The clutch system performs the function of short-term disconnection of the internal combustion engine from. As a result, the transmission of torque from power unit on the transmission drive shaft. This system includes many components. One of them is and master cylinder clutch, which we will talk about today.

What is he like?

This mechanism is a small cast iron steel with a flange for attachment to the body. On its top is a plastic tank with a lid. It is attached to the body with a threaded nipple. Thanks to this mechanism, the clutch master cylinder receives special liquid... Inside the cast-iron part there is a piston with a collar and an O-ring. There is also a spring resting on It compresses the piston to the extreme right position. When these parts are heated, expansion occurs, respectively, the liquid in the system must go somewhere. For these cases, there is a special expansion hole through which it enters the tank from the cylinder cavity.

How does 2107 work?

This mechanism is designed so that each time the clutch pedal is pressed by means of the pusher, it moves forward. And when the piston closes the hole, the pressure in the cylinder increases. Thus, fluid flows to the slave cylinder and disengages the clutch. When you release the pedal, a similar action occurs, only in the reverse order. The liquid flows back - the valves open, the spring is compressed and it moves from the working cylinder to the main one. If the pressure level drops to a point below the compression force of the spring, the first part closes, and more pressure is generated in the system. This is necessary to sample the clearances of the mechanical part of the drive.

If the pedal is released abruptly, then the fluid will not completely fill the space behind the piston. Then a vacuum occurs in the clutch master cylinder. Due to this, the liquid will flow from the plastic tank through the bypass hole directly into the piston. Then it passes through the piston head and fills all the space that has arisen in the part after vacuum. At the same time, the liquid removes the edges of the cuff and pushes back the spring plastic. And again, if it becomes more than the norm, all of its excess passes through a special expansion hole back into the tank. ![]()

This is how the VAZ clutch master cylinder is arranged. In conclusion, I would like to note several ways by which you can independently identify the breakdown of this mechanism:

- First, you should check the level of the working fluid in the reservoir. If this indicator drops rapidly, this indicates a malfunction of the piston or cuff.

- Secondly, this part is replaced if you feel the characteristic sound of gears when shifting gears.

- Third, the clutch cylinder is replaced with vibration

Troubleshooting in the clutch drive Lada 2105, replacing oil seals in the master cylinder, adjusting the clutch Lada 2107, pumping the car clutch with your own hands VAZ 2104, VAZ 2105, VAZ 2107. Disassembly and assembly of clutch cylinders Clutch device VAZ 2107, VAZ 2105, VAZ 2104 , do-it-yourself repair transmission repair clutch, troubleshooting and repair

Disassembly and assembly of the main and slave clutch cylinders VAZ 2107, VAZ 2105, VAZ 2104, Lada Zhiguli, Classic

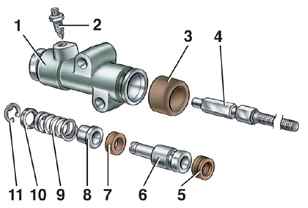

Details of the clutch master cylinder VAZ 2107: 1 - body; 2 - lock washer; 3 - fitting; 4 - gasket; 5 - cap; 6 - retaining ring; 7 - pusher piston; 8 - a sealing ring; 9 - the piston of the master cylinder; 10 - spring

Master cylinder... Remove the protective rubber cap 5 of the cylinder body of the VAZ 2104, VAZ 2105, VAZ 2107 and the retaining ring 6. This will allow you to remove the piston 7, the O-ring 8, the floating piston 9 with the O-ring and the piston return spring 10 from the housing.

The cylinder mirror and the outer surface of the piston must not be damaged or scratched. The inner diameter of the master cylinder should be 19.05 + 0.025–0.015 mm.

Check the condition of the piston return spring and replace it if it loses its elasticity.

Replace O-rings. Check the protective cap on the rear end of the cylinder and, if the cap is damaged, replace it with a new one. Clean and rinse parts carefully before assembly brake fluid... Avoid contact with parts mineral oil, gasoline, kerosene or diesel fuel, as rubber seals swell from these substances.

After checking all the parts, assemble the clutch master cylinder of the VAZ 2107, VAZ 2105, VAZ 2104 in the reverse order of disassembly; moreover, lubricate all parts of the cylinder with brake fluid or NG-213 preservation fluid.

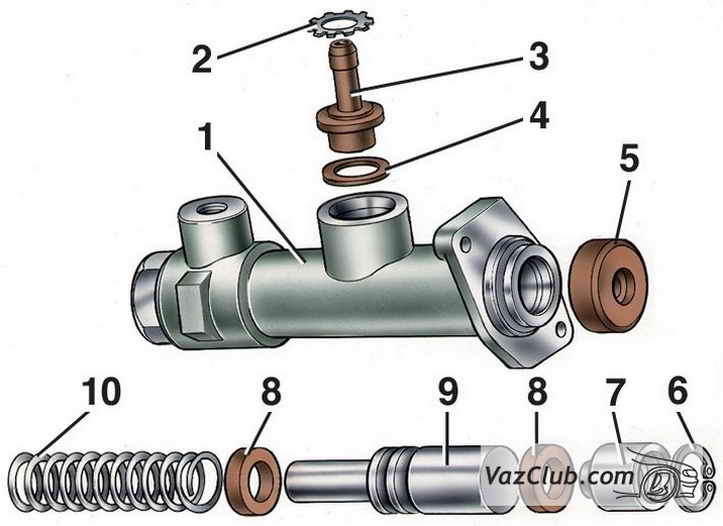

Details of the clutch actuator cylinder VAZ 2104, VAZ 2105, VAZ 2107 (working cylinder): 1 - body; 2 - fitting; 3 - cap; 4 - pusher; 5 - a sealing ring; 6 - piston; 7 - O-ring; 8 - plate; 9 - spring; 10 - washer; 11 - retaining ring

Slave cylindervaz 2104, vaz 2105, vaz 2107. Remove the protective rubber cap 3 together with the pusher 4, remove the piston and disassemble it after removing the retaining ring 11.

After disassembly, carefully wash and check all parts as indicated for the master cylinder. Installation of a deformed pusher is not allowed.

After checking, proceed to assembly (reverse order to disassembly), lubricate the parts with hydraulic fluid for the classic fret.

Clutch VAZ 2107, VAZ 2105, VAZ 2104

Clutch deviceClutch device VAZ 2107, VAZ 2105, VAZ 2104 |

Clutch release adjustmentClutch release adjustment VAZ 2107, VAZ 2105, VAZ 2104 |

Clutch bleedingClutch bleeding VAZ 2107, VAZ 2105, VAZ 2104 |

Removing and installing clutchInstalling and removing the clutch VAZ 2107, VAZ 2105, VAZ 2104 |

Checking the car's gripChecking the clutch VAZ 2107, VAZ 2105, VAZ 2104 |

Troubleshooting the clutchClutch malfunctions VAZ 2107, VAZ 2105, VAZ 2104, their causes and methods of elimination |

Removal and installation of clutch cylindersRemoval and installation of the clutch slave and master cylinders VAZ 2107, VAZ 2105, VAZ 2104 |

Hello dear readers! I recently wrote an article about, today we will talk about replacing the clutch master cylinder (GCC) of the "seven".

The principle of operation of the clutch master cylinder VAZ 2107.

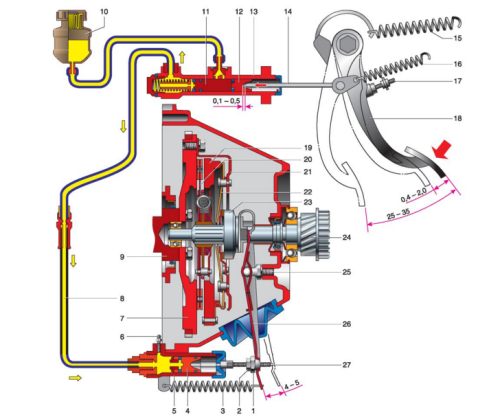

When you press the clutch pedal, the pusher pushes the master cylinder piston (see diagram), which in turn displaces the brake fluid through the clutch hydraulic line to the slave cylinder and then through the clutch release fork disconnects the clutch from the flywheel.

Clutch operation diagram on classic VAZ models.

| 1 | adjusting nut; |

| 2 | lock-nut; |

| 3 | clutch fork release spring; |

| 4 | clutch slave cylinder piston; |

| 5 | working cylinder; |

| 6 | bleeder fitting; |

| 7 | flywheel; |

| 8 | clutch hydraulic drive pipeline; |

| 9 | crankshaft; |

| 10 | master cylinder reservoir; |

| 11 | master cylinder piston; |

| 12 | pusher piston; |

| 13 | master cylinder; |

| 14 | pusher; |

| 15 | clutch pedal servo spring; |

| 16 | clutch pedal release spring; |

| 17 | clutch pedal travel stop screw; |

| 18 | clutch pedal; |

| 19 | pressure disk; |

| 20 | driven disk; |

| 21 | clutch cover; |

| 22 | pressure spring; |

| 23 | clutch release bearing (release bearing); |

| 24 | input shaft of the gearbox; |

| 25 | ball joint of the clutch release fork; |

| 26 | clutch release fork; |

| 27 | clutch release fork pusher. |

Where is the GVC located?

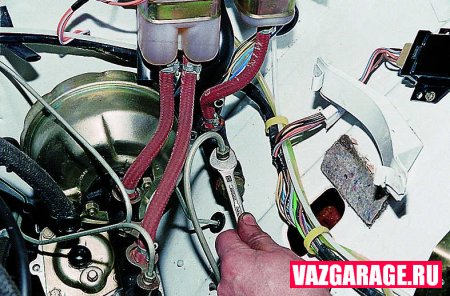

The clutch master cylinder is located in the engine compartment on the driver's side between the reservoirs, see photo.

Signs of a malfunction of the clutch master cylinder.

- If the gears are engaged with a crunch and hard when the pedal is fully depressed, this indicates an incomplete engagement of the clutch, the cause may be a malfunction of the HCC.

- Brake fluid leaks.

How to replace the master cylinder of the VAZ 2107 clutch with your own hands: instructions.

Tools:

- set of wrenches,

- pliers,

- brake fluid,

- rubber pear.

Sequencing:

- The first step is to dismantle expansion tankdetaching the rubber strap.

- Use a rubber bulb to pump out the brake fluid from the master cylinder reservoir.

- Loosen the clamp with which the master cylinder reservoir hose is attached to the cylinder. Disconnect the hose from the cylinder.

- Unscrew with a 13 key the nut securing the clutch hydraulic pipe to the cylinder, take it to the side.

- Next, using an extension cord with a union head, unscrew the two nuts securing the master cylinder to the car body. Dismantle the cylinder, drain the remaining brake fluid from it.

- Install GZS in reverse order. Important: required.

Video.

And today you will find out what it is vaz clutch master and slave cylinderhow to remove and install them on a car, structure.

In order to understand how the master and slave cylinders of the VAZ clutch work, you need to know their design and the details of which they are composed.

In principle, the master and slave cylinder of the VAZ clutch are very similar in operation and design with.

1 - main cylinder body; 2 - lock washer; 3 - fitting; 4 - gasket; 5 - cap; 6 - retaining ring; 7 - pusher piston; 8 - a sealing ring; 9 - the piston of the master cylinder; 10 - spring.

Before disassembling the clutch master and slave cylinders, they must be removed, for this:

- remove from the system working fluid, for this we put a hose on the fitting, substitute the container and unscrew it to the floor - three quarters of a turn of the fitting;

- press the pedal until the flow of fluid from the system stops;

- disconnect the main and working cylinders from the pipelines;

- remove the retractor spring 7 and the cotter pin from the edge of the pusher, then remove the working cylinder, for this we unscrew the two bolts;

- to dismantle the master cylinder, disconnect its hose from the tank and unscrew the two nuts that hold it on the pedal bracket studs.

To assemble all this in a heap, they do everything the same only for a turn.

And do not forget to fill in the liquid after assembly and pump the system.

Disassembly of the VAZ clutch master cylinder

1. Unscrew the plug, remove the protective rubber cap 5 and the retaining ring 6.

This will give you the opportunity to get all the contents from the body of the piston 7, the O-ring 8, the floating piston 9 with the O-ring and the piston return spring 10.

2. We check by visual inspection the condition of the cylinder and the outer surface of the piston should not have any damages, stripes and scratches. The inner diameter of a serviceable master cylinder should be within aisles: 19.05: +0.025 –0.015 mm.

3. We also check the elasticity of the piston return spring and, if necessary, replace it with a new one.

4. Change the O-rings and check the protective cap at the rear end

cylinder and, if damage is noticeable on it, you will have to replace it with a new one. In order to collect all the parts in a heap, they need to be cleaned of contamination and rinsed with brake fluid.

Be careful to avoid contact with rubber products different liquidsthat can destroy them.

5. All parts are lubricated with brake fluid and assembled in reverse order... Can be used for lubrication with preservation liquid NG-213.

1 - case; 2 - fitting; 3 - cap; 4 - pusher; 5 - a sealing ring; 6 - piston; 7 - a sealing ring; 8 - plate; 9 - spring; 10 - washer; 11 - retaining ring.

Disassembly of the VAZ clutch slave cylinder

1. Unscrew the plug, remove the protective cap 3 together with the pusher 4, remove

piston and disassemble it after removing the circlip 11.

2. After disassembly, carefully rinse and inspect all parts as indicated for

master cylinder... Installation of a deformed pusher is not allowed.

3. After checking, proceed with the assembly (order, reverse to disassembly), lubricating the parts

fluid for hydraulic drive.

One of the most important parts of a car, when the clutch fails, it becomes almost impossible to use the car. The master cylinder is installed on top, it creates excess pressure by the clutch pedal, which forces the slave cylinder to move.

Signs of malfunction of the master cylinder

- insufficient disengagement of the clutch (clutch leads)

- any kind of leakage, that from under the nuts of the fastening of the hose and pipes, that from the end from under the rubber seals

- jamming of the master cylinder in the pressed position

My symptom of malfunction is a leak that is caused by a worn O-ring. The fluid flowed down the pedal straight to my salon. It was decided to immediately replace the faulty master cylinder with a new one.

Replacing the clutch master cylinder VAZ 2106

1. With a rubber bulb we take fluid from the clutch hydraulic reservoir.

2. Having loosened the band clamp, remove the hose from the cylinder union.

3. Using the "13" key, unscrew the pipe union.

4. Using the "13" head, unscrew the two nuts securing the cylinder to the pedal bracket studs.

5. Then remove it from the studs.

6. Install the clutch master cylinder in the reverse order of removal. Pour liquid into the tank and pump the clutch hydraulic drive.