Page 1 of 3

Design features of the Lada Granta checkpoint

Transmission - mechanical, two-shaft, with five gears forward motion... It is constructively combined with a differential and main gear.

The gearbox housing consists of three parts: the clutch housing 25, the gearbox housing 7 and the rear cover of the gearbox housing 1. During assembly, a gasoline-oil-resistant sealant is applied between them - a gasket. In the socket of the clutch housing there is a special magnet that retains metal wear products.

The input shaft 5 is made as a block of driving gears, which are in constant mesh with the driven gears of all forward gears. The secondary shaft 40 is hollow (for supplying oil under the driven gears), up to the removable driving gear of the main drive 17. It has driven gears 31, 33, 34, 36, 38 and synchronizers 32, 35, 39 forward gears. The front bearings of shafts 18 and 12 are roller bearings, the rear bearings 3 and 37 are ball bearings. The radial clearance in roller bearings must not exceed 0.04 mm. An oil sump 19 is located under the front bearing 18 of the secondary shaft, which directs the oil flow into the shaft.

|

R |

The differential is two-satellite. The preload in bearings 29 (0.25 mm) is adjusted by selecting the thickness of the ring 28, which is installed in the housing of the gearbox under the outer ring of the differential bearing. The driven gear of the main drive 27 is attached to the flange of the differential box. The gearbox is in communication with the atmosphere through the breather 14 located in its upper part.

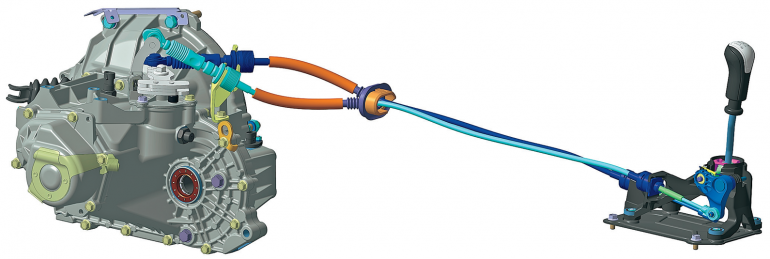

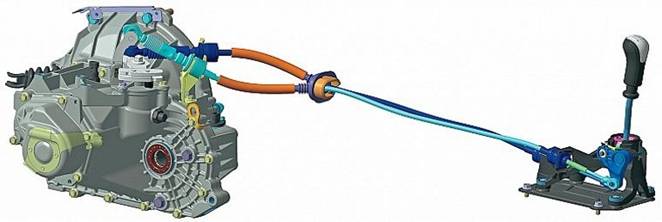

The gearbox control drive consists of a gearshift lever, ball joint, control rod, rod

gear selector and gearshift mechanism. So that the gears do not spontaneously turn off due to the axial movement of the power unit when the car is moving, a jet thrustone end of which is connected to power unitand the other end is attached to the base of the gear lever.

A switch (lever) is attached to the inner end of the rod, which acts on the three-arm gear lever. This mechanism is made as a separate unit and is attached to the clutch housing. There are three axles in the gear shift housing. One has a three-arm gear selection and shift lever and two locking brackets. The other axis passes through the holes of the locking brackets, fixing them from turning. The gear selector, mounted on the rod, acts on the lever of the gear selection lever, which in turn engages forward gears with one arm and reverse gear with the other. On a separate axle there is a fork for engaging the reverse gear.

To avoid accidental engagement of reverse gear, a solenoid for engaging reverse gear is installed in the transmission. The protruding part of the solenoid core does not allow the locking brackets to move along the axes until the reverse gear is engaged. A solenoid switch is installed on the gear lever. When the ring under the handle is lifted, the switch contacts are closed and voltage is applied to the solenoid. The solenoid core retracts and makes it possible to engage reverse gear. If the solenoid fails or its electrical circuit is broken, it becomes impossible to engage reverse gear. In order to engage reverse gear and drive to the garage or service station, where it will be possible to eliminate the malfunction, unscrew the solenoid from the gearbox housing and screw the plug of the gear shift rod retainer in its place, which we recommend to carry with you. In this case, while driving the car, you should be careful not to accidentally engage reverse gear instead of first. After eliminating the malfunction, add oil to the gearbox, since some of it will leak out when the solenoid is turned out.

At the factory, the gearbox is filled with gear oil designed for 75,000 km. The oil level should be between the reference marks on the oil level indicator.

|

Tightening torques threaded connections Checkpoint |

||

|

Name of assemblies and parts |

Thread |

Torque, Nm (kgs.m) |

|

Drain screw |

28,7-46,3 (2,9-47) |

|

|

Reversing light switch |

28,4-45,3 (259-4,6) |

|

|

Speed \u200b\u200bsensor drive housing retaining nut |

4,5-7,2 (11,7-18,6) |

|

|

Nuts for fastening the gearbox to the clutch housing |

15,7-25,5(1,6-2,6) |

|

|

Bolt with a tapered part of a joint of a rod of a drive of a gear shift |

16,3-20,1 (1,7-2,1) |

|

|

Shift lever housing retaining bolts |

15,7-25,5 (1,6-2,6) |

|

|

Shift mechanism retaining bolts |

6,4-10,3 (0,7-1,1) |

|

|

Nuts of clamps of the drive of a gear shift |

15,7-25,5 (1,6-2,6) |

|

|

Shift lever stop retaining bolt |

11,7-18,6(1,2-1,9) |

|

|

Tie rod bracket retaining bolts |

14,0-32,0 (1,4-3,2) |

|

|

Reverse fork retainer plug |

28,4-35,0 (2,8-3,6) |

|

The installation of an improved gearbox on the Grant and Kalina models allowed many motorists to take a fresh look at the transport from AvtoVAZ.

The improved cable-driven gearbox on the Lada Granta can significantly reduce vibration while driving. This difference is due to the replacement of the usual traction with the wings with connecting cables. All vibrations and vibrations when switching when transferring direction through the cable system will be completely eliminated.

Features of the design and operation of the cable checkpoint Grants

An important development innovation was the reduction in the volume of the required oil and the conditions for replacing the composition itself. Previously, mineral mixtures were used in a volume of about 3 liters, now it is required to fill 2.2 liters of a semi-synthetic composition.

Many drivers are interested in the question: what kind of oil to pour into the Lada Grant cable box for normal operation. Manufacturers require a mixture with a viscosity of 75W-85 and GL-4 specification.

Unlike its progenitor gearbox 2108, the new Lada Granta cable box received a slightly different switching scheme. Now the reverse gear is not located to the left of the first gear, but opposite the fifth.

This design is more convenient than conventional mechanics, so many motorists will like it. In addition, the problem of accidentally engaging reverse gear is completely gone. The equally important advantages of the new checkpoint include the following:

1. Work in cold weather down to -42 degrees without thickening of oil and difficult movement of the switch.

2. Ability to dismantle and repair the switch without removing the entire box.

3. Fast gear shifting with minimal effort.

4. Installation of new multi-cone synchronizers in 1st and 2nd gear provides stage protection.

5. Coating the intermediate rings of the synchronizers with a composition that ensures the high-quality operation of the installation.

All these features on the Lada Granta cable transmission, which has undergone numerous and useful changes, made it possible to reduce or completely get rid of some control problems. The safety of the box is ensured through a unique design process.

AvtoVAZ specialists carried out the fitting of parts using precise computer calculations, based on the requirements for the final product. The loads on individual parts, the frequency of component activation, and the actual load were taken into account.

The uniqueness of the cable box design Grants

Replacement of rods with wings was caused by the need to reduce vibrations. Originally the developers considered hydraulic system, which is installed on many foreign car brands.

But unlike the expensive novelty, a high-quality cable transmission Lada Granta will become available to every buyer.

The final cost of transport due to the updates made will be increased by approximately 5 thousand rubles. The resulting quality, reliability and comfort for such low cost - an acceptable and profitable solution.

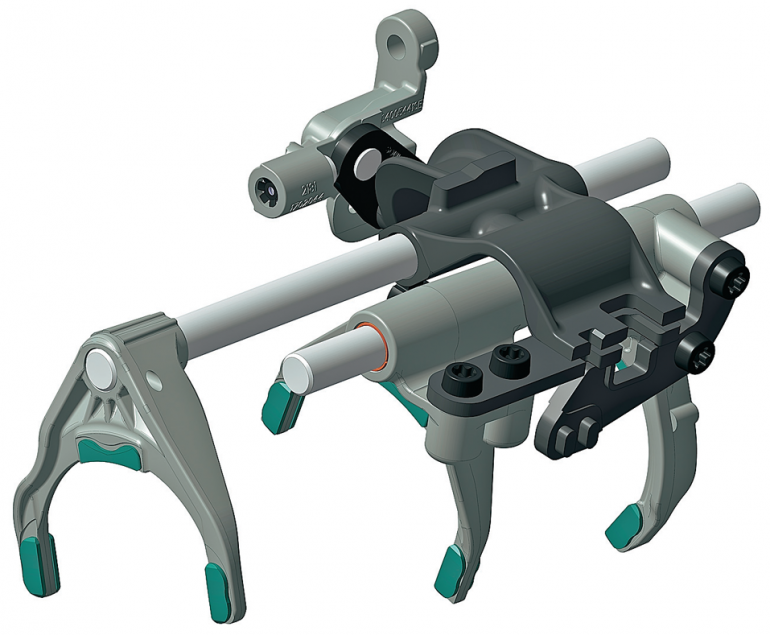

Buyers will like the Lada Granta cable transmission and the fact that the new shift forks have become more durable. Previously, steel parts with bronze wear protection were installed. Over time, the protective layer simply abraded and, as a result, deteriorated the composition of the oil due to dust entering it.

The new forks are lightweight and highly durable as they are made of aluminum alloy. Additionally, they are protected by special plastic pads to reduce wear.

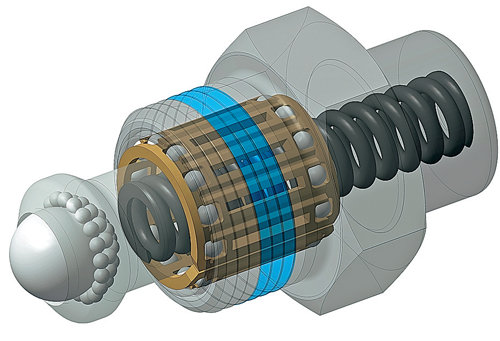

Outdated locks and springs in the shifting mechanism have also been replaced. They were replaced by a plate, which is one of the defining elements for fast gear changes.

A retainer moves along the plate, transmitting changes made by the owner along speed mode... And the original design of the retainer, which the Lada Granta cable gearbox "got", reduces mechanical friction during reading (due to the absence of bearings). Therefore, the operation of the switch is optimized.

The used cable drive of the Lada Granta gearbox becomes a guarantor of high-quality and convenient control without any interference. All vibrations and vibrations are reduced to a minimum and therefore the driver will not feel discomfort when changing gears.

Perhaps, in the future, specialists will install a hydraulic switching system on Grant. But for now, the cable type is more attractive due to the excellent ratio of the price category and the opportunities obtained.

The development of a new gearbox made it possible to take into account the emerging mechanical problems and completely get rid of them. The gear part (excluding the synchronizers) has remained practically unchanged, which is why the price of the upgrade is minimal and affordable for every buyer.

At the same time, Grant's new cable transmission is easy not only to operate, but also to repair. A separately removable control mechanism, new transmission oil and its rare replacement (every 200 thousand km or every 5 years) will allow you to easily carry out inexpensive and high-quality service.

The fact that the Lada Granta gearbox has been cabled for several years now has been known to many domestic motorists, but what exactly are the differences between the new manual transmission and the old one have not yet figured out. Meanwhile, the new drive design solved several problems at once and made it possible to significantly improve the comfort of the driver and passengers.

The new mechanical transmission Lada Granta is called KP VAZ-2181, and it was created on the basis of the oldest mechanics from AVTOVAZ, which appeared on the VAZ-2108. The manual transmission has been repeatedly modernized over the years, but all the changes were minor, therefore weak spots of this box have become trademark features of the Lada cars themselves: large lever moves, difficult gear shifting, smeared shift pattern, low vibration comfort and increased hum at certain stages.

It was simply impossible to modernize the Grants gearbox itself under the current conditions, since this would require new high-precision equipment to produce more advanced shafts, synchronizers and gears. All this required large financial costs, which would be too risky, provided the cars for which the new manual transmission - Kalina, Grant and Priora.

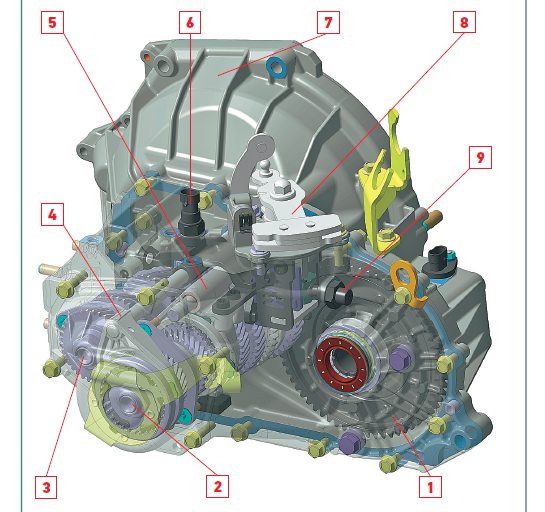

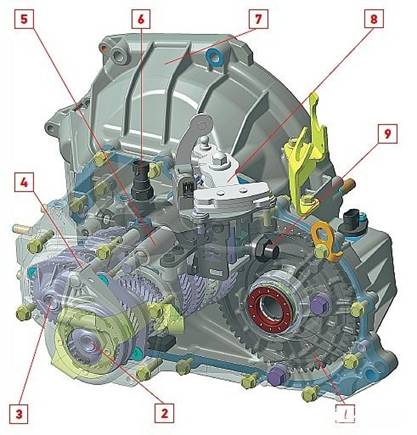

The main elements of the VAZ-2181 gearbox on the Lada Grant:

1 - leading gear wheel of the main stage;

2 - secondary shaft;

3 - primary shaft;

4 - fifth stage inclusion plug;

5 - plug of inclusion of the third and fourth stages;

6 - switch for reversing lights;

7 - clutch housing;

8 - gear shifting mechanism;

9 - central locking device.

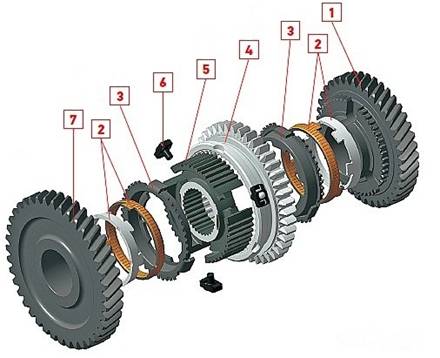

Synchronizers

Still, they decided to change the gear part a little. Multi-cone synchronizers were installed in the first and second gears, which made it possible to increase the reliability of the unit and reduce the effort when engaging these gears. In the future, the box Lada Grant VAZ-2181 will be installed on cars with more powerful engines, therefore, the clutch diameter has already been increased, which has a greater moment of inertia. On the old manual transmission, the clutch housing accommodated a maximum disc size of 200 mm, the new crankcase allows the installation of 215 mm discs. These changes forced the developers to change the position of the starter, now it is located along the engine, and not along the box, as before.

It is noteworthy that the first samples of the new Granta box used three-cone synchronizers, but later it was decided to opt for two-cone synchronizers. They have a sufficient margin for the transmission of torque, but at the same time they are much cheaper to manufacture and do not require such a high manufacturing accuracy. New set synchronizer wheels ensured smooth and efficient synchronization. German company Herbiger, who manufactures these parts, coats them with additional coatings to ensure consistent performance and reduce wear.

The bevel angle of the synchromesh teeth was reduced from 125 to 100 degrees, which facilitated gear shifting, and the preload force was also reduced from 150 to 70 N. here the two-cone options have a large working surface, which eliminates various problems.

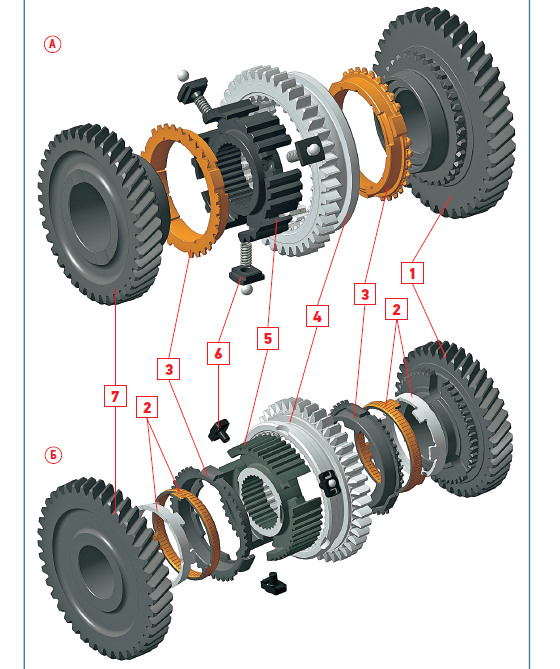

Comparison of the device of synchronizers boxes VAZ-2110 (A) and VAZ-2181 (B):

1 - gear wheel of the first stage;

2 - intermediate rings;

3 - blocking ring;

4 - synchronizer clutch;

5 - hub of the synchronizer coupling;

6 - retainer;

7 - gear wheel of the second stage.

Gearbox switching mechanism Grants

Many important elements of the old manual transmission were located at the bottom and bathed in an oil bath - a gearshift mechanism, locking rods and reverse forks, an oil seal for a set of gears, a switch for reversing lights. All of these elements were potential sources of leakage. Many people solved the problem with the help of a sealant, but moving the elements upstairs solved the problem once and for all.

The new gear shift module on Grant is a separate mechanism that can be removed without disassembling the gearbox if necessary. The mechanism received a selector grille, which clearly repeats the gearshift pattern and excludes accidental reverse engagement.

Lada Grant box cable drive

Traction drive has long been the simplest and cheapest option for shifting gears. But most manufacturers have abandoned this option at the moment in favor of designs with multiple rods and complex wings, or in favor of a cable drive.

AVTOVAZ has long wanted to use the latter option on its cars, but the high price of this design in the past and the low location of the shifting mechanism interfered. Now these problems have been solved and Granta received a manual transmission cable drive

The use of a cable drive on the Lada Grants box made it possible to remove unpleasant vibrations on the gearshift lever, make the gearshifts clearer and reduce the play of the lever itself.

In the clutch drive, it was planned to abandon the cable in favor of hydraulics, but this could not be done for economic reasons. Note that using hydraulic drive in this case, it would make the clutch pedal more understandable and logical in operation. The layout of the engine compartment would also benefit from such a solution, since the hydraulics are easier to lay.

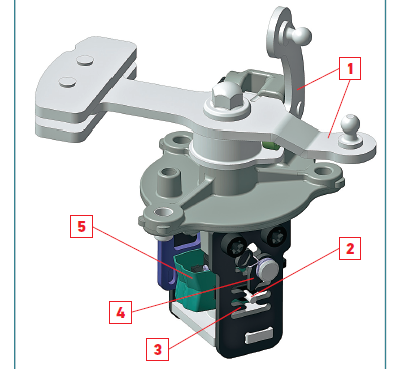

1 - stage selection levers;

2 - pin of the selector lattice;

3 - selector lattice;

4 - reverse gear blocking mechanism;

5 - central three-dimensional plate.

Further development of the manual transmission Lada Grants

The result of modernization of the box Grants

Gear shifting became clearer and easier, and vibration on the gear lever was eliminated.

Minimal changes in the internal design allowed not only to improve the quality of gear shifting, but also to make the entire unit more reliable and demanding on the driver.

The VAZ-2181 manual transmission became the first AVTOVAZ gearbox for which a full computer calculation of all parts subject to stress was carried out.

The volume of oil in the Grants box was reduced by a third, the plant began to fill in semisynthetics, not mineral water, the oil itself now does not require replacement for the entire service life of the car - five years or 200,000 kilometers.

Lada Granta is budget carslightly simplified and accessible to a wide range of motorists. Grant from Kalina got a power frame, some mechanical units, a modified suspension and a manual transmission. Standard complete set The car included a slightly modified Kalina box. Although it was redesigned, the problems that the drivers talked about more than once remained.

This is unnecessary resistance when engaging a particular gear and a large lever travel. Motorists complained that in order to turn on the fifth gear at the Lada Granta "standard" checkpoint, it was necessary to reach out and make an effort. Also, car owners complained about vibration during operation.

The engineers listened to all the complaints and since the fall of 2011, the manufacturer has replaced the car with a modified version of the transmission with a cable shift mechanism. Since October 15, 2012, all Grant models that come off the assembly line, except for the "standard", are equipped with this box.

Modified manual transmission

According to experts, this updated mechanic is considered more reliable. However, the main advantage of manual transmissions is the shift quality. New box transmission received a cable drive. It replaced the rigid rods that were in previous versions. This change resolved the vibration issue during operation. This manual transmission also has 5 speeds.

The mechanics received new synchronizers in the first and second gears. This significantly increased the overall resource of the entire system. Engineers have managed to make the shift softer. The mechanism that allows you to select a gear has been moved to the upper sections, which makes the system independent of temperature. Other changes have resulted in lower oil consumption.

In Grant with modified boxes, you need to fill in 2.2 liters of oil, other models required 3.3 liters. But mineral oil not suitable for this checkpoint. semi-synthetic transmission oils... The mechanisms of the box have undergone major changes. Some of the units were developed in cooperation with Schaeffler.

The box has now received a lock. It is designed to better control the engagement of reverse gear. The position of the reverse gear was also changed. Now, according to motorists, the new gearbox has become much easier to manage. The engineers managed to reduce the effort when engaging the gear by three times.

But that's not all. The most popular car in Russia in 2015 will receive a new mechanical one. The updated transmission will be installed in Granta "norm" and "luxury". Already now you can find and read information about the test drives of the pre-conveyor Grant with a robot. Robotic manual gearbox completely eliminates errors due to the influence of the human factor.

Feature of automatic box

Lada Granta was lucky, she was the first to get automatic gearbox... The decision arose back in August 2010. In December, Togliatti residents signed a contract for the production of automatic transmissions. The manufacturer was japanese company Jatco, known for the production of automatic transmission systems and variators.

Received not the most advanced, but already proven four-speed gearbox. The same automatic transmission was installed on Nissan Note subcompact cars. Japanese manufacturers have slightly modernized it and in March 2011 the first prototype was released. After many trials and tests, specialists were able to produce in March 2012 the first pre-pilot batch of 3 Grants.

It took a long time to fully adapt the gearbox. In the process of combining the Russian Grants and the Japanese box, many calibrations were made. In this adaptation, Japanese and Russian engineers were assisted by representatives of Austrian firms. Over 30 different changes were made before it worked. This unit has been tested by time, as well as by extensive foreign experience of use.

The hand immediately rests on the handle: both the engineers and the ergonomists have done a good job. The handle was set at the optimum height. The gear selector is equipped with mode icons. The selected box mode is reflected on the screen on-board computer car. However, the lever is fixed in one position not very well.

Features of automation

The box has several modes of operation. First gear and second gear are fixed here. There is a button to disable the overdrive. It prevents the automatic transmission from shifting to 4th gear. This is great for overtaking on the tracks. Engineers have developed fixed gears for long uphill climbs or off-road driving. In winter, the Lada Granta machine starts up immediately, without warming up.

The box will not want to include overdrive. In order not to expose the box to unnecessary loads, the electronics will turn on the third only after the oil in the box warms up to 15 ° C. The fourth will turn on when the temperature is 60 ° C. For those who love and are interested in technical nuances, it must be said that there is no flywheel in the power units. A drive disc is used instead.

The location of the crankcase led to the fact that the clearance of the Grants with automatic transmission decreased slightly. The electronics that controls the operation of the box are installed slightly behind and below the left headlight. Many car enthusiasts think that in the event of possible accidents it is unsafe. However, the creators claim the opposite. Automation reliably controls the system. You can turn on any mode, but it will only work under the necessary conditions. Car enthusiasts claim that the system works and it is very convenient.

This car is designed for residents of big cities. Automatic transmission settings are mainly focused on them. The box works normally in torn modes, quickly responds to pressing the "gas", quickly switches necessary transfers... In addition, it practically does not make noise. Therefore, you should think about which is preferable - an automatic or mechanic.

Pros and cons of automatic and mechanical box gear Lada Granta

Fuel consumption Lada Grants with automatic gearbox

Fuel consumption Lada Grants with automatic gearbox

Features and specifications auto Lada Granta

Features and specifications auto Lada Granta

A car is presented to your attention Lada granta... Most of the grant gearboxes are mechanical, but in the car market you can also find cars equipped with an automatic or robotic box gear. This article describes in detail about each type of gearbox lada grant. In a car dealership, the consumer is offered to choose a car equipped with different switching mechanisms with different engine power.

When buying Lada grants with automatic transmission, the buyer needs to think about reliable protection the crankcase, as well as the gearshift mechanism itself. Automated boxes for this car produced in Japan. It is necessary to constantly take care of the grant checkpoint, since it is rather difficult to drive on our roads and not damage the aluminum pallet.

Replacing the box costs the consumer a substantial amount of money, especially when it comes to an automated gearbox. Modification of the transport that is sold with such a gearbox, 20-30 thousand more expensive than a carequipped with mechanics. Also, the machine on the machine has a smaller ground clearance 15 mm than with mechanics.

There is no need to save on crankcase protection. When buying a car, it is better to immediately select protection for it - this will provide the driver with peace of mind while driving on bumpy roads.

Mechanical transmission Lada Granta

The grant's manual transmission is a five-speed. This transmission is included in basic configuration a car equipped with an 8-valve power unit with a capacity of 87 horse power... You can buy a car with the same gearbox, equipped with a 16-valve power unit with a capacity of 106 horses.

The gearbox is two-shaft. Includes five forward speeds and one reverse. Synchronizers are installed at all forward speeds. The mechanism is fully integrated with the final drive and differential.

The main transmission housing consists of three die-cast aluminum elements:

- clutch housing;

- main crankcase of the gearshift mechanism;

- rear cover of gearbox housing Lada Grant.

When assembled at the factory, a special gas-oil-resistant adhesive sealant is applied between them, which acts as a gasket. A specially designed magnet is located in the crankcase seat, which traps iron-containing particles when the mechanism is worn.

The Lada Granta car is equipped with a manual transmission-2181 or a manual transmission-2180, while the gearbox drive itself is different. It can be a shift rod or a transmission cable drive.

It is required to change the oil in the gearbox every five years or after the car has driven a distance of more than 75,000 kilometers, whichever comes first. If the gearshift mechanism is traction, then the required amount of oil is 3.10 liters. If the gearbox is cable-operated, the required amount of oil for replacement is 2.25 liters. The Lada Granta developers did not bother with the quality of traction mechanisms, therefore, after long term oil leakage problem may appear. In the transmission of the MKPP-2181 type, such problems are not observed.

Robotic transmission Lada Granta

Lada Granta robotic transmission mechanism - similar cable drive Manual transmission, only the gears are not switched manually here, but by a special mechanism that obeys the control of the electronic unit. The system compares the speed of the vehicle and the rpm of the power unit according to the algorithm specified during the development and, accordingly, the gear is turned on higher or lower. The volume of oil in this gearbox is 2.25 liters, since the design of the mechanism is similar to the mechanics of type 2181.

This transmission was previously equipped only with a grant. Today, such gearshift systems are installed on lada cars X-Ray and Lada Vesta... The replacement and repair of the clutch in the robotic version is carried out in frequency and principle in the same way as in the simple mechanical version of the transmission. If the electronic unit control fails, experts are trying to reconfigure it, returning it to the factory data. If this is not possible, the block is simply changed to a new, similar one. notice, that car row Lada Granta is equipped with control units developed by the world concern ZF.

The video below shows how a robotic transmission is assembled and tested for operability on the conveyor of the AvtoVAZ automobile company:

Automatic transmission Lada Granta

This gearshift mechanism is a classic Jatco development. The transmission is installed on Lada Granta modifications equipped with a 16-valve power unit with a capacity of 98 horsepower. Automatic transmissions this company is also installed on the available modification options car nissan Note and others like that. For engine auto Lada Granta, which works in conjunction with the automation, has developed a special aluminum pallet. The developers firmly attach this body to power plant... Note that the oil pan for such a transmission is made of steel.

The photo below shows what the automatic transmission handle looks like from the interior of the car:

This photo shows what the automatic transmission looks like from under the car:

Lada Granta equipped with automatic transmission gears developed by Jatco will cost the consumer an average of 30-40 thousand rubles more than a car equipped with simple mechanics or a robot.

Accordingly, the repair of this transmission will also cost the owner twice as much. The advantages include the fact that the car owner does not have to worry at all about when to switch gears correctly, because this is done by a mechanism in automatic mode... But the disadvantages include sluggish dynamics and fuel consumption, which is much higher than that of cars with a manual transmission or a robot. Of course, if the buyer can afford to pay a little more, then it is better to buy a car equipped with automation.

Comparison of gearbox models 2180 and 2181

In fact, the difference in these models is significant:

- for the functionality of the second model, a cable developed by Atsumitec is used. The vibration level of the second model is lower due to the cable structure;

- in the first and second gears, special synchronizers are installed to increase the service life;

- since the clutch diameter of model 2181 is increased by 21.5 centimeters, a different crankcase is installed in the gearbox, and the starter is placed not along the box, but along the engine;

- a completely new speed selection mechanism developed by Schaeffler;

- shifting gears in cold weather is much easier, and the level of vibration on the switch is much less;

- the gearbox design provides for blocking in case of accidental switching to reverse gear;

- as mentioned above, the oil volume has been reduced from 3.10 to 2.25 liters;

- in new checkpoint pour in semisynthetics, and not as before - a simple mineral water.

- Main gear of the main transfer;

- Secondary shaft;

- Main shaft;

- Fifth speed fork;

- Forks for third and fourth speeds;

- Reversing headlight switch;

- Clutch housing;

- Basic mechanism for speed adjustment;

- Central locking device.

The image below shows the synchronizer device for the 2181 gearbox:

Under the number 1, a gear is shown that is responsible for switching the first gear. Under the numbers 2 and 3 are intermediate and blocking rings, respectively. The synchronizer clutch is located after them and is designated by the number 4. The synchronizer clutch hub is located under the number 5. The retainer is under the number 6. And the number 7 shows a gear that is responsible for switching the second speed mode.

The figure shows the switching mechanism itself:

- Gearshift lever;

- Selector grille pin;

- Selective grille;

- Reverse lock, in case of accidental switching;

- Three-dimensional plate.

And this is how the whole mechanism looks like:

The gearbox design has been improved, that is, optimized. Now it has become even more reliable and durable. It was possible to eliminate almost all extraneous vibrations on the lever, which is located in the passenger compartment. Switching speed modes is now much easier. Note that the use of this gearbox in the design of Lada Granta attracted many new buyers, as it is convenient to operate.

The developers of the mechanism did not finalize the first model - manual transmission 2180. Now all the defects have been eliminated, and some parts have been completely replaced with new ones.

List of oils:

- G-BOX EXPERT - 80W85, 75W90

- Gazpromneft - 80W90, 80W85

- TNK TRANS KP - 80W85

- TNK TRANS KP SUPER - 75W90

- LUKOIL TM-4 - 75W85, 75W80, 80W85, 75W90, 80W90

- ROSNEFT KINETIC (Angarsk) - 80W85

- ROSNEFT KINETIC (Novokuibyshevsk) - 80W85 (GL-4), 75W90 (GL-4 / GL-5)

- TATNEFT TRANSLUX TM-4-12 - 75W85

- SHELL: SPIRAX S5 ATE or TRANSAXLE OIL - 75W90 (GL-4 / GL-5)

When choosing oil for the box, use the table:

- Range "-12 - +50 Gr. Ts " - 85W90

- "-26 - +45" - 80W90

- "-26 - +35" - 80W85

- "-40 - +35" - 75W80 or 75W85

- "-40 - +45" - 75W90

Below are the articles used by AvtoVAZ:

- 21230-1701326-00 - turnkey plug "17"

- 21900-3710410-00 - reverse switch

- 21080-3512115-00 - washer under the switch

Partial causes of malfunction

Below are the possible reasons breakdowns of the transmission of the Lada Granta car and how to eliminate them:

There was a rumble in the transmission

This problem is caused by wear on the gears or bearings in the shifting system. Also, if there is not enough oil, noise may occur, which is perfectly audible when driving. To eliminate them, it is necessary to replace the leaky parts or change the oil in the gearbox.

Difficulty switching

Distortion of the drive linkage system and loosening of the lever fastening screws make it difficult to change the speed. Requires replacement or repair of the traction. Tighten all screws. Breakage of the plastic components of the transmission is also a problem. Replacing worn parts will fix the problem.

Arbitrary shutdown of speeds

Most likely, the essence lies in the wear of the teeth on the synchronizer gear or the appearance of cracks on the mechanism supports. To eliminate the problem, you should disassemble the transmission and replace the unusable parts.

There is noise during gearshift

Synchronizer ring worn out causes noise. To eliminate noise, it is sufficient to replace the locking ring.

Oil flows

Possible oil leakage if oil seals are outdated input shaft or speedometer roller seal. It is necessary to replace the oil seals and the seal. The crankcase or box cover may be loose. To stop the leak, you need to tighten the drain plug, all nuts and bolts.

In conclusion, I would like to note that repair Lada Granta and others vehicle not an easy task at all. It requires special skills, abilities, knowledge and proper training. Car owners who do not understand such matters are better off entrusting renovation work specialists at the service station or give the car for inspection at a service center.