Gasoline engine internal combustion with fuel injection. The element in question is designed to adjust the volume of air that enters the engine for the purpose of formation.

In fact throttle - this air valve... When it is open, the atmospheric pressure level corresponds to the pressure in the intake system, when the damper is closed, the pressure level is reduced to a vacuum state. These features are relevant when the vacuum brake booster is operating, as well as for blowing out the adsorber in the gasoline vapor control system.

Throttle valves on different types:

- for a carburetor with a falling current, the flap is presented in the form of a rigid plate, which is attached to a rotating axis in the lower part of the mixing chamber;

- for a carburetor of constant vacuum, the element is no different from the previous one;

- in a horizontal carburetor, the damper is presented in the form of a vertical gate regulating the flow area of \u200b\u200bthe small diffuser, in the zone of which it is located. When raised, the gate increases the flow area of \u200b\u200bthe diffuser;

- in the fuel injection system, this is a separate unit that doses the volume of air at the inlet to the manifold.

Throttle valve actuator types:

- electric drive with electronic control;

- damper with a mechanical drive.

Electrically operated butterfly valve

Modern cars have a throttle valve with electric drive instead of a mechanical analogue, due to which the optimum torque value is achieved much more efficiently in all engine operating modes. Also, the level of fuel consumption is reduced, the movement becomes safer and more environmentally friendly.

Highlights of the electrically operated butterfly valve:

- possibility of adjustment idle move by moving the flap;

- lack of mechanical connection between the throttle valve and the gas pedal.

Since there is no rigid connection between the damper and the gas pedal, it is relevant to use an electronic control system. Thanks to the electronics, in this case, you can effortlessly influence the amount of torque, even if the driver does not use the accelerator pedal.

System elements:

- executive device;

- the engine control unit;

- input sensors;

- clutch pedal position switch;

- gas pedal position sensor;

- brake pedal position switch.

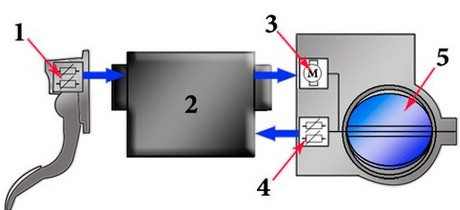

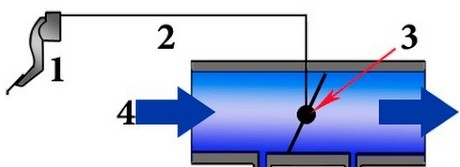

Electronic throttle control:

1 - gas pedal position sensors; 2 - electronic engine control unit; 3 - engine direct current (throttle valve drive); 4 - throttle position sensors; 5 - throttle valve.

When working, it is also important to use signals from the cruise control, the climate system, and automatic box gear. The engine control unit, in turn, after sensing the signals from the sensors, converts them into a control action relative to the throttle valve.

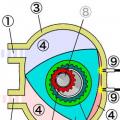

The throttle body includes a body, throttle body, gearbox and motor, position sensors and a return spring mechanism.

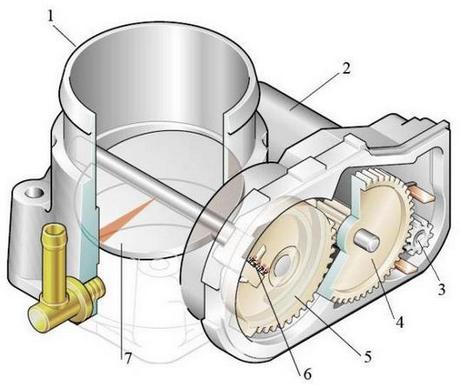

Throttle control module:

1 - throttle body; 2 - electric throttle valve; 3 - drive gear; 4 - intermediate gear; 5 - gear wheel of the spring return mechanism; 6 - angular sensors of the throttle valve drive; 7 - throttle valve.

To increase reliability, it is possible to install not one, but two damper position sensors in the module. Non-contact magnetoresistive sensors or sliding contact potentiometers can play their role. The latching curves of the output signals are directed towards each other, so that the engine control unit can distinguish between them.

The design of the module implies an emergency position of the damper in the event of a malfunction of the drive, which is carried out by a spring return mechanism. A defective throttle module must be replaced as an assembly.

Mechanically actuated butterfly valve

To date, you can only meet a mechanical throttle valve in budget car options. The drive is represented by the connection of the throttle valve and the gas pedal due to a metal cable.

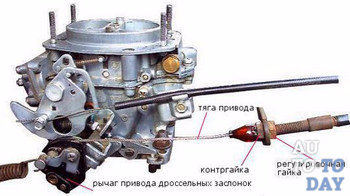

Mechanical throttle actuator:

1 - gas pedal; 2 - gas pedal cable; 3 - throttle valve; 4 - inflow of incoming air.

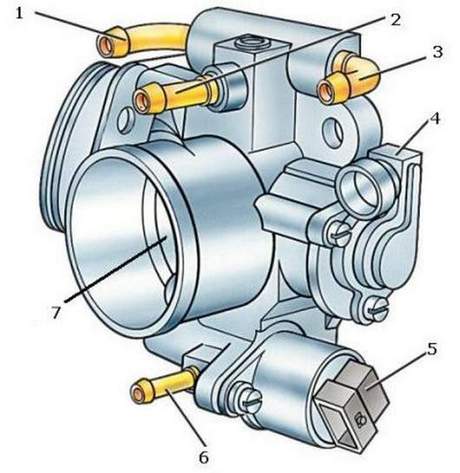

Throttle body parts are assembled in a separate block, consisting of a throttle body on the shaft, a housing, an idle speed regulator, and a throttle position sensor. The housing in this case refers to the engine management system. It has branch pipes, due to which the crankcase is successfully ventilated and gasoline vapors are captured.

Mechanically actuated throttle body:

1 - coolant supply pipe; 2 - branch pipe of the crankcase ventilation system; 3 - coolant outlet branch pipe; 4 - throttle position sensor; 5 - idle speed regulator; 6 - branch pipe of the gasoline vapor recovery system; 7 - throttle valve.

The idle speed regulator maintains the specified speed crankshaft motor when the damper is closed during start-up, as well as when the load changes when additional equipment and when warming up. The idle speed control system includes a valve connected to the stepper motor. Due to these elements, the amount of air flowing around the throttle valve into the intake system changes.

The principle of operation of the throttle valve - video:

Title

The throttle valve is structural element car fuel system with gasoline engine internal combustion, which regulates the flow of air masses and the formation of an air-fuel mixture. This element of the intake system is located between the manifold and air filter. The throttle is one of the main components of the vehicle power system.

The throttle valve is a kind of air valve that allows you to control the pressure in the system. If the valve is open, the pressure level tends to atmospheric, and when it is closed, it decreases, approaching vacuum. Thus, the throttle valve also regulates the operation of the vacuum amplifier. brake system... This means that the smaller the valve opening angle, the lower the speed.

Throttle body

The throttle valve is a circular plate that can rotate 90 degrees around itself - it is a cycle from opening to closing. It is located in a corpus containing:

- Drive - mechanical or electrical;

- Position sensor - throttle potentiometer;

- Idle speed regulator.

Together, all of these components form the throttle assembly or throttle body.

The damper body is rather complicated. After all, he himself is part of the cooling system. It is the throttle assembly that opens the channels through which the coolant circulates. Equipping the hull with special branch pipes connected with the ventilation system and the fuel vapor recovery system makes the design even more complex. You should study this system in more detail.

Idle speed regulator

With the help of the idle speed regulator, the required crankshaft speed is maintained with the damper completely closed. For example, if the motor heats up or the load increases, additional equipment is connected to the process.

The regulator is arranged as follows: the case where the stepper is attached electric motorconnected to a tapered needle. When the motor is running, idle, the needle is like a piston, regulates the cross-sectional area of \u200b\u200bthe air channel.

Drive unit

There are two types of actuators - mechanical and electrical. Their difference is only in the principle of work. The mechanical structure is much simpler and is connected to the gas pedal using a steel cable. Electric, on the other hand, has no direct connection with gas. How, then, does regulation take place? This is where the throttle potentiometer comes in. This special sensor communicates with the engine control unit, and the controller supplies the desired signal.

Potentiometer

In other words, the potentiometer changes the opening angle of the damper and thus affects the controller. When the damper is closed, the voltage does not exceed 0.7 V, and when fully opened, it reaches 4 V. This is how the fuel supply is controlled.

If the throttle valve stops responding to the impulses coming from the position sensor, such breakdowns may occur as:

- Floating speed when the engine is running. Increased idle speed;

- The engine stalls when switching to neutral;

- Uncontrolled fuel consumption;

- The engine runs at half strength;

- The CHEK light is on - check if the throttle valve is working properly.

How to fix the problem

If you suspect that the throttle valve is faulty, you need to check the entire assembly where it is attached. To do this, follow the following algorithm exactly:

- Disconnect battery negative terminal.

- It is necessary to drain the liquid from the cooling system.

- Move the hoses away from the throttle assembly.

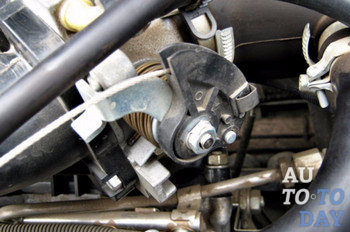

- Remove the damper drive cable.

- Disconnect the potentiometer from the pads and the idle speed controller.

- Remove the throttle assembly.

- Check the condition of the throttle gasket and the rest of the assembly.

- If necessary, replace some of the components or the entire unit.

- Reassemble the structure in reverse order.

After you have installed the unit in place, you need to check the tightness of the cooling system, where you refilled the liquid. There should be no drips or drips.

Damper adjustment

In order for the throttle valve to work like a clock, its sensor must be periodically adjusted. To do this, take a few simple steps:

- The ignition is turned off in order to move the valve to the closed position.

- The sensor connector is de-energized.

- The sensor is adjusted using a 0.4 mm dipstick located between the screw and the lever.

To check the health of the sensor, the voltage level is measured using an ohmmeter. If voltage is detected, the sensor should be replaced. In the opposite situation, you can continue to adjust the sensor.

To do this, the damper rotates until you see the same indicators that are spelled out in the auto passport. Do not forget to check the tightness of the bolts and nuts after adjustment, during the process they could loosen.

As known, fuel system a car is its viability. If it is even slightly disturbed, the car may surprise you unpleasantly at the most inopportune moment. If the throttle valve or other element of the unit fails, then the consequences can be dire. Therefore, it is much better not to skimp on car diagnostics, if you have the slightest suspicion of a malfunction. Remember - safety on the road comes first.

Gasoline internal combustion engines with fuel injection and is designed to regulate the amount of air entering the engine to form a fuel-air mixture. The throttle valve is installed between the air filter and the intake manifold.

The throttle valve is essentially an air valve. When the damper is open, the pressure in the intake system corresponds to atmospheric pressure, when it is closed, it decreases to a state of vacuum. This property of the throttle valve is used in the operation of the vacuum brake booster to purge the adsorber of the gasoline vapor recovery system.

The throttle valve can be mechanically operated or electrically controlled.

Mechanically actuated butterfly valve

The mechanical throttle valve is currently used in most budget cars... The drive involves the connection of the gas pedal and the throttle valve using a metal cable.

The throttle valve elements are combined into a separate unit, which includes a body, a throttle valve on the shaft, a throttle position sensor, an idle speed regulator.

The throttle body is included in the engine cooling system. It also has branch pipes that ensure the operation of the crankcase ventilation system and the gasoline vapor recovery system.

The idle speed control maintains the set engine speed with the throttle valve closed during start-up, warm-up, and load changes during bodywork. It consists of a stepper motor and a valve connected to it, which change the amount of air entering the intake system bypassing the throttle valve.

Electrically operated butterfly valve

On modern cars the mechanical drive of the throttle valve has been replaced by an electric drive with electronic control, which allows achieving the optimal torque value in all engine operating modes. This ensures a reduction in fuel consumption, performance environmental requirements, traffic safety.

The electric throttle body features:

- lack of mechanical connection between the accelerator pedal and the throttle valve;

- idle speed regulation by moving the throttle valve.

Since there is no rigid connection between the gas pedal and the throttle valve, it is used electronic system throttle control. The electronics in the throttle control allows the amount of engine torque to be influenced even if the driver does not operate the accelerator pedal. The system includes input sensors, an engine control unit and an actuator.

In addition to the throttle position sensor, the control system uses an accelerator pedal position sensor, a clutch pedal position switch, and a brake pedal position switch.

The throttle control system also uses signals from the automatic transmission, braking system, air conditioning, cruise control system.

The engine control unit receives signals from the sensors and converts them into control actions for the throttle valve module.

Throttle valve module consists of a housing, a throttle valve itself, an electric motor, a gearbox, a return spring mechanism and throttle position sensors.

To increase reliability, the module is equipped with two throttle position sensors. Potentiometers with sliding contact or non-contact magnetoresistive sensors are used as sensors. The graphs of the change in the output signals of the sensors are directed towards each other, which allows the engine control unit to distinguish them.

The design of the module provides for an emergency position of the throttle valve in the event of a drive failure, which is carried out using a return spring mechanism. The defective throttle module is replaced as an assembly.

How does an electronic throttle work, what surprises it can give you and why manufacturers put an electronic throttle and not everyone familiar cable drive... What you should know and do in order for the electronics to serve reliably and reliably - read about everything in this very voluminous article.

How an electronic choke works

To control the electronic throttle valve, an engine control unit (ECU) and a stepper motor with a gearbox are used, structurally combined with the throttle valve.

The ECU usually uses the engine torque as the calculation parameter. So that the unit understands what actions the driver is doing, an integral part of the electronic control is the accelerator pedal position sensor.

The pedal position sensor is a variable resistor, the resistance of which (and hence the conducted voltage) changes depending on the position of the accelerator pedal.

Based on all the readings, the computer calculates the required engine power and accordingly opens or closes the damper (thereby regulating the air supply to the cylinders), and also regulates the amount of fuel injected by the injectors.

At the same time, the throttle position sensor indicates to the unit how much the throttle valve is actually open, thus providing feedback. That is, the control unit not only opens the shutter with its commands, but it also “sees” whether it has actually opened.

The entire control process requires only a few milliseconds to achieve the desired characteristics of the car at the moment.

Emergency operating modes

The use of electronics makes it difficult to diagnose through external inspection. You can only visually check the cleanliness of the throttle itself and the ease of movement of the damper. The throttle must be clean! And the shutter should not have a snack.

In case of node failure electronic throttle system includes emergency mode "Jerk limits" to enable safe movement to the place of repair, or complete shutdown movement capabilities.

In this mode, two scenarios are possible:

1. The system cannot control the throttle valve for some reason. For example, the throttle position sensor is faulty or not, or the stepper motor is faulty and the throttle is unable to move (open and close).

In this case, the ECU disables the engine ignition control. The electronic damper is set to the off position. The system completely disables the ignition control functions.

2. The system cannot control the driver's intention... In this case, the ECU limits the power output of the motor. For example, this is possible if the signal from the accelerator pedal position sensor is faulty or not.

To prevent damage to the engine, the control unit reduces the increase in engine speed and power. The entire engine management system is placed in forced idle mode. The engine speed practically does not change when you press the gas pedal.

Electronic Throttle Restricted Modes

1. Forced closing

The control unit reports a malfunction when there is a malfunction in the air supply and throttle valve control system. In this case, the ECU shuts off the fuel supply to the cylinders, turns off the ignition, closes the throttle and the engine stalls.

2. Forced idle power control mode

If, when the engine is idling, the control system cannot normally use the throttle valve (for example, it bites when moving), then the ECU stops controlling the throttle valve.

It is set to the default position. And all control is carried out by turning off the fuel supply to one cylinder and delaying the ignition timing.

3. Forced idle mode

We have already talked about this mode with you above. Let's repeat. When the driver's intention cannot be recognized (for example, when the signal from the accelerator pedal position sensor is lost). In this mode, the engine does not react to pressing the pedal. The car does not develop momentum and practically does not drive.

4. Limited power control mode

When the system cannot use the throttle to regulate power. In this case, the system determines from the position of the accelerator pedal whether the engine is idling or accelerating.

The system controls engine power by cutting off fuel or delaying ignition. At such a moment, the engine speed can float. The machine may move unevenly in this mode, as the rpm will float. Such a car will be difficult to drive.

Before looking at the throttle actuator, let's take a look directly at the throttle itself. The throttle valve is a mechanism that controls the supply of air to the internal combustion engine, during which fuel and air are mixed, or, to put it simply, it is a regular air valve. Includes a housing in which the parts are assembled: coolant inlet and outlet connections, ventilation connection, fuel vapor detection connection, idle speed regulator, throttle position sensor and the damper itself. Most carburettors on cars are two-chamber. The throttle valve of the first chamber is controlled by the accelerator from the cab of the machine, provides air supply at low gas (idle), cruising mode, nominal mode. The secondary chamber damper opens when the primary damper is fully open and provides air supply from nominal to maximum mode.

The purpose of the throttle valve drive follows from the above - air supply control. When you press the accelerator pedal, the damper opens, air is supplied and mixed with fuel, after which this mixture burns, giving power to the engine.

Types of throttle valve actuators.

There are two types of throttle valve actuators - mechanical and electric.

MECHANICAL. A mechanically driven throttle valve is most often used in domestic (last century cars), classic and inexpensive cars... This type of damper is set in motion due to its close connection with the accelerator pedal through the gas cable.

MECHANICAL. A mechanically driven throttle valve is most often used in domestic (last century cars), classic and inexpensive cars... This type of damper is set in motion due to its close connection with the accelerator pedal through the gas cable.

ELECTRIC. An electrically actuated throttle valve is installed on modern vehicles. Comes into action due to precise control electronic unit, in connection with which the process occurs instantly.

Throttle actuator device.

The mechanical throttle actuator includes: accelerator, rods and swing arms, metal cable. When you press the accelerator, the throttle valve rotates around the axis, opening up the air supply for preparing the fuel-air mixture. IN this type drives, parallel to the control with the accelerator is also provided manual control, consisting of a control knob, a cable in a metal sheath of the Bowden type, a control lever on the carburetor.

The electric drive, by virtue of its constructive solution, allows to achieve a more efficient transmission to the wheels with each change in the position of the accelerator; with all this, the efficiency of the engine increases, the content of CO in the exhaust gases decreases, and the performance characteristics that affect the safety of the machine are improved. The electric drive is quite complicated and includes:

The electric drive, by virtue of its constructive solution, allows to achieve a more efficient transmission to the wheels with each change in the position of the accelerator; with all this, the efficiency of the engine increases, the content of CO in the exhaust gases decreases, and the performance characteristics that affect the safety of the machine are improved. The electric drive is quite complicated and includes:

- electrical engine with two position gauges associated with the throttle control lever;

Accelerator with position meter;

Electronic control unit.

In addition to the above items, the system includes the brake and clutch pedal position switches. A feature of this drive and its positive side are: electrical connection of the accelerator with the damper; the ability to control the engine speed at idle (by changing the rotation of the throttle valve).

The principle of operation of the throttle actuator.

Mechanical. By pressing the accelerator, the driver overcomes the force of the return spring, acting on the rods and steering levers (metal cable), moves the throttle valve. The flow area of \u200b\u200bthe throttle increases, which increases the air supply to the mixing chamber. Depending on the amount of incoming air, a certain amount of fuel is injected. Fuel is mixed with air, supplied to the combustion chamber of the cylinders, due to which the engine speed increases.

When the accelerator is fully released, the throttle closes the flow area of \u200b\u200bthe throttle. For normal work of the engine in idle mode, there is an adjusting screw that limits the closing of the damper (starting the engine, operation with the engaged neutral gear). In some cases, especially for starting and running a cold engine, opening the damper with the adjusting screw is not enough, therefore, manual opening of the damper in the machine cab is used in parallel. With an intermediate, manual opening of the damper, the driver can, by pressing the accelerator, reach a higher speed, but when the accelerator is released, the damper will turn to the manually opened position and will not close further. For complete closure, you must close it manually.

When the accelerator is fully released, the throttle closes the flow area of \u200b\u200bthe throttle. For normal work of the engine in idle mode, there is an adjusting screw that limits the closing of the damper (starting the engine, operation with the engaged neutral gear). In some cases, especially for starting and running a cold engine, opening the damper with the adjusting screw is not enough, therefore, manual opening of the damper in the machine cab is used in parallel. With an intermediate, manual opening of the damper, the driver can, by pressing the accelerator, reach a higher speed, but when the accelerator is released, the damper will turn to the manually opened position and will not close further. For complete closure, you must close it manually.

The opening of the secondary chamber is carried out using a system of levers connecting both flaps. After opening the damper of the primary chamber by 2/3 of the stroke, the second chamber begins to open. In some carburetors, the secondary chamber starts to open only after the primary chamber is fully open. Carburettors with pneumatic secondary valve opening are also applicable.

Electric.When the driver moves the accelerator, the accelerator pedal position sensor, which is the presence of two independent variable resistors (potentiometers) that change the resistance from the position of the accelerator, transmits a signal to the electronic control module power plant cars. The module, having received the signal, performs the necessary operations and issues a command to the electric motor to close or open the throttle valve. monitors its actual position and signals this to the power plant control module.

The throttle position is corrected if necessary. If one of the sensors (potentiometers) fails, the engine automatically goes into reduced operation with a maximum torque of 80Nm. In case of failure of both potentiometers to the operating mode of 55 Nm. When shifting gears, the clutch pedal position sensor transmits a signal to the module, and the supply of the fuel-air mixture to the engine is corrected. When braking the machine, similar manipulations are performed. This saves fuel, reduces the CO content in the exhaust gases, and improves driving safety.

The throttle position is corrected if necessary. If one of the sensors (potentiometers) fails, the engine automatically goes into reduced operation with a maximum torque of 80Nm. In case of failure of both potentiometers to the operating mode of 55 Nm. When shifting gears, the clutch pedal position sensor transmits a signal to the module, and the supply of the fuel-air mixture to the engine is corrected. When braking the machine, similar manipulations are performed. This saves fuel, reduces the CO content in the exhaust gases, and improves driving safety.

The electronic control module for the power plant provides an emergency mode.In the event of a malfunction, a signal is sent to the control module, which analyzes it and issues a command to close the throttle valve to a position that provides limited vehicle movement, allowing you to reach the station maintenance... The electronic control module of the power plant has a built-in European diagnostic system, which constantly monitors the presence of CO in the exhaust gases, determines and warns of its excess.

Having examined and analyzed the device and operation of the throttle valve drive, we see that structurally they are both the simplest mechanical and complex and expensive electrical, electronically controlled drives. If a driver, having some skills, can independently repair simpler ones, then a highly qualified specialist with the necessary diagnostic equipment... We can also see that on cars with an electric throttle valve, an improvement is achieved performance characteristicsaffecting fuel consumption, traffic safety and ecology.

Having examined and analyzed the device and operation of the throttle valve drive, we see that structurally they are both the simplest mechanical and complex and expensive electrical, electronically controlled drives. If a driver, having some skills, can independently repair simpler ones, then a highly qualified specialist with the necessary diagnostic equipment... We can also see that on cars with an electric throttle valve, an improvement is achieved performance characteristicsaffecting fuel consumption, traffic safety and ecology.

Subscribe to our feeds in