After you opened the hood for the first time, you saw a lot of wires, sensors, connectors. You may be intimidated by the work ahead. But you shouldn't be afraid, I will try to explain which sensors are on the intake manifold, throttle, as well as their features in the D14 and D14 engines.

MAP

Manifold Absolute Pressure - Sensor absolute pressure

intake manifold, aka DMRV. Most often I met exactly as in the image below, the sensor is the same in mountings, and parameters on many honda models... Located on the throttle body - on top.

The range of the measured pressure in the intake manifold is from 10 to 170 kPa. The range of returned values \u200b\u200bis shown in the table (there are versions with dimensions from 400 to 4770 mV).

When the key is placed on top, the sequence of wires: 1 - Power supply, 2 - Ground, 3 - Signal. Total: 3 wires.

MAP measurement method

- Disconnect the MAP sensor electrical connector.

- Switch on the ignition, do not start the engine!

- Check the voltage at the connector, 5.0 V.

- Unscrew the MAP sensor screws.

- Disconnect the sensor from the throttle valve.

- Connect the connector, turn on the ignition, do not start the engine!

- Connect the voltmeter to the signal wire (red-green) and body ground.

- Check the resistance values \u200b\u200bwith the parameter table.

MAP absolute pressure sensor Honda civic

MAP sensor voltage table

TPS

Throttle Position Sensor - throttle position sensor, keeps track of the degree of opening. Full open, full close, quarter, eighth, etc. has 3 pins, riveted to the throttle valve at the level of the pivot axis. Black sensor on the side of the throttle body.

Bottom line: 3 wires, powered by 5 volts.

IAT and TA

Intake Air Temperature - air temperature sensor in the intake tract. A two-contact sensor for measuring the air temperature in the intake tract, thanks to its measurements, the ECU control unit introduces characteristics into the mode idle move... Mounted either in the filter box or directly in the intake tube. The values \u200b\u200bare the same as on the TA.

Temperature Air - Air temperature sensor. Also an air sensor in the intake manifold, but an outdated version of measuring the air temperature, the polarity also does not matter, the same was used in different models. It was attached to the rear lower part of the intake manifold with 2 screws. The screws are usually acidified, the caps are sheared off with a dremel. Can be changed from different models Honda. Bottom line: 2 wires, polarity is not important.

Intake Manifold Temperature Sensor Honda Civic

Temperature sensor resistance table

EGR

IACV

RACV

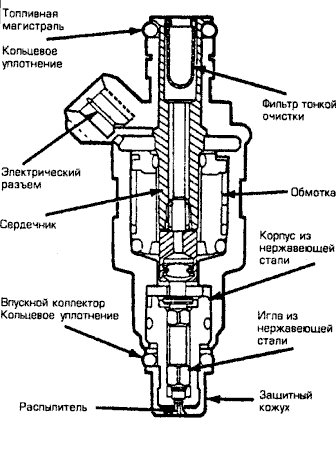

Injector nozzle

Nozzle, in engines of the D motor series, 4 pieces are installed, for each cylinder 1 injector. Needed to spray fuel under the action of high pressure... Due to the current in the winding, the core opens or closes the channel. The resistance of each type of nozzle is different, so be careful. There were cases of installing the wrong nozzles, and part of the ECU burned out. More details in the article. All four nozzles are connected by one contact on the splitter. On the other contact, a signal passes to the injector.

Result: 4 nozzles \u003d 8 wires, of which 4 are signal and 1 common - power.

Sectional view of the Honda Civic fuel injector

This article is relevant for honda cars release of 1992-2000, such as Civic EJ9, Civic EK3, CIVIC EK2, CIVIC EK4 (partially). The information will be relevant for honda owners Integra in DB6, DC1 bodies, with ZC, D15B, D16A motors.

Helpful hints: To remove the drum by the jammed wheel, remove the wheel and install the M8 bolts in the two holes. Tighten alternately 1-2 turns of each bolt to "extrude" the drum. Complete list of tips

The community can help you with most questions.

Hello.

On copper, we had to dig deeper into Dzhimka Autolady, which, in addition to obvious faults, had a very tricky defect.

Symptoms of Dzhimka's disease (Lyulya - so called her mistress):

Unstable speed of XX (about 1000).

When you press the gas - the desire to stall.

The car does not go forward or backward. Strives to stall.

Oil leaking from all the cracks low level antifreeze.

They brought Lyulu to their garage and let's revive her.

We measured the fuel pressure in the rail - the norm.

Further, the oil leaks were eliminated, the KXX gasket was replaced (there was a coolant leak into the intake) and at the same time it was cleaned.

In general, Lyula suffered greatly from the previous repairmen. Broken, confused / missing bolts

were present everywhere. The intake manifold was too short. They removed the manifold (drowned the USR and checked for cracks), then changed the gaskets and assembled the engine. I start to launch Lyulya in the confidence that it will cheerfully launch - but no. The main sore remained. We wash the MAP sensor and holes and Lyulya came to life. Two days later, the hostess calls: (Lula is bad again. The symptoms are the same. We take Lula to our place and thoroughly check the MAP - and he issues heresy in the ECU. know about yourself.

Luli sensor

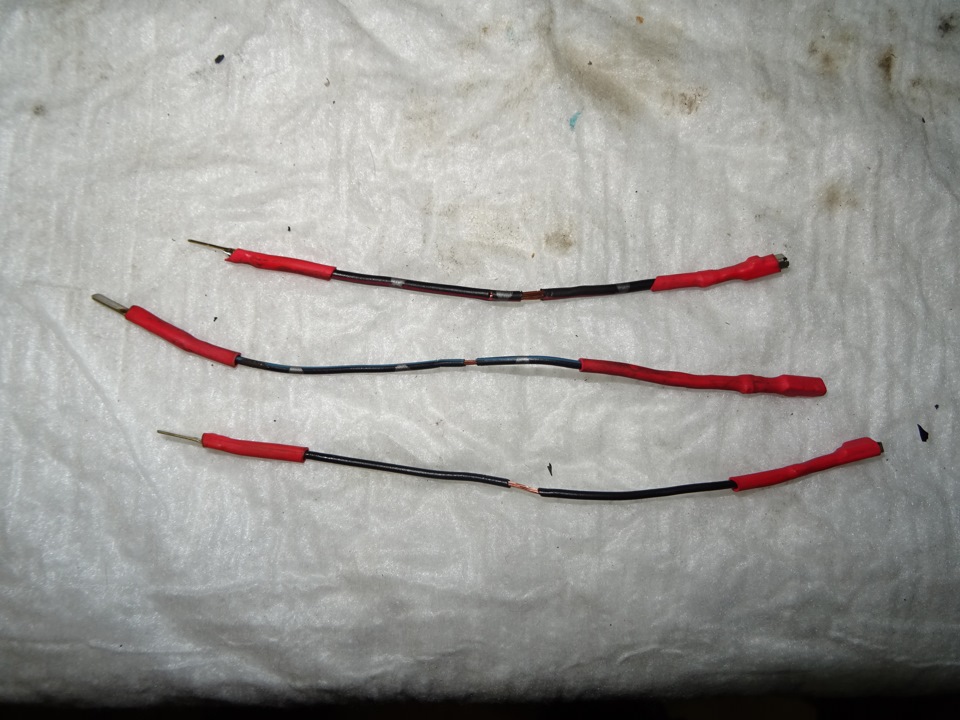

We made an adapter for checking the sensor, so that you don't need to disfigure the insulation and pierce the wires when measuring and taking readings.

Table of voltage from the sensor output when checking.

They shot a video with Nikolai, in which in simple language, without abstruse terms, they explained how to check the absolute pressure sensor on a Suzuki Jimny car.

This technique is suitable for many vehicles that have these sensors.

Everyone konichiwa and nihao!

I didn't want to talk about politics, but since April new excise taxes on gasoline have been introduced and all analysts are predicting possible rise in gasoline prices. At 2-2.5 rubles per liter. And not only for him, for everything in the end, the price of gasoline lies in all goods ...

What then should the peasants do? That's right, armed with knowledge, start checking all the systems of your favorite car so that you eat less and drive more!

So I took care and checked what we have with the DBP sensor, it is also the MAP sensor, it is the absolute pressure sensor in the intake manifold. There is an opinion that he is degrading and starts to lie, then he must be changed. The purpose of the test was to fix the extreme points for analyzing its characteristics. At the same time, we managed to reproduce a malfunction characteristic of Avelka, in which at idle the rpm rhythmically drop and jump from 200 ... 300 to 1500 ... 2000, the stink of gasoline from the glushak and the car goes as it wants.

First, the video. As always, I remind you that getting into the systems of the machine you act at your own peril and risk! Always make sure there are no shortcuts in the connections. We connect to the middle contact by inserting a pin along the wire all the way into the contact and hanging a probe to it. I took the minus from the battery.

If you accurately measure the vacuum at idle and the corresponding output voltage, and then the same values \u200b\u200bat atmospheric pressure and plot a graph based on these two points, then superimposing it on the factory vacuum / voltage in the DU built according to the table on the sensor can be seen, in tolerance whether he.

Table from the manual for the MAP sensor from GM and Delphi

So why does the buildup of revolutions begin when there is a hole in the vacuum hose of the sensor or what is the leak in the manifold? Then everything is IMHO. The sensor thinks that the damper has opened and the pressure has dropped, there is no vacuum. The ECU obediently pours gasoline, first increasing the speed, and then the oxygen in the manifold runs out, the damper is then closed, and through the hole does not flow in the required volumes. And the engine stops. And when the engine sags, the ECU realizes that something needs to be done and opens the xx valve, a portion of oxygen comes in, the speed rises, the engine accelerates and burns it out, the speed falls and so on again. It is enough to open the throttle and the buildup passes. This is exactly what I did right after starting - I screwed in the persistent screw dz and the motor began to rumble, albeit at increased speeds, but smoothly. And then he revised all the pipes, cleaned the throttle with the xx valve and, having eliminated all the leaks, was able to set normal idle speed.

PS Check out my Driveway blog. Some materials on the car are being laid out there now.