The temperature of gases in the cylinders of a running engine reaches 1800-2000 degrees. Only part of the heat released in this case is converted into useful work... The remainder is discharged into the environment by the cooling system, lubrication system and the outer surfaces of the engine.

An excessive increase in engine temperature leads to burnout of the lubricant, disruption of the normal gaps between its parts, which results in a sharp increase in their wear. There is a risk of seizing and seizing. Overheating of the engine causes a decrease in the cylinder filling ratio, and in gasoline engines also detonation combustion of the working mixture.

A large decrease in the temperature of a running engine is also undesirable. In a supercooled engine, power is reduced due to heat loss; the viscosity of the lubricant increases, which increases friction; part of the combustible mixture condenses, washing off the lubricant from the cylinder walls, thereby increasing the wear of parts. As a result of the formation of sulfur and sulfur compounds, the cylinder walls are corroded.

The cooling system is designed to maintain the most favorable thermal conditions. Cooling systems are divided into air and liquid. Air is nowadays extremely rare in cars. Systems liquid cooling can be open and closed. Open systems - systems that communicate with the environment through a steam pipe. Closed systems are disconnected from environment, and therefore the pressure of the coolant in them is higher. As you know, the higher the pressure, the higher the boiling point of the liquid. Therefore, closed systems allow heating the coolant to higher temperatures (up to 110-120 degrees).

By the way the liquid circulates, the cooling system can be:

- forced, in which the circulation is provided by a pump located on the engine;

- thermosiphon, in which the circulation of the liquid occurs due to the difference in the density of the liquid heated by the engine parts and cooled in the radiator. During engine operation, the liquid in the cooling jacket heats up and rises to its upper part, from where it enters the upper radiator tank through a branch pipe. In the radiator, the liquid gives off heat to the air, its density increases, it goes down and returns to the cooling system through the lower tank.

- combined, in which the most heated parts (cylinder heads) are cooled forcibly, and the cylinder blocks are cooled according to the thermosiphon principle.

Cooling system device

Most widespread in automobile internal combustion engines got closed fluid systems with forced circulation of coolant (coolant). Such systems include: a jacket for cooling the block and cylinder head, a radiator, a coolant pump, a fan, a thermostat, pipes, hoses, an expansion tank. The cooling system also includes a heater radiator.

The coolant in the cooling jacket, heated by the heat generated in the engine cylinder, enters the radiator, cools in it and returns to the cooling jacket. The forced circulation of the liquid in the system is provided by a pump, and its enhanced cooling is due to the intensive blowing of air into the radiator. The degree of cooling is regulated by a thermostat and by automatically turning on or off the fan. Liquid is poured into the cooling system through the radiator neck or expansion tank. Cooling system capacity passenger car, depending on the engine size - from 6 to 12 liters. The coolant is drained through the plugs located usually in the cylinder block and the lower radiator reservoir.

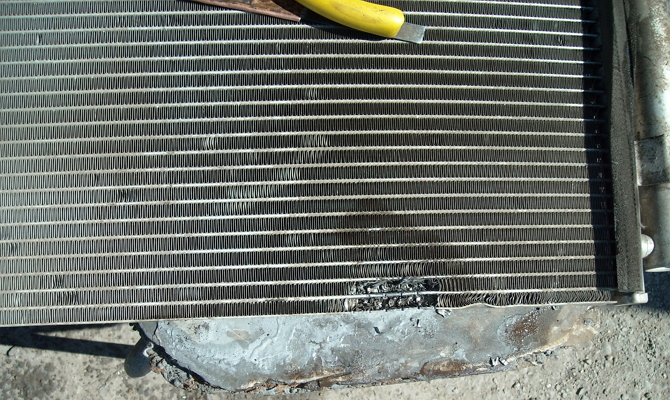

Radiator gives off heat from the coolant to the air. It consists of a core, upper and lower tanks and mounting parts. For the manufacture of radiators, copper, aluminum and their alloys are used. Depending on the design of the core, radiators are tubular, plate and honeycomb. The most widely used are tubular radiators. The core of such radiators consists of vertical tubes of oval or circular cross-section passing through a row of thin horizontal plates and soldered to the upper and lower radiator tanks. The presence of fins improves heat transfer and increases the rigidity of the radiator. Tubes of oval (flat) cross-section are preferable to round ones, since their cooling surface is larger; in addition, if the coolant freezes in the radiator, the flat tubes do not break, but only change the shape of the cross-section.

In plate radiators, the core is arranged so that the coolant circulates in the space formed by each pair of plates welded together along the edges. The upper and lower ends of the plates are also soldered into the holes of the upper and lower radiator reservoirs. The air that cools the radiator is sucked in by the fan through the passages between the brazed plates. To increase the cooling surface, the plates are usually wavy. Plate radiators have a larger cooling surface than tubular ones, but due to a number of disadvantages (rapid contamination, a large number of soldered seams, the need for more careful maintenance) they are used less often.

In the core of the honeycomb radiator, air flows through horizontal, circular tubes that are washed outside by the coolant. To make it possible to solder the ends of the tubes, their edges are expanded so that in cross-section they have the shape of a regular hexagon. The advantage of cellular radiators is a large cooling surface compared to other types of radiators.

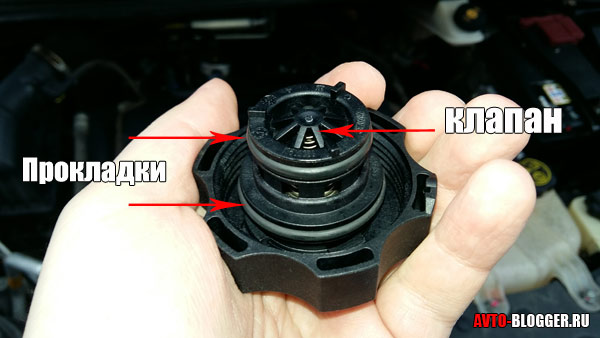

A filler neck, closed with a plug, and a branch pipe for connecting a flexible hose supplying coolant to the radiator are soldered into the upper tank. On the side, the filler neck has an opening for a steam pipe. A branch pipe of the discharge flexible hose is soldered into the lower tank. The hoses are secured to the nozzles with tie straps. This connection allows for relative displacement of the engine and radiator. The neck is hermetically sealed by a plug that isolates the cooling system from the environment. It consists of a body, a steam (outlet) valve, an air (inlet) valve, and a closing spring. If the liquid in the cooling system boils, the vapor pressure in the radiator increases. When a certain value is exceeded, the steam valve opens and steam is released through the steam outlet pipe. After stopping the engine, the liquid is cooled, the vapor condenses and a vacuum is created in the cooling system. This creates a risk of crushing the radiator pipes. To prevent this phenomenon, an air valve serves, which, when opened, lets air into the radiator.

To compensate for changes in the volume of coolant due to temperature changes in the system, a expansion tank... Some radiators do not have a filler neck and the system is filled with coolant through an expansion tank. In this case, steam and air valves are located in its traffic jam. The labels on the expansion tank allow you to monitor the coolant level in the cooling system. The level check is carried out on a cold engine.

Coolant pump ensures its forced circulation in the cooling system. The centrifugal pump is installed at the front of the cylinder block and consists of a housing, a shaft with an impeller and an oil seal. The pump casing and impeller are cast from magnesium, aluminum alloys; the impeller, in addition, is made of plastics. The pump is driven by a belt from the engine crankshaft pulley. Under the action of the centrifugal force arising from the rotation of the impeller, coolant from the lower radiator tank enters the center of the pump housing and is thrown to its outer walls. From a hole in the wall of the pump housing, coolant flows into the hole in the cooling jacket of the cylinder block. The leakage of coolant between the pump housing and the block is prevented by a gasket, and an oil seal at the shaft exit.

To enhance the air flow through the radiator core, a fan... It is mounted either on the same shaft with the coolant pump, or separately. It consists of an impeller with blades screwed to the hub. To improve the air flow to the engine and radiator, a guide casing can be installed on the latter. The fan can be driven in several ways. The simplest is mechanical, when the fan is rigidly fixed on the same axis with the coolant pump. In this case, the fan is constantly on, which leads to unnecessary consumption of engine power. In addition, the fan works even in non-optimal modes, for example, immediately after starting the engine. Therefore in modern engines this connection is not used, and the fan is connected to the drive through a coupling. The design of the clutch can be different - electromagnetic, frictional, hydraulic, viscous (viscous coupling), but they all provide automatic switching on fan when a certain coolant temperature is reached. This inclusion provides a temperature sensor. Moreover, the use of a fluid coupling and a viscous coupling makes it possible not only to automatically turn on and off the fan, but also to smoothly change its rotation frequency depending on the temperature.

The fan can be driven not by the engine crankshaft, but by a separate electric motor. Such a connection is used most often, since it makes it quite simple to carry out automatic regulation of the on and off moments using a thermistor sensor (its electrical resistance changes depending on heating). If the operation of the cooling system is controlled by the engine controller, then it becomes possible to change the speed. In addition, the fan “reacts” to driving modes. For example, it turns on on idling when driving in traffic jams to prevent overheating and turns off when driving out of town on high speedwhen the natural airflow of the radiator is sufficient to cool it.

During the engine start-up period, in order to reduce wear, it is necessary to warm it up faster to the operating temperature and maintain this temperature during further operation. To accelerate engine warm-up and maintain its optimal temperature thermostat... The thermostat is installed in the cylinder head cooling jacket on the path of fluid circulation from the jacket to the upper radiator tank. Cooling systems use liquid and solid filled thermostats.

The liquid filled thermostat consists of a body, a corrugated brass cylinder, a stem and a double valve. Inside the corrugated brass cylinder, a liquid is poured, the boiling point of which is 70-75 degrees. When the engine is cold, the thermostat valve is closed and circulation occurs in a small circle: coolant pump - cooling jacket - thermostat - pump.

When the coolant heats up to 70-75 degrees in the corrugated cylinder of the thermostat, the liquid begins to evaporate, the pressure rises, the cylinder, expanding, moves the stem and, lifting the valve, opens the way for the liquid through the radiator. At a liquid temperature in the cooling system of 90 degrees, the thermostat valve opens completely, at the same time the beveled edge closes the liquid outlet into a small circle, and circulation occurs along a large circle: pump - cooling jacket - thermostat - upper radiator tank - core - lower radiator tank - pump.

A solid-filled thermostat consists of a housing, inside which is a copper balloon filled with a mass of copper powder mixed with ceresin. The top is closed with a lid. A diaphragm is located between the cylinder and the cap, on top of which there is a stem acting on the valve. In a cold engine, the mass in the cylinder is solid and the thermostat valve is closed by a spring. When the engine warms up, the mass in the cylinder begins to melt, its volume increases and it presses on the diaphragm and stem, opening the valve.

The coolant temperature is monitored by the temperature gauge and by means of the engine overheating warning lamp on the instrument panel. Control warning light and the pointer is implemented by sensors screwed into the upper radiator tank and into the cylinder head cooling jacket.

Water (in outdated engine designs) or antifreeze can be used as a coolant. The quality of the coolant used for the engine cooling system is no less important for the durability and reliability of its operation than the quality of fuel and lubricants.

Antifreeze - coolants for the car cooling system, which do not freeze at negative temperatures. Even if the ambient temperature is below the minimum operating temperature of the antifreeze, it will turn not into ice, but into a loose mass. With a further decrease in temperature, this mass will harden without increasing in volume and without damaging the engine. Antifreeze is based on an aqueous solution of ethylene glycol or propylene glycol. Propylene glycol base is used less frequently. Its main difference is harmlessness to humans and the environment, but also a higher price with the same consumer qualities. Ethylene glycol is aggressive to engine materials, so additives are added to it. There can be up to a dozen of them in total - anti-corrosive, anti-foaming, stabilizing. It is the set of additives that determines the quality and scope of antifreeze. By the type of additives, all antifreezes are divided into three large groups: inorganic, organic, and hybrid.

Inorganic (or silicate) - the most "ancient" liquids, in which silicates, phosphates, borates, nitrites, amines, nitrates and their combinations are used as corrosion inhibitors. This group of antifreezes also includes the widespread Tosol in our country (although many mistakenly consider it a special type of coolant). Their main drawback is a short service life due to the rapid destruction of additives. Degraded additive components form deposits in the cooling system, impairing heat transfer. The formation of silicate gels (clots) in the coolant is also possible.

In the most modern organic (or carboxylate) antifreezes, additives based on carboxylic acid salts are used. Such antifreezes, firstly, form a much thinner protective film on the surfaces of the cooling system, and secondly, inhibitors act only in places where corrosion occurs. Consequently, the additives are consumed much more slowly, thereby significantly increasing the life of the antifreeze.

Hybrid antifreezes occupy an intermediate position between organic and inorganic antifreezes. Their additive package mainly includes carboxylic acid salts, but also a small proportion of silicates or phosphates.

Antifreezes are available either as concentrates or as ready-to-use liquids. The concentrate must be diluted with distilled water before use. The proportion is determined by the required minimum freezing point of the antifreeze. The base of antifreezes is colorless, so manufacturers paint them in different colours using dyes. This is to make it easier to control the level of antifreeze and to warn about the toxicity of fluids. Color matching is not always indicative of antifreeze compatibility.

In modern engines, the engine cooling system can be used to cool exhaust gases in their recirculation system (EGR), cool oil in automatic box gear, turbocharger cooling. Some engines with direct injection fuel and turbocharged have a dual-circuit cooling system. One circuit is for cooling the cylinder head, the other for the cylinder block. In the cylinder head cooling circuit, the temperature is maintained 15-20 degrees lower. This improves the filling of the combustion chambers and the mixture formation process, and also reduces the risk of knocking. The circulation of liquid in each of the circuits is controlled by a separate thermostat.

The main malfunctions of the cooling system

External signs of malfunctions in the cooling system are overheating or overcooling of the engine. Engine overheating is possible as a result following reasons: insufficient coolant, poor tension or breakage of the coolant pump belt, failure of the clutch or fan motor, the thermostat stuck in the closed position, a large amount of scale deposits, heavy dirt on the outer surface of the radiator, malfunction of the outlet (steam) valve of the radiator plug or expansion tank, coolant pump malfunction.

A stuck thermostat in the closed position stops fluid circulation through the radiator. In this case, the engine overheats and the radiator remains cold. An insufficient amount of coolant is possible if it leaks or boils away. If the coolant level has dropped as a result of boil-off, add distilled water, if the liquid leaks out, add antifreeze. You can open the cap of the radiator or expansion tank only when the coolant has cooled down enough (10-15 minutes after stopping the engine). Otherwise, the pressurized coolant may spill out and cause burns. Leakage of liquid occurs through leaks in the connections of the pipes, cracks in the radiator, expansion tank and cooling jacket, if the coolant pump oil seal, radiator plug is damaged, or the cylinder head gasket is damaged. When operating a car, it is necessary to monitor not only the level, but also the condition of the antifreeze. If its color turns reddish-brown, it means that the system parts are already corroding. Such antifreeze must be replaced immediately.

Overcooling of the engine can occur due to a jammed thermostat in the open position, as well as in the absence of insulation covers in winter time... If the closed cooling system is leaking, then high blood pressure it does not create and the engine does not warm up to operating temperature. And since the engine does not warm up, the ECU constantly enriches the mixture. Thus, a leaky cooling system increases fuel consumption. The systematic operation of the engine on a rich mixture leads to oil dilution, an increase in carbon formation, and a rapid failure of the catalytic converter.

The cap of the expansion tank of the car's engine cooling system, as a rule, does not raise suspicions of serviceability. This, as many people think, very "modest" in its importance, the detail is entrusted with a very important task - to regulate the pressure in the cooling system. When the lid is no longer able to handle it, the best case liquid will boil or flow out, and at worst, it will lead to breakage of some units.

What is the main role of the tank cap?

A running engine, as is known, creates a pressure in the cooling system that differs from the usual atmospheric pressure. This happens due to the fact that (coolant) heats up together with the motor, as a result of which it expands - increases in volume. As a result, the pressure inside (SOD) increases, and it is not in contact with the external environment, and it has nowhere to relieve excess pressure.

With increased pressure in the SOD developers modern cars do not fight "radically" - do not try to get rid of it completely. It is adjusted with the help of the tank lid. The increased pressure in the SOD is used to shift the boiling point of the coolant. After all, it is no secret to anyone that at normal atmospheric pressure for water it occurs at a temperature of 100 ° C, for antifreeze - 105-110 ° C, and for antifreeze - 120 ° C. The operating temperature of modern car engines is very close to these critical values.

So, for example, for carburetor VAZ it should be in the range of 90–95 ° C, and for injection - 97–105 ° C.

However, in some operating modes of the engine, its temperature rises for a short time to higher values, which, however, does not lead to the failure of a serviceable motor, but causes the same heating of the coolant. For example, on injection VAZ 2109, the liquid at such moments can be 120-125 ° C. Obviously, even antifreeze will not tolerate such heating. At the same time, an increase in the pressure of any liquid leads to an increase in its boiling point.

Engineers who design engines have long found out that so that the coolant does not boil even with a short-term critical heating of the engine, it is enough to maintain the pressure in the SOD at the level of 1.1–1.5 kgf / cm 2 (1.1–1.5 bar). A higher temperature is not needed, because the engine is not designed for it, and it will lead to its failure. And it makes no sense to allow a greater spontaneous increase in pressure, which can nevertheless occur, because it will complicate the process of manufacturing and servicing the motor, as well as an increase in its cost, since it will require a more durable and sealed SOD (more durable pipes and expansion tank, strong clamps).

Therefore, the tank lid must be sealed, but only up to the required pressure limit values \u200b\u200bindicated above, after reaching which it maintains them, connecting the system with the external environment as necessary to release the air compressed inside the expansion tank.

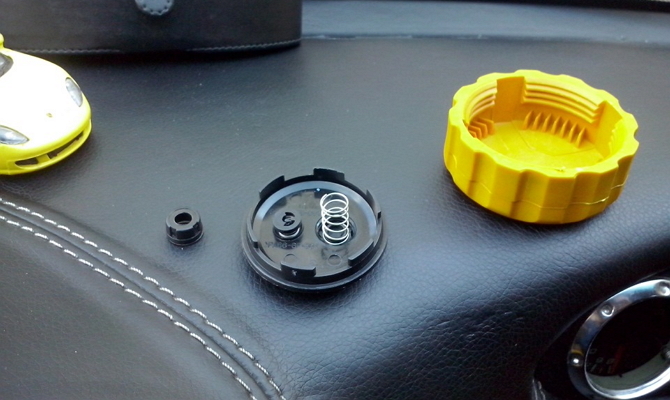

The device and principle of operation of the expansion tank cover

In order for the necessary pressure to be created in the SOD when the engine is running, the lid device ensures a tight hermetically sealed tank. A safety valve is provided to relieve excess pressure. It works (opens) only when the pressure inside the POD becomes 1.1–1.5 kgf / cm 2 (depending on the design of the cover and its manufacturer).

While it is lower, the valve is closed, and immediately after the excess pressure is released to a value that is less than the value indicated above - the partial release of the air compressed in the tank - it closes. There is one more valve in the lid - an inlet valve, it is also called a vacuum valve. Its purpose is directly opposite to the safety one. The inlet valve serves for intake (suction) of air into the SOD. The fact is that after stopping the engine, it, as you know, begins to cool down. The coolant temperature also drops.

At the same time, it decreases in volume, which is accompanied by a decrease in pressure inside the SOD. The coolant that entered the tank, with its own heating, begins to go back into the system, making room for the air remaining in the expansion tank and ceasing to press on it. Then the moment comes when the pressure in the SOD is compared with the external atmospheric one. If at the same time the coolant temperature turns out to be higher than in the external environment, then it, continuing to cool, will further decrease in volume.

This will lead to the fact that the pressure in the SOD will become below atmospheric, that is, to a vacuum, a vacuum effect. Outside air will put pressure on the elements of the system and at the same time will strive to occupy its internal volume. If in any part of the SOD there is a "weak" place, where, when it cools down and the pressure exerted from the outside, the tightness is broken, then air will enter the system, and a so-called air lock can form in it. When the engine is started again, it can of course be pushed by the coolant into the expansion tank.

But if this does not happen, the air lock will disrupt the circulation of liquid in the SOD, prevent the cooling of the motor and may even cause it to fail. Usually, air enters the system due to suction between the nozzles and the fittings on which they are worn. To prevent this from happening, the pressure in the SOD is equalized with the external atmospheric inlet valve. It is triggered when the system is discharged 0.03–0.1 kgf / cm 2 and lets air into the expansion tank, which actually replaces the air pushed out through the safety valve when the coolant heats up. There is an equalization of the internal pressure in the SOD with the external one.

Signs and possible consequences of part failure

Most often, the consequence of a lid malfunction is the boiling of the coolant, sometimes accompanied by the ejection of the latter from the expansion tank - a common occurrence for VAZ cars. If this occurs at engine operating temperatures, then most likely the plug is not holding the required pressure.

Another reason for the same phenomenon is that due to a malfunction of the vacuum valve, air entered the SOD and formed a plug, which disrupts normal circulation, and hence the cooling of the coolant. In winter, due to an airlock, the stove may not work well. Unpleasant consequences: loss of coolant, which has to be refilled regularly. This happens when, due to the increased pressure in the SOD, the liquid is "expelled" through the joints between the fittings and the nozzles put on them, through the clamps.

Disastrous consequences:

- rupture of low-quality pipes or those that have not changed for a long time (a picture familiar not only to VAZ owners);

- the appearance of a leak in the main or heating radiator;

- breaks the thermostat housing (for Nexia, it is common to split into 2 parts);

- a burst expansion tank.

All these signs are the consequences of a lid malfunction are the result of increased pressure in the cleaning system. The latter is not uncommon for VAZ 2108, 2109 and especially 2110 cars with new tanks. Of course, it is obvious that the plastic of these expansion tanks leaves much to be desired, but, nevertheless, there is a problem with the cork. So the cover, by regulating the pressure in the SOD, also protects its elements from mechanical damage.

How to check the cover and identify problems?

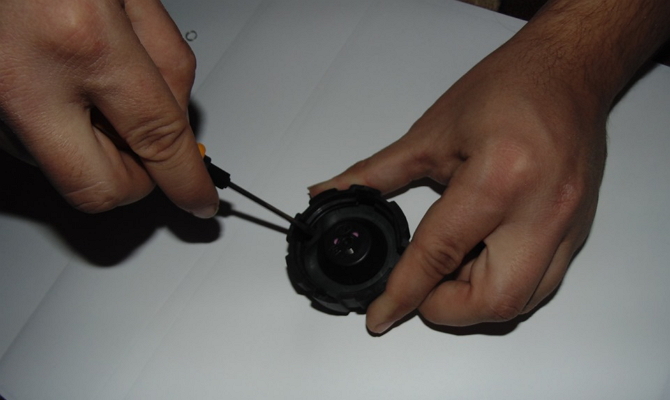

Before checking the expansion tank cap, you must first inspect it to make sure that it is intact and missing. mechanical damage in the form of scratches, cracks and heavy wear, and also there is no rust, dirt, scale and other flaws. Then you should check the performance of its valves. Some simple ways diagnostics, allowing only an approximate determination of their serviceability, are given below.

For safety valve. With the engine running and warm, we wrap the cover. There should be a hissing sound coming out of the tank compressed air... This means that the valve is holding pressure. But which one - not every professional can determine.

For vacuum:

- If the SOD pipes look deformed (squeezed, flat) before the first start of the motor in the morning, the valve is definitely faulty.

- Unscrew and remove the cover. Then we strongly squeeze one of the SOD pipes and, holding it like this, put and screw the plug back. We release the pipe. If it begins to take its original shape, most likely the valve is working properly.

More reliable way check the operation of the valves - use a pump with a pressure gauge for this. Any empty expansion tank will also be required. We connect to one of its fittings, and then fix the pump hose with a clamp, from which the tip for the nipple was previously removed. We muffle the rest of the conclusions from the tank with some kind of traffic jams. Then close the tank with the lid to be checked.

You can also check on the reservoir installed on your car without draining the coolant. To do this, for example, on a VAZ 2109, we disconnect a branch pipe from the expansion tank that fits from above and discharges steam from the cleaning and heating system. Instead, we install the pump hose. In order to plug it into the disconnected branch pipe, we insert something of a circular cross-section and a suitable diameter, for example, a drill. Then we put a clamp on this hose and tighten it.

We turn on the pump and, observing the arrow of its pressure gauge, we fix the moment the click appears, and then the hissing sound coming out of the tank through the air plug. If this happened at around 1.1-1.5 kgf / cm 2, and further inflation leads only to an increase in hiss, but the pressure does not increase, then vacuum valve does not poison, but the safety one works as expected.

Refinement of a new part - what if it does not work?

When it turns out that the cover stubbornly does not want to relieve excess pressure and / or is not able to restore air loss in the POD, it can be modified. Most of all, for some reason, complaints from the owners of the VAZ, model 2109, including those who buy new plugs. It is clear that the reason for the incorrect operation of the cover valves lies in the too high rigidity of their springs.

To rework the cover, for example, for a VAZ 2109, it must first be disassembled. This must be done carefully, using pliers and a thin flat-blade screwdriver. We must try to remember where what stood so that the springs do not fly away, God knows where. After the lid for the VAZ 2109 tank was disassembled, it is time for the nippers. They need to shorten the springs: a large one, for a safety valve, as a rule, by 1 turn, and a small one by 2.

For the second, the length of the section to be removed is not critical - if only it would generally support the vacuum valve when it was closed and would not resist the outside air pressure of 0.03–0.1 kgf / cm 2. It is more difficult with a large spring - as if not to overdo it. It is necessary to look at its rigidity and the pressure at which the safety valve opened when checking the VAZ 2109 tank lid. After shortening the springs, we assemble the lid in the reverse order. Before use, it is advisable to check again how it works.

To be honest, none of us attach any serious importance to this device. Well, the lid - what to take from it - it is only suitable so that the coolant does not spill out! 90 percent of motorists think so. Although this is fundamentally not true, if this "plug" on the expansion tank of your car fails, at least the coolant will constantly spill out, and at most it can provoke a number of unpleasant breakdowns. So you need to know how it works and the basic principles of its structure. As you guessed, today I will talk about it ...

First, a little definition

Tank lid Is a locking element that has two valves in its structure, high and low pressure. This element protects the cooling system (CO) of the car from damage, and also normalizes operation.

In fact, to call it a lid or a plug - the tongue does not turn, I would say so - it is a pressure control sensor, only with a plug on top!

Tank lid task

As you know, when the engine warms up, the coolant also heats up - it expands. Accordingly, this creates an increased pressure, which is greater than atmospheric pressure, this is natural. It should be noted that the slightly increased pressure in the CO is neither bad nor good, the engine, by and large, doesn't care! The main thing is that it is enough for the functioning of the system. It must also be airtight.

If you want, it can be compared to a home heating boiler. A boiler is an engine, nozzles are pipes, an expansion tank is there and there.

The more it heats up, the more pressure builds up in the system. It should be noted that many old units operate at temperatures of 90 - 95 degrees. But modern engines have great performance, so it is not uncommon to work at 100 - 110 degrees Celsius, for example, my AVEO is a high-temperature motor, its normal indicator is about 115 degrees. As you understand, these are average values, but at peaks they can reach even higher values \u200b\u200bof 120 - 125. The coolant at such temperatures can increase by 20, sometimes even by 25% - that's the excess pressure for you.

In order not to burst pipes, radiators, nozzles and the expansion tank itself, a special valve was invented, which is located in the lid.

Normal pressure in different systems, on warm engines should be in the range from 1.1 to 1.5 (bar) atmospheres. More is already dangerous.

Even if the pressure rises much higher, the cooling system can be damaged, in simple terms, it will simply rupture all your hoses or even worse radiators.

This is where the expansion tank cap comes into play, it "bleeds off" excessive pressure, bringing it to the norm, say, 1.1 atmospheres. This way, all your pipes and hoses remain unharmed.

Low pressure is also dangerous!

Just imagine - you went on business in the winter, and then you put the car on a joke (to spend the night in the parking lot), the antifreeze will start to cool down and decrease in size, that is, "settle down." And the pressure will also begin to fall (after all, the valve threw off the excess and closed), thus, a decrease in pressure will begin to create a slight vacuum. Hoses and pipes will squeeze inward - which is also not good.

Again, the expansion tank cap begins to work, it also has a reduced pressure valve, that is, if a vacuum begins to build up, then the system opens and replenishes with air. The hoses expand - to the normal level.

Thus, the expansion tank cap works both in one (high pressure) side and in the other (low). This is a very smart and very necessary element of the system, despite its simplicity.

Very often, first of all, it protects radiators from damage (after all, they are expensive on foreign cars).

Device, principle of operation of the tank lid

As I already indicated from above, the task of the cover is to maintain pressure up to a certain limit. It becomes clear that it should sweaty adhere to the tank and not let the pressure bleed off, up to a certain limit - in 1.1 - 1.5 atmospheres.

The cap itself practically does not hold anything, it is only needed to press the high-low pressure valve, which is immersed in the neck of the expansion tank.

As a rule, there are one or two sealing gaskets on the valve body, which act as a kind of oil seals. In many foreign cars, the valve is one, it is the same inlet and outlet, that is, it can release and build up pressure.

Worth noting on many domestic VAZ, the lid is arranged differently, there are physically two valves here, one, as you guessed it, works only to relieve pressure, the other to pump it (normalize) to normal.

These valves are named:

- Safety - against high rates

- Vacuum - from low values

But while the pressure in the system is normal, both are closed - they do not work, this is the norm! However, the cover often breaks, it is very difficult for a simple motorist to determine (and it is very difficult for a beginner), although this entails quite expensive breakdowns. Now a few words about the signs of such a malfunction.

Signs of a bad expansion tank cap

The valve often fails high pressure, he simply starts to throw off antifreeze at a normal rate, or does not throw it off at all.

- When the normal pressure drops (with a warm engine), antifreeze or antifreeze splashes out and, accordingly, decreases. Often, steam can pour out from under the hood, because the liquid enters the red-hot exhaust manifold. Moreover, the engine temperature is not in the red zone, that is, it is working - it means 90% cover.

- If the vacuum valve fails, completely different symptoms will appear. This often happens air locks in the system - this leads to the following, the engine overheats, and cold air comes from the stove.

To be honest, there can be a lot of reasons, for example, another sign is when it breaks the pipes or breaks the clamps. YES, and the tank itself can burst - this says that the high-pressure valve does not throw off the "excess" and it starts to exceed 1.5 atmospheres, it can damage the radiators themselves, let me remind them of two main and stoves (in the cabin).

So if you have started to "snot", connecting clamps or other connections, often knocks out the hoses - change the cover.

How to check the work yourself?

To be honest, this is a little problematic, the valve-lid needs to create either increased pressure or reduced pressure.

However, first you need to inspect it visually, if you notice cracks, scuffs, rupture of gaskets, or other mechanical damage, then this is most likely a cover. Also from time to time they can become unusable and internal elements valves, some manufacturers recommend changing these plugs every two to three years, then there will be no problems.

Now a few simple ways to identify a malfunction:

- Start the engine, warm it up, then gently start unscrewing the lid, if there is a "puff", then it keeps its "atmosphere", most likely working.

- We look at the thick hoses, if they are strongly deformed, as if squeezed, then the vacuum valve does not work - a cover for replacement.

- There is one more way, but it is not always possible to use it. We unscrew the lid from the tank, strongly squeeze one of the thick hoses, then, without letting go of the hose, we twist the lid - if they take their original shapes, then our plug is working. If not, change. The only downside is that it is quite difficult to do this on many modern foreign cars.

Of course, at many stations there are special pressure pumps, to which the lids from the tank are screwed and injected - 1.5 atmospheres, after this critical indicator is crossed, the valve should open, if this does not happen, then it is faulty.

In conclusion, I would like to say - on many foreign cars the lid breaks when unscrewed, the valve itself remains inside the tank, and does not come out of there. This suggests that the vacuum that has been created inside does not allow it to come out! A replacement is needed, not because it broke, but because the valve is dead.

This is how the article turned out, for those who are lazy, watch the video version.

I finish here, I think it was interesting, read our AUTOBLOG.