For those who want to understand what the Wheel Alignment Angles (Camber / Toe) mean and thoroughly understand the issue, this article has answers to all questions.

A digression into history shows that sophisticated wheel alignment was used on various vehicles long before the advent of the automobile. Here are some more or less well-known examples.

It is no secret that the wheels of some carriages and other horse-drawn carriages intended for "dynamic" driving were installed with a large positive camber that was clearly visible to the eye. This was done so that the mud flying from the wheels did not fall into the carriage and important riders, but was scattered around. Thus, pre-revolutionary guidelines on how to build a good cart recommended installing wheels with negative camber. In this case, with the loss of the dowel locking the wheel, it did not immediately jump off the axle. The driver had time to notice the damage to the "running gear", fraught with especially big troubles in the presence of several tens of poods of flour in the cart and the absence of a jack. In the design of gun carriages (again, vice versa), positive camber was sometimes used. It is clear that not with the aim of protecting the gun from dirt. So it was convenient for the servants to roll the gun over the wheels with their hands from the side, without fear of crushing their legs. But at the cart, its huge wheels, which helped to easily get over the ditches, were tilted in the other direction - towards the cart. The resulting increase in track gauge contributed to an increase in the stability of the Central Asian "mobile", characterized by a high center of gravity. How do these historical facts relate to wheel fitting? modern cars? Yes, in general, not any. Nevertheless, they provide a useful conclusion. It can be seen that the installation of the wheels (in particular, their camber) is not subject to any single pattern.

When choosing this parameter, the “manufacturer” in each case was guided by different considerations that he considered priority. So what constructors are striving for car suspensions when choosing UUK? Of course, to the ideal. The ideal for a car that moves in a straight line is considered to be such a position of the wheels when the planes of their rotation (rolling plane) are perpendicular to the road surface, parallel to each other, the axes of symmetry of the body and coincide with the trajectory of movement. In this case, the loss of power due to friction and wear of the tire tread is minimal, while the grip of the wheels with the road is maximal. Naturally, the question arises: what makes you deliberately deviate from the ideal? Looking ahead, there are several considerations. First, we judge wheel alignment based on the static picture when the vehicle is stationary. Who said that in motion, when accelerating, braking and maneuvering a car, it does not change? Second, reducing losses and extending tire life is not always a priority. Before talking about what factors are taken into account by the developers of suspensions, let us agree that out of a large number of parameters describing the geometry of the car's suspension, we will limit ourselves only to those that are included in the primary or main group. They are called so because they determine the tuning and properties of the suspension, are always monitored during its diagnosis and are adjusted, if possible. These are well-known toe-in, camber and tilt angles of the steering axle. When considering these critical parameters, we will have to remember about other characteristics of the suspension.

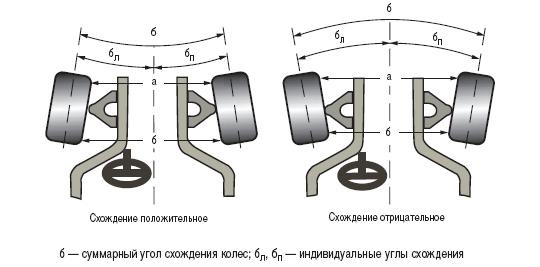

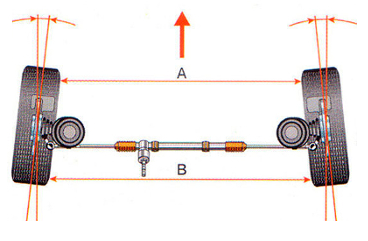

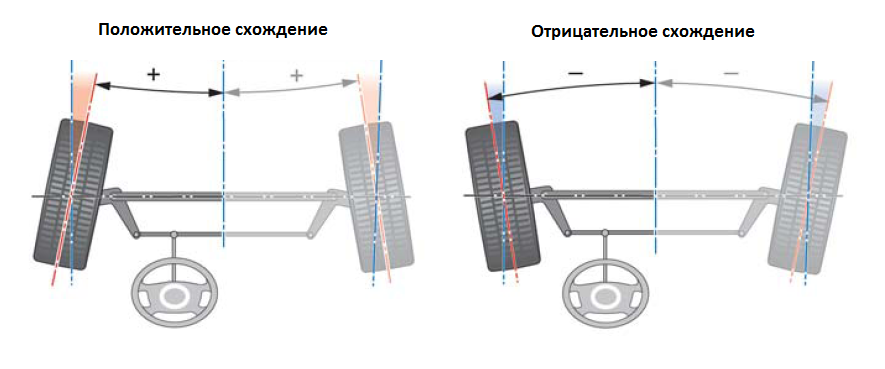

Toe-in (TOE) characterizes the orientation of the wheels relative to the longitudinal axis of the vehicle. The position of each wheel can be determined separately from the others, and then one speaks of individual convergence. It is the angle between the plane of rotation of the wheel and the axis of the vehicle when viewed from above. Total convergence (or simply convergence) of wheels of one axle. as the name suggests, is the sum of the individual angles. If the planes of rotation of the wheels intersect in front of the car, the toe-in is positive (toe-in), if at the back - negative (toe-out). In the latter case, we can talk about wheel alignment.

In the adjustment data, sometimes the convergence is given not only in the form of an angular, but also a linear value. This is due to the fact. that the toe-in of the wheels is also judged by the difference in the distances between the rim flanges, measured at the level of their centers at the rear and in front of the axle.

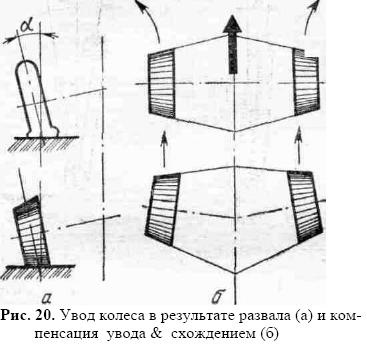

In various sources, including serious technical literature, a version is often cited that wheel alignment is necessary to compensate for the side effects of camber. They say that due to the deformation of the tire in the contact patch, the "collapsed" wheel can be represented as the base of the cone. If the wheels are installed with a positive camber angle (why is not important yet), they tend to "roll out" in different directions. To counteract this, the planes of rotation of the wheels are brought together. (Fig. 20)

The version, I must say, is not devoid of grace, but does not stand up to criticism. If only because it assumes an unambiguous relationship between collapse and convergence. Following the proposed logic, wheels with a negative camber angle must be installed with a divergence, and if the camber angle is zero, then there should be no toe. In reality, this is not at all the case.

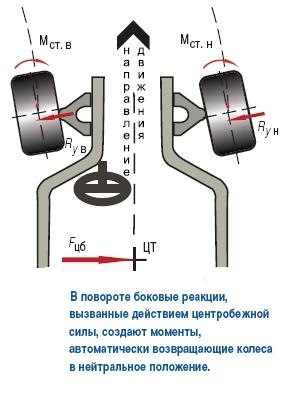

Reality, as usual, obeys more complex and ambiguous patterns. When a tilted wheel rolls, there is indeed a lateral force in the contact patch, which is often called camber thrust. It results from the elastic deformation of the tire in the lateral direction and acts in the direction of the slope. The greater the angle of inclination of the wheel, the greater the camber thrust. It is precisely this that is used by drivers of two-wheeled vehicles - motorcycles and bicycles - when cornering. It is enough for them to tilt their steed in order to make it "prescribe" a curved trajectory, which can only be corrected by the steering control. Camber thrust also plays an important role when maneuvering vehicles, which will be discussed below. So it is unlikely that it should be intentionally compensated for by convergence. And the message itself, that due to the positive camber angle, the wheels tend to turn outward, i.e. in the direction of discrepancy, is incorrect. On the contrary, the design of the suspension of the steered wheels in most cases is such that, with a positive camber, its thrust tends to increase toe-in. So there is nothing to do with "compensation of side effects of camber." The nature and depth (and hence the result) of the influence depends on many circumstances: drive wheel or freely rolling, controlled, or not, finally, from the kinematics and elasticity of the suspension. Thus, a rolling resistance force acts on a freely rolling car wheel in the longitudinal direction. It creates a bending moment tending to turn the wheel relative to the suspension attachment points in the direction of divergence. If the suspension car tough (for example, not a split or torsion beam), then the effect will not be very significant. Nevertheless, it will certainly be, since "absolute rigidity" is a purely theoretical term and phenomenon. In addition, the movement of the wheel is determined not only by the elastic deformation of the suspension elements, but also by the compensation of structural clearances in their joints, wheel bearings, etc.

In the case of a suspension with high flexibility (which is typical, for example, for lever structures with elastic bushings), the result will increase many times over. If the wheel is not only free to roll, but also controlled, the situation becomes more complicated. Due to the appearance of an additional degree of freedom at the wheel, the same resistance force has a double effect. The moment that bends in the front suspension is complemented by a moment that tends to turn the wheel around the steering axis. The turning moment, the value of which depends on the position of the pivot axis, affects the parts of the steering mechanism and, due to their pliability, also makes a significant contribution to the change in wheel toe in motion. Depending on the run-in shoulder, the contribution of the reversing moment can be with a plus or minus sign. That is, it can either increase the wheel alignment or counteract it. If you do not take all this into account and initially install the wheels with zero toe, they will take a divergent position in motion. From this "follow" the consequences typical for cases of violation of the toe-in adjustment: increased consumption fuel, sawtooth tread wear and handling problems, which will be discussed later.

The resistance to motion depends on the speed of the vehicle. therefore perfect solution would be variable toe, providing the same ideal position of the wheels at all speeds. Since it is difficult to do this, the wheel is preliminarily "lowered" so as to achieve minimum tire wear in the mode cruising speed... The wheel located on the drive axle is subjected to tractive force most of the time. It exceeds the forces of resistance to movement, so the resultant forces will be directed in the direction of movement. Applying the same logic, we get that in this case the wheels in statics must be set with a discrepancy. A similar conclusion can be made with regard to the steerable drive wheels.

The best criterion for truth is practice. If, with this in mind, you look at the adjustment data for modern cars, you might be disappointed not to find much difference in wheel alignment between rear and front wheel drive models. In most cases, both those and others will have this parameter positive. Unless among front-wheel drive vehicles, cases of "neutral" toe adjustment are more common. The reason is not that the above logic is not correct. It is just that when choosing the value of convergence, along with the compensation of longitudinal forces, other considerations are taken into account, which amend the final result. One of the most important is ensuring optimal vehicle handling. With the growth of speeds and dynamics of vehicles, this factor is becoming increasingly important.

Controllability is a multifaceted concept, so it is worth clarifying that wheel alignment most significantly affects the stabilization of the straight line trajectory of the car and its behavior at the entrance to the turn. This influence can be clearly explained by the example of steered wheels.

Suppose, in motion in a straight line, one of them is a random disturbance from the unevenness of the road. The increased drag force turns the wheel in the direction of decreasing toe-in. Through the steering mechanism, the impact is transmitted to the second wheel, the convergence of which, on the contrary, increases. If initially the wheels have a positive toe-in, the resistance force decreases on the first and increases on the second, which counteracts the disturbance. When the convergence is zero, there is no counteracting effect, and when it is negative, a destabilizing moment appears, contributing to the development of indignation. A car with such a toe adjustment will scour the road, it will have to be constantly caught by steering, which is unacceptable for a regular road car.

This "coin" has a downside, a positive side - negative toe allows you to get the fastest response from the steering. The slightest action of the driver immediately provokes a sharp change in the trajectory - the car willingly maneuvers, easily "agrees" to turn. This toe adjustment is used all the time in motorsport.

Those who watch TV shows about the WRC championship have probably paid attention to how actively the same Loeb or Grönholm have to work at the wheel, even on relatively straight sections of the track. Toe-in of the rear axle has a similar effect on the behavior of the car - reducing toe-in up to a small offset increases the "mobility" of the axle. This effect is often used to compensate for understeer in vehicles such as front wheel drive models with an overloaded front axle.

Thus, the static toe-in parameters, which are given in the adjustment data, represent a kind of superposition, and sometimes a compromise between the desire to save on fuel and rubber and to achieve optimal handling characteristics for the car. Moreover, it is noticeable that in recent years the latter has been prevalent.

Camber is a parameter that is responsible for the orientation of the wheel relative to road surface... We remember that ideally they should be perpendicular to each other, i.e. collapse should not be. However, most road cars he is. What's the trick?

Reference.

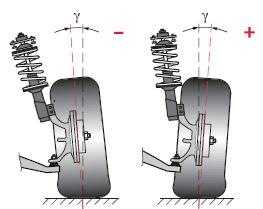

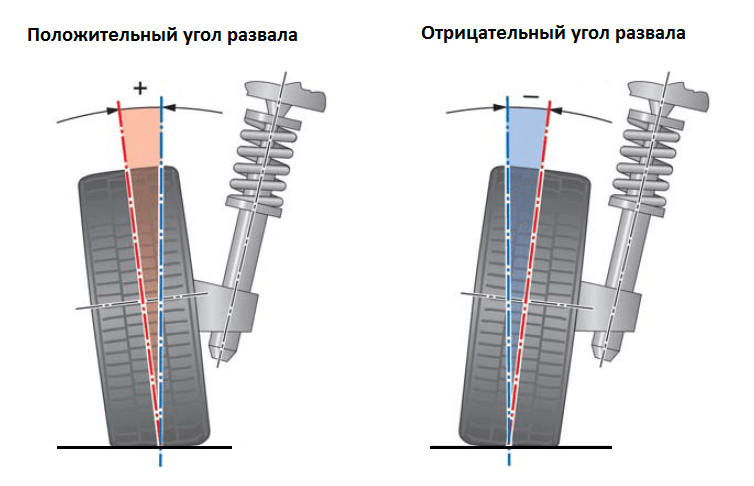

Camber reflects the orientation of the wheel relative to the vertical and is defined as the angle between the vertical and the plane of rotation of the wheel. If the wheel is actually “broken”, i.e. its top is inclined outward, the camber is considered positive. If the wheel is tilted towards the body, the camber is negative.

Until recently, there was a tendency to break the wheels, i.e. give positive values \u200b\u200bto camber angles. Many, for sure, remember textbooks on the theory of the car, in which the installation of wheels with camber was explained by the desire to redistribute the load between the external and internal wheel bearings... Like, with a positive camber angle, most of it falls on the inner bearing, which is easier to make more massive and durable. As a result, the durability of the bearing assembly is beneficial. The thesis is not very convincing, if only because if it is true, then only for an ideal situation - a straight-line car movement on an absolutely flat road. It is known that during maneuvers and driving irregularities, even the smallest, bearing unit undergoes dynamic loads that are an order of magnitude higher than static forces. And they are distributed not exactly as "dictated" by positive camber.

Sometimes people try to interpret positive camber as an additional measure aimed at reducing the break-in shoulder. When we get to know this important parameter of the steering wheel suspension, it becomes clear that this method of influence is far from the most successful. It is associated with a simultaneous change in the track width and the included angle of inclination of the wheel axis, which is fraught with undesirable consequences. There are straighter and less painful options for changing the break-in shoulder. Moreover, minimizing it is not always the goal of suspension designers.

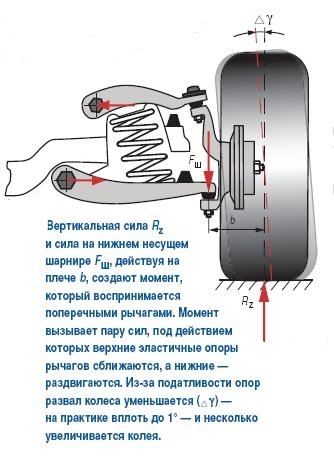

A more convincing version is that the positive camber compensates for the displacement of the wheels that occurs when the axle load increases (as a result of an increase in the load on the car or the dynamic redistribution of its mass during acceleration and braking). The elasto-kinematic properties of most types of modern suspensions are such that with an increase in the weight per wheel, the camber angle decreases. In order to ensure maximum grip of the wheels with the road, it is logical to "break up" them a little beforehand. Moreover, in moderate doses camber has little effect on rolling resistance and tire wear.

It is known for certain that the choice of the camber value is also influenced by the generally accepted profiling of the roadway. In civilized countries, where there are roads, not directions, their cross-section has a convex profile. In order for the wheel to remain perpendicular to the support surface in this case, it must be given a small positive angle collapse.

Looking through the specifications for the UCC, one can notice that in recent years the opposite "breakdown trend" has been prevalent. The wheels of most production vehicles are mounted in static position with negative camber. The fact is that, as already mentioned, the task of ensuring their best stability and controllability comes to the fore. Camber is a parameter that has a decisive influence on the so-called lateral reaction of the wheels. It is she who counteracts the centrifugal forces acting on the car in a corner, and helps to keep it on a curved trajectory. From general considerations, it follows that wheel grip (lateral reaction) will be maximal at the largest contact patch area, i.e. when the wheel is in a vertical position. In fact, for a standard wheel design it peaks at small negative tilt angles due to the contribution of the camber thrust mentioned. This means that in order to make the wheels of the car extremely tenacious in the turn, you need not to break them apart, but, on the contrary, to "dump" them. This effect has been known for a long time and has been used in motorsport just as long. If you take a closer look at the "formula" car, you can clearly see that its front wheels are installed with a large negative camber.

What's good for racing cars, not quite suitable for production vehicles. Excessive negative camber causes increased wear on the inner tread area. With increasing wheel inclination, the contact patch area decreases. Wheel grip during straight-line movement decreases, in turn, the efficiency of acceleration and braking decreases. Excessive negative camber affects the car's ability to stay in a straight line in the same way as insufficient toe, and the car becomes overly nervous. The same thrust of camber is to blame for this. In an ideal situation, the lateral forces caused by camber act on both wheels of the axle and balance each other. But as soon as one of the wheels loses grip, the camber thrust of the other is uncompensated and forces the car to deviate from the straight line. By the way, if we remember that the amount of thrust depends on the inclination of the wheel, it is not difficult to explain the lateral drift of the car at unequal camber angles of the right and left wheels. In short, when choosing the value of the camber, you also have to look for the "golden mean".

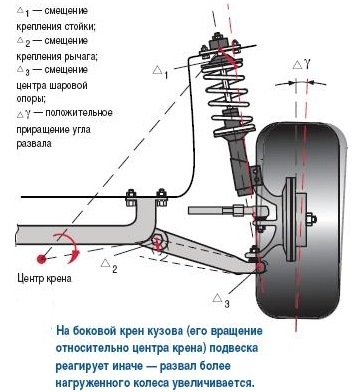

To provide the vehicle with good stability, it is not enough to make the camber angles negative in statics. Suspension designers must ensure that the wheels remain at or near optimum orientation in all driving conditions. This is not easy to do, since during maneuvers, any changes in the position of the body, accompanied by displacement of the suspension elements (pecks, side rolls, etc.), lead to a significant change in the camber. Oddly enough, this problem is easier to solve on sports cars with their "furious" suspensions, characterized by high angular rigidity and short strokes. Here, the static values \u200b\u200bof camber (and toe) differ least of all from how they look in dynamics.

The greater the range of travel of the suspension, the greater the camber change in motion. Therefore, it is hardest for the developers of conventional road vehicles with the most elastic (for the best comfort) suspensions. They have to puzzle over how to "combine the incompatible" - comfort and stability. Usually a compromise can be found by "conjuring" over the suspension kinematics.

Solutions exist to minimize the variation in camber angles and to give these changes the desired "trend". For example, it is desirable that in a corner the most loaded outer wheel would remain in the same optimal position - with a slight negative camber. For this, when the body rolls, the wheel should "roll over" on it even more, which is achieved by optimizing the geometry of the suspension guide elements. In addition, they are trying to reduce the body roll themselves by using anti-roll bars.

It's fair to say that suspension elasticity isn't always the enemy of stability and handling. IN " good hands»Elasticity, on the other hand, promotes them. For example, with the skillful use of the effect of "self-steering" of the rear axle wheels. Returning to the topic of conversation, it can be summarized that the camber angles, which are indicated in the specifications for passenger carsmobileswill be significantly different from how they turn out to be.

Completing the "disassembly" with toe and camber, we can mention another interesting aspect that has practical significance. In the adjustment data on the UUK, not the absolute values \u200b\u200bof the camber and toe angles are given, but the ranges of permissible values. Tolerance for toe is stiffer and usually does not exceed ± 10 ", for camber - several times more free (on average ± 30"). This means that the master adjusting the ACC can tune the suspension within factory specifications. It would seem that several tens of arc-minutes is nonsense. I drove the parameters into the "green corridor" - and order. But let's see what the result might be. For example, the specifications for the BMW 5 Series in the E39 body indicate: toe-in 0 ° 5 "± 10", camber -0 ° 13 "± 30". This means that, while remaining in the "green corridor", the convergence can take a value from –0 ° 5 "to 5", and the camber from –43 "to 7". That is, both toe and camber can be negative, neutral, or positive. Having an idea of \u200b\u200bthe influence of toe and camber on the car's behavior, you can deliberately "shaman" these parameters so as to get the desired result. The effect will not be dramatic, but it will definitely be.

The camber and toe we have considered are parameters that are determined for all four wheels of the car. Next, we will talk about the angular characteristics, which are related only to the steered wheels and determine the spatial orientation of the axis of their rotation.

It is known that the position of the steering axis of a car's steering wheel is determined by two angles: longitudinal and transverse. Why not make the pivot axis strictly vertical? In contrast to the cases with collapse and convergence, the answer to this question is more unambiguous. Here different sources are practically unanimous, at least with regard to the longitudinal tilt angle - caster.

It is fairly noted that the main function of the caster is high-speed (or dynamic) stabilization of the steering wheels of the car. In this case, stabilization is the ability of the steered wheels to resist deviation from neutral (corresponding straight motion) position and automatically return to it after the termination of the action of external forces that caused the deviation. Perturbing forces constantly act on a moving car wheel, striving to bring it out of neutral. They can be the result of passing road irregularities, imbalance of wheels, etc. Since the magnitude and direction of disturbances are constantly changing, their effect is of a random oscillatory nature. Without the stabilization mechanism, the driver would have to fend off the oscillations, which would make driving a torment and certainly increase tire wear. With proper stabilization, the vehicle moves steadily in a straight line with minimal driver intervention and even with the steering wheel released.

The deflection of the steered wheels can be caused by intentional actions of the driver associated with a change in direction. In this case, the stabilizing effect assists the driver out of the bend by automatically returning the wheels to neutral. But at the entrance to the turn and in its apex, the "driver", on the contrary, has to overcome the "resistance" of the wheels, applying a certain effort to the steering wheel. The reactive force generated at the steering wheel creates what is called steering feel or steering information, which has received a lot of attention from both car designers and automotive journalists.

3 years

Wheel alignment plays an important role in the operation of the vehicle - when properly observed, they can increase the life of various components, as well as improve driving comfort. But at the same time, many do not understand how to comply with them and why it is needed.

What does this affect?

Ideally, the wheel should always be positioned strictly perpendicular to the road surface, and such wheel alignment angles will maximize stability as well as provide minimal resistance. In addition, compliance with this rule allows you to reduce tire wear and fuel consumption, which also has an extremely positive effect on the operation of the car. But, unfortunately, such an ideal cannot be achieved.

Wheel alignment angles are constantly changing as they change road conditions, load or at different turns, therefore, the designers put into the car several dozen different parameters that determine the most optimal position under different conditions. Most of these parameters are set as constant values, while other wheel alignment angles can be adjusted during vehicle operation.

In modern foreign cars, adjustment of only such a parameter as wheel alignment is provided at all, but this seemingly positive side has its drawbacks. For example, if, due to physical damage, the geometry of the body or chassis is disturbed, then the wheel alignment can be adjusted, and if only the toe adjustment is carried out, it is necessary to carry out full replacement damaged parts, which are often far from so cheap.

Caster angle

It is measured between the vertical and the line that passes through the center of rotation and the support bearing in a plane parallel to the longitudinal axis. It helps stabilize the steering wheels, that is, it allows the car to move straight if the driver does not hold on to the steering wheel. For a visual understanding of the caster, remember a motorcycle or bicycle that has steering column always deviates back, which is why in the process of movement, if the wheel alignment is not adjusted, they constantly tend to return to the straight position.

It is at the expense of the caster, if the driver does not hold on to the steering wheel, the car drives straight, and after turning it begins to automatically return the wheels to the standard position. If you change the angles of the front wheels, then in this case it will be more difficult to drive the car, since you need to constantly steer, and this is a rather tedious task not only for the driver, but also for his tires, which wear out quickly enough. If you increase the caster, then the car will start driving along the road, as if on tracks, and turning the steering wheel will require extremely hard physical efforts. Of course, all of the above applies more to rear-wheel drive cars, in which the angles of the front wheels are adjusted slightly differently, because in front-wheel drive cars, a slight positive caster value is done in order to stabilize the wheels during coasting, as well as when sudden side loads or braking appear.

If the alignment angles of the steered wheels are not adjusted correctly, the car will start to move to the side while driving, and the driver will have to make significant efforts to turn his vehicle to the left and right sides.

Camber angle

It is measured between the vertical and the plane of rotation of the wheel. In other words, regardless of how the struts and levers are tilted during movement or changes in loads, the angles of the steering wheels in relation to the road must remain within the specified limits. In the event that the upper part of the wheel deviates outward, camber is usually called positive, and if it is tilted inward, negative. If there are any deviations from the recommended wheel alignment data, the car begins to gradually move to the side, and uneven tread wear is observed.

Convergence

It is the angle between the longitudinal axis of the vehicle and the plane of rotation of the wheel. Setting the wheel alignment angles allows you to achieve correct position at all speeds and regardless of the steering angles of the vehicle. If there is increased toe, it will cause sawtooth wear on the outside of the tread, while a negative angle also affects the inside. It should be noted that when such problems arise, the tires can start screeching in corners, the car's handling is significantly reduced, and fuel consumption also increases significantly, since there is an increased rolling resistance of the front wheels, which negatively affects the car's coasting.

In addition to those indicated, there are also angles, the occurrence of which is undesirable - these are the angles of movement, as well as displacements in one or more axes. If a motorist encounters such problems, you need to send the car to a car service, where the wheel alignment angles will be checked by professionals. Nissan and other high-quality foreign cars are also subject to similar problems, and if they are available, most often it is necessary to repair the suspension or restore the car body.

When and why is the adjustment carried out?

In most cars nissan brands, VAZ and others that are not equipped with a McPherson suspension, camber for the front wheels often has a small positive value (from 0 o to 45 o), due to which the efforts on the steered wheel are reduced, as well as the transmission to steering all kinds of jerks. If the vehicle uses a McPherson suspension, the wheels have little or no negative camber.

During operation, various suspension parts are subject to natural wear and tear, as a result of which the installation angles are violated. That is why from time to time (in accordance with the instructions) you need to measure the installation angles rear wheels and, if necessary, adjust them.

Most often, "unscheduled" adjustment is required by modern vehicles after hitting all kinds of pits or obstacles, as well as after participating in an accident that led to damage to the body. If you notice any changes in the behavior of the car due to such cases, you should immediately send it to the service station.

Among other things, it also happens that you have to go to the "flarers" after the suspension and steering parts that affect the position of the wheels have been replaced.

If you have not encountered any of the above cases, but at the same time you think that you have violated the parameters of the wheel alignment angles, then try to analyze the current situation and understand what could precede the change in the nature of driving. For example, if you had other wheels before, then if they are imbalanced, vibration and uneven tread wear may appear. It is also worth noting that if the wheel bolts are insufficiently tightened, the car may periodically shake, and in addition, tires with defects, different sizes, patterns and even the degree of inflation can also lead to abnormal behavior of your car on the road.

If the car is pulled to the side, this often happens due to the braking of a wheel, as well as due to malfunctions brake mechanism, while broken shock absorbers negatively affect the behavior of your car on the road. Heavy rotation of the steering wheel is due to malfunctions in the power steering, and a decrease in stick out is the cause of wheel bearings.

Thus, it is not always worth "sinning" on the wheel alignment angles. VAZ and others domestic cars especially susceptible to such malfunctions, so it is best to start checking with them.

Where to repair?

First of all, try to find a truly professional craftsman, and do not try to look for people with the best equipment and stands. The service should be chosen in accordance with your needs, since otherwise you will overpay for what you really don't really need.

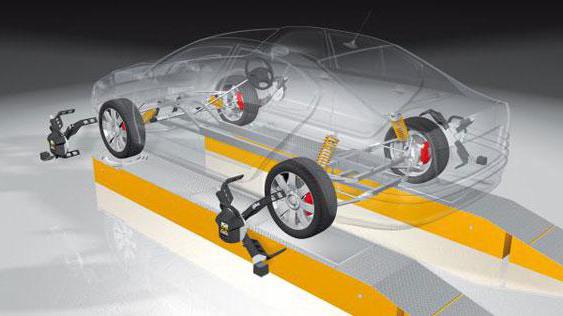

For example, if the car is in good working order, and you just want to check and adjust the toe-in, it is not at all necessary to use a 3D wheel alignment stand for this. A competent technician can handle such problems quite well using a measuring rod and a standard lift, and with the same result will offer a much lower cost. If you want to check all the geometry, then you really need specialized equipment.

What kind of equipment is there?

The stands where the wheel alignment angles are checked and their adjustment are divided into two main types - computer and optical. Each of the options has its own characteristics and advantages.

Optical

These stands are divided into two categories - laser and beam. In the latter, an incandescent lamp acts as a light source. Two sources are fixed on wheels, and measuring screens are installed on the side and in front of the car, onto which the light beam is projected. When the vehicle's wheel alignment angles are adjusted, the beams are directed to a measuring rod in front of the vehicle. Laser ones are more accurate, and it is more convenient for the master to work with them. On the sides of the elevator or pit, measuring screens are installed, in the center of which holes are made, through which the lasers are directed at each other. Mirrors are installed on the wheels, with which the rays are reflected on the screens.

The advantage of optical stands is their simplicity, as well as reliability in use and relatively low cost, but they also have significant disadvantages. First of all, they are less accurate, in comparison with computer ones, they can work simultaneously only with a specific axle of the car, and also do not provide for the possibility of using a special database of models in operation. Among other things, they do not have the ability to measure some of the parameters that characterize the overall "geometry" of the car. Thus, if the car uses the check and adjustment of the wheel alignment angles on optical stands, it is contraindicated.

Computer

This type of stands also has two subspecies - 3D and CCD (sensor). In the latter, measuring heads are fixed to each wheel, the data from which will be processed by a computer. According to the used method of connection between the heads, the stands can be cordless, as well as infrared wired or wireless. The latter type is currently the most common, but when choosing, one should also take into account the fact that even today, computer stands with an open circuit are sometimes used, which, in terms of their functionality, are much worse than devices with a closed circuit.

The advantages of computer stands are obvious: multitasking, extremely high accuracy, the ability to measure many more characteristics, as well as the use of a continuously updated database. It is also worth noting that such equipment uses a specialized program that tells the mechanics the sequence of actions. But such stands are not without drawbacks - rather fragile sensors are installed in them, and they also depend on lighting and temperature conditions.

With the advent of 3D computer stands, there has literally been a revolution in the field of checking and adjusting wheel alignment angles. A special camera is attached to the rack in front of the car, which allows you to fix the position of plastic reflective targets on the wheels with perfect accuracy. To measure the angles, you just need to drive the car back and forth literally 20-30 centimeters, and then turn the steering wheel in different directions. After that, the information received from the video cameras is carefully processed by a computer, which produces all the necessary geometric parameters in real time. This technology is today called "machine vision".

Special attention should be paid to the fact that modern 3D stands, unlike others, do not provide for the need to place the car on a perfectly flat surface.

Subtleties of work

You can go to wheel alignment only if you have a serviceable and running gear, and before the adjustment is carried out, the master must check these parameters. The machine is lifted on a hoist, and then a technician inspects and moves the wheels, levers, rods, springs, and many other necessary actions.

It is mandatory to measure and, if necessary, bring the tire pressure to normal. In the event of too large backlash or any physical damage to the parts, the specialist must necessarily stop the procedure and refuse the client to adjust if it is not possible to fix the problem on the spot.

If, nevertheless, no deviations were found, the car is installed on a horizontal platform, after which it is loaded in full accordance with the manufacturer's recommendations. In other words, if the factory specified the angles for a particular load, then it would be a direct violation to try to adjust them on a completely empty machine. To install suspension parts in working position first, it is squeezed with effort, pressing down the rear and front of the car. To avoid serious errors in the measurement process, preliminary compensation of the disc runout is carried out, regardless of which stand the adjustment is carried out on. To carry out this procedure, the master hangs out the axle, attaches to the wheels measuring instruments, and then they scroll. On modern 3D stands, compensation is carried out without hanging it by rolling the car in different directions by 20-30 cm.

How is the adjustment done?

Since all installation angles are interconnected, professionals try to follow an extremely clear sequence when adjusting them. First, the caster is adjusted, and then the camber and toe are changed. In the vast majority of modern foreign cars only the last parameter is set.

Adjusting the castor involves changing the number of washers, while the wheels of the car are braked by the working braking system (but not a handbrake) - for this, a specialized pedal lock is used in workshops. In principle, the procedure for adjusting the castor is one of the most time-consuming for "razhalnikov", takes a lot of time, and therefore many do not like it. Some professionals may even cut the washers with a chisel, while others simply do not focus on castor or try to convince their clients that this angle is in order, so you should always be vigilant.

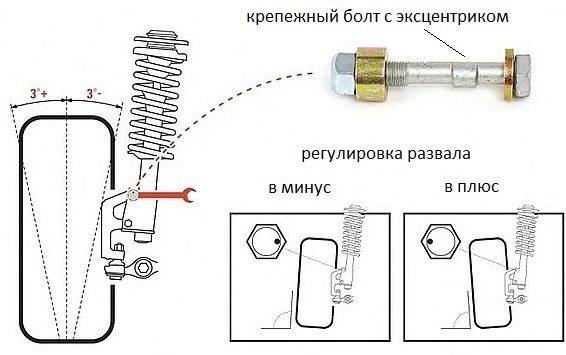

Camber adjustment on double wishbones is carried out in the same way as in the case of castor. On a McPherson type suspension, in most cases, the camber is changed by rotating a special eccentric bolt, with which the strut is fixed to, but other options can also be used. For example, on some models, instead of such a bolt, a special slider mechanism is installed, or an adjusting element can be located at the base of the lever. There are also such designs in which the camber is adjusted by moving the ball joint.

Before adjusting the toe-in, the specialist must first set it to the middle position and the steering wheel must stand straight and secure it with a special lock. Adjustment is made by rotating the tip adjusting sleeve on each side (never on one side). One of the signs of a correct operation is the straight position of the rudder without any distortions in the process of rectilinear movement. At least on this basis, you can always determine how well the adjustment was made and whether it really helped you cope with problems while driving.

Correct wheel alignment is one of the most important factors in ensuring normal handling, stability and stability of the vehicle in straight-line driving and when cornering. The optimal suspension geometry parameters for each model are laid down at the design stage. The preset values \u200b\u200bof the wheel alignment angles are subject to change and require periodic adjustment due to natural wear of the components and elements of the chassis or after repair of the suspension.

Correctly tuned suspension geometry allows the car to more effectively absorb the forces and moments arising in the contact patch of the wheel with the road surface during various driving modes. This ensures the predictable behavior of the car, namely: stability of movement in a straight line, stability in corners, stabilization during acceleration and braking. Also, due to the absence of excessive rolling resistance of the wheels, the tires wear more evenly, which allows them to increase their service life.

The wheel alignment values \u200b\u200bset by the manufacturer are optimal for a particular vehicle and correspond to its purpose and suspension settings. However, if necessary, it is structurally provided for the possibility of changing or adjusting them. The number of parameters that can be adjusted for each vehicle is individual.

Types of basic car wheel alignment angles

| Parameter | Car axis | Adjustable parameter | What affects |

|---|---|---|---|

| Camber angle (Camber) | Front Back | Yes (depends on the car) | Cornering stability Premature tire wear |

| Toe Angle | Front Back | Yes | Stability in straight motion Premature tire wear |

| Lateral Pivot Angle (KPI) | Front | No | |

| Longitudinal angle tilt axis of rotation (Caster) | Front | Yes (depends on the car) | Vehicle stabilization while driving |

| Break-in shoulder | Front | No | Vehicle stability when braking Vehicle stabilization while driving |

Camber

Positive and negative camber

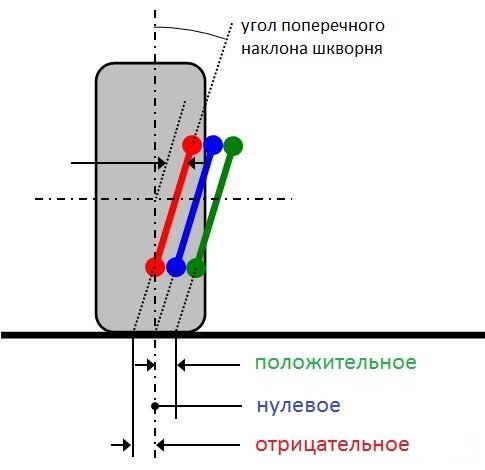

Positive and negative camber Camber (eng. camber) Is the angle formed by the midplane of the wheel and the vertical passing through the intersection of the midplane of the wheel and the bearing surface. Distinguish between positive and negative camber:

- positive (+) - when the top of the wheel is tilted outward (away from the car body)

- negative (-) - when the top of the wheel is tilted inward (towards the car body)

The camber is structurally formed by the position of the hub assembly and provides maximum area contact spots of the tire with the road. In the case of a double wishbone independent suspension, the position of the hub is determined by the upper and lower wishbones... In a MacPherson strut, the camber is influenced by the lower arm and strut.

The deviation of the values \u200b\u200bof the camber angle from the norm affects the car as follows.

- good stability of the car in turns

- wheel grip deteriorates when driving in a straight line

- increased wear inside tires

- good grip

- deteriorates cornering stability

- increased wear on the outer side of the tire

Wheel alignment

Car wheel alignment

Car wheel alignment Wheel alignment (eng. toe) Is the angle between the longitudinal axis of the vehicle and the plane of rotation of the wheel. It can also be defined as the difference in the distance between the front and rear walls of the wheel rims (in the figure, this is the value of A minus B). Thus, convergence can be measured in degrees or millimeters.

Distinguish between total and individual convergence. Individual toe is calculated separately for each wheel. This is the deviation of the plane of its rotation from the longitudinal axis of symmetry of the vehicle. Toe-in is calculated as the sum of the individual toe angles of the left and right wheels of one axle. The total convergence in millimeters is determined similarly. With positive convergence (eng. toe-in) the wheels are mutually turned inward in the direction of travel, with a negative value (eng. toe-out) - outward.  Positive and negative wheel alignment

Positive and negative wheel alignment

The deviation of the values \u200b\u200bof the toe angle from the norm affects the car as follows.

Too large negative angle:

- increased tire wear on the inside

- acute reaction of the car to the steering

Positive angle too large:

- deterioration of the trajectory of movement

- increased tire wear on the outside

Transverse angle of inclination of the axis of rotation (eng. KPI) Is the angle between the axis of rotation of the wheel and the perpendicular to the supporting surface. Thanks to this parameter when turning the steered wheels, the car body rises, as a result of which forces arise,

seeking to return the wheel to a straight-line position. Thus, the KPI has a significant impact on the stability and stability of the vehicle in straight-line driving. The difference in the values \u200b\u200bof the lateral tilt angles of the right and left axles can lead to the vehicle's sideways tilt. This effect can also appear if the normal values \u200b\u200bof the other wheel alignment angles are consistent.

Caster angle of the wheel axis

Longitudinal angle of inclination of the axis of rotation

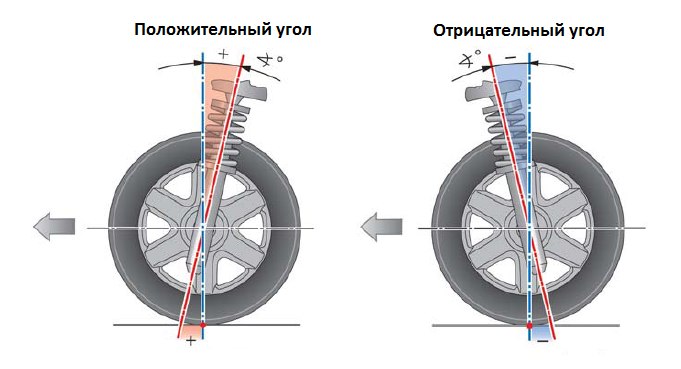

Longitudinal angle of inclination of the axis of rotation Longitudinal angle of inclination of the axis of rotation (eng. caster) -the angle between the axis of rotation of the wheel and the perpendicular to the bearing surface in the longitudinal plane of the vehicle. Distinguish between positive and negative caster angles of the axis of rotation of the wheel.

A positive caster promotes additional dynamic stabilization when driving on average and high speed... This worsens understeer at low speed.

Break-in shoulder

Break-in shoulder value

Break-in shoulder value In addition to the above parameters, another characteristic is of great importance for the front axle - the run-in shoulder. This is the distance between the point formed by the intersection of the axis of symmetry of the wheel and the support surface and the point of intersection of the line of transverse inclination of the axis of rotation and the support surface. The roll-in shoulder is positive if the point of intersection of the surface and the axis of rotation of the wheel lie to the right of the axis of symmetry of the wheel (zero shoulder), and negative if it is located to the left of it. If these points coincide, then the run-in shoulder is zero.

This parameter affects the stability and steering of the wheel. The optimal value for modern cars is zero or positive shoulder running in. The sign of the run-in shoulder is determined by camber, lateral tilt of the wheel steering axis and wheel offset.

Automakers do not recommend installing wheel disks with non-standard departure, because this can lead to a change in the set run-in shoulder to a negative value. This can seriously affect the stability and handling of the vehicle.

Changing wheel alignment values \u200b\u200band adjusting them

Camber adjustment on MacPherson strut

Camber adjustment on MacPherson strut Wheel alignment angles are subject to changes due to natural wear of parts, as well as after replacing them with new ones. Without exception, all tie rods and tips have threaded connection, which allows you to increase or decrease their length to adjust the values \u200b\u200bof the toe angles. Toe-in of the rear wheels, as well as the front ones, is adjustable on all types of suspensions, except for the rear dependent beam or axle.

Adjustment of camber values \u200b\u200bfor the rear and front axles is not provided for on all cars: it is absent on the dependent suspension, on the MacPherson suspension (with the exception of a small number of car models in which the upper strut mount is a bolt with an eccentric). There is a camber setting, usually on both axles with upper and lower wishbones.

Improper camber on a front wheel drive vehicle has less impact on handling and uneven tire wear because the rear is less stressed. The parameters caster and KPI, the adjustment of which is usually not provided in the car's suspension design, must always correspond to the permissible values.

To enjoy driving, a car must not only be easy to drive, but also safe on the road.

An important role in the ease of driving is played by the correct descent - wheel camber.

Let's try first of all to understand the concept of camber and toe-in.

Collapse

So what exactly is wheel camber? This is the angle of inclination of the vehicle's wheels in relation to the road. As a rule, camber is understood as the static camber of the driving wheels. But in some cars the camber-convergence and "passive" wheels are adjusted. When the top edge of the tire is leaning more towards the machine, camber is negative or negative. When the top edge of the tire is further from the center of the vehicle, then camber is positive or positive.

A negative camber value has a negative effect on vehicle stability. Great importance negative camber indicates that the suspension is either already worn out or adjusted incorrectly. As a result, the rubber wears out quickly, the grip deteriorates, and the vehicle's directional stability on the road decreases.

Ideal camber is when the camber value is zero, so that the tires wear less.

If you need to increase traction, you need to put 2 or 1.5 degrees on the front wheels and 1.5 degrees on the rear, to the detriment of rubber, of course.

The main purpose of the camber of the drive wheels is to reduce the transmission of road irregularities to the steering wheel, which are extinguished due to the elasticity of the rubber. Camber also serves to increase the adhesion of the wheel protectors to the road, makes the car more stable when cornering, which affects the stability and "obedience" of the car in management.

In terms of kinematics for the suspension, camber, as well as the angle of inclination across the line along which the drive wheels turn, affects the roll-off radius, but this influence is much lower than the second factor given. In fact, the camber angle of a car without movement is set rather approximately (the error during installation can be compared with its value), plus the camber value changes significantly when the suspension is working.

Caster

Caster, in other words, is the angle obtained between the conventionally drawn vertical line and the axis used to turn the wheel in a plane passing along the car. The function of the caster is to "automatically" align the steering wheels with the speed of the vehicle.

That is, after turning, the car leaves it by itself, namely: wheel It has free run, thanks to which he himself is able to return to rectilinear motion (provided, of course, that all mechanics are adjusted correctly). Which is the result of a positive caster. In some cases, changing the factory caster value will make the straight forward movement more stable.

Excessive caster value gives the steering wheel a so-called "heaviness". For fans of experiments, it may seem interesting to set the caster at +1 or +2 degrees relative to the "factory settings". Such changes make the car's course more stable, it tends to move even more straight ahead.

Convergence

Toe-in can be defined as the difference in distance from the front to the rear of the wheels.

In some cars, it is possible to adjust the toe-in of all four wheels.

The purpose of toe-in is to compensate for the vehicle's sideways movement due to positive camber, thus avoiding significant rubber wear. Toe and camber are always controlled at the same time.

The advantage of positive convergence is stability at high speed movement, disadvantage - the car becomes somewhat "clumsy".

Dignity negative convergence is the increased sensitivity of the wheels to the "commands" of the steering wheel, and of the minuses - the rubber "eats up" quickly, we feel all the bumps through the steering wheel, or just "beat".

Misaligned toe is considered one of the main reasons for rapid wear. Typically, the first sign that a toe value is set is a squeal when cornering at low speed. If the toe value is 5 mm or more, the tire will be completely worn out in less than 1000 km. It is desirable to have zero convergence.

When is it necessary to adjust the wheel alignment.

It is necessary to regulate the camber camber of a VAZ car or any other if:

- You have changed tires;

- The "Horse" has already covered a good 10-11 thousand km;

- The chassis was repaired;

- When driving fast increased tire noise is heard;

- The car drives on a flat and straight road and begins to be led away;

- The car is getting worse to drive.

What is the estimated cost of camber for cars? For passenger cars, it will be about 1600 rubles. And besides, when installing the triangular levers, the caster angle is adjusted much easier and to a greater value.