Brake system designed to reduce the speed of movement and stop the vehicle (working brake system). It also allows you to keep the car from spontaneous movement during parking (parking brake system).

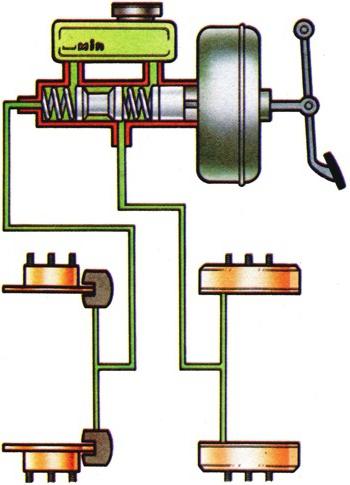

General diagram of the brake system

1 - front brake; 2 - brake pedal; 3 - vacuum amplifier; 4 - master cylinder hydraulic brakes; 5 - pipeline of the front brake drive circuit; 6 - a protective casing of the front brake; 7 - front brake caliper; 8 - vacuum pipeline; 9 - tank of the main cylinder; 10 - button of the parking brake drive lever; 11 - parking brake drive lever; 12 - thrust of the lever latch; 13 - lever latch; 14 - parking brake lever arm; 15 - returnable lever; 16 - drive circuit pipeline rear brakes; 17 - flange of the cable sheath tip; 18 - rear brake; 19 - rear brake pressure regulator; 20 - pressure regulator drive lever; 21 - rear brake pads; 22 - lever for manual drive of pads; 23 - thrust of the pressure regulator drive lever; 24 - bracket for fastening the tip of the cable sheath; 25 - rear cable; 26 - lock nut; 27 - adjusting nut; 28 - bushing; 29 - rear cable guide; 30 - guide roller; 31 - front cable; 32 - switch stop control lamp parking brake; 33 - brake light switch

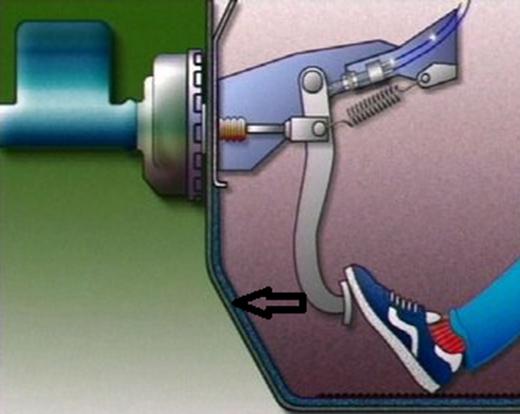

Working brake system it is activated by pressing the brake pedal, which is located in the passenger compartment. The driver's foot force is transmitted to the brakes of all four wheels.

The disadvantage of such solutions is the complexity of the entire system and the higher cost. The brake disc is attached to the wheel hub using small locking screws or a pin that secures the wheel. However, even after unscrewing, most of them cannot remove the shield. Usually, stopping support with friction components must also be removed.

Brake disc indicator

Most wear indicators are usually located on the brake disc. Most often these are special grooves on the periphery. If the brake pad reaches specified place, the disc needs to be replaced. If there are no indicators, the thickness of the dial can be measured with a caliper.

Parking brake system is needed not only in the parking lot, it is also necessary to prevent the car from rolling back when starting up an uphill. Using the parking brake lever, which is located between the front seats of the car, the driver can operate the brakes with his hand rear wheels.

Working brake system includesof:

In some cars, the brake caliper was supplemented with a mechanism emergency braking... This system can be recognized by the protruding emergency brake lever, and a different piston rod design. Before we start digging into the design of the handbrake, we need to test its correct function. First we go up the hill and stop. We make sure that no one is behind us. If the road is empty, we can take the test. Let's check the handbrake and find out where the latches are locked to keep our car from falling.

The brake drive is used to transfer the force of the driver's foot from the brake pedal to the brake actuators of the vehicle wheels. On modern passenger cars, a hydraulic brake drive is used, which uses a special brake liquid.

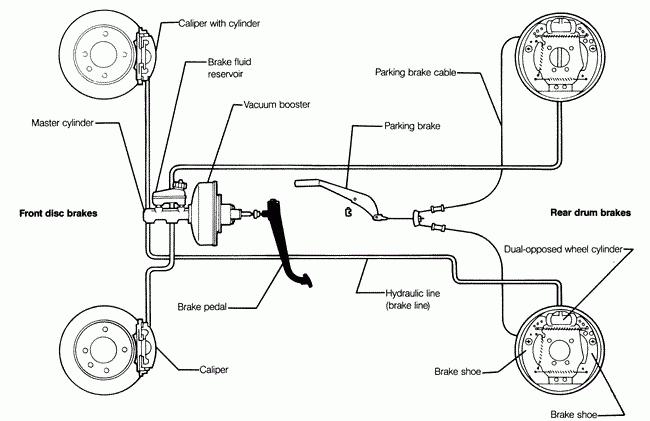

Brakes hydraulic drive diagram

1 - front wheel brake cylinders; 2 - front brakes pipeline; 3 - rear brakes pipeline; 4 - rear wheel brake cylinders; 5 - reservoir of the main brake cylinder; 6 - main brake cylinder; 7 - the piston of the main brake cylinder; 8 - stock; 9 - brake pedal

The hydraulic brake drive consists ofof:

In many cases, the hand must completely block the wheels on the third or fourth latch. What is responsible for locking the wheels and possibly changing the latch on which the wheels are completely locked? In the case of worn friction linings, the brake lever has increased travel, and therefore we need to use more force, so that the total locking of the wheels will only be after the fifth and even the sixth latches. The hand brake in most vehicles affects the two rear wheels. In some cars, we also find an assist guide that brakes the front wheels.

When the driver's foot presses the brake pedal, its force is transmitted through the rod to the piston of the master brake cylinder. The fluid pressure on which the piston presses is transmitted from the master cylinder through the pipes to all the wheel brake cylinders, forcing their pistons to move. Well, they, in turn, transfer the force to the brake pads, which do the main work of the brake system.

The principle of the hand brake is very simple. When we lift the lever up, the tie, which is just below the lever, moves forward. Along with the direct drive, they slide towards the rear braking system. The hand brake is always in the drum, where - thanks to the use brake pads - he can work normally and do his job.

The most common hand brake faults

One of the most common hand brake faults is uneven braking on the two rear wheels. In this case, you need to configure. Make sure the parking brake lever is released before starting work. Then, let's wedge the wedges under the front wheels of the vehicle to avoid rolling.

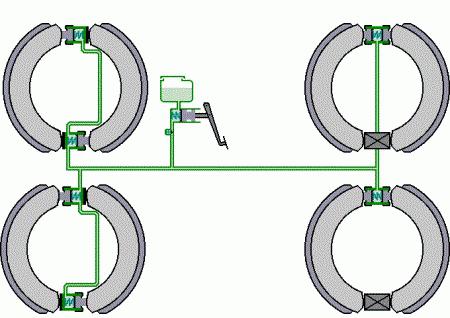

The modern hydraulic brake system consists of two independent circuits connecting a pair of wheels. If one of the circuits fails, the second is triggered, which provides, although not very effective, but still braking the car.

To reduce the effort when pressing the brake pedal and more efficient operation of the system, a vacuum booster is used. The amplifier clearly makes it easier for the driver, since the use of the brake pedal when driving in an urban cycle is constant and tiresome quite quickly.

When the car is secured, we can continue to raise it. For this treatment, it is best to use the so-called. frog. We have to remove the cover, which is made of plastic and is located just behind the brake lever. After the shot is taken, we will see the adjusting screw. When we have everything ready, we will pull the handbrake lever until it stops at the other latch. Then tighten the adjusting nut until the rear wheels begin to brake. At this point, pull the lever on the third latch.

If done correctly, the rear wheels should be locked. It is good practice to apply a small amount of grease to the arm attachment point. After installation, you must install the cover. If they are damaged it won't even help with a professional setup. Replacing a brake pad requires removing the rear wheels and the rear brake system. Depending on the system, also a brake drum or brake disc. Don't forget to swap. It is unacceptable to exchange with only one side.

Vacuum amplifier circuit

1 - the main brake cylinder; 2 - the body of the vacuum amplifier; 3 - diaphragm; 4 - spring; 5 - brake pedal

Vacuum boosterstructurally connected with the main brake cylinder. The main element of the amplifier is a chamber divided by a rubber partition (diaphragm) into two volumes. One volume is connected to the engine intake manifold, where a vacuum of about 0.8 kg / cm2 is created, and the other to the atmosphere (1 kg / cm2). Due to the pressure drop of 0.2 kg / cm2, due to the large area of \u200b\u200bthe diaphragm, the `helping` force when working with the brake pedal can reach 30 - 40 kg and more. This greatly facilitates the work of the driver when braking and allows him to maintain his performance for a long time.

After the exchange, it is usually recommended to make the brake adjustment as efficient as possible. Handbrake repair requires a lot of patience as well as skill, so before starting work we must consider if our skills are sufficient to make the repair ourselves.

Brake system malfunction. Of all building systems vehicle most important is the braking system, which depends on the safety of our and other members road traffic... The main function of the braking system is to reduce the vehicle speed, stop the vehicle and its motionless movement.

The brake mechanism is designedto reduce the speed of rotation of the wheel, due to the forces of friction arising between the lining of the brake pads and the brake drum or disc. Brakes are divided into drum and disc brakes. On domestic cars, drum brakes are used on the rear wheels, and disc brakes on the front. Although depending on the car model, drum only or only disc brakes on all four wheels.

The braking process involves the use of friction between the friction pad and the surface brake disc or drum brake track. AT standard equipment middle class cars - by pressing the brake pedal, we activate the brake pump piston, creating hydraulic pressure.

The movement of the master cylinder piston is assisted by a vacuum assist device. Pressurized brake fluid flows through the brake lines to each wheel. In disc brakes - the pressure activates the clamp where the pistons press against the pads against the brake disc.

Drum brake operation diagram

1 - brake drum; 2 - brake shield; 3 - working brake cylinder; 4 - pistons of the working brake cylinder; 5 - clamping spring; 6 - friction linings; 7 - brake pads

The drum brake consists ofof:

The brake shield is rigidly attached to the beam rear axle the car, and on the shield, in turn, the working brake cylinder is fixed. When you press the brake pedal, the pistons in the cylinder diverge and begin to press on the upper ends of the brake pads. The pads in the form of half rings are pressed by their linings against the inner surface of a round brake drum, which, when the vehicle is moving, rotates together with the wheel attached to it.

AT drum brakes the pressure activates the pistons of the plunger piston, which expand the jaws, pressing them against the inside of the brake drum. Typical malfunction brake system. Uneven braking. The car pulls to one side. Worn, damaged, damaged front or rear brake pads on one side of the vehicle. Partially clogged or partially worn front or rear brake collar or tapered plunger in the rear drum brake cylinders. Clamping rail loosening screws. leaking brake fluid from the cylinder. Corrosive brake hoses.

- Using different friction on both sides of the vehicle.

- Inadequate supply of brake fluid to the cylinders.

- Oil friction pads or jaw pads.

Wheel braking occurs due to the frictional forces between the pads and the drum. When the impact on the brake pedal stops, the compression springs pull the pads back to their original positions.

The scheme of the disc brake mechanism

1 - outer working cylinder (left) of the brake; 2 - piston; 3 - connecting tube; 4 - brake disc of the front (left) wheel; 5 - brake pads with friction linings; 6 - piston; 7 - inner working cylinder of the front (left) brake

The disc brake consists ofof:

Corrosion of the brake disc or drum - most often when the vehicle is idle for a long time, the friction lining is incorrect.

- Friction liners for metal plates.

- Oval brake drum.

Swollen master cylinder piston gaskets due to incorrect brake fluid.

- Worn piston in the brake pump.

- The clutch pedal is on the pedal sleeve.

- Brake air.

- Damaged rubber ring on the plunger in the brake pump.

- Leaking brake fluid from the system.

- Too little brake fluid in the reservoir.

- Excessive brake pedal at idle speed.

The caliper is fixed to steering knuckle front wheel car. It contains two brake cylinders and two brake pads. The pads on both sides 'hug' the brake disc, which rotates with the wheel attached to it.

When you press the brake pedal, the pistons begin to come out of the cylinders and press the brake pads against the disc. After the driver releases the pedal, the pads and pistons return to their original position due to the slight beating of the disc. Disc brakes are very efficient and easy to maintain. Even for the amateur, replacing brake pads in these mechanisms gives little trouble.

Excessive beating or warping of the disc or brake drum. worn brake linings or brake jaws of the toggle switch. loosening the brake caliper mounting bolts. Abrasive brake pads on discs or drums.

- Plugged clip or piston in the brake cylinder.

- Damage to the master cylinder.

- Incorrectly set auxiliary brake.

- Washed piston in brake cylinder or caliper.

- Defective braking force corrector.

- Freeze the armored parking brake cable.

- Oil, incorrect friction linings.

- Product damage to the device or porous vacuum hose.

The parking brake is activated by lifting the parking brake lever (in common use - the parking brake) to the upper position. This pulls on two metal cables, the last of which forces the rear wheel brake pads to press against the drums. And as a consequence of this, the car is held in place in a stationary state. When raised, the parking brake lever is automatically latched. This is necessary to prevent spontaneous release of the brake and uncontrolled movement of the car in the absence of the driver.

Broken brakes. loose springs detaching the drum brake jaw.

- The compensation hole in the brake pump is received.

- Too little play between the tappet and the master cylinder piston.

It is a metal element on which our safety depends. Already the quality of molding brake discsand then machining must ensure high requirements, that is, resistance to high temperatures, cracks, deformation and abrasion. Precision machining provides the required dimensions and performance for proper wheel alignment. As with blocks, you should always replace both discs on the same axis. Then the braking will be even.

The main malfunctions of brake systems

Increased pedal travel or "soft" brake pedal occurs due to severe wear of the brake pads, the presence of air in the hydraulic system, and brake fluid leakage.

To eliminate the malfunction, it is necessary to replace the brake pads, eliminate the brake fluid leak by replacing the damaged parts, bleed the hydraulic drive system to remove air.

The most common brake disc malfunctions. Overheating - when the heat capacity of the blade is exceeded and its ability to dissipate heat. Excessive wear on the rear axle braking force causes all of the braking weight to be borne by the front wheels, resulting in faster wheel wear. Vibration due to wheel overturning during braking. ... To measure the thickness of the brake disc, measure at the thinnest point of the arrow in the illustration.

Used for measurement special test or micrometer. Keep in mind that as the blade wears down, the notch will not reach the edge of the blade. In case of large cracks or depressions with a depth of more than 0, 4, replace the brake discs.

- If the limit of one drive is reached, replace both wheel rim the same axis.

- The lateral travel of the disc surface should not exceed 0.05.

Driving to the side (when braking) is possible due to the failure of one of the wheel brake cylinders, excessive wear or oiling of the brake pads of one of the wheel brake mechanisms.

To eliminate the malfunction, the defective cylinder and brake pads must be replaced, and the contaminated pads must be washed.

The main function of brake pads is to generate braking force on the disc brakes by pressing the brake disc twice. The building block technology and their composition are the secret of every manufacturing company. Today's environmentally friendly blocks, braking efficiency and durability - have friction blanks completely free from heavy metals and other harmful substances... For example, keral and bituminous rubber are used in the production process. Kevlar - Provides very high strength.

The most important parameter of every brake pad is durability and temperature stability, i.e. constant coefficient of friction along with increasing temperature. The friction coefficient of the brake pad decreases, increasing the braking distance.

Noise when pressing the brake pedal or vibrations occur due to dirty brake mechanisms, excessive wear of the brake pads, loosening or breakage of the tension springs of the rear brake pads, uneven wear brake drums or disks.

To eliminate the malfunction, the contaminated pads should be washed, and worn out and damaged pads, drums, discs and springs must be replaced with new ones.

Operation of the brake system

Any malfunction in the braking system can lead to very unpleasant consequences. Therefore, when operating a car, you should carefully consider the operation of the brakes of your car.

Of course, it is easier for the driver to notice changes in the braking performance of his vehicle while driving while sitting in the passenger compartment. But it can be funny and sad when a `` rider-driver '' loses the brakes only because he did not pay attention to the constantly decreasing fluid level in the brake reservoir in time. And he was too lazy to open the hood of the car and examine some tanks there. As a result, the level of the brake fluid dropped to zero and, when the brake pedal is pressed again, the driver no longer `pressed 'the brakes, but the air. I hope I persuaded, and you will control the level of the brake fluid. And you will be calmer and we, the rest, will be safer.

`Where did the level go? 'Is a legitimate question on your part. Unfortunately, `nothing lasts forever under the moon` and parts of the brake system as well. Over time, the sealing cuffs of the cylinder pistons wear out, the tubes and hoses of the hydraulic brake drive lose their tightness from vibrations and rust, and indeed any liquid can evaporate a little.

If you notice leaks on the wheels or wet marks on dry asphalt, coinciding with the location of the brake system elements, then you should abandon the trip and eliminate the malfunction. A car without brakes is a killer (no matter how tough it sounds).

During the operation of the brakes, all parts of the working mechanisms and the space around them become very hot. This is a natural process, since braking a car is nothing more than the transition of the kinetic energy of a moving car into thermal energy, due to frictional forces in the braking mechanisms.

And what happens to the brake fluid, which is located nearby in the cylinders and pipes? It heats up noticeably and there may come a moment when the liquid boils. Well, and then - school physics. Air bubbles, unlike liquid, are compressed instead of transferring the driver's foot pressure from the brake pedal to the brake actuators. And until you compress all the air in the tubes, hoses and cylinders, repeatedly and quickly pressing the brake pedal, until then - you will not have the brakes (the well-known expression - `the brakes work from the third pitch ')! Well, when you do stop your car, you should figure out how it all happened and how now to get rid of air bubbles in the system.

In order to avoid the above-described "nuisance", you should often use engine braking, and on steep and long slopes - this is generally the only reasonable option for braking! Otherwise, you have to often press the brake pedal, increasing the heating of the parts, and you already know what this can lead to.

After the brake fluid boils or as a result of a leak in the hydraulic drive, air bubbles appear in the system. How to determine this?

Obvious signs of air in hydraulic drive the brakes are as follows:

How to get rid of this air? And it's not very difficult, but you will need an assistant. He "inflates the pedal", and you drain portions of brake fluid with air bubbles alternately from each impeller cylinder. The operation is carried out until the air is completely removed from the system, just do not forget to periodically add fluid to the brake reservoir during the `pumping 'process.

During the operation of the car, other problems with the braking system may arise.

Suddenly the brake pedal becomes stiff and requires a lot of force to press it. There may be several reasons. Here are two of them:

If parking brake does not keep the car on the rise, then it is necessary to adjust it or replace the cables, or it may be time to change the rear brake pads. The adjusted handbrake, with three to four clicks of the lever lock, should ensure that the car is held on a slope of up to 23%.

V. A. Molokov, S. F. Zelenin

Malfunctions of the brake system in which traffic rules prohibit operation transport funds .

1.1. During road tests, the following braking performance standards with the service braking system (for passenger cars) are not observed:

path no more than 12.2 meters.

The steady-state deceleration is not less than 6.8 m / s2.

Note: The tests are carried out on a horizontal section of the road with a smooth, dry, clean cement or asphalt concrete pavement at a speed of 40 km / h at the beginning of braking. Vehicles are tested in running order with the driver by a single action on the control of the service braking system.

The traffic police are armed with a device that, when testing the brakes, is rigidly attached to the car body. It displays the braking rate, which is measured in the same units as normal acceleration and deceleration. When carrying out the so-called 'instrumental control' for technical condition transport, both of the above parameters are taken from the readings of the test brake stand.

1.2. The tightness of the hydraulic brake drive is broken.

Leakage of pipes, hoses and cylinders is one of the reasons for the appearance of air bubbles in the system, and you already know what this threatens. In addition, initially insignificant leakage can lead to a "dam break" at a specific point in the hydraulic brake actuator. This usually happens when the brake pedal is pressed hard and hard. The pedal `falls to the floor` and then no one knows who or what will help stop the car.

1.5 Parking brake system does not provide stationary state:

- vehicles with a full load - on a slope up to 16% inclusive, - cars in running order - on a slope up to 23% inclusive.

Why do you need a parking brake, you recently learned. The safety of both the car and its passengers and the safety of other road users depends on its performance.

Imagine a mass of about a ton, which, without the participation of the driver, begins to spontaneously move. There will probably be many problems! That is why, when stopping on a slope, the driver must engage the parking brake. And when the vehicle is parked for a long time with the engine off, a competent driver additionally includes the first (or reverse) gear. The idle engine, through the connected transmission units, reliably keeps the wheels and the car itself from spontaneous movement in the absence of the owner.

This article will discuss the brake system diagram passenger car... You will also learn how to bleed the system correctly. We will consider constructions with anti-lock braking system... At the moment, no one can do without them quality car... We are talking, of course, about cars of the middle price category and above. Budget cars can be equipped with this design, but it goes like additional option... In general, the braking systems of all cars are the same, they consist of identical elements.

A little theory about the brake system

As you can imagine, it is necessary in order to change the speed of the car. This can be signaled by either the driver's action or electronic system management. It is also necessary to keep the car stationary while parked.

There are three types of braking systems. The first is, of course, the worker. It is necessary for the normal operation of the machine. With its help, braking is carried out at high or low speeds. The features of the "Niva-2121" brake system, the scheme of which is classic, will be discussed below.

The second type is parking. It is better known as a handbrake, if you need to put the car on long term... In particular, if there is a slope in the road surface, this system is a must. The handbrake can be used during an emergency stop. And there are also systems of a spare type. They have recently begun to be used on cars. Most often they can be found on those cars that have an electric handbrake. Its main purpose is to enable the driver to stop the car if it refuses. working system... It is mounted on cars with electric hand brake for one reason: the parking brake cannot be applied if the vehicle speed is greater than zero.

Functioning principle

We are used to the fact that when you press the brake pedal, the car starts to slow down. But not everyone goes into the details of what processes take place at the same time. Not everyone knows how the VAZ-2109 brake system works, the diagram of which is given in this article. To put it simply, the car stops only due to the compression of the liquid in the pipes and hoses. The pressure is generated by the brake master cylinder, which is the main unit of the system.

There are certain requirements for brake fluid. It should not lose its properties during compression and heating, it experiences colossal overloads during braking, as well as other elements. What requirements are imposed on the liquid will be discussed below. The pressure in the tubes drives the calipers, which in turn move the pads. The latter rub against the surface of the drum or disc, slowing down the movement of the wheel around its axis. Thus, the car gradually stops.

Brake master cylinder

It is necessary to tell a little about the design of the brake master cylinder. This is the main element of the system, and it does not matter whether there is ABS or not. It is necessary for one purpose - to convert the force applied to the pedal into fluid pressure. It also distributes the latter to the calipers.

For example, the VAZ-2109 brake system, the diagram of which is presented in the article, is equipped with a master cylinder installed in the engine compartment (it is attached with two pins to a vacuum amplifier). An expansion tank is fixed on top of it. Excess fluid is thrown into the latter when the pedal is fully released. Liquid is drawn from it during depressing of the pedal. The brake master cylinder is hollow inside. Pistons move in it, which create pressure in the system. Repairs need to be carried out from time to time. In its process, all rubber elements are completely replaced.

Pressure regulator

It is attached to the rear of the vehicle as it has a specific purpose. It is worth noting that approximately 75 percent of the braking occurs with the front wheels. The remaining 25 percent are back. It should be borne in mind that locking of the rear wheels must not be allowed, as a force arises that tends to overturn the car. Consequently, the VAZ-2110 brake system, the circuit of which is discussed in the article, contains a pressure regulator.

It is able to reduce the pressure applied to the rear wheel drive mechanisms. Moreover, the change in this indicator depends on how loaded the rear axle is. The fact is that when stopping without a regulator, the front of the car begins to sag, and the rear starts to rise. As a result, the rear wheels are blocked and an uncontrolled skid occurs. The regulator allows you to avoid blocking completely or to make it happen later.

Work contours

So, now about what the VAZ-2110 brake system is, the diagram of which is in the article. There is a working brake circuit, which, in turn, consists of an auxiliary and a main one. In the event that there are no malfunctions, the auxiliary and the main work together. But if there is a depressurization of any circuit, the second will continue to work as an emergency. There are several schemes for dividing the circuits: brakes connected in parallel - front plus rear. Mechanisms can be connected diagonally, for example, the right rear and left front are in the same circuit. There may be a scheme in which one of the circuits contains all the drive mechanisms. And the second is only a circuit to which only the mechanisms of the front wheels are connected. It is difficult to talk about the advantages or disadvantages of these schemes, since emergency situation can happen for various reasons. And all the contours can be damaged, not just one.

Anti-lock braking system

Of course, the VAZ-2106 brake system, the circuit of which is classic, like the car itself, does not contain ABS. But it is still necessary to talk about such a system, since the future lies behind these structures. It has several sensors, a central control unit, modulators. When the vehicle stops, the control unit is activated. Its microprocessor begins to monitor the readings of all sensors. It analyzes the signals from the vehicle speed sensor. It also monitors the angular velocity of each wheel. Nothing escapes the attention of the microcontroller brake control system.

Of course, the 2110 brake system does not have such devices, its scheme is much simpler. Special modulators are executive devices. With their help, the brake fluid pressure is regulated in all circuits. In other words, each wheel brakes differently. Much depends on quality road surface, on the speed of the car. But anyway aBS system will not allow any wheel to completely lock if you perform emergency braking. Namely, blocking is dangerous when the asphalt is wet or on ice. This will keep you safe, since the likelihood of skidding is extremely small.

Disc brakes

This is one of the most common types of brake actuators. For example, braking circuitry 2106 includes two disc brakes on the front axle. The rear wheels are stopped by drum wheels, they will be discussed a little below. Don't think that disc mechanisms are all the same. Their support can be both fixed and movable. But the latter are found in cars much more often. For the driver, the main thing is reliability. And the movable caliper has a design that completely eliminates uneven wear of the brake pads. But there is another feature of the mechanisms in which the caliper is movable.

The distance from the brake disc to the outer edge of the caliper is constantly changing, depending on how worn out the pads are. In addition, we can say about the main advantage of disc brakes. They are more efficient than drums and can operate at high temperatures. Ventilated discs are also often used. Increasing the thickness makes it possible to install several stiffeners. They can provide airflow to the metal. Moreover, during the rotation of the wheel, the centrifugal force sucks in air and distributes it evenly from the center to the edges. It is due to this that the metal is cooled.

Drum brakes

Most budget cars have them on the rear axle. But if we take, for example, the 21st "Volga", then all four wheels have drum brakes.

There are schemes that consist entirely of disc mechanisms. Such designs are increasingly used in tuning. domestic cars, since with an increase in engine power and torque, it is necessary to carry out a complete modernization of all other systems. And first of all, of course, brake. But the circuit of the VAZ-2121 brake system is the same as that of the "ten", and the "nines", and other models of this manufacturer. Only quality and reliability differ. "Niva" is an off-road vehicle, and therefore it is subjected to much greater loads than an ordinary passenger car.

Drum mechanisms are less efficient, but still able to fulfill their main purpose - to stop the car. True, over time, the pads wear out, the gap between the drum and its working surface increases. In this case, use special mechanical-type regulators. With their help, the pads are supplied. This happens during a sharp depressing of the brake pedal. Pay attention to what the VAZ-2114 brake system is, its diagram is given in the article. On the rear axle, the pads can be opened with a handbrake. In designs with disc mechanisms at the back, the circuit includes additional cylinder, the rod of which is driven by the handbrake of the parking brake.

Brake actuators

If you look at what scheme of the UAZ brake system, you can see that there are several types of actuators in it. We are talking, of course, about the pad drives. Systems can contain disc and drum mechanisms. They have significant differences. For example, disc brakes work with specially designed calipers. But the drum mechanisms are equipped with cylinders. The liquid is supplied to the middle of this cylinder. Pistons are located on both edges, which drive the pads, expanding them.

The front wheel calipers of domestic VAZ cars are located on both sides of the disc. One half of the support is working, it contains brake fluid under pressure. It also has a steel piston, which is squeezed out of the body by pressure and pushes the pad towards the disc. Simultaneously with this back side the disc is pressed against the second block. Consequently, the disc is clamped on both sides. And the pads wear out as evenly as possible. It is also worth noting that the "Niva" brake system diagram contains the same elements as the "six", but they are stronger and more durable.

How to bleed the brakes

It is worth mentioning a little about such a procedure as bleeding the brakes. Without this, you will not be able to drive a car normally, since there will be a lot of air congestion... This makes the braking performance much lower.

To get rid of air pockets, you need to fill all tubes and calipers with liquid. All work is best done together. One person should press the pedal. The second timely opens and closes the pumping fittings. And they are found on all calipers. True, you will need to constantly raise all sides of the car, remove the wheels one by one. It is much easier to perform this procedure on inspection pit... Pumping must be carried out according to a certain scheme. And it must be adhered to, otherwise the air will remain and no efficiency can be achieved from the brakes.

This is how the VAZ brake system is pumped, the scheme is quite simple. It is necessary to start with the mechanism that is located at the maximum distance from the GTZ. It's right rear wheel... After him, you can only do the left rear, then the right front goes. And the last one you will have is the wheel that is near driver's door... You can even do the whole procedure yourself. But for this you need to make from car camera a kind of receiver for air storage. It is necessary to provide the brake system with pressure. Therefore, the chamber must be connected using a union with an expansion tank. Using the above scheme, you get rid of air jams in all circuits. In doing so, do not forget to ensure that in expansion tank was required level liquids.

Conclusion

In this article, you learned about what the braking system consists of. modern car... It was also told a little about modern facilities ensuring security. In particular, it is the ABS system. It is used as an additional option, but more and more often it can be seen even on budget cars standard configuration... In addition, the braking system includes cruise control, various amplifiers for emergency braking, exchange rate stability mechanisms, anti-slip design, differential lock.

Everyone is used to seeing hydraulic brakes, but there are designs that use compressed air rather than fluid pressure. They are identical with hydraulic ones, only their reliability is much higher. Components used in pneumatic brakes must withstand very great pressure... True, it is comparable to that in the hydraulic drive. Only need to embed the storage receiver compressed air... There are also electromechanical brakes. They are driven by electric motors and special cables.