Title

Throttle valve - this structural element fuel system a car with a gasoline engine internal combustionregulating the flow of air masses and the formation of air fuel mixture. This element of the intake system is located between the manifold and the air filter. The throttle is one of the main components of the vehicle power system.

Once the defective throttle body assembly is replaced with a new one, your car will start smoothly again without hesitation. And if your throttle body has gotten worse and hasn't been performing for a long time, the level of performance that recovers will be nothing short of refreshing!

Throttle Body Service - Clean the throttle body and wipe the bore and throttle body. Service is essential to ensure a smooth, efficient and safe work car. The throttle controls the flow of fluid and can increase or decrease engine power. It does not control the power or speed of the engine, as many people think. During maintenance A throttle valve technician cleans or wipes the hole and throttle valve.

The throttle valve is a kind air valveallowing you to control the pressure in the system. If the valve is open, the pressure level tends to atmospheric, and when it is closed, it decreases, approaching vacuum. Thus, the throttle valve also regulates the operation of the vacuum amplifier. brake system... This means that the smaller the valve opening angle, the lower the speed.

When this is done and the air speed has been checked and adjusted, the sensor performs a downtime, which is controlled by the computer. If done correctly, the vehicle should run in standby mode as if it were new. This charcoal and sludge is cleaned up during throttle body service. How well an engine is performing about a year after service is determined by how the car starts, how idle it is, when it's cold or warm, and when accessories like air conditioning and heating work.

Throttle body

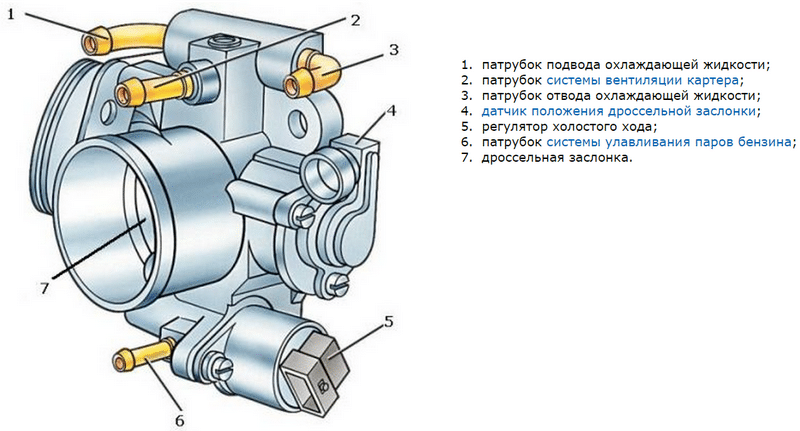

The throttle valve is a circular plate that can rotate 90 degrees around itself - it is a cycle from opening to closing. It is located in a corpus containing:

- Drive - mechanical or electrical;

- Position sensor - throttle potentiometer;

- Idle speed regulator.

Together, all of these components form the throttle assembly or throttle body.

Carbon and sediment will also affect how the car starts from a standstill. A service such as this will keep the clean valve, which is computer controlled, clean. If left dirty and covered in carbon, it will have to be replaced, and such replacement can be costly.

Mechanically actuated butterfly valve

An important part of the engine is the throttle body, which is part of the air intake system. An air intake system increases the amount of oxygen used to burn fuel. You can either gain or lose electricity with the air intake system depending on the tank vehicle... The throttle body is part of this air intake system. Keeping the throttle body in good working order will keep the car running without costly accidents.

The damper body is rather complicated. After all, he himself is part of the cooling system. It is the throttle assembly that opens the channels through which the coolant circulates. Equipping the hull with special branch pipes connected with the ventilation system and the fuel vapor recovery system makes the design even more complex. You should study this system in more detail.

The importance of throttle body maintenance

Thorough and regular maintenance throttle body will keep emissions from exhaust system engine under control. There is also a heightened sound when the throttle is applied with an accelerator. If the car runs for more low speeds, there is more noise from the engine. However, for more high speeds the engine becomes very noisy. These two statements make throttle body maintenance important in and of itself, as it makes the vehicle more environmentally friendly.

Idle speed regulator

With the help of the idle speed controller, the required speed is maintained crankshaft, with the damper completely closed. For example, if the motor heats up or the load increases, additional equipment is connected to the process.

It is very important to regularly service the throttle body to avoid high replacement costs. The cost of servicing the throttle body or replacing the throttle body varies by year, model, and vehicle model. But, no matter what this year, the model or make it may be, the replacement is not inexpensive. Excluding the cost of replacing the throttle body at the moment, perhaps more importantly, is to regularly service the throttle body to keep your vehicle running smoothly and efficiently.

The regulator is arranged as follows: a housing where an electric stepper motor is attached, connected to a conical needle. When the engine is idling, the needle, like a piston, regulates the cross-sectional area of \u200b\u200bthe air channel.

Drive unit

There are two types of actuators - mechanical and electrical. Their difference is only in the principle of work. The mechanical structure is much simpler and is connected to the gas pedal using a steel cable. Electric, on the other hand, has no direct connection with gas. How, then, does regulation take place? This is where the throttle potentiometer comes in. This special sensor communicates with the engine control unit, and the controller supplies the desired signal.

Although the throttle body is the primary way to control air flow through the throttle body, these components sometimes include additional valves or air flow paths. In addition to these major components, the throttle body usually also includes a throttle position sensor. This component is usually located on the main body of the throttle body opposite the throttle body, allowing it to be mechanically connected to the throttle plate.

How does the throttle valve work?

Some choke elements are attached directly to the MAF sensor, but these sensors are sometimes located next to the box. The throttle bodies control the air flow, allowing the driver to manipulate the throttle valve.

Potentiometer

In other words, the potentiometer changes the opening angle of the damper and thus affects the controller. When the damper is closed, the voltage does not exceed 0.7 V, and when fully opened, it reaches 4 V. This is how the fuel supply is controlled.

Throttle bodies work by providing the vehicle driver with a way to control the amount of air flowing through the intake system at any given time. Although the accelerator pedal is often referred to as the gas pedal, and phrases such as "step on the gas" are ingrained in our minds, the accelerator actually controls the flow of air into the engine.

When you press the accelerator pedal, one of two things happens. In most cases, the mechanical link between the pedal and the throttle body pulls on the throttle plate causing it to open. In cars with electronic control With the throttle valve it does the same thing, but the electric motor opens the throttle instead of a mechanical connection. When this happens, an increased amount of air can flow into the engine's intake manifold, and the MAF sends this information to the engine control unit.

If the throttle valve stops responding to the impulses coming from the position sensor, such breakdowns may occur as:

- Floating speed when the engine is running. Increased idle speed;

- The engine stalls when switching to neutral;

- Uncontrolled fuel consumption;

- The engine runs at half strength;

- The CHEK light is on - check if the throttle valve is working properly.

How to fix the problem

If you suspect that the throttle valve is faulty, you need to check the entire assembly where it is attached. To do this, follow the following algorithm exactly:

How is throttle body injection different?

This is a typical throttle body including throttle body, vacuum connections and gauges. Most modern gasoline engines Internal combustion uses direct injection, but many other types of fuel injection have been used over the years. One type that does not occur as often as it once was is the single-point injection. These systems are also called "throttle bodies" because there is only one fuel injector and it is located inside the throttle body.

- Disconnect battery negative terminal.

- It is necessary to drain the liquid from the cooling system.

- Move the hoses away from the throttle assembly.

- Remove the damper drive cable.

- Disconnect the potentiometer from the pads and the idle speed controller.

- Remove the throttle assembly.

- Check the condition of the throttle gasket and the rest of the assembly.

- If necessary, replace some of the components or the entire unit.

- Reassemble the structure in reverse order.

It combines fuel and air supply into one component, similar to the functionality of carburetors. The throttle bodies in these systems are similar to those used in other, more modern systems fuel injection, except that they have built-in fuel injectors.

When the throttle body degrades, there are several different common points of failure. Although they can fail mechanically, external parts and sensors are much more likely to fail. The specific diagnostic procedure depends on the problem you are experiencing as there are many different components that can fail.

After you have installed the unit in place, you need to check the tightness of the cooling system, where you refilled the liquid. There should be no drips or drips.

Damper adjustment

In order for the throttle valve to work like a clock, its sensor must be periodically adjusted. To do this, take a few simple steps:

Coking can lead to idle problems and other problems to a sticky or partially blocked throttle plate. One of the common problems with throttle bodies is called "coking". This is a problem where there is coarse, black deposit on the throttle plate or inside the bore and this can result in anything from rough idle to hard starting. In many cases, this problem can be fixed by simply cleaning the residue from the throttle body and bore, although precautions may be required.

- The ignition is turned off in order to move the valve to the closed position.

- The sensor connector is de-energized.

- The sensor is adjusted using a 0.4 mm dipstick located between the screw and the lever.

To check the health of the sensor, the voltage level is measured using an ohmmeter. If voltage is detected, the sensor should be replaced. In the opposite situation, you can continue to adjust the sensor.

Some throttle bodies are covered in materials that can be removed with harsh solvents, so cleaning the throttle body can actually damage it if you're not careful. The throttle body is part of the air intake system. It controls the flow of air to the engine, which controls the power and speed of the engine. It is located between the air intake hose and the intake manifold. When you step on your car's accelerator pedal, the throttle valve in the throttle valve opens to provide more air in intake manifold - hence the phrase "wide open throttle."

To do this, the damper rotates until you see the same indicators that are spelled out in the auto passport. Do not forget to check the tightness of the bolts and nuts after adjustment, during the process they could loosen.

As you know, the fuel system of a car is its viability. If it is even slightly disturbed, the car may surprise you unpleasantly at the most inopportune moment. If the throttle valve or other element of the unit fails, then the consequences can be dire. Therefore, it is much better not to skimp on car diagnostics, if you have the slightest suspicion of a malfunction. Remember - safety on the road comes first.

Throttle valve in the carburetor

The fuel injection system then adds more fuel to match the increase in air volume. When the pedal is returned to the up position, the rotary valve closes and effectively throttles, or “throttles,” the air flow. So in fact you could call the gas pedal an air pedal.

Throttle valve adjustment

In older cars, the throttle valve was controlled directly by a cable that was attached to the accelerator. These days, the throttle bodies are electronically controlled by the vehicle's computer. The computer sends a signal to the electric motor to open the throttle valve. However, the principle remains the same - open the throttle to let in more air and move faster.

We will tell you about what a throttle valve (DZ) is, how it works and how to correctly adjust it. The characteristics of the vehicle depend on how this element of the fuel system functions, one of which is fuel consumption.

Throttle body problems cause the throttle to supply too much or too little air. Too much air causes the engine to swell and idling... Too little air causes slow or uneven acceleration and sometimes decelerates. Throttle body problems can also reduce fuel consumption.

Throttle actuator device

The throttle body can get clogged from carbon build-up from exhaust gases engine and any dirt that slips past your air filter... You can often fix this problem by cleaning the throttle body assembly with solvent. It is also possible for the throttle valve to gradually wear out the throttle body. The space that wears out then allows more air to pass through.

DZ is an element of the fuel system of a gasoline engine. Its main task lies in the metered supply of air supplied to the cylinders of the internal combustion engine, and the formation of a fuel mixture. This element is installed after the air filter and in front of the intake manifold.

Throttle body appearance

Some throttle body problems arise from throttle body motor problems. The engine can get stuck in the open or closed position. Sometimes the electrical contacts of an electric motor build up or are worn out and act as if the throttle were wide open or fully closed when not. This can lead to many of the symptoms mentioned above. In some cases, when the engine is at the root of the problem, you can replace the engine yourself.

Throttle valve actuator types

Doing the job with some prior experience can certainly replace the throttle body assembly. First, you need to separate the air intake hose from the throttle body of your car or truck. Then you will need to remove the other hoses from the throttle body. Then remove the sensors such as the idle air control valve and the throttle position sensor. If the choke is controlled by a cable, separate the cable. If your vehicle is equipped with electronic technology throttle control, and not the aforementioned mechanical link, disconnect the wire harness from the throttle body motor.

In fact, the DZ is used as an air bypass valve. If it is in the open position, then there is no excess pressure in the intake system. If the damper is closed, then negative pressure is formed in the system.

There are two main ways to control the throttle:

- mechanical;

- electric.

Let's consider both variants of the mechanism operation.

Mechanics

This drive option is awarded to cars in the budget category. So the manufacturer reduces the cost of the car for the buyer. The principle of operation of the throttle valve with mechanics is quite simple: the remote control is directly controlled through the accelerator pedal by means of a steel flexible cable.

Mechanical drive DZ

The components of the remote sensing system are assembled in a single module. It combines the body, the remote control itself fixed on a rotating axis, the regulator idle speed, DZ position sensor.

You need to know that the engine cooling system heats the housing of the DZ.

For speed control function power plant the regulator provided in the design meets. Its task is to change the volume of air flowing past the damper when starting any additional equipment. Its main elements are a valve and an electric motor.

Electrician

For modern cars it is typical to use more expensive but effective electric drive. By installing such a unit, designers achieve the required torque value. This happens in all main modes of the power plant. It is also possible to achieve a decrease in fuel consumption, the requirements for safety and cleanliness of emissions are observed.

DZ electric drive

Features of DZ driven by electric motor is as follows:

- there is no direct contact between the accelerator pedal and the remote control;

- idle speed is adjusted by moving the remote control.

The lack of direct influence on the remote sensing when pressing the accelerator pedal allows you to use electronic system for remote sensing control.

The work of the electronics helps to set the desired engine speed even without pressing the pedal by the driver.

The control sensors are connected, the unit that controls the motor is started, and the actuator is activated.

The electronic device must be additionally equipped with a gas pedal position sensor, a clutch position lock, and a brake pedal position lock.

If the car is equipped with climate control, automatic transmission, cruise control and other nodes that affect the power of the car, then the sensors from them are also connected to the remote sensing.

Throttle valve operation

The engine control unit receives signals from sensors and reacts accordingly, giving "orders" to the damper.

Throttle valve malfunctions

Experts have calculated the approximate number of accelerator pedal clicks while driving on the road for a half-hour trip. It was a little over a hundred times. Such a considerable amount of work is performed by this device on a regular basis.

Carbon deposits on the flap

Unsurprisingly, failure of this assembly is a common problem. But how to diagnose the failure or reduced performance of this element? It is necessary to rely on some indirect signs:

- instability of engine idle speed;

- problems when starting both cold and hot engines;

- "Braked" response to the "recessed" accelerator pedal;

- a slight decrease in the power of the car.

If the damper becomes covered with dirt, then this negatively affects the consumption of gasoline.

Flap clearance

Cars with turbines are especially sensitive to this factor. Long-term operation of a vehicle with a dirty damper can lead to its jamming, which will entail sharp wear of the servo drive, and in conclusion will result in a rather expensive car repair.

DZ device

You need to know that a signal is sent to the dashboard about a problem with the damper.

Most often, information is obtained using a signal light with the signature "CHEK".

You need to know that new cars also react slightly with a delay to pressing the accelerator pedal. And this is not the reason for the poor-quality operation of the damper.

In this case, the car adjusts the electronics for driving. Therefore, a delayed reaction is possible. But if such a process is delayed, then you need to contact a specialist for more accurate diagnostics or to carry out the adjustment yourself.

Throttle valve adjustment

When starting the adjustment process, you must turn off the engine. After that, we disconnect the damper sensor and check the circuit for an open with an electric tester. If the readings show the absence of voltage, then the malfunction is practically found, and lies in the inoperative sensor.

Adjustment

If there is voltage, then you need a probe of the order of 0.4 mm. We measure the gap between the lever located next to the gasket and the screw. When the measurement is carried out, then we check the voltage, if there is one, the breakdown lies in the damper position sensor. If it is not there, then we turn the drive to the value between the terminals specified in the technical documentation.

After completing all adjustments, tighten all fastening hardware. This will help to avoid loosening the fastening of the elements on the damper.

If the adjustment was successful, then this will be announced by the reduced consumption and the increased power of the car.

You need to know that the throttle valve is one of the main factors affecting gas mileage in a car.

Therefore, timely repairs and adjustments will save money and increase vehicle power.