Every car owner knows that the choice of transmission is a key factor that affects the dynamic performance of the car. Developers are constantly trying to improve transmissions, but most motorists still prefer manual transmissions, because, due to the prevailing stereotype, they believe that it is more reliable and easy to use. However, the reason lies elsewhere - most people are simply not familiar with the principle of the machine, and therefore are afraid of it.

The spindle at the rear of the clutch has several functions. A stronger spring puts more pressure on the belt and prevents it from sliding, thereby transferring more force. The downside or rather the danger of using a strong spring is unnecessarily high strengthwhich can wear out too much. Conversely, if the spring is not strong enough, the gear ratio changes too early and unevenly, and, moreover, the gear ratio cannot go back, it can be recognized especially when driving uphill when the speed decreases and you can finally push off their legs.

In today's article we will try to describe the principle of operation of an automatic transmission in the most detailed and accessible way.

What is automatic transmission?

Automatic transmission is the main element of the vehicle transmission design, the main purpose of which is to change the torque, as well as change the speed. There are three variants of automatic transmission:

It is also important to know that the contrast spring will become weaker over time and must then be replaced with a new one. Thus, the spring force affects the engine speed during acceleration and hence the choice of roller weight. If you choose a weak spring, the belt will push the pulleys out more easily and you will need lighter rollers. Conversely, when using a strong spring, you will need rollers. The heavier the spring, the faster you will wear the skates. By maintaining the weight of the rollers by using a stronger spring, you increase the engine speed and vice versa.

- Variable speed drive;

- Hydroautomat;

- Robotic;

Which is better - mechanics or automatic?

As many may have already noticed, most Russian motorists prefer manual transmissions. Some experts believe that this is due to the mentality of the nation, others - with the established negative stereotypes.

Another thing is the Americans, 95% of whom cannot imagine the process of driving a car, without automatic box... But this is not at all surprising, because the automatic transmission was invented by American engineers who wanted to simplify the lives of drivers.

In all scooters we find a centrifugal clutch. When starting the clutch rotates with the belt and pulleys, the speed gradually increases, the centrifugal force overcomes the force of the springs that hold the clutch LIQUID. This shoe clutch contact with the clutch bell, rotate the shaft and finally we start to rotate rear wheel... So how do you affect the speeds at which the scooter starts? Selecting the correct clutch springs. Stronger springs hold longer clutches longer and start at higher speeds.

Travel speed should be about the same as scooter acceleration, that is, those that will influence the choice of contrast rollers and springs. All together will give us both a racing start and excellent acceleration. The belt is the part of the transmission system that causes the most power loss. Friction and movement creates a lot of heat, resulting in a loss in performance. Therefore, it is desirable to keep friction at the lowest possible value. But, of course, a force that prevents the belt from sliding and provides uniform acceleration must be developed.

The situation is the same in Europe. If 15-20 years ago, everyone without exception used mechanics, but now it is almost ousted from the market.

In Russia, the popularity of the automatic transmission is also growing, but, according to experts and analysts, Russians do not know how to properly use an automatic transmission. Every day, a lot of motorists turn to car repair shops with malfunctions, the main reason for which is just improper operation.

It is important to summarize the facts of the interaction of the spring and the belt - force rear spring is of great importance for sliding. The spring must be strong enough to prevent the belt from slipping. When deciding which spring you will take into account both the driver's weight and the conditions in which the scooter is most often used. The spring force should be chosen very carefully as conditions rarely change during the race. For general use, consider if you work often with your driver or the hills - then a stronger spring is recommended.

Some manufacturers offer Kevlar belts that are stronger and more resistant to temperature and slippage than standard belts. They are not the cheapest, but they are recommended for use in modified engines. Some manufacturers offer so-called overload kits, a CVT combined with a longer belt. When a longer belt is installed, the range of the entire transmission system is increased, for example, if a longer belt is running at a smaller diameter on one pulley, logically, the larger diameter on the pulley may be the opposite.

How does automatic transmission work?

In order to make the principle of operation of an automatic transmission more understandable, we will conditionally divide it into three parts: mechanical, electronic and hydraulic.

Let's start the discussion, of course, with a mechanical one, since it is this element that changes gears.

The hydraulic part is a kind of intermediary, which is a connecting link.

This is especially useful for accelerating acceleration from idle speeds and increasing speed. Now you know what it works and how it works, and you will see that you quickly acquire acquired knowledge when tuning the gearbox and allow yourself a few extra seconds to accelerate. These are automatic transmissions with smooth gear shifting. Between these two extremes, the gear can shift smoothly without any bump or break. The change in the gear ratio is carried out by a coordinated axial displacement of the tapered discs, thereby changing the diameter of the pulleys.

And finally, the electronic one, which is considered the brain of the transmission, responsible for switching modes, as well as feedback.

Everyone understands that the heart of the car is the motor. The transmission does not claim this role at all, because it can be safely called the brain of a car. The main goal of the automatic transmission is considered to be the transformation of the KM motor into a force that creates conditions for the movement of the vehicle. An important role in this process is played by the torque converter and planetary gears.

The originally tensioned tensioning V-belt has been replaced with modern belted belts made of flexible steel rings with hundreds of steel strings. Smooth gear changing can keep the motor as long as possible in this optimal working area. At normal driving speed and constant speed, the engine can be maintained at optimal power rotation, at maximum acceleration the engine rises to its highest power level and only accelerates the vehicle's gear ratio.

In addition, the development of electronics made it possible to program "fixed" gearboxes for the mode manual switching... The automatic transmission is gradually becoming popular and popular, especially among newcomers, as well as women and drivers who move mainly throughout the city. But how to buy a slot and what to look for?

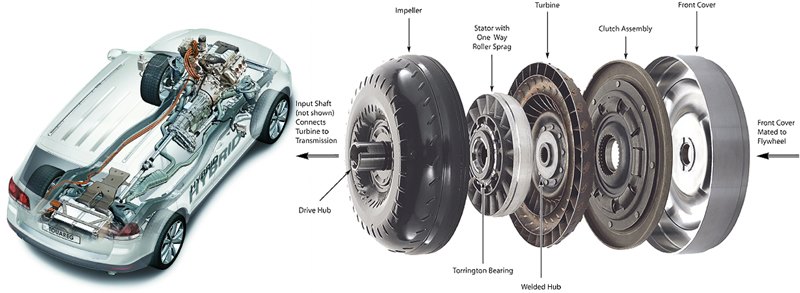

Torque converter

By analogy with the manual transmission, the torque converter acts as a clutch, and also regulates the KM, taking into account the speed and the produced engine power.

The converter design consists of three parts:

- Centripetal turbine;

- Centrifugal pump;

- Guiding device-reactor;

Due to the fact that the turbine and pump are as close as possible to each other, the working fluids are in constant motion. It is thanks to this that it is possible to achieve minimal energy losses. In addition, the torque converter boasts a very compact size.

You can buy your car on almost every car, and the choice is even greater among cars. Plus, it's not just luxury brands, and you may already have automatic mechanisms in cheap city cars. Disadvantages of an automatic transmission.

Difficult and expensive service Old machines increase consumption In weakened cars, dynamics deteriorate. As you can see, the automatic transmission has many advantages. If you decide to buy an automatic transmission, you need to know what type of car the transmission is in. This is not a slot machine.

It is worth noting that the crankshaft is directly connected to the impeller, and the box shaft is connected to the turbine. It is due to this, in the torque converter there is no rigid connection between the driving and driven elements. The working fluids transfer energy from the motor to the transmission, which, in turn, transfers it through the pump blades to the turbine blades.

In small cars, robotic gearboxes, which do not have a clutch and a gearbox, are self-acting, they most often occur, but in principle it is a classic mechanical gearbox, only the change of speed and switching of the classic clutch is electronically controlled.

The classic type of automatic transmission is a hydrodynamic transmission that replaces the conventional clutch. The indisputable advantage of these gearboxes is the very smooth and fluid displacement of the gears. These types of automatic transmissions are most often found in stronger and big cars... In addition, modern vending machines are already very efficient and fuel consumption can often be reduced.

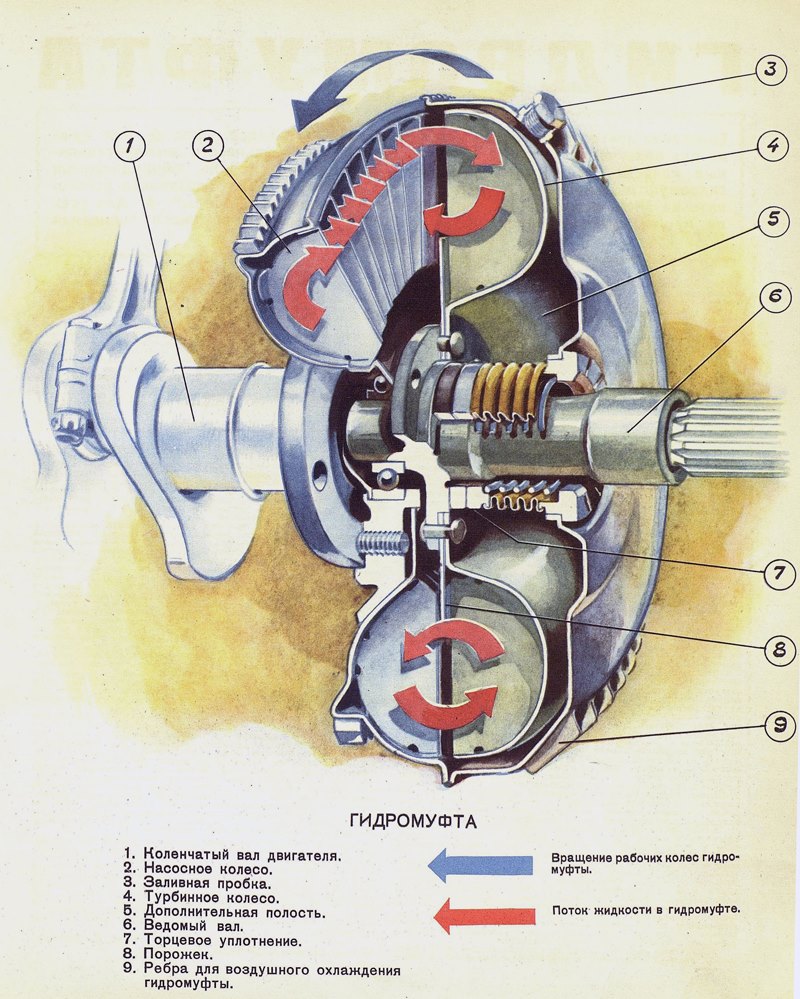

Fluid coupling

If we talk about the fluid coupling, then its principle of operation is very similar - it also transmits CM without affecting its intensity.

The torque converter is equipped with a reactor primarily in order to change the CM. In fact, this is the same wheel with blades, except that it is more rigidly set and less maneuverable. It returns the oil from the turbine to the pump. Some features have reactor blades, the channels of which are gradually narrowed. Due to this, the speed of movement of working fluids increases significantly.

You will most often encounter them in hybrid vehicles. The high-tech solution combines the speed and fluidity of a hydrodynamic transmission with the efficiency of classic manual transmissions. If you are buying a used car with an automatic transmission, check which slot machine is available to you and focus on its function. A thorough test drive that focuses on the automatic function is essential.

Take a look at how the machine works, how it behaves when driving, and what it does when full throttle is depressed. This works if you quickly press the gas pedal to the floor. The gearbox must immediately engage the lowest gear in order to drive the engine to achieve the highest possible output. A special feature of the machine is that if the car is stationary in order to release the brake, it must spontaneously decelerate if you have a mechanism. Beware, some robotic gearboxes need a light pedal command to start, depending on the type of vehicle.

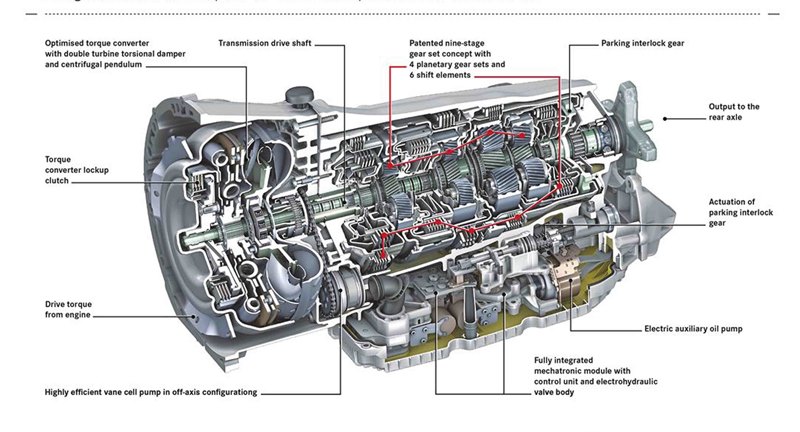

What does an automatic transmission consist of?

Torque converter - interacts with the clutch and does not contact the driver.

Planetary gear - interacts with the gears in the box and changes the configuration of the transmission when shifting gears.

Brake band, rear and front clutch - directly change gears.

The hydrodynamic transmission must not be severely damaged when shifting. Instead of this robotic box the gear should turn off the gas when you turn it manually. When you buy a vehicle, check the manufacturer's prescribed service intervals for the automatic transmission. It is important to follow these service inspections and change if necessary transmission oil... Although some manufacturers claim that the transmission has a lifetime oil content, it is recommended to change the oil after a run.

The control device is a unit that consists of a pump, a valve box and an oil sump.

Valve body is a system of valve channels that monitor and control the engine load.

Torque converter - designed to transmit torque from power unit to the elements of automatic transmission. It is located between the gearbox and the engine, and thus serves as a clutch. It is filled with a working fluid that traps and transfers the engine's forces to the oil pump, which is located directly in the box.

The automatic transmission is the best invention in the automotive industry by many drivers. Of course, "auto" also has many opponents who argue that it does not allow the car to feel and feel that the driver is in complete control of everything. On the other hand, owners of cars with automatic transmission often claim that they will never go back to manual transmissions. it a good choice for fans of manual transmissions who want to get a taste of driving with "automatic", but due to the cost, not everyone can afford this solution.

Concerning oil pump, then it already transfers the working fluid to the torque converter, thus creating the most optimal pressure in the system. Therefore, the myth that a car with an automatic transmission can be started without a starter is a pure lie.

The gear pump receives energy directly from the engine, from which it can be concluded that when the engine is off, there is no pressure in the system at all, even if the automatic transmission shift lever is not in its initial state. Therefore, forced rotation cardan shaft will not be able to start the engine.

Of course, there is no way to change gears bypassing multiple gears - everything happens one after the other: from first to last and vice versa. Likewise, in the rally and racing cars series gearboxes available. Of course, there are varieties with more gears. The driver has the ability to select the mechanism, which in turn directly affects the driving dynamics and characteristics.

Due to numerous safety and certain operating rules, the driver is not able to spill too many gears at once, as a manual gearbox will lead to an out of turnover on a red field - however, a fairly wide range of car controls and start them in accordance with your preferences. In many cases maximum speed the car can be reached on the penultimate run. Thanks to this solution, the normative ratio can act as a so-called overdrive, useful on the road.

Planetary gear - is often used in automatic transmissions, as it is considered more modern and technologically advanced than the parallel shaft used in mechanics.

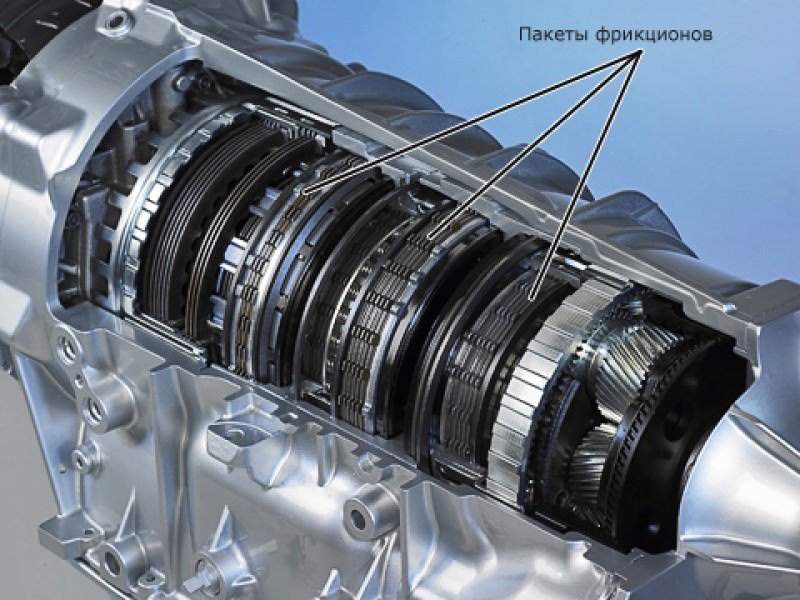

Friction parts - The piston is driven by excessive oil pressure. The piston itself very tightly presses the driving elements to the driven ones, forcing them to rotate as a whole, and transfer the CM to the bushing. It should be noted that the automatic transmission contains several such planetary mechanisms at once.

On automotive market fought for years mechanical boxes transmission with an automatic transmission. Recently, the result of this collision is increasingly leaning towards the other side. When comparing gearboxes, the interesting conceptual and purely technical ideas of continuously variable transmission are often forgotten. How does such a chest work?

The rear wheels were driven by rubber bands. There was also an initial clutch and vacuum regulator. With this tradition, they attract other companies, fueled by the idea that an infinite number of gears can be achieved without interrupting the transmission of torque.

Friction discs transfer CM directly to the wheels of the vehicle.

Brake band - used to block elements of the planetary gear.

The valve body is one of the most complex mechanisms in the automatic transmission, which is called the "brains of the transmission". It should be noted that the repair of this element is very expensive.

Types of automatic transmission

Permanent race technical equipment cars, forces developers to come up with more and more sophisticated technologies and designs in order to overtake competitors. It should be noted that this has a positive effect on the development of the vehicle's chassis. One of the most important discoveries was the invention of the automatic transmission. She immediately began to enjoy incredibly high demand, as it greatly simplifies the management process. In addition, it is very easy to operate and reliable. Analysts say that in the near future it will completely oust manual transmission from the market.

Today, the automatic transmission is used as in passenger carsand trucks, regardless of the type of drive.

It is known that when driving a car with a manual transmission, you have to constantly keep your hand on the gear selector, which significantly reduces concentration on the road. The automatic transmission is practically devoid of such disadvantages.

The main advantages of the automatic transmission:

- Management efficiency increases;

- Smoother gear transitions even at high speeds

- The engine is not overloaded;

- Gears can be switched both manually and in automatic mode;

Modern automatic transmissions, from the point of view of the control and management system, can be divided into two types:

- Hydraulic transmission;

- Transmission with electronic device, or the so-called robotic box;

This should become clearer after reading the example below:

“Imagine a situation where the car is driving on a flat road and gradually approaching a steep incline. If you simply observe this situation from the sidelines for some time, you will notice that after increasing the load, the machine begins to lose speed, and, therefore, the intensity of rotation of the turbine also decreases. This leads to working fluid begins to counteract the movement. In this case, the circulation rate sharply increases, which contributes to an increase in CM up to the index at which equilibrium will arise in the system. "

The principle of operation is the same when the vehicle starts moving. The only difference is that in this case the accelerator is also involved. It increases the speed of the crankshaft and pump wheel, while the turbine remains stationary, which allows the engine to idle. It is worth noting that the KM increases sharply, and when a certain mark is reached, the torque converter begins to perform the functions of a link that connects the driven and driving elements together. It is all these moments that make it possible to significantly reduce the level of fuel consumption while driving, and more efficiently carry out engine braking if necessary.

So why then connect the automatic transmission to the torque converter, if it is independently capable of changing the intensity of the CM?

Here's why: The torque converter's torque change ratio is usually less than 2-3.5. This is not enough for the full operation of an automatic transmission.

Unlike a mechanical one, an automatic gearbox shifts speeds using friction clutches and band brakes. The system automatically determines the required speed based on the driving speed and the effort on the accelerator pedal.

In addition to the planetary gear and the torque converter, the automatic transmission also includes a pump that lubricates the gearbox. The oil is cooled by a cooling radiator.

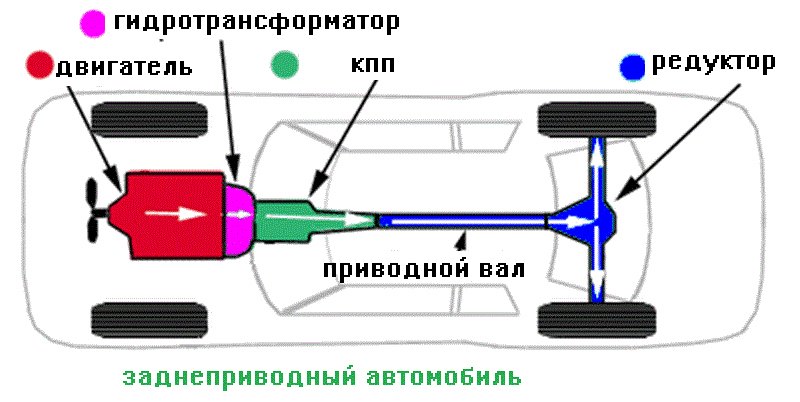

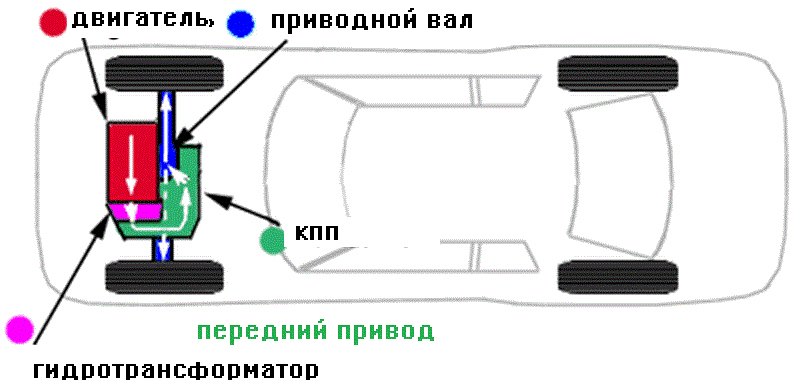

The difference between an automatic transmission in rear-wheel drive and front-wheel drive vehicles

There are a number of differences between the automatic transmission layout of cars with front and rear wheel drive. Automatic transmission front-wheel drive cars are more compact, and has a separate compartment, which is called a differential.

In all other respects, both transmissions are identical, both structurally and functionally.

For the effective performance of all functions, the automatic transmission has the following elements: a torque converter, a control unit and a mechanism for selecting the driving mode.

We hope that our article has become as useful as possible for you, and has helped you understand the principles of automatic transmission.

Video

An automatic transmission is a device that provides a choice gear ratio according to conditions road surface, terrain and speed without the direct involvement of the driver. In a car equipped with automatic transmission, the accelerator (gas pedal) sets the speed at which the car is moving, and does not determine the engine speed - this is the principle of the automatic transmission.

History indicates that the automatic transmission was invented somewhere in the thirties of the twentieth century. Since the very appearance of such a transmission, the principle of operation of an automatic transmission has practically not changed, but depending on the time and those or other technical requirements constantly updated. Thanks to such additions, automatic transmissions appeared, differing in their options, models. Have different manufacturers they have different specifications.

When distinctive characteristics all automatic transmissions have one principle of operation. This is due to the fact that they have almost the same device, if you do not take into account some small nuances.

Automatic transmission device

Automatic transmission device

- The main one is the torque converter, which is also called the fluid coupling - this is a mechanism located between the engine of the machine and the gearbox housing. The functional task of the fluid coupling is the transmission and redistribution of torque during the start of the car;

- The torque is transmitted indirectly using planetary gearboxes;

- Friction clutches are responsible for the choice of a particular gear, they are often called a "package";

- One of the mechanisms is freewheel, which mainly performs the function of reducing in "bursts" of shocks during gear changes. In some cases, when the automatic transmission is operating, the overrunning clutch disables engine braking;

- The box device also includes drums and connecting shafts;

The principle by which the automatic transmission works

To control the automatic transmission, there is a special set of so-called spools that direct the oil under a certain pressure to the friction clutches and brake bands to pistons. It is possible to set the position of the spools in automatic or manual mode, using the gear shift knob.

You also need to know that automation, control automatic transmission, can be hydraulic and electronic. Hydraulic is an automation that uses oil pressure obtained from a centrifugal regulator. In turn, the centrifugal regulator is connected to the automatic transmission shaft, which is located at the outlet. Hydraulic system is designed to use oil pressure in accordance with the position of the accelerator. The machine receives information about the position in which the gas pedal is located - this is a command for the spools to switch.

Automatic transmission scheme

IN electronic system control there are solenoids responsible for moving the spools. The solenoids are connected to the automatic transmission control unit by cables; it is also possible to connect them with the control of the ignition and fuel injection system. In this case, the movement of the solenoids is controlled by the electronic unit management. The block also controls the solenoids depending on the position of the gear shift lever, the speed at which the vehicle is moving and the position of the accelerator.

Features of using automatic transmission

In order to avoid various breakdowns and troubles, you need to know how the automatic transmission works and how to use it. Cars equipped with an automatic machine are very practical and comfortable vehicles... Even though many car enthusiasts are skeptical about such transmissions, they are very popular. Usually it all depends on what the person is used to. If the driver loves dynamics, speed, then automatic transmission is not an option for him. Having considered the device, technical characteristics and how the automatic transmission works, it becomes clear that it is intended for people who prefer a more relaxed driving style.

The torque converter performs the function of smoothly connecting the box to the engine

In any case, before you start to master a car with a machine gun, you need to study all the nuances and rules for using such a transmission. It is important to understand that neglecting some of the features, you can disable the automatic transmission in a fairly short time. You also need to know that repair or replacement of the entire automatic transmission will cost a lot of money.

Rules for operating the machine

Even if the entire transmission is electronically controlled, the driver is required to follow certain rules for operating it using the gear selector knob: