Today, gasoline pump breakdowns are not rare. The culprit is only the drivers themselves. Among the main reasons for these breakdowns are the following:

- dirty or clogged fuel filters,

- frequent driver trips with an empty tank.

Regardless of these two situations, the gas pump works at full capacity, therefore it develops its resources much faster. Therefore, the driver must remember:

- firstly, that he should fill the tank with at least half of the fuel

- secondly, periodically change the fuel filters, since the fuel is not always of high quality

The fuel pump is one of the main components of the propulsion system of every car. With the help of it, the combustible mixture is transferred to the engine. So, it connects the gas tank and the engine unit, which are located from each other in different directions. It is known that old car brands were developed without a gas pump, since fuel was supplied to the engine through a fuel hose using gravity.

Today automakers are equipping cars with mechanical or electric fuel pumps. The first type is intended for carburetor type cars. In this case, the fuel enters itself at low pressure. The electric model, on the other hand, supplies fuel to the engine under high pressure.

The principle of operation of mechanical fuel pumps is that fuel is sucked from the tank and enters the engine cylinder. The components can operate at low pressures due to their proximity to each other.

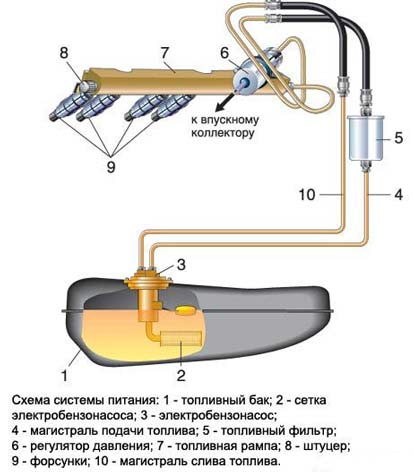

The scheme of the car power system and the operation of the electric fuel pump

Electric fuel pumps operate under high pressure compared to mechanical ones. So, due to strong pressure, the fuel is pushed into the engine itself. In older models of cars, the gas pump worked constantly, unlike modern ones, in which its speed depends only on the requirements of the unit. Responsible for the operation of this type of fuel pump electronic system car. This system automatically calculates the position, content exhaust gases, as well as the ratio of air mixture to combustible.

It is worth noting that the electric type of the gasoline pump is noisy and heats up quickly, as fuel is supplied to the engine under pressure. Because of this, such pumps are placed in the fuel tank, which allows the fuel pump to be cooled with fuel. In addition, this positioning of the pump makes it virtually silent.

This type of pump operates on a signal from the electric motor. After the ignition switch is turned to ON mode, on-board computer signals the start of the gasoline pump, which is then supplied with an electric charge. The motor installed inside the pump starts rotating for a few seconds, after which pressure rises in the fuel system. If the computer does not receive a signal to start the engine for 2 seconds, the fuel pump is immediately turned off for safety reasons.

Just the first two seconds after starting the engine, the driver can hear the pump work. After that, the fuel enters through a special tube into the fuel pump, after which it goes out and enters the fuel filter, which cleans the combustible mixture from contamination and debris. Therefore, in this sense, it is better to periodically change the filter so that it effectively cleans the fuel. The pre-cleaned fuel then enters the engine itself. The gasoline pump continues to work until the engine is turned off.

The fuel pump is one of the most important components of the engine power system. A pump failure will interrupt iCE operation, failures when you press the gas, or even problems with starting. Consider the device, the principle of operation of fuel injection pumps and carburetor motors; let's talk about breakdowns and diagnostic methods.

According to their operating principle, fuel pumps (HP) of gasoline internal combustion engines are divided into 2 types:

- electrical;

- mechanical.

In engine operation, a gasoline pump is used to pump fuel from a tank to a carburetor or fuel rail with nozzles. By car with direct injection and a high pressure fuel pump (TNVD), the fuel pump is used as a booster section.

VT with electric drive

Long-term operation, ease of manufacture and greater efficiency can be obtained by using an electric fuel pump, which is controlled by a special relay. It allows you to create a pressure in the range of 0.3-0.4 MPa (in engines with direct injection - up to 0.7 MPa), which exceeds the capabilities of a mechanical HP. The device largely depends on where it is located fuel pump: in the tank or in the engine compartment. But the principle of operation of all VTs of this type can be considered identical. Overwhelmingly modern cars a submersible gas pump is used, which is located in the tank. Although this is fraught with small mechanical losses and vulnerabilities associated with the long length of the fuel line, the pump gets much better cooling.

During operation, the fuel that washes the body and passes through the electric motor removes a significant part of the heat. That is why driving with an almost empty tank affects the resource so strongly.

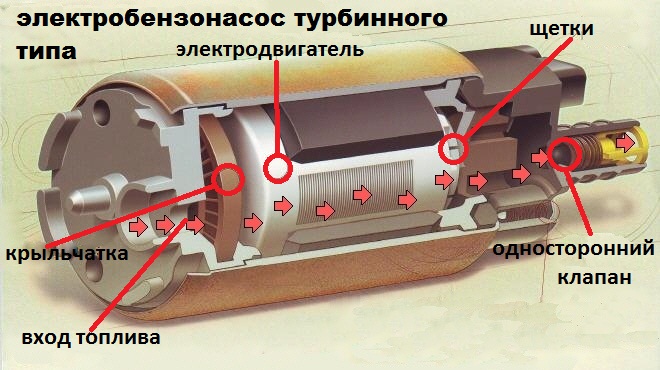

Device

An electric fuel pump consists of two parts: electric drive (represents a conventional electric motor) and the pumping part (pumps fuel from the fuel intake). Submersible pumps are housed in a single casing with a mesh for coarse fuel cleaning.

Depending on the design of the intake mechanism, there are several types of the pumping part:

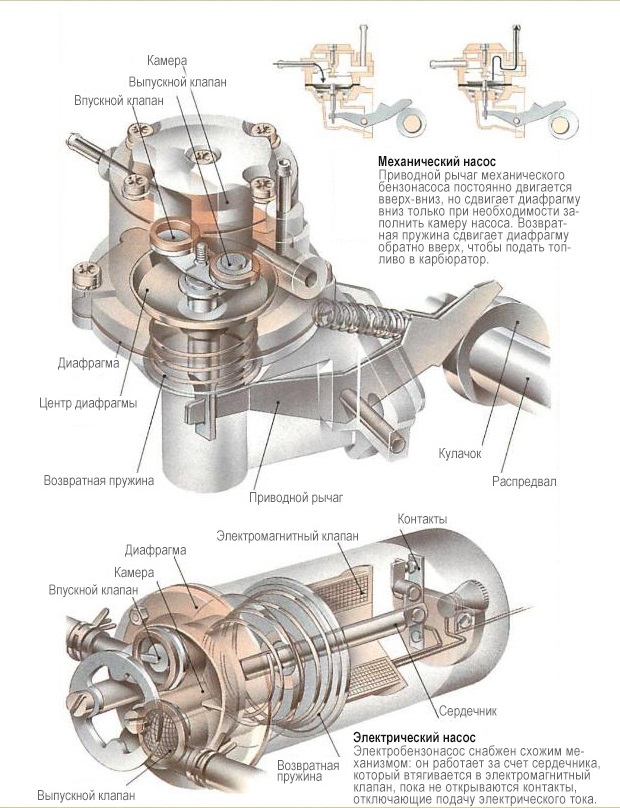

Additionally, hybrid fuel pumps can be distinguished. Structurally, they resemble mechanical devices, but the movement of the diaphragm is carried out not by the drive of the pusher, but solenoid valve and a special relay.

Work logic

Work logic

In cars in which the control of the main life support units of the internal combustion engine is carried out via the CAN bus, the petrol pump receives the command to start the fuel pump from electronic unit engine control. Front starting the internal combustion engine it is necessary to create pressure in the fuel line, therefore, immediately after turning on the ignition, the computer sends a signal to the relay, which turns on the gas pump. In some cars, power is supplied to the relay and the fuel pump is turned on at the moment of opening driver's door... The operating time of the fuel pump in this mode is calculated in seconds, after which the power is turned off. The next start will occur when the starter starts rotating.

Major malfunctions, simplest diagnostics

The main breakdowns, due to which the gas pump may not work, include:

To understand why the gas pump does not work, basic skills are enough. The presence of power on the VT connector after turning on the ignition will mean that there is a malfunction in the pump. If power does not come and the fuel pump does not start, then you should check the circuit to the connector, as well as the relay.

The main symptoms of a malfunction:

- increased noise, the appearance of extraneous sounds;

- dips at hard pressing for gas;

- the engine periodically stalls (especially when hot);

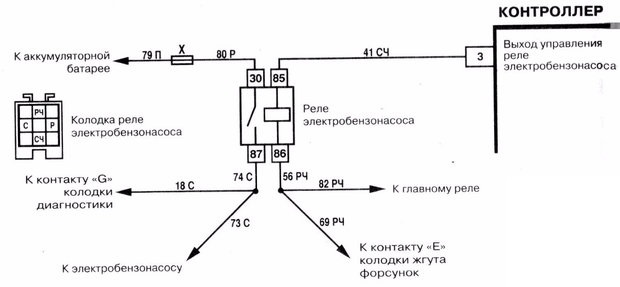

Relay

One of the most important elements of the fuel injection engine power system is the fuel pump relay. It is used to reduce the load on on-board network, since the control of the power contacts is carried out by applying a low voltage to the corresponding terminals of the electromagnetic relay. Schematic diagram connecting a gas pump.

You can see the principle of operation of the relay, as well as test methods in the video.

Mechanical VT

This type of pump operates from camshaft engine. The rotation of the eccentric provokes pressing the lever (pusher). The photo shows a domestic design, consisting of a lever and a balance bar. Foreign manufacturers have a more common scheme with a two-arm lever (rocker).

The thrust of the pump with a diaphragm, when the pusher acts on the balancer, overcoming the resistance of the spring, lowers and sucks fuel through inlet valve... As soon as the eccentric releases its pressure, the spring returns the diaphragm, pushing fuel towards the carburetor through exhaust valve... When the float chamber is filled, a pressure is created in the space above the diaphragm, which the spring cannot overcome. And since the balance bar and the pump thrust are not connected to each other, the balance bar can be idle. As soon as the pressure in the float chamber drops, the diaphragm squeezes out the gasoline - the fuel pump resumes.

Major malfunctions

- Breakout of the diaphragm. Breakage happens quite rarely, but upon the attack it can turn around overhaul ICE. With a significant violation of the integrity of the diaphragm, gasoline begins to flow into the oil, thinning it.

- Worn eccentric, pusher and rocker joints. In this case, the gap between the elements is too large, which affects the magnitude of the thrust and diaphragm travel.

- Wear seats bypass valves, as a result of which the valves begin to leak fuel. There are also cases of valve misalignment, loss of elasticity and clogging.

- Spring diaphragm breakage.

- Clogged strainer, due to which the gas pump may even burn out.

A large number of parts that require adjustment, as well as general design flaws, forced the designers to abandon mechanical gas pumps in engine operation. An example of structural defects is fuel boiling in the above-diaphragm space. The formed gasoline vapors overcome the resistance of the needle valve. As a result, in intake manifold fuel spills in unintentionally, which turns into difficulties during the next start.

The fuel pump is one of the main components of a car. Without it, it is simply impossible to start the engine, let alone operate it. Therefore, if there are any problems with starting or operating the engine, first you need to check the gas pump. To find out how to check a gas pump, you must first determine the basic principles of operation of this unit and possible breakdowns... As a rule, the gas pump is not repaired, and it is replaced by a worker. However, it is necessary to identify that the problem lies precisely in him.

![]()

Schematic diagram of a fuel pump

The main function of the fuel pump is to transfer fuel from the tank to the engine. IN injection engines the fuel pump is connected to the fuel rail, and in carburetor ones - to the carburetor. In this case, it is necessary not only to pump fuel, but also to provide a certain pressure. Too high pressure leads to an increased enrichment of the mixture and high consumption fuel. Too low pressure leads to a lean mixture and a drop in power. Both the first and second cases negatively affect the engine resource. That is, the fact that the fuel pump pumps fuel does not indicate its complete serviceability.

When to check the fuel pump

It is necessary to check all potentially faulty components one by one, and the gas pump in the first place.

Engine starting and running problems are not always related to the fuel pump. Sometimes the signs of a fuel pump breakdown are the same as with nozzles or jets, candles and high-voltage wiring. Even experienced specialists, who know by heart all the signs of a "dying" pump, cannot unambiguously determine the type and cause of a breakdown from the first try, and it is necessary to check all potentially faulty components one by one. In this case, the gas pump is usually checked first.

Malfunction in this case is of two types - the gas pump does not work at all or does not give out the required pressure. In the first case, the malfunction can be recognized by ear, since it should start when the ignition is turned on. In the second case, you need to know how to check the fuel pump pressure. Here you need to use a special pressure gauge. We list the main symptoms of a fuel pump malfunction:

- the engine does not start;

- the engine is unstable;

- the engine lacks traction during sharp acceleration;

- the engine lacks traction at low revs.

The main reasons for the malfunction of the fuel pump

1. Coarse filter clogged

Old and new filter rough cleaning of the fuel pump

Clogged filter It has brown colorbecause its cells are completely clogged with deposits.

The most common problem due to which the fuel pump does not pump is a clogged coarse filter. This filter usually installed in the tank just before delivery to the pump itself. This is where the primary filtration of the fuel takes place. You can determine this malfunction visually. The clogged filter is brown, and the cells in its mesh are almost completely clogged with deposits. Even a serviceable pump cannot pump fuel through such a filter, as a result, the system does not provide the required pressure.

The coarse filter must be replaced. Its cost is low (about 50 rubles). However, it takes time and a set of tools to replace it. First, you need to remove the fuel pump itself, which is usually screwed to the tank. Before removing the fuel pump, you must disconnect the terminal on the battery. Then the fuel pump is removed and the filter is removed from it. The filter itself is installed on the pump manually, without tools. It is recommended to change the coarse filter every 20 thousand. However, it can clog up much faster. It depends on fuel quality and condition fuel tank... You only need to refuel once low-quality fuel on to clog the filter. It can also easily become clogged with rust if the tank is old and corroded.

2. Incorrect operation

An electronic fuel pump can be installed in the engine compartment.

With a small amount of gasoline in the tank, the electronic fuel pump quickly overheats.

Unlike a mechanical pump, which is installed on carburetor engines, an electronic pump can fail due to improper use. The electronic pump gets very hot during operation. It is cooled by the fuel in the tank. Therefore, with a small amount of fuel, the pump may overheat. At the same time, short work with practically empty tank not critical to the pump. If you constantly operate the car with an almost empty tank, the fuel pump will overheat and quickly break down. It is recommended to keep the tank at least one third full at all times.

Especially often the gasoline pump breaks down due to overheating on cars with gas equipment... Here, gasoline is used only to start the car, then gas is used for work. As a rule, the owners of such vehicles keep a small amount of gasoline in the tank. At the same time, the fuel pump constantly works to maintain a certain pressure in the fuel rail. If there are only a few liters of gas in the tank, the fuel pump will quickly overheat.

3. Wear

The fuel pump contains rotating parts that are subject to friction. They wear out over time. Therefore, if the fuel pump hums strongly, it is advisable to replace it. The operation of the fuel pump should not be heard from the vehicle interior when running engine... Over time, a pump that is too worn can jam and stop pumping fuel. To find out how to replace a gas pump, you need to look in the instructions for your car.

In mechanical gasoline pumps, membranes wear out quickly, especially with their low quality. As a result, traction is lost and the engine is unstable due to a lean mixture. It is especially common for mechanical pumps to break down in summer due to overheating. Therefore, an electric low-pressure gas pump for the carburetor is often installed, which is connected to the fuel line, instead of the usual mechanical one. This avoids problems in the summer when the mechanical pump stops pumping. In addition, the dynamics of the car is improved, since the electric pump allows fuel to be supplied to the carburetor at a constant pressure.

4. There is no power supply to the fuel pump

![]()

The reason for the lack of power supply to the fuel pump can be oxidized terminal contacts

If the gas pump does not work when the ignition is turned on, this is usually due to its power supply. When turning the ignition key, the fuel pump should be running. This ensures the maintenance the right pressure in the ramp to start the engine. If there is no sound when turning the key, then there is most likely no power supply. Typically, the fuel pump does not suddenly fail. At first, it works with lower performance, and only then it breaks down completely.

Using a tester or an ordinary 12 volt light bulb, you can check the entire power supply circuit of the fuel pump.

Using a tester or an ordinary 12 volt light bulb, you can check the entire circuit that goes to the pump. First you need to check the fuse, its malfunction can be determined visually, since the thread in it burns out. You can find out where the fuse for the fuel pump is located only in the instructions for the car or on the Internet. Each vehicle has a different fuse arrangement. However, if the fuse is blown, it is better to check the entire circuit after replacing it. Usually the fuse does not blow by itself, it is due to some other breakdown.

Also, the lack of power in the circuit can be caused by a relay malfunction. You can find out where the fuel pump relay is located only in the instructions for a specific car. As a rule, it is located in the fuse box in the engine compartment. If the check does not light up and the fuel pump does not work, the problem is most likely in the mechanical part of the fuel pump. In this case, power is supplied, but there is no fuel supply.

The described symptoms of a fuel pump malfunction can appear both constantly and periodically. For example, with a poorly warmed up engine, when driving uphill, in winter, if the tank is less than half full. Even if problems do not appear constantly, it is better to check everything and fix it. A fuel pump that is already worn out and does not work for full power, can stop completely at any time.

Hello.

And again an interesting article.

🔧 If the gasoline pump does not pump gasoline

The gas pump is an important component fuel systemresponsible for supplying fuel from the tank to the carburetor or injector.

Earlier car models used fully mechanical pumps for circulation fuel mixture. Modern carsare increasingly equipped with electrical counterparts. This type of pump is most relevant for vehicles with an injector. Besides standard function supplying fuel, an electric fuel pump performs another very important task. The device creates optimal pressure in the fuel system to circulate the mixture through the injectors.

The principle of operation of the fuel pump and the basic rules of operation.

The principle of operation of an electric pump is quite simple. Thanks to electric current, the pump moves the fuel mixture at a certain pressure. The principle of operation of the mechanical analogue is somewhat different, but also not particularly difficult. The stop pushes the pump lever, which drives the stem. Thus, a regular reciprocating movement of the membrane is created, due to which the fuel mixture flows into the carburetor. As a rule, gasoline pumps are unpretentious in operation and do not require much attention. But at the same time, like any car device, the gas pump has certain operating rules. To maintain a fuel cell in good condition, the use of quality fuel is fundamental.

The use of fuels with various impurities contributes to the premature wear of the element. Thus, it becomes clear that correct work pump largely depends on the condition fuel filter... Regular replacement of a clogged filter will help to avoid considerable repair and maintenance costs for the fuel pump. The electric analogue has its own characteristics, based on which it is not necessary to allow the maximum consumption of gasoline. The fact is that the electric pump is cooled by the passing fuel flow. If the gasoline level falls below the minimum allowable, the pump stops cooling and the wear of the working component increases.

If these rules are not followed, the pump may gradually malfunction. Over time, the car enthusiast can face unpleasant consequences. Insufficient supply of the fuel mixture leads to a decrease in engine performance. If the pump is badly clogged, then the car will simply refuse to start.

Signs of improper operation of the gasoline compressor.

The first indicator of a pump malfunction is a malfunctioning car engine. If the car is unstable in motion and starts to randomly pull out or brake, most likely, the fuel compressor is faulty. Also, abnormal sounds during vehicle operation and deterioration in vehicle acceleration may indicate pump malfunction. When properly functioning, the petrol compressor is virtually silent. Otherwise, it becomes necessary to diagnose the device. If during the operation of the mechanical analogue leaks are found working fluid it also becomes necessary to check the fuel system component.

We are looking for a malfunction of the fuel system.

To determine a pump malfunction, it is necessary to recall the main components of the fuel system. The system includes: tank, fuel compressor, filter element, fuel lines, nozzle and pressure controller.

Violation of the function of one of the above components, inevitably leads to a violation of the pressure in the fuel system. Let's analyze the most common fuel system malfunctions.

Gasoline tank.

Special conductors connect the tank to the atmosphere to prevent deformation of the inner cavity. Due to the loss of communication with the atmosphere, the tank may be discharged. In this case, there is a reduced pressure in the fuel system.

Gasoline pump.

Due to the violation of the function of the element, the pressure in the system can change. There may be several reasons:

The compressor is developing insufficient pressure. Subsequently, the pressure in the fuel system decreases.

-The pump valve does not hold pressure as a result of a rapid drop in the pressure in the system after the starter is turned off.

- Clogged gasoline pump filter. In this regard, the fuel pump does not pump or its productivity is significantly reduced.

Filter element.

If the cell is clogged, the fuel lines are not passing enough gasoline. As a result, the pressure in the system decreases. If the filter element is broken, the nozzles will rapidly clog. As a result, the correct function of the fuel system is impaired.

Fuel conductors.

Fuel conductors may be pinched while using the vehicle. If the supply line is transmitted, the pressure can drop. Accordingly, if the drain conductor is clamped, the pressure in the system will become.

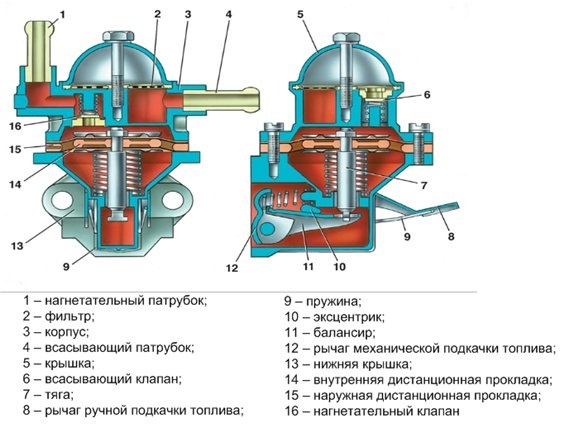

The VAZ 2106 automobile gas pump is one of the main components of the fuel supply system, which pumps fuel from the tank to the carburetor. Directly in the carburetor unit, an aerosol mixture of fuel and air is formed, which enters the power plant.

The device and principle of operation of the fuel pump

The basic structure of the VAZ 2106 fuel pump can be seen below.

According to its principle of operation, the "six" fuel pump is focused on creating excess pressure, which, regardless of the stage of operation of the engine, must constantly maintain the required level of gasoline in the float-type fuel chamber. The diaphragm is designed and developed so that the fuel flow is stopped or reduced when the pressure in the fuel line is reached.

The standard fuel pump is located on the left on a special tide of the engine block and is attached with pins through a thermal spacer and an adjusting gasket. This spacer also serves as a guide element for the pusher of the VAZ 2106 gasoline pump, driven by an eccentric through the fuel pump drive, powered by the operated gas distribution mechanism. The length of the new fuel pump rod is 82.5 mm, the allowable value for operation is 81.8 mm; when this parameter is reduced, the product must be adjusted by selecting the installation gaskets or replaced with a new spare part.

For manual supply of gasoline by the pumping method, a special lever is provided in the product, which is recommended to be used after a long period of operation vehicle for filling the fuel line with fuel. It is capable of creating a pressure of 20-30 kPa with an injection rate of at least 60 l / h at a frequency of 2000 frictions (strokes) per minute.

Our Internet resource describes the device of a VAZ 2106 gasoline pump under the nomenclature number 2101-1106010, produced at DAAZ in the city of Dimitrovgrad. Alternatively, you can use the Pekar petrol pump manufactured at the Saratov Fuel Equipment Plant. The design and development of the product was carried out by JSC Pekar from St. Petersburg.

By the way, many motorists praise the so-called. "Plunger fuel pump VAZ 2106", which improves the start of the vehicle and operates with a high degree of reliability. A product of this type is nothing more than a Pekar gasoline pump, the top cover of which is made in a high style and resembles 2 connected cylinders, on the end parts of which arrows of the direction of gasoline flow are engraved. The valves inside the product are very similar to plunger pairs, and with the light hand of motorists they began to be called plunger fuel pumps for the "six".

Signs of defects in the fuel pump

Many motorists know that the fuel pump is such a component of the fuel system of the "six", which repeatedly malfunctions or, speaking in simple words, - he knocks. Reasons: low-quality gasoline, clogged fuel filter that was not replaced in time, high loads on product parts, exposure to active ingredients during oil and antifreeze leaks, poor-quality rubber components, etc.

The main malfunctions of the fuel pump are a violation of the sealed conditions of the fuel pump, gasoline leaks and "the VAZ 2106 fuel pump does not pump", i.e. failure of the product membrane. In this case, repairs "in the field" are possible, when drivers have, for example, to install high-density cellophane instead of a standard membrane, which allows them to reach their destination. A more civilized repair of a gasoline pump for the "six" is to purchase a repair kit for a gasoline pump and replace parts that have been worn out.

The preferred option for car enthusiasts who do not want to do such repair work, the purchase of an electric fuel pump for a VAZ 2106, which is more durable and reliable in operation, may become.

Replacing a fuel pump in a VAZ 2106 car

We carry out preparatory work, we concentrate in one place the necessary locksmith tools and a new product to be installed. Replacing the fuel pump is carried out in the following order:

- We loosen the fastening clamps with a curly screwdriver or wrench.

- We disconnect the ends of the gas line from the product fittings with their subsequent plug to prevent fuel leakage.

- We dismantle the fuel pump with a wrench.

- Dismantle the thermal insulation spacer and the installation gasket.

- The installation gasket should be replaced, and the thermal spacer should be cleaned and replaced in its original place of attachment.

- If the fuel pump needs to be repaired, it must be disassembled and worn out components replaced.

- If it is necessary to replace the assembled product, then we put the gasket on the mounting pins, then we install the "six" fuel pump.

The final installation of a fuel pump on a VAZ 2106 is carried out in the reverse order.