A liquid, as we know, is a fluid substance. Brake fluid, like all technical vehicle fluids, is no exception. The only difference is that the leak, like any other technical fluid, threatens at least - the failure of some unit, but at most ... an emergency while driving.

The process of cleaning old brake fluid from the system. It is necessary after renovation brake systemwhen the air entered the line to avoid the spongy brake pedal and the braking force decreased. Insofar as brake fluid usually contaminated with moisture and other unwanted toxins over time, many car manufacturers report complete bleeding of the brake system every 2-3 years, including the addition of fresh brake fluid.

Brake fluid level control

It is for this simple reason, to constantly visually monitor the brake fluid level, and engine oil and antifreeze, you should look under the hood of the car every day before driving out of the garage. Thus, you can observe how much brake fluid is in the system and guarantee yourself relative safety while driving.

A brake caliper, found only on disc brakes, houses pistons that use the force of the hydraulic brake fluid to compress the brake pads against the rotor - creating braking force. Calipers can contain a different number of pistons and have a "fixed" or "floating" mounting option.

A removable bolt that allows the brake pads to slide back and forth when the brake pressure is applied and released. When replacing the brake pads, the mounting bolts must be temporarily removed during which they must be cleaned and re-lubricated with grease to prevent seizing.

Visual control of the brake fluid level is carried out on the filler reservoir. There are marks on it: "min" and "max". Most the best option Is the liquid level between the marks. If he began to decline to min, it means that you have a brake fluid leaking somewhere and you need to urgently start identifying the leak. Test the system beforehand. Topping up the brake fluid, see if it leaves, and at what speed.

Ceramic brakes

Floating brake calipers are secured in mounting brackets that bolt directly to the spindle or vehicle suspension.

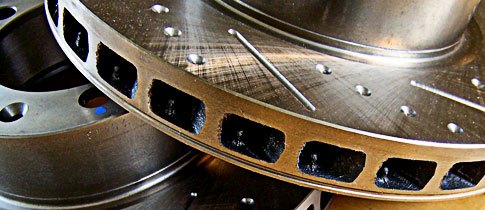

These are brake pads and rotors made from special porcelain mixtures instead of traditional materials. Ceramic brake components resist heat much better, provide greater stopping power and resistance to corrosion. A favorite of racers, their availability as optional factory equipment on high-end performance models is steadily increasing.

At the same time with visual control, at intervals of once every six months or a year, it is necessary to check the qualitative composition of the brake fluid. This check is done. The frequency of the check depends on the operating mode of your vehicle.

The availability of aftermarket ceramic brakes is lower than any other because their high cost makes them a specialized item. In the above picture, a ceramic brake pad is shown over a traditional metal one. Browse the performance-oriented ceramic brake pads and ceramic brake kits we offer.

A brake valve that combines two or more brake fluid valves into one body. ![]()

A pressure gauge with a finely tuned needle that measures any deformations or irregularities at the end of the brake rotor as the rotor spins around. The amount of runout detected can then be compared to the vehicle manufacturer's specifications to determine if the rotor should be replaced or floated. This sensor can also be used to determine the position of the wheel bearing. You can see an example of a dial indicator.

When visually observing the TAS level, pay attention to the presence of deposits on the inner walls of the tank. If you see dirt deposits, any foreign particles or water droplets, then this is another "call" in favor of replacing the brake fluid.

Rotary surfaces with holes that have been partially drilled are also known as "pit" surfaces. While they don't have the same risk of cracking as fully drilled rotors do, pit rotors sweep away less heat and debris.

Most often specified by car manufacturers, this type of brake fluid meets the specifications of the US Department of Transportation for glycol-based fluids with a wet boiling point of 284 degrees Fahrenheit and a dry boiling point of 401 degrees Fahrenheit.

Common Causes of Brake Fluid Leaks

If, during a visual check of the level on the reservoir, you notice that your brake fluid is leaking, we proceed to identify the leak. Moreover, note that in the event of a brake fluid leak, obvious traces of it are not necessary, as, for example, in cases with an engine oil leak or.

It is suitable for more difficult conditions operation and higher braking temperatures thanks to a higher wet boiling point of 311 degrees Fahrenheit and a dry boiling point of 446 degrees.

It is a silicone-based liquid with a boiling point of at least 500 degrees Fahrenheit.

Rotors with disc brake holes have holes that extend to the other side - a layout that maximizes heat and debris dissipation. Some drilled rotors may also have slots on their faces. Because they dissipate heat faster, drill rotors have an advantage over slits during high-performance driving and racing. As the drilled holes take mass out of the rotors, cracks can occur between the perforations when used on a vehicle that takes on a heavy weight load due to heavy load or stable towing.

So, low level brake fluid can result from:

- Excessive brake pad wear

- Worn brake master cylinder cuffs (with this malfunction, brake fluid may enter the vacuum booster). In this case, it is difficult to immediately visually determine the presence of a TAS leak.

- Wear of the cuffs of the brake cylinders of the wheels (in this case, when removing the wheel, you can notice traces of a leak).

- Defect in the system of brake hoses, pipes

Vehicles with built-in motors or superchargers can also have a devastating effect on drilled rotors, especially with drive abuse or drift.

An annular outer casing that rotates with the vehicle wheel and fits all internal components of the drum brake mount. The inner part of the drum provides friction surface protection for drum brake pads. While most drums are made of iron, some features a lightweight aluminum construction with a cast iron liner.

Thorough troubleshooting of the entire brake system is essential. She is especially needed in winter time years when all rubber-technical products "dubbed" from low temperatures. By doing this, by spending time, you will protect yourself from the law of a “falling sandwich” when the brakes fail at the most crucial moment.

A brake setup that uses curved brake pads that move outward and apply braking pressure to the inner surface brake drum... Compared to more modern disc brake units drum brakes cheaper to produce. Since they also don't dissipate heat, they are more prone to overheating and reduce braking performance. Drum brakes are found on older cars and on the back of some inexpensive trims in newer cars and trucks.

After finding the place of brake fluid leakage, it is naturally required to repair (replace) the failed unit, and complete it.

Good luck with regular. Never let it go down in your car.

The safety of the driver and passengers in the car directly depends on the brake fluid. A sharp drop in the level of brake fluid is fraught with extremely unpleasant consequences. If the brake fluid level falls below the minimum mark, the safety of the driver and passengers is jeopardized. At least in modern car and there is a sensor that monitors the level of the brake fluid, it is still not worth relying entirely on electronics, it is recommended to periodically check its level visually.

These are essentially curved brake pads designed for drum braking systems. The spacers are attached to metal brake shoes, which provide structural support, similar to the shims used on disc brakes. brake pads... In some cases, brake linings are available separately. In most cases, however, pads are sold with brake shoes.

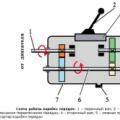

Master cylinder, which is split into two separate hydraulic circuits - each with a separate fluid reservoir and piston. If the brake system develops a leak anywhere, only one of two circuits will be affected - leaving some braking power to stop the vehicle.

Checking the brake fluid level is straightforward. There is a special tank under the hood of the car for it. Most often, the brake fluid reservoir is made of translucent plastic. Directly on the side of the tank there are two marks "MAX" and "MIN" located at different levels. The brake fluid level in the reservoir must be between these marks. Some motorists recommend maintaining the brake fluid level at the upper "maximum" mark.

A rubber seal on the disc brake caliper that prevents moisture and external contaminants from entering the area of \u200b\u200bthe cylinder where the piston compresses the brake fluid. An example of dust collectors as part repair kit may be.

For vehicles with disc brakes The dust shield is a thin sheet of metal permanently attached to the rotor. This protects the rotor, caliper, gaskets and other components from stones, sand and other debris found on the road.

Important! Before checking and adding brake fluid to the car, it is strongly recommended to read the instructions for it. Since some car manufacturers are equipped with anti-lock braking system "ABS", before checking and adding brake fluid, require "bleeding" the brakes.

If, when checking the brake fluid level, big loss... In no case is it allowed to operate the car until the cause of the loss of brake fluid is clarified and eliminated. Since the loss of brake fluid during operation may increase, and as a result, cause a failure during emergency braking. By endangering both the driver and passengers of this vehicle, and other road users.

More modern installation on vehicles with rear disc brakes. Instead of pulling the hand lever that is connected to the brake shoes to emergency braking via cable, electronic settings use electric servo motors to apply electronic brakes. The car electronics can also be used to automatically activate the electronic brake whenever the car is parked or when sensors detect that vehicle stopped on a hill with the brake pedal applied.

Reason for leaving brake fluid

The reasons for the loss of brake fluid in a car system can be varied.

Let's take a closer look at the main causes of fluid loss in the brake system.

brake fluid is leaking, a crack in the reservoir, driver's actions

If a large amount of brake fluid is lost during inspection. Do not immediately start disassembling the entire braking system of the vehicle. The first step is to make a thorough visual inspection of the brake fluid reservoir itself. A crack or damage to the tank will be indicated by a characteristic wet mark and drips.

Important! If the brake fluid barrel is damaged, in some cases it can be repaired, but it is still better to make it full replacement on new. Since a sealed crack can run again at any time.

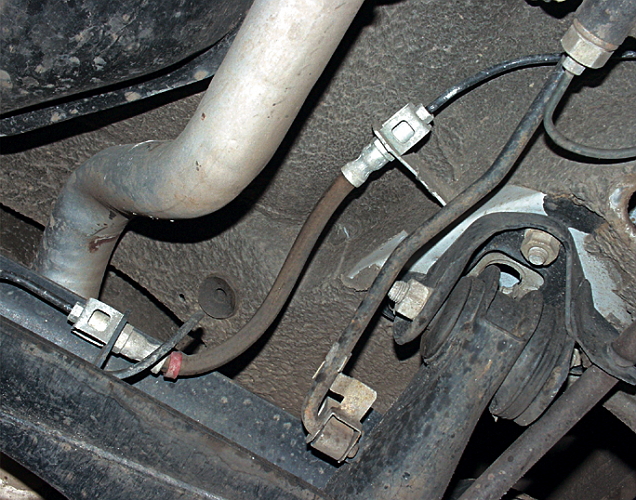

brake fluid is running out, brake cylinder drip, driver's actions

If the reason for the loss of brake fluid is not in the damaged reservoir, the next step is to look directly under the car. If the vehicle is idle for a long time, if the brake cylinder is damaged, characteristic spots of brake fluid will remain under it.

Finding a brake fluid stain under the car. It is necessary to find out the exact reason for its appearance. To detect damage to the brake cylinders, proceed in the following sequence:

- Remove the wheel;

- Thoroughly visually inspect the brake disc;

- Checking the calipers for leaks;

- We do the same with the second wheel.

- In the event that on rear wheelsah drum brakes are installed, we remove them and also inspect.

Important! Leakage of the rear brake cylinders, as a rule, is associated with wear or the quality of special rubber seals. This is especially true for residents of northern regions in very coldy... Since rubber seals at low temperatures lose their elastic properties.

brake fluid is leaking, not density in the brake hose, driver's actions

The brake hose can also cause loss of brake fluid in the vehicle. Its inspection is carried out visually for drips. A normal, undamaged brake hose must be dry.

Important! Quite often it happens that the brake hose simply flies off the fitting. This problem can be solved simply, the hose is put in place and tightened with a special holding clamp.

brake fluid is running out, brake master cylinder is faulty, driver's actions

In addition to the above reasons for the loss of brake fluid. It can occur due to damage to the main brake cylinder "GTZ", namely its rubber seals.

Cracks form in the rubber seals, through which the brake fluid oozes.

Moreover, the absence of drips does not at all mean the serviceability of the main brake cylinder, since the brake fluid can go directly to the vacuum brake booster. This malfunction is detected only by removing the brake master cylinder and identifying leaks inside the redemption amplifier. If this problem occurs, the main brake cylinder complete replacement.

Important! This problem can be eliminated by replacing the rubber seals, but experts strongly recommend a complete replacement of the brake master cylinder.

Bleeding the brake system after repair

Finishing renovation works associated with the brake system, it is necessary to bleed it. This can be done either independently or by contacting a specialized car service. Bleeding the brake system is an extremely simple process that is within the power of every car owner, but for this you need a partner whose task will include pressing the brake pedal at the right time. Even a child can take on the role of a partner.

To bleed the brake system, we need:

- Small capacity;

- Brake fluid;

- A small hose for the fitting.

And so, finding a partner and preparing everything you need, we pump the brake system in the following sequence:

- Fill the brake fluid into the reservoir up to the "maximum" mark;

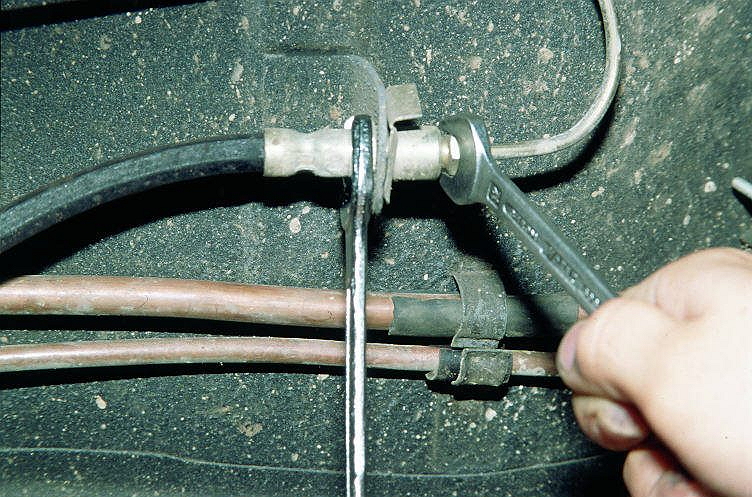

- We clean and wipe the brake fittings of each wheel;

- Pour brake fluid into a small container;

- We hook up the prepared hose to the fitting;

- We lower the other end of the hose into a container with brake fluid;

- We give the command to the partner so that he starts to press the brake pedal evenly and intensively. After the 4th pressing, the partner must fix the pedal in the pressed position;

- Unscrew the fitting slightly and watch how the brake fluid comes out. The presence of bubbles indicates the presence of air in the brake system;

- After the air has left, we wrap the fitting and repeat this process on all wheels.

Important! Before bleeding the brake system, it is recommended to read the instructions for the car. It is necessary to find out in which sequence it is necessary to bleed the wheels. In the absence of this information, you should start from the far wheel to the near one, where the end point is the brake master cylinder. As a rule, pumping begins with the rear wheels, first the right then the left, then we come to the front in the same sequence.

- Leakage of brake fluid should be taken very seriously and under no circumstances should the vehicle be operated without it or with a severe leak.

- You should regularly check the brake fluid level yourself and not rely on the car electronics. This is best done in conjunction with an engine oil check.

- After completing the repair work, it is imperative to bleed the brake system. It is not allowed to operate the car with uncompleted brakes.

- In the event of a malfunction of one or more elements of the brake system, they should be completely replaced. This will allow you to avoid unpleasant, and somewhere even dangerous consequences while driving.

- We also recommend reading the article on our website.