or repair of boxes of all types, manufacturers and modifications.

Tools for dismantling UAZ gearboxes

A qualified gearbox repair is based on a careful and well-coordinated preparatory process. Initially, the specialists of the auto center carried out diagnostics to identify the essence of the malfunction and find its cause. The data obtained are the basis for the development of a competent repair plan, which is subject to prompt and high-quality implementation.

In the process of repair, it is important to dismantle the gearbox. Sometimes the repair of the box of a UAZ PATRIOT IVECO car or another popular model comes down to replacing a worn out part and topping up transmission oil. That is why the dismantling of the manual transmission must be competent and extremely accurate.

The bulkhead of the manual transmission will allow you to determine the cause of the malfunction, so the importance of high-quality dismantling is difficult to overestimate. It is difficult to imagine the accurate removal of a manual transmission from a UAZ vehicle without the following set of tools:

⦁Set of socket or open-end wrenches and a wide range of sizes (from 10 to 36).

⦁Special wrench, which will be used for working with flat nuts. In this case, amateurs often use bicycle keys.

⦁ Sets of flat and Phillips screwdrivers.

⦁ Pliers - service keys with curved or straight tips.

⦁Copper rod (rod for working with gears).

⦁A small piece of metal pipe for holding the nut when screwing each nut in a hard-to-reach place of the gearbox.

⦁High-quality imported sealant, without which it is difficult to imagine a tight and reliable installation of gaskets, which will not allow the mechanisms to wear out prematurely.

All of the listed tools are a mandatory set of both a professional specialist and a novice master who will repair the gearbox or replace worn parts. Attention to the tools and the preparatory process as a whole will make the repair of mechanical boxes a well-coordinated, high-quality and qualified procedure that will restore the car to its former safety, maneuverability and ease of control.

The procedure for dismantling UAZ 3151 gearboxes depends on:

⦁ car models - UAZ has three gearbox options, each of which is characterized by its own design features;

⦁ the reasons for the breakdown - if the breakdown is very serious, the specialist should promptly get rid of the broken gearbox for the qualified installation of a new gearbox;

⦁ preliminary diagnostics.

Dismantling of gearboxes is considered the second stage, without which it is difficult to imagine a modern qualified repair of manual transmissions of all UAZ models.

Functional differences between the ADS and Dymos gearboxes

The multipurpose cross-country vehicle UAZ is equipped with a high-quality five-speed manual transmission, which has two main improved versions - ADS and Daimos.

The five-speed manual transmission is produced at the Ulyanovsk Automobile Plant to provide all basic models of domestic SUVs. That is why the gearbox is characterized by a one-piece crankcase and synchronization in all forward gears. The first box appeared on the UAZ Patriot car, however, then the advantage of this production modification could be assessed by other models. So, owners of Simbir, Hunter and UAZ-3160 can use a high-tech manual gearbox.

The ADS gearbox is characterized by the following features:

⦁Smooth functioning of mechanisms due to lengthening of the gear lever - with calm or professional driving, the driver may not apply for a gearbox repair for at least 5 years.

⦁Presence of a bracket for fastening the return spring for quick and simplified fastening of the gearbox.

⦁Change of the general scheme of the gearbox and the selective device - modifications became the reason for preventing oil leakage and ensuring safe gearbox skin.

⦁ The presence of a special sensor for uninterruptible power supply of the rear lights.

⦁Displacement of the filling hole by 2 cm - this minimal modification made it possible to improve the circulation of the oil-lubricant and prevent its leakage.

The manufacturer followed all the canons of modern high-quality manual transmissions, and at the same time tried to minimize the influence of negative factors on the mechanism as much as possible. Thanks to the standard structure, diagnostics and manual transmission bulkheads will become operational and easy procedures.

The Korean company Daimos offered Russian manufacturers its improved gearbox in 2013. The main difference between the gearbox and the domestic version is the presence of electric control, due to which drivers can completely abandon the use of the usual manual gearbox lever.

The Daimos gearbox is distinguished by the following technical characteristics:

⦁Using a built-in special washer instead of the usual manual gear lever. Thanks to this regulator, the control of the domestic SUV has become pleasant, comfortable, light and smooth.

⦁Changing the rear propeller shaft - the absence of an intermediate support and taming the shaft.

⦁Presence of a one-piece cardan of the rear axle.

⦁Lack of an intermediate bearing, since the cardan of the rear axle has become a one-piece mechanism that dispenses with gaskets.

The UAZ PATRIOT IVECO car has a mechanical five-speed three-shaft gearbox from the Korean company Dymos, which contributes to accurate and safe movement of the car and full control over it, even on an icy road or off-road.

This gearbox can be considered a modern and high-tech equipment that is not subject to rapid wear, even with an aggressive off-road driving style. Korean manufacturers remain true to their style - they are always ready to offer reliable mechanisms to motorists.

The transfer case of UAZ is characterized by a two-stage mechanism, which is complemented by an aluminum case. This mechanism is based on a chain drive for transmitting torque to the front axle.

The modified UAZ razdatka has the following changes:

⦁Stunning endurance due to the absence of the usual gear lever.

⦁Reduction of body vibrations due to the absence of an intermediate bearing in the rear axle cardan (this mechanism has become one-piece).

⦁The design of the new transfer case is based on a chain drive.

⦁Lack of a handbrake brake - the additional braking device is now located on the rear wheels, like most modern models of off-road and endurance cars.

Transfer case UAZ is a modern and modified set of mechanisms, which made it possible to achieve maneuverability and smooth movement of the car even by an inexperienced driver. Due to technical improvements, the distributor made it possible to prevent oil leaks, vibrations or knocks, excessive wear due to strong shock loads.

Gearboxes for UAZ vehicles are produced by both Korean and Russian manufacturers. Both options are modern, reliable and quality. However, they differ significantly in technical content. Repair of manual transmissions from two manufacturers is a process of prompt replacement of worn-out mechanisms and oil refilling.

The DYMOS gearbox can undoubtedly be called an attempt to create a high quality and reliable gearbox, which is located at the junction of manual and automatic gearboxes. At the same time, the ADS gearbox is aimed at preserving the original technical characteristics of the UAZ HUNTER vehicle (and other model) and making it more comfortable, smooth and easy to control.

Technical features of the UAZ BUKHANKA gearbox

UAZ BUKHANKA is considered an all-wheel drive utility vehicle, which appeared on the domestic automotive market back in 1965. Over a half-century history, this vehicle has become multifunctional and versatile - it was used to transport goods, meet the needs of the army and deliver patients to hospitals.

The UAZ BUKHANKA gearbox performs a fundamental and responsible task - it monitors the variability indicators of the magnitude of the motor torque and transfers them from the engines to the driving wheels.

The four-speed gearbox of the UAZ-452 and other models is characterized by the following features:

⦁ the presence of inertial synchronizers for engaging and shifting gears without extraneous noise or rumble - synchronizers help to equalize the speed of the teeth, which are connected before engaging;

⦁ one-piece cast-iron crankcase, which is the place of installation of the primary, secondary and intermediate shafts;

⦁ with helical gears of the intermediate shaft drive;

⦁ the presence of two plungers as a locking mechanism against accidental or deliberate engagement of several gears at the same time;

⦁four modes of forward motion with the following transfer values: 4.12; 2.64; 1.58; 1.00.

Despite the fact that the manual transmission is prepared for high loads, it cannot do without planned and qualified repairs. The need for repairs is usually the result of such negative factors:

⦁Using the car in extreme modes - UAZ 469 does not tolerate constant aggressive driving and operation only off-road or in icy conditions.

⦁Operation of a car with a faulty clutch - ignoring this breakdown may cause an emergency.

⦁Using low-quality oils for the drive axle - experienced auto center specialists advise car owners to follow the manufacturer's recommendations so that the car remains in service as long as possible.

⦁ Unprofessional or untimely maintenance - despite the fact that the UAZ is a hardy car, its repair should not be trusted by the hands of non-professionals. So, the sale of a gearbox allows you to solve half of the problem - the correct installation of the gearbox is important.

If the use of the gear cover is accompanied by extraneous noises or rattles, the car owner should send his car for diagnostics and carry out a prompt repair of the gearbox. If the diagnostics did not reveal serious breakdowns, the cause of the unpleasant grinding may lie in worn bearings and gears. Prompt replacement of these parts will again make gear shifting quiet and comfortable. To update the entire mechanism, auto centers often offer to buy a gearbox.

Worn synchronizers can “ask for replacement” when a motorist has to deal with tight or jerky gear changes. Synchronizer wear can be either planned or extraordinary. The second type of malfunction is usually caused by a critical decrease in the amount of oil in the crankcase.

Leaky gaskets should be replaced using imported sealant - it is of higher quality, reliable and proven.

Repair of gearboxes should be a complex, well-coordinated and qualified process, which is based on thorough diagnostics, troubleshooting, building a competent repair plan, preparing parts and grinding mechanisms.

The smooth operation of gearboxes depends on the use of quality lubricants in sufficient quantities. A minimum amount of oil can cause increased wear on gears and synchronizers, which may require attention with jerky gear changes or arbitrary activation of neutral mode.

Advantages and features of the UAZ FERMER checkpoint

UAZ FERMER is considered a cargo-and-passenger all-wheel drive vehicle, which is characterized by comfort, versatility and increased cross-country ability. Popularly, the UAZ-3909 model is nicknamed "FARMER", because in this car you can easily fit the driver, 7 passengers and plus 450 kg of cargo in an isolated cargo compartment.

Full cross-country ability, spaciousness and reliability make this car a versatile assistant in the field, fishing or hunting.

The presented model has a four-speed manual transmission, the mechanisms of which are distinguished by an amazing resistance to wear. The first signs of abrasion of synchronizers and gears appear only after 70,000 km. At the same time, the repair of mechanical gearboxes is reduced to the replacement of worn parts.

The gearbox of this model is characterized by:

⦁ Long stroke when first gear is engaged.

⦁Two plungers and a pin at the junction of 3rd and 4th gears to block the inclusion of two modes at the same time.

⦁Spring-loaded fuse to prevent accidental reverse engagement.

⦁ Interchangeability - components and assemblies of various four-speed transmissions are interchangeable.

Transmission malfunctions of this model are usually expressed in jerky gear changes, unauthorized transition to neutral mode, or knocking of the gearbox. These malfunctions are provoked by irregular and poor-quality maintenance, lack of quality oil in the required dosage, or abrasion of mechanisms.

The driver's inattention to the abrasion of parts can cause premature wear of the entire gearbox. In this case, the driver will have to buy a gearbox and contact a service station to dismantle the old gearbox.

Specificity of the transfer case of modern UAZ modifications

The transfer case allows you to distribute the torque from the engine, so this mechanism is a mandatory unit for all-wheel drive vehicles, which include all UAZ modifications.

The Ulyanovsk Automobile Plant was the first to offer a helical transfer case for serial production for the UAZ Simbir. A feature of this mechanism is the presence of helical gears for transmitting torque to the front axle of the car. The use of this technological modification allowed the manufacturer to get rid of the general noise level of the transfer case and make it more durable. In the low gear mode, the noise level remained at the same level, since the manufacturer left the spur gear drive gear for low and direct transfers.

The Ulyanovsk plant introduced motorists to the UAZ-2360 (CARGO) low-tonnage truck in 2002. Taking into account the fact that this modification is based on the UAZ SIMBIR platform, its transfer case has a similar configuration.

The UAZ KARGO car is characterized by the following features of the transfer case:

⦁ replacement of ball bearings with roller bearings to significantly increase their carrying capacity;

⦁compatibility with engines, the torque of which is up to 30 kg × m;

⦁ reducing the noise level to 8-10 dBa due to the use of helical gears;

Minimum maintenance - the transfer case only needs a timely replacement of the lubricant in accordance with the operating instructions.

The gearshift mechanism on the UAZ PIKAP car, as well as on other trucks of the PATRIOT family and HUNTER models, remains single-lever - it provides for the alternating engagement of the front axle, and then neutral and downshifting.

The transfer case of UAZ is mechanical and two-stage, it does not have an center differential, but it is possible to disable the front axle.

The helical razdatka is characterized by the following fundamental features:

⦁Rotation ratio of underdrive - 1:94.

⦁Centering on the outer race of the double-row bearing of the gearbox secondary shaft.

⦁Parking brake mechanism on the rear of the transfer case.

⦁Transferring torque to the drive shaft.

⦁When the front axle drive is engaged, the shafts are connected using a toothed coupling.

⦁Mounting the idler gear on the countershaft.

The use of the helical transfer case helped to minimize unpleasant noises, knocks and rattles during the operation of UAZ trucks.

Despite the fact that UAZ is a true pensioner of the domestic auto industry, these four-wheel drive vehicles have a dozen models that differ in their design features and gearbox.

In UAZ cars, the gearbox can be either four-speed or five-speed. Despite a respectful list of features and specifications, these transmissions differ from each other by one indisputable fact: four-speed transmissions are interchangeable, despite the fact that they may differ in gear ratios. A five-speed gearbox should be bought very carefully - it cannot replace another modification.

The checkpoint needs routine diagnostics and timely repairs to keep the vehicle agile and safe. Screaming signs for repair can be considered:

⦁ Appearance of unpleasant knocking, grinding, vibration during gear shifting.

⦁Oil leaking.

⦁ Jammed gear lever in one mode or all.

⦁Jet gear shifting.

⦁Available switching to neutral mode.

The UAZ car itself is hardy - it is designed for high loads, off-road conditions, driving on an icy road and transportation of bulky goods. However, this creation of the Ulyanovsk Automobile Plant, like most other cars, needs timely and high-quality maintenance, regular diagnostics and oil refilling, the use of quality parts and lubricants, as well as a calm or professional management style.

A jerky gear change for no apparent reason provokes the mechanisms to work with a double shock load, due to which they are more quickly exposed to wear. Disassembling and troubleshooting the gearbox in a reliable and proven car service allows you to determine the cause of the malfunction.

Photo report of disassembly and repair of the gearbox of the UAZ HUNTER gearbox

The car came in for repairs due to harsh noise from the manual transmission. As a result of disassembling the box, a defect in the bearing bearings on the gearbox shafts was revealed. We change bearings, gearbox oil seals. We wash the gearbox housing with nefras from inclusions of steel chips and old oil. Photos below: