The presence of an inspection hole in the garage makes it possible to carry out self-repair own car. It can be done with minimal knowledge in the field of construction and the availability detailed instructions. Using a step-by-step master class, it will not be difficult to carefully and efficiently prepare and independently build a pit, regardless of the size and layout of the garage.

Determining the optimal size and shape of the inspection hole

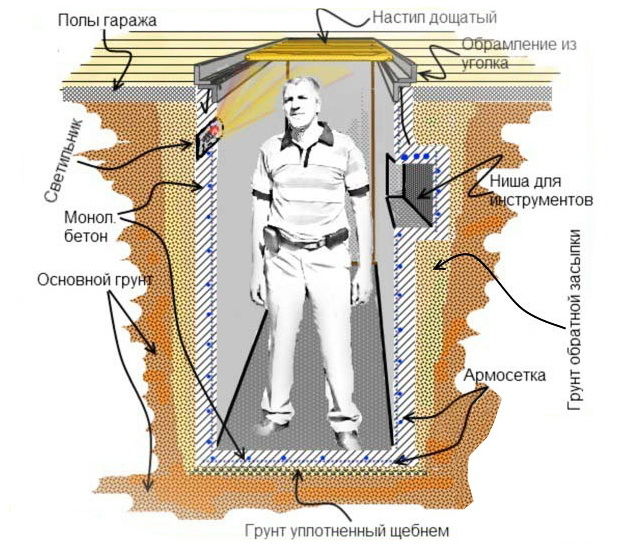

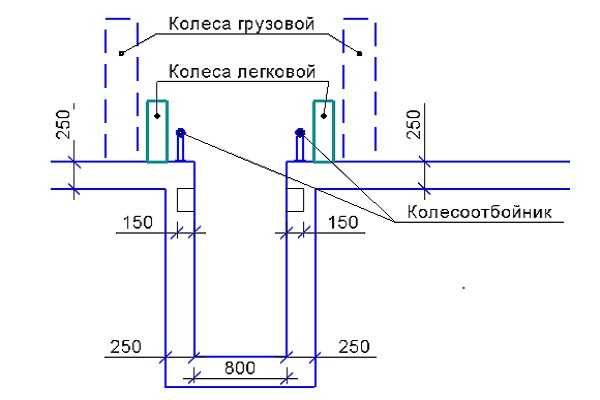

The finished inspection pit should be both safe and convenient to use. Therefore, before starting work, it is recommended to study geological survey data on the condition of the soil and the location of groundwater under the garage. This will allow you to determine the optimal depth of the hole. If the groundwater is quite deep, then the recommended height from the floor to the “ceiling” may be about 2 m or less (owner’s height + 20-30 cm). The dimensions can be found in the drawing.

An inspection hole is made in the garage with your own hands after drawing up a project plan for the facility. Its width is determined according to the wheelbase of the car: it should be smaller, ensuring the possibility of safe entry of the car. The length should be at least 1 meter longer than the length of the car: this will allow you to work comfortably in the pit.

The installation of an inspection pit allows the presence of small niches. They can be used to store parts and conveniently arrange tools. They should not be made too deep. It is recommended to determine the dimensions of the niches according to the available quantity of auto tools and spare parts.

Laying out walls and niches in the inspection pit

After digging a pit with predetermined dimensions, you should begin strengthening the walls, protecting them and then laying bricks. The use of brick is optimal due to the ease of working with it and ease of purchase. You can find out how to build a viewing hole in a garage from the most affordable building materials in the following instructions:

1. First, you need to make the floor of the inspection hole in the garage: level the bottom of the pit, lay down roofing material (with an overlap of about 0.5 m on the walls for each of them). Concreting is carried out with the M-200 grade, the thickness of the floor should be about 10 cm. The length and width of the floor should include the sum of the thickness of the two walls, the length/width of the pit itself and an increase of 10 cm. After pouring, leave the concrete to harden for 4 days.

2. The construction of the walls begins with the laying of 4 rows and subsequent waterproofing of the inspection pit from the outside using bitumen mastic. This will prevent the destruction of the walls due to exposure to moisture from the earth cover adjacent to the brick. After laying out the walls, you need to fill in the remaining gap from the ground to the brick.

3. The final stage of work will be the installation of a metal frame around the entrance to the pit. It should protrude slightly above the floor level of the garage box.

The frames of the niches should also be made of metal corners. This will prevent the bricks from subsiding or breaking.

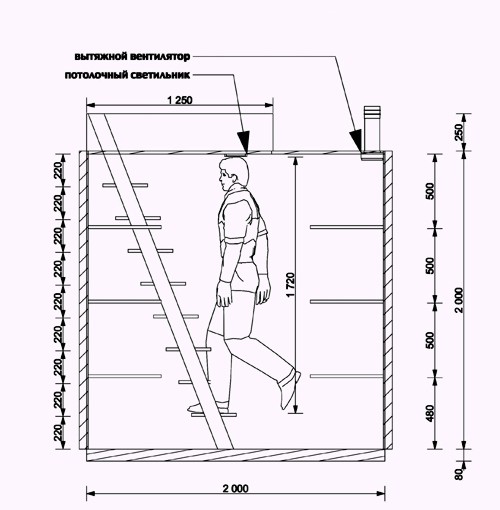

Features of the ventilation device and the choice of stairs

High-quality ventilation in the inspection pit of the garage will prevent the appearance of mold and the gradual destruction of the walls. It can be made exclusively exhaust or supply and exhaust. In the first case, when laying out the last rows of bricks, it is necessary to install a pipe that will allow air to be removed from the pit through the garage box upwards (it will approach the garage ventilation pipe or be discharged directly to the street). In the second case, an additional pipe is installed, which is diverted outside. Its end should be located at a distance of 15 cm from the floor.

You can make a convenient ladder for the inspection hole from wood and metal corners. For a small block, a repositionable ladder will be much more convenient. In the attached photos you can also see examples of pits in which the steps were laid out of brick or concreted.

Lighting supply

In the process of laying niches, you need to connect a 36V wire in an insulating rubber hose. This will allow you to connect the light in the pit and conveniently illuminate the car during repairs. When performing these stages of work, it is advisable to invite a qualified electrician who will help to correctly determine the optimal location of the wire and ensure its protection, and will ensure its correct connection to the power supply. When doing the work yourself, you should study the auxiliary video lessons on creating the correct lighting in the inspection pit.

Video of building a viewing hole in a garage with your own hands

Inspection pit for car repair

DIY inspection hole in the garage

Inspection pit, my construction experience.

Carrying out maintenance or minor repairs Many people try to make a car themselves. To avoid lying on your back under the car, you need an inspection hole in the garage.

Dimensions of the inspection hole in the garage

This is far from dogma. Everyone does as they see fit. Some people find deep holes inconvenient and they make them almost exactly tall, and sometimes even lower - 1.5 meters. If you take into account the car's ground clearance, from the floor of the pit to the bottom of the car it will be about 1.7-1.8 meters. You can do it this way.

Another point about length. Sometimes it is not possible to make a long hole. Then it is made approximately half the length of the car, driving it in front or back, depending on which part of the car needs inspection or repair.

Now about where to place the pit in the garage. Usually it is shifted slightly towards one of the walls, leaving a wide side for installing equipment, storing spare parts, etc. In this case, there must be at least 1 meter from the edge of the pit to the near wall.

That's all the parameters. Just note that we were talking about the final dimensions of the pit. When marking the pit, you will need to add thickness to the walls, and dig deeper to the height of the floor screed (if you make one).

What materials are they made from?

The inspection pit in the garage (its walls) is lined with bricks, heavy building blocks, and made of monolithic concrete. If we talk about bricks, it is better to use ceramic bricks: they are not afraid of moisture. The walls are made of half a brick or brick. The wall thickness, depending on the laying method, is 12 cm or 25 cm. This must be taken into account when marking the pit.

Brick can be used on dry, dense soils. The groundwater level must be low. If the water comes up high, it is better to make the walls of the pit from reinforced concrete.

Building blocks also need to be selected those that are not afraid of high humidity. These are concrete blocks. The rest, if used, must require external waterproofing, and this is not a guarantee that they will not crumble, especially if groundwater is located close.

With a concrete inspection hole, everything is simpler: concrete is not afraid of moisture, it only makes it stronger. To fill the walls, concrete grade M 250 is used; for the floor, M 200 is sufficient. Why is this so? Because during winter heaving the main load falls on the walls. To prevent them from “collapsing”, a margin of safety is required, which is achieved by reinforcement and the use of high-strength concrete. By the way, to avoid heaving of the soil under the garage, you need to make a good blind area so that the water leaves and does not soak into the soil.

The wall thickness when filling the inspection hole with concrete is from 15 cm. Stacks must be reinforced. To do this, use a ready-made mesh with a wire thickness of 5-6 mm and a pitch of 150 mm (if the groundwater is deep) or knit a frame from reinforcement with a diameter of 10-12 mm. The reinforcement installation step is 20 cm. For greater strength, you can make a single rod for the bottom and walls, bending it accordingly.

Waterproofing methods

An inspection pit in a garage can be protected from moisture penetration in two ways: with the help of external waterproofing, which is carried out exclusively during the construction process, and internal, which can be done during operation.

External protection

If in the place where the garage is being built the groundwater is deep, lower than 2.5 meters, and even in the spring or after heavy rains it does not rise higher, you can do without waterproofing. On the other hand, the hydrological situation is constantly changing, and where it was previously dry, water may appear. If the inspection hole in the garage has already been built, external waterproofing cannot be done. All that remains is to use deep penetration impregnations to reduce the hygroscopicity of the walls. Therefore, if possible, do external insulation in any case.

How to prevent moisture from entering the inspection hole in the garage? Most often, waterproofing films or membranes are used (butyl rubber, aquaizol, etc.). They are laid in sheets, covering the pit from one edge to the other, with 10-15 cm released from each side of the pit onto the garage floor. The panels are laid overlapping. They must overlap by at least 15 cm. To obtain a more airtight joint, they are glued together with double-sided tape, possibly in two stripes - at the beginning and end of the “overlap”. The film is well straightened so that it fits tightly to the walls of the pit. During further work, it is important not to damage the membrane.

Internal waterproofing

Internal waterproofing is usually the impregnation of walls with coating waterproofing. If possible, use a composition for swimming pools. It creates a waterproof, dense film that closely resembles rubber. It is blue in color and washes well after hardening. It is better to treat the walls with this composition twice, or more.

Another option is a cement-based deep penetration primer. The polymer particles contained in it block the capillaries through which moisture penetrates through the thickness of the material. One such treatment significantly reduces the hygroscopicity of the material. In the case of water in a garage pit, at least twice the treatment is required (and preferably more).

Caisson device

There is another option to escape from the ground - to make a metal caisson. A box of appropriate dimensions is made from sheet metal, treated with anti-corrosion compounds, and then installed in a pit. If the welds are made airtight, there will be no water, but another problem may arise. If there is a large amount of water, it can squeeze out the caisson. They say that it "pops up".

To avoid such a situation, corners and rods are welded to the sides of the caisson from the outside, which go 1-1.5 meters into the ground. So that the volume of excavation work is not very large (the foundation pit, taking into account these spacers, turns out to be large), you can cheat. Before installing the caisson, drive corners or metal rods into the ground, letting their ends out. You can weld them to the caisson body after installation. The pit will still have to be made larger (you need to cook it from the outside), but its dimensions will still be smaller. The second advantage of this method is that the rods will be driven into dense soil, which means they will hold the caisson better.

Another way to prevent the caisson from “floating up” is to make a hole in the wall at a certain height. If the water rises to its level, it will begin to pour inside. The water can subsequently be pumped out, the main thing is that everything remains in place. An inspection hole in the garage, built according to this principle, stood for more than 20 years - until the metal rusted.

Water collection pit

If the pit has already been built, and coating waterproofing or impregnation did not give the required result, it is necessary to either install a drainage system around the garage or collect water in one place. To do this, a pit is made in the garage inspection pit, at one of its ends. Water accumulates in it, from where it is pumped out. For the system to work in automatic mode, install a water presence sensor, which, when triggered, turns on the pump.

Formwork is made under the pit and filled with concrete. Then they waterproof the pit along with waterproofing the entire pit. For reliability, you can also put a metal caisson inside.

Since it is not possible to completely get rid of dampness in this case, a boardwalk is knocked down onto the floor of the pit. To prevent the boards from rotting, they can be soaked in waste. If you don’t like its smell, take a special impregnation for wood that has direct contact with the ground (Senezh Ultra, for example).

Insulation of the inspection pit in the garage

If you spend a lot of time in the garage, then you will most likely have heating. In order to warm up faster, it makes sense to insulate the pit. EPS (extruded polystyrene foam) is best suited for these purposes. It can withstand significant loads, is not afraid of dampness, does not rot, and fungi and bacteria do not multiply on it.

The thickness of the EPS to create a noticeable effect is from 50 mm. Place it between the soil and the wall of the pit. Then from the outside to the inside the pit will look like this:

Expanded polystyrene can also be placed under the screed at the bottom of the inspection hole. A reinforcing mesh is usually laid on top of it, and then concrete is poured.

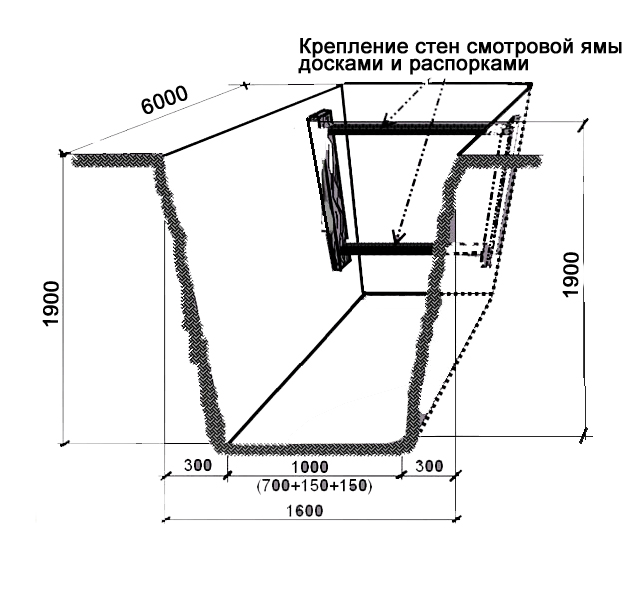

How to make a viewing hole in the garage

Once you have decided on the dimensions and what material you will make the walls from and how thick they will be, you can begin marking the pit. This can be done using pegs driven around the perimeter. The second option is to stretch a twine/rope between the stakes driven into the corners. According to the markings, we begin to dig a pit. The earth is usually taken out and temporarily stored near the gate.

Made of brick: step-by-step photo report

While excavating, monitor soil moisture. If you have reached the design depth (required + thickness of the floor screed), but there is still no moisture, you can do without waterproofing. Those who do not want to take risks can be advised to immediately lay down the film.

We level the walls. There is no need to achieve ideal geometry, but there should be no noticeable humps or holes. We also level the bottom of the pit and tamp it, compacting the soil well. A hand tamper is usually used. A layer of crushed stone is poured onto the bottom (twice 5 cm each), each layer is also carefully compacted. Next comes a layer of sand. 5 cm is enough. The sand is moistened and compacted to a high density so that the foot does not leave imprints. Next we lay the waterproofing film.

We even it out well, tucking it into the corners. We lay the panels with an overlap of 15 cm, which we glue with double-sided tape. To prevent the edges from rolling, we press with available materials - boards, stones.

We lay a layer of insulation on the bottom, and a reinforcing mesh of wire on top of it. We fill all this with concrete grade M 200. The thickness of the layer is at least 5 cm. To make it easier to navigate when laying, we make marks on the film by which you can control the thickness of the layer.

If you use Portland cement M 400, the proportions will be as follows: 1 part cement, 3 parts sand, 5 parts medium and fine crushed stone.

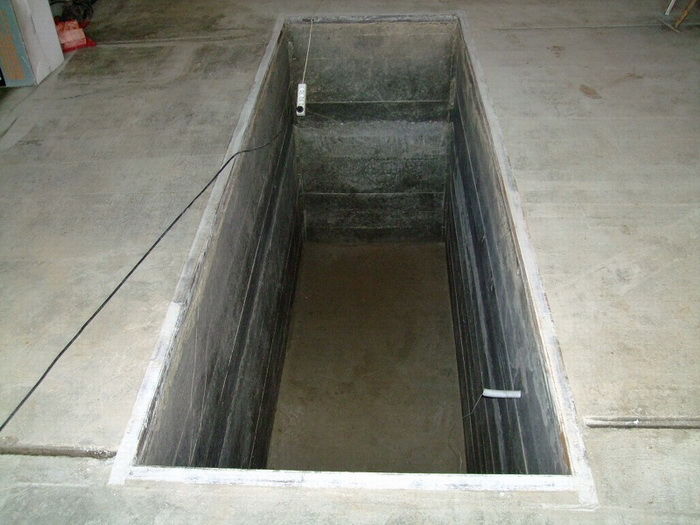

An inspection hole is being built in the garage: the floor is filled with concrete

We wait several days until the concrete gains 50% strength. The exact period depends on the temperature. If it is around +20°C, you will have to wait 5-6 days. If +17°C is already two weeks.

Let's start laying out the walls. It was decided to make it in half a brick. We used used bricks, about 850 pieces were used (pit size 4.2 * 0.8 * 1.7 m). The walls were laid out in a circle up to the level of the elbow.

It was decided to make a niche for the tool at a level of 1.2 meters from the floor. Its height is 3 rows of bricks, the top is covered with a treated board.

To avoid having to lay out a brick niche, a metal liner is inserted. A box is welded to suit the size.

Next, the walls were driven almost level with the garage floor. Part of the walls was replaced with two sections of channels. If necessary, jacks rest on the bottom. A metal corner with a 50 mm shelf, steel thickness 5 mm, is placed on the top row.

The corner is unfolded so that one of its shelves hangs down, the second covers part of the upper surface of the brick. To prevent the wall from collapsing under load, embeds are welded to this corner, which are then connected to the reinforcing belt of the concrete.

Pouring the floor in the garage - concrete level along the upper edge of the corner

Features of making concrete walls

When casting concrete walls Ok, you need to make formwork. It is easier to make it from sheet material - construction moisture-resistant plywood with a thickness of 16 mm or more, OSB. Shields of the required size are knocked down and reinforced with bars on the outside. They are necessary to prevent plywood or OSB from bending under the pressure of concrete. First, the outer parts of the formwork are installed. If the walls of the pit are smooth, there will be no problems. You simply lean them against them and place them level.

Then the internal formwork panels are installed. There should be a distance of at least 15 cm between them. To prevent the walls from deforming during the pouring process, spacers are placed between them.

It is advisable to fill the filling at one time. The poured portions must be bayoneted or treated with a submersible vibrator for concrete. The formwork is removed after two to three days. Afterwards, you can install a corner with welded embedded rods (strips) and begin pouring the floor.

The need for an inspection hole in the garage is obvious, since in cases of oil changes, minor repairs to the bottom of the body or a routine inspection, you have to set aside several hours to travel to the station Maintenance and pay for expensive services.

The pit for technical inspection of a car can also be used as a cellar or vegetable storage. For this purpose, niches and shelves are constructed inside it.

The condition for high-quality use of an inspection pit as a technical structure and a place for storing products is compliance with all construction standards and the presence of reliable waterproofing of the floor and walls.

Even this simple design requires careful planning of actions. An important point This involves determining soil quality and groundwater levels. The most suitable foundation for such structures is clay soil. Its peculiarity is that it does not allow moisture to pass through, which means it can become a kind of waterproofing layer.

If there is a large accumulation of groundwater and a high level of its location, the inspection pit is additionally equipped with a drainage system to remove excess moisture, as well as submersible pumps so that the room can be quickly drained.

The staircase will provide a convenient and safe descent

Step-by-step guide to making a viewing hole

You can install the inspection pit yourself. There is nothing complicated about this if you follow the detailed instructions.

How to determine size

To calculate the area of the future inspection pit, you need to take into account the thickness of the walls and base. For such calculations, it is necessary to remember the geometry course and resort to a simple formula that determines the area - S = ah, where a is the length, h is the width of the pit. The finished inspection pit will have dimensions of 75x185x300 cm. The thickness of the concrete walls and floor, as a rule, is about 10 cm. The calculations will be as follows: 0.85x3 = 2.55 m² - this is the area of the pit for the inspection pit.

Comfortable work in the inspection pit is created by a correctly calculated space, namely, its parameters should be convenient for the build of the person in it. Typically, the width of the pit is built in the range from 70 to 75 cm. This width is enough for you to move freely inside. The same distance between the walls makes the observation structure convenient for a passenger car to enter.

The pit may be wider if the inspection pit is intended for large or trucks. Distance between internal parties The wheels of such vehicles are much larger (from 80 to 90 cm).

The inspection pit is arranged in such a way that the walls are slightly narrower towards the floor. Schematically, in cross-section, its design resembles an inverted trapezoid. This shape provides convenient access to tools in niches and free movement.

The length of the inspection hole is selected based on the size of the garage. If the space of the room allows, then a staircase can be provided in the pit. To do this, the length of the pit is increased by 100–120 cm.

Depth of the pit “with reserve” for installing the floor

The height of the pit is at least 170–180 cm. These dimensions are relative, since the depth is made in accordance with the height of the car owner. While in the inspection hole, a person should not touch the bottom of the car with his head.

For additional security the vehicle and its owner, the inspection pit is equipped with metal limiters. They usually consist of four pillars fixed at the corners of a niche. They rise 10–15 cm above it. Sometimes for technical inspection, not four pillars, but two metal corners are used. They are fastened against each other along the edges of the length of the pit.

The depth should be 25–30 cm greater than the owner’s height. With such a distance from the base to the body, the arms will not get tired quickly, as this makes it possible for them to be in a bent position.

Materials and tools

Most often, concrete, wood, metal or brick are used for manufacturing.

To calculate the required amount of concrete, you must use a formula that determines the volume. To do this, you need to multiply the length, width and height of the wall. Similar calculations are carried out for the floor.

If brick is used in the construction of the pit, then, knowing its parameters, it is easy to calculate the required amount of this material in pieces. The dimensions of the red brick are 250x120x60 mm.

When building a viewing hole, you cannot do without the following tools:

- shovel and bayonet shovel;

- buckets for excavated earth and concrete mixture;

- trowels;

- welding machine;

- hacksaws.

The following materials are also required:

- bricks;

- cement, sand, crushed stone;

- M200 concrete for the base;

- boards with a section of 400x50 mm;

- reinforcing bars;

- metal corner 50 mm wide;

- waterproofing material.

Instructions for making an inspection pit from bricks, boards, concrete and iron

All work must be done in a strict sequence of steps:

Features of installation of partitions depend on the material used.

Concrete inspection pit

Before pouring the mixture, it is necessary to make formwork. For this, it is best to use OSB boards. This material does not allow the poured mixture to pass through and does not deform over time. The plates are fastened together using boards and screws so that the distance between them is at least 15 cm.

To maintain the shape of a wooden structure, it must be secured with spacers. Gaps in the joints of the slabs should be absent or minimal. A reinforcing mesh should be installed inside the finished formwork.

There is an option for pouring concrete with one-sided formwork. To do this, it is necessary to cover the walls of the pit with waterproofing material. Next, OSB boards are installed along the inner perimeter of the pit. A metal mesh is placed between them and the waterproofing. Concrete is poured inside this structure.

After the concrete has hardened, a monolithic structure is obtained.

Brick inspection pit

A waterproofing sheet is placed in the finished pit. It should completely cover the floor and walls. The canvas must be laid with an overlap. To prevent the edges of the material from lifting up, they are pressed down with boards. A half-brick masonry is made on top of the waterproofing. When the wall reaches a height of 135 cm, you can make niches and then continue laying to the top edge of the pit. On the last row It is recommended to install a metal frame from a corner, and it should be welded in such a way that one shelf on each side is parallel to the floor. Thick boards will be laid on it to cover the pit. Next, they pour the concrete floor in the garage.

Inspection pit made of metal sheets (caisson)

This design resembles a large box. During its manufacture, the sheets must be joined by continuous welding. The finished structure must be carefully treated with anti-corrosion coatings. The box should be equipped with fasteners. They are welded metal corners that rest 100–150 cm into the ground. They are attached to the body on four sides. They will hold the box in place. If this is not done, the entire structure will simply float when the groundwater level rises.

The staircase is made of the same material

Inspection pit made of wooden planks

Wood without proper treatment quickly rots. Therefore, the material must be impregnated with special antifungal substances and additionally waterproofed. It is better to take thick boards for walls. The material is installed horizontally. Spacers are secured along the edges of the narrow sides of the inspection hole.

For reliability, the bottom of the pit is made of concrete

Waterproofing device

This process is carried out both before the construction of the structure (external insulation) and after its construction (internal insulation).

If the garage is located on a plot with low level groundwater, many owners are in no hurry to isolate the inspection hole from moisture. However, the hydrological situation of any area changes every year, so it is recommended to take care of insulation at the construction stage. For this purpose, special films or membranes are used, for example, butyl rubber, aquaizol. They need to be laid in a pit. The edges of the material should be laid with an overlap of 10–15 cm. To obtain a sealed seam at the overlap, use double-sided tape.

When installing a film or membrane, it is important not to damage its integrity. Otherwise, moisture from the soil will enter the hole.

The laid waterproofing layer is melted using a blowtorch. As a result, the film straightens, fitting more tightly to the walls and bottom of the inspection pit.

The overlap of the material will prevent moisture from seeping into the pit

Do-it-yourself internal waterproofing of an inspection pit in a garage involves treating the surface of the finished inspection structure with liquid substances, which, when dry, form a dense water-repellent layer. The composition for treating swimming pools has proven itself well. It is applied with a thick, wide brush, and when it hardens, the substance forms a waterproof material resembling rubber. For greater reliability, more than two layers should be applied.

Insulating material can be applied using a spray gun

There is another way of internal insulation from moisture - this is the use of special cement-based primers, which tend to be deeply absorbed into the applied material. This effect is achieved thanks to the polymer particles that are in the mixture. They block capillaries that allow moisture to penetrate through the base material.

How to close a finished inspection hole

A covered inspection hole will not only protect the car from accidental failure, but will also serve as an additional waterproofing layer. In the absence of a cover, evaporated moisture settles on the lower parts of the car body, thereby creating favorable conditions for the formation of metal corrosion. To avoid similar problems The inspection hole is covered. For this purpose, sheets of metal or boards are used.

Wood is a relatively inexpensive and lightweight material. If necessary, the boards are easy to replace. They are selected from hard woods, such as oak and larch. Before use, the boards are coated with antifungal impregnations and antiseptic substances. They are placed in the openings of metal corners fixed at the top of the inspection hole. The thickness of each board must be more than 40 mm.

Most suitable option boards are for this purpose

Using metal is less convenient, since this material is heavy, expensive, and not resistant to corrosion. During use, its surface bends.

Video: DIY inspection hole in the garage

Step-by-step guide to building an insulated vegetable pit

The construction of a vegetable pit has its own characteristics.

Drawing

For a vegetable pit, both the presence of waterproofing and depth are important.

The place for storing vegetables must be below the freezing point. Otherwise, the point of storing food is lost, since it will be spoiled by low temperatures.

The freezing point depends on the region where the garage is located, for example, Vin the northern regions the ground freezes up to 150 cm. Taking this fact into account, you should dig a pit with a depth of at least 190 cm. From 10 to 15 cm must be allocated for the drainage layer under the base, another 10 cm is required to install the ceiling. 170–175 cm remains for placing shelves, racks and niches for vegetables and lighting. The depth also depends on the height of the owner.

Option with optimal sizes for this building

The optimal width of the pit for vegetables is 150 cm. This size allows you to optimally place shelves and racks, while a person will not be constrained in movement inside the pit. To select the length, you need to follow the rule - the pit should not reach closer than 50 cm to the walls of the garage.

Required materials and tools

To make a vegetable pit in the garage you will need the following materials:

- waterproofing sheet;

- reinforcing bars;

- sand;

- gravel;

- boards for formwork;

- metal corners;

- wire;

- bricks, metal sheets, boards or concrete M 250.

When building this structure, you cannot do without the following tools:

- bayonet and shovel;

- concrete mixers;

- containers for concrete mixture and water;

- blowtorch;

- double-sided tape;

- screwdriver.

Calculations of materials for the construction of a vegetable pit are similar to the inspection pit.

Manufacturing instructions

Having prepared everything necessary tools and materials, you can start building a vegetable pit:

Waterproofing device

The issue of insulating the inner surface of the cellar from moisture should be treated with particular care. This is important, since the slightest hole in the waterproofing will become a source of dampness and cause spoilage of vegetables.

You can proceed to this stage only if the concrete is completely dry. You will need a waterproofing sheet or aquaizol. This material must be used to cover the walls and floor of the vegetable pit. The canvas must be laid with an overlap of at least 15 cm. The joints are secured using a blowtorch or double-sided tape. All actions with the lamp should be carried out very carefully so as not to damage the canvas, otherwise moisture will get inside the vegetable pit. The same materials cover the outer part of the ceiling of the pit.

Making a viewing or vegetable pit in the garage with your own hands is not at all difficult. It is enough to listen to the recommendations of specialists and follow step-by-step instructions. If desired, these two rooms can be combined.

If you want to arrange your garage in such a way that it has maximum functionality, then its space must be supplemented with an inspection hole. At the same time, you can not only store your car in it, but also store things, repair and inspect the car.

Features of the inspection pit

If you are installing an inspection hole in the garage with your own hands, you need to choose the dimensions at the first stage. But it’s important to think about whether you really need such a component. Two decades ago, the presence of this element in the garage was not discussed, but with the development of service stations, a category of car owners appeared who did not see the point in servicing the car themselves. An inspection hole in the garage can be made from iron with your own hands. But if you don’t want to waste time and effort on your own technical inspection, then you won't need it. Some argue that a recess in the garage can negatively affect the elements of the car, because fumes rise from the bottom. This is only true if the work is not carried out using technology. After all, it is important to insulate the pit and make it convenient for your own use. By providing the underground space with a sealed lid, you can be sure that even a poorly insulated pit will not be a source of fumes.

When it is not possible to equip a viewing hole

An inspection hole in a garage cannot be equipped with your own hands in all cases. This will depend on the groundwater lines. If their level is above 2 meters, then carrying out such work will be impractical, this is due to the fact that the space will be filled with water. But if necessary, even the most critical conditions can be overcome by having a good drainage system, as well as high-quality waterproofing. A do-it-yourself inspection hole in a garage is often built from concrete; it also needs to be supplemented with drainage, but this task is quite complicated and should only be done by knowledgeable people at the stage of constructing the garage. If you have to create this system on existing buildings, this may require a large amount of effort and resources. Among other things, such manipulations are not always effective.

If the occurrence of groundwater under an existing building indicates that the pit should be abandoned, then this hint must be heeded. An alternative solution may be to equip a recumbent pit, which may well replace a full-fledged one in some cases. If you are installing an inspection hole in the garage with your own hands, then you need to invite the appropriate specialists who will be able to analyze the level of groundwater. If you decide to spend the least amount of money on these manipulations, then you can carry out the check yourself, but it will take much more time. To do this, you should dig a pit, but you should not immediately concrete it. We need to wait for the flood season; heavy rain will do. After this, you will be able to assess its consequences.

Dimensions of inspection hole

If you think that the inspection hole is a fairly standard part of the garage, you may be mistaken. Such a device may have several options. It can be combined with a cellar and basement, make a narrow recess that will be operated with the help of an extension ladder, and also arrange a recumbent pit, which was mentioned above. Dimensions should be selected depending on the craftsman who will most often use the pit. It is important to take into account the size of the car, as well as its intended placement. The width should not be less than 80 centimeters, as optimal parameter You can choose 1 meter. The depth of the pit should measure from 1.8 to 2 meters. This parameter is the most important, and it will depend on the person’s height. The most suitable option is considered to be a depth that is 15 cm greater than the height of the master. Most often, a size within 2 meters is used as the length. If you are installing an inspection pit in the garage with your own hands, then when planning it is necessary to take into account that the mentioned indicators are not given for the pit itself. It must be dug with allowances of 50 cm for width and length. As for the depth, it needs to be increased by 25 cm. If you plan to insulate the walls, then the dimensions of the pit must be increased by the width of the insulation, most often this figure is 50 millimeters.

Floor arrangement

After the pit has been prepared taking into account the selected dimensions, you can start working on the floor. If you approach construction competently, then issues with dampness will not arise during operation. Thus, it is necessary to take into account that the inspection hole in the garage, equipped with your own hands, must be equipped with ventilation. To do this, a hole is left in the floor through which a flexible hose is inserted underground and onto the surface. It is an air duct onto which a cover is placed. Initially, it is necessary to fill in the concrete preparation. It will be represented by two layers, the first of which assumes the presence of gravel, while the second - sand. The first layer is filled with a thickness of 10 centimeters, the second - 5 centimeters. Each of them should be watered and well compacted. The floor surface should be treated with clay and a layer of waterproofing should be laid. Next, the reinforcement is installed and concreting is carried out. As soon as the layer of mortar gains its strength, another layer of waterproofing should be applied, only after which the master can begin finishing.

Alternative flooring option

If you don’t want to bother yourself too much, then you can take the easier route; to do this, just line the bottom of the inspection hole with bricks. However, this approach can be considered rational only if the groundwater is located at a sufficient depth. This is due to the fact that good waterproofing cannot be achieved.

Selection of materials for waterproofing

If you set up a homemade inspection hole in your garage with your own hands, you can choose its dimensions yourself. However, it is important to think about waterproofing. There are a great variety of such materials on the market, but please note that the one you choose must be effective. This is especially important for the reason that the pit will be subject to severe stress due to excess moisture. However, it is important to exclude the option of overpayment. Based on the above considerations, from a number of commercially available materials, polymer membranes, which are presented in a single-layer version, can be especially distinguished. Their thickness can vary from 1.5 to 2 millimeters. As for double-layer membranes of this type, their maximum thickness can be 3.1 millimeters. This material is characterized by resistance and durability. But it has the most impressive price compared to others. Or rather, installation will be expensive, which requires the presence of special tools and certain skills.

If you want to save money, you should choose bituminous materials, these include roofing felt and bitumen lubricant. They are quite easy to install, but you should not count on a service life that exceeds 20 years. A self-constructed inspection hole in a garage, the dimensions of which were mentioned above, can be waterproofed with bitumen components. The material is sold in rolls, you can cut it to the required dimensions, and then glue it with an overlap of 15 cm. You can glue it by heating or using a bitumen solvent. An alternative solution to the two above methods is considered to be a waterproofing lubricant. It was invented relatively recently and is inexpensive. It's quite easy to apply. The surface must be damp, then the material will completely saturate the concrete and protect it from excess moisture.

Insulation of inspection pit

A do-it-yourself inspection hole in a garage (photos of which are presented in the article) is rarely insulated. Experts say that inexperienced craftsmen needlessly neglect this manipulation.

This is especially true for those garages that are heated. If you provide thermal insulation, you will minimize heating costs.

The insulation must be glued to brick or concrete, after which the walls and floor can be subjected to decorative finishing. If, when carrying out waterproofing work, you may doubt the choice of a certain material, then experts advise using polystyrene foam as insulation. However, it is important to consider the labeling. Thus, PSB-S-35 is perfect for the floor, while PSB-S-25 can be used for the walls.

Construction of walls

If you are installing a homemade inspection hole in the garage, then you can choose one of the two most common solutions for its walls. One of them involves the use of concrete, while the other involves the use of brick. If desired, both options can be plastered or tiled, as well as fiberglass. The preparation before using concrete or brick looks the same. The surface of the walls is covered with a layer of clay, which is covered with dense polyethylene. At the next stage, the formwork is installed; the thickness should be fifteen centimeters.

When making a homemade inspection hole in a garage with your own hands, the construction of walls must be accompanied by the fulfillment of two conditions. One of them requires the presence of a safety rail. Its task is to prevent the car wheel from falling into the hole. Among other things, it prevents water from getting from the wheels directly into the pit. It should be made in the form of a plank, which resembles the shape of the letter T. It is based on metal, and the element must be strengthened to the formwork, placing it flush with the floor surface. This strip will act as a support for the lid. Additional components include niches and ledges in the wall; they will become shelves for various tools and necessary things. The master will be able to evaluate the convenience of such protrusions the first time the pit is used for its intended purpose.

Lighting

If you build an inspection hole in the garage with your own hands, it simply needs lighting. Some craftsmen are against having lighting fixtures inside. A number of car enthusiasts use portable lamps that have a powerful battery. However, if you take into account the level of comfort, then the presence of internal lighting is worth considering. If you want to arrange everything according to the rules, then you should be guided by SNiP, which indicate that the voltage in the socket inside the pit should not exceed 36 V. You can find special lamps for this voltage. Using standard 220 volts inside is strictly prohibited, as they can become a threat to life.

Pit cover

When you set up an inspection hole in the garage with your own hands, you can create a reliable cover from the boards. To do this, use wood whose thickness is 50 mm. However, a thickness of 35 millimeters will be sufficient. This is due to the fact that the boards will not experience constant load. The cover can be made from different materials, this will depend on what the edging of the pit was formed from. If it is a steel corner, then the cover can be made from several panels. Small rollers can be fixed at their bottom. Shields can be formed from wooden planks, the width of which varies from 30 to 35 millimeters. When you make an inspection hole in a garage with your own hands from brick, the lid can be formed according to the roller shutter principle. To do this, you should use boards whose thickness is 40 millimeters, while the length will correspond to the width of the pit. On each board, you need to make grooves at both ends into which the steel cable is threaded. Springs should be installed between it and the bar to ensure mobility. The cable is fixed on the last board, while a handle is installed at the opposite end. You will only need to pull it a little, which will allow you to open the pit as much as necessary to carry out a certain type of work. In general, almost all materials can be used to make any part of the pit and its components.

Correct arrangement holes in the garage– this is the car owner’s confidence that in the event of a simple breakdown, with basic knowledge of car mechanics, he will be able to save on visiting a service station.

And this is today, and in the midst of another protracted economic crisis, with our broken roads leading to breakdowns, this is simply a necessary condition.

But how to make a hole in the garage with your own hands and is this possible when the garage has already been built? We will answer all these questions later in the article.

In contact with

Do-it-yourself inspection hole in the garage: planning

Before you build inspection hole in the garage with your own hands, let's figure out what it is.

Inspection hole– this is the working space of the motorist, which should be as comfortable as possible, allowing him to turn around and stand in full height. If these conditions are not met, fixing even a tiny problem will turn into a nightmare, which should not be allowed to happen.

How to properly make a hole in the garage?

First of all, we must measure the length, width and depth in order to find out inspection hole dimensions in the garage with your own hands.

Parameter length calculated based on the length of the machine. Add one meter to it, it will be optimal space, convenient for work.

The second parameter again directly depends on the dimensions vehicle. On average, this is 75 cm, but professionals also use another way to measure the optimal width: you need to measure how far the front wheels are from each other. 20 cm is subtracted from the obtained value to be sure that when entering the pit, the car won't fail.

IMPORTANT: Before making a hole in the garage, keep in mind that its width should be slightly less than the width of your vehicle, otherwise the car will simply fall through.

And finally, the last parameter - depth. It is calculated based on the driver’s height, to which 20 cm is added. The obtained parameters must be increase by 30 cm, which will constitute hydro- and thermal insulation. After calculation you can make drawing holes in the garage.

Do-it-yourself inspection hole in the garage: dimensions - photo below:

Having received the required dimensions, we begin construction. inspection hole in the garage with your own hands. Of course, it is much easier to build an inspection pit when the garage has not yet been built; here you need to do this work before the floors are poured with concrete, but even when you think about how to make a garage with a pit with your own hands, this question is quite we decide.

Construction work consists of the following:

- Preparing the pit. We mark the land plot according to the obtained dimensions. Before digging a hole in the garage, we stock up on shovels and a level. The hole must be of the required depth and have a flat bottom.

- Formation of smooth walls. It is also necessary to carefully compact the bottom of the pit.

- Arrangement inspection hole in the garage: floors, walls and niches.

REFERENCE: How to make a viewing hole in a garage when it has already been built? We mark the floor, and then, according to the markings, using a power tool we cut through the screed, after which the digging work is carried out.

We build a hole in the garage with our own hands step by step:

We lay a cushion of crushed stone on the ground, on top of which we pour sand about 5 cm and compact it.

The next layer in this “pie” is 30 cm clay. A reinforced mesh is already placed on the clay, which becomes the backbone of our structure, strong, reliable, durable.

The mesh is poured concrete. We mix sand and cement in a ratio of three to one and pour it 7 cm thick.

We wait for the concrete to harden and only after that we treat the floor bitumen mastic solution. We put roofing felt and glue the joints with bitumen, be sure to hot.

Foam plastic is laid on the roofing material, and then the entire structure is generously filled with concrete, about 15 cm. And again we wait until the concrete dries.

After the concrete has dried, you can begin for the design of walls and niches:

- The walls are coated with clay, then polyethylene is laid, which adheres well to fatty types of clay.

- A layer of roofing material is applied to the film and again, as in the case of the floor, we go through the joints with bitumen.

- We repeat the technology for creating the floor, and attach a layer of foam plastic to the walls, using any construction adhesive.

- The hardest part of the job is erection of formwork. The formwork is made from plywood; if you want to get a more durable structure, then from boards, at a distance of 7 cm from the walls.

- We reinforce the perimeter of the wall and fill it with concrete mortar.

You need to pour concrete in layers, here you need to be guided rule, the quieter you go, the further you'll get. You need to fill the hole in the garage within a few days, every day - 20 cm in height.

When the concrete has hardened and you are satisfied with the result, remove the formwork, we don't need it now. Well, we are moving on to the next stage, creating niches.

As in the construction of floors and walls, when constructing niches, we use fittings And clay. But here we no longer need concrete, we will have an inspection hole in the garage with our own hands made of brick, with which niches are lined. If you don’t like this option and you are interested in another way to lay out the inspection hole in the garage, then use ceramic tiles, it will be more effective.

See how to do it DIY inspection hole in the garage- photo:

Before making a hole in the garage, you also need to take care of waterproofing, because humidity is unacceptable in the inspection pit, where, not only do you need to work in comfortable conditions, but it is also important to observe safety precautions when working with electrical appliances in the car.

Today we can choose from a wide range of materials:

Polymeric. This is a material with a complex synthetic structure and excellent waterproofing properties. There are two types: multilayer And single-layer, the first have best qualities and can last much longer, up to fifty years, the latter are cheaper. Polymer waterproofing is laid on reinforcement with cells of size 10x10.

We must cover the frame geotextiles. Polymer plates, if they have a self-adhesive base, are installed with an overlap of 30 cm; if the membranes are not self-adhesive, then the overlap is 10 cm. The joints between the polymer plates are necessarily treated with a special adhesive.

Bituminous. This waterproofing option is available in several types: rubemast, euroruberoid And roofing felt, each is interesting in its own way, each has its own pros and cons.

Installation bitumen insulation, perhaps the simplest, in addition, this material is classified as economical, although its service life is much lower, only 10 years; if the work is done efficiently, the shelf life increases to 15 years, but no more.

Installation bitumen insulation, perhaps the simplest, in addition, this material is classified as economical, although its service life is much lower, only 10 years; if the work is done efficiently, the shelf life increases to 15 years, but no more.

Bitumen insulation is applied in a double layer.

Dry mixes. This is one of the modern methods of isolation. It is effective, durable, and allows you to eliminate even microscopic cracks in walls and floors, which increases the service life of the inspection pit. The mixtures, diluted with water in the consistency indicated on the packaging, are applied to the concrete layer.

If dry mixes- this is a modern method, which, however, is often used as additional insulation supporting another, polymer or bitumen, then mixture of clay and petroleum products- This is the oldest method of insulation. It is good because it is easy to carry out work and requires minimal financial costs.

The disadvantage of this method is that petroleum products toxic, and experts do not recommend working for a long time in a pit treated with such a composition.

IMPORTANT: do not forget to always glue the joints, whether it is a polymer material, bitumen or some other. Failure to comply with this condition may result to the destruction of the entire structure and the nullification of your labors.

Thermal insulation is an equally important issue, because in our country warm weather is established only for five months, while the rest of the time there is rain, cold and bitter frosts.

At installation of an inspection pit in the garage, the material can act as a durable, effective insulation polystyrene. The positive properties of the material are minimum percentage water absorption, versatility, excellent thermal insulation characteristics. The downside is that it is not durable, about 10 years.

Finishing touches

As finishing touches we will designate:

- safety (iron grate on the pit);

- niches;

- lighting;

- ventilation.

Safety involves installing an iron grate on the pit.

Inspection hole in the garage - how to close it? Under no circumstances should it be always open. You may think, forget, not see... the consequences of such inattention are usually disastrous. Therefore it's better trellis during the absence of repairs to the inspection hole in the garage.

Niches in the wall are needed to store tools in them, so as not to have to run upstairs every time for pliers or a screwdriver. The niches also serve as room decor, creating an atmosphere indescribable in words that is conducive to work.

For lighting It is necessary to carry out wiring and install sockets in the wall. You can, of course, use a portable lamp, but it will not be as convenient and aesthetically pleasing.

Ventilation- one of the main issues in the design of an inspection pit, because it is often necessary to use toxic substances, varnishes, paints, which are unacceptable to breathe in a closed room. Therefore, give the issue of ventilation a significant part of your attention.

In addition, ventilation is needed to eliminate the possibility of creating condensation effect: high humidity can lead to destruction of the inspection hole and damage to the car and electrical tools. Ventilation can be built by installing an air vent. Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!