Any malfunction of a car is a serious test for a driver of any qualification. And if the voltage of the on-board network of the VAZ 2141 falls, then this is one of their many. Electrical problems are further complicated by the need to have specific knowledge in this area.

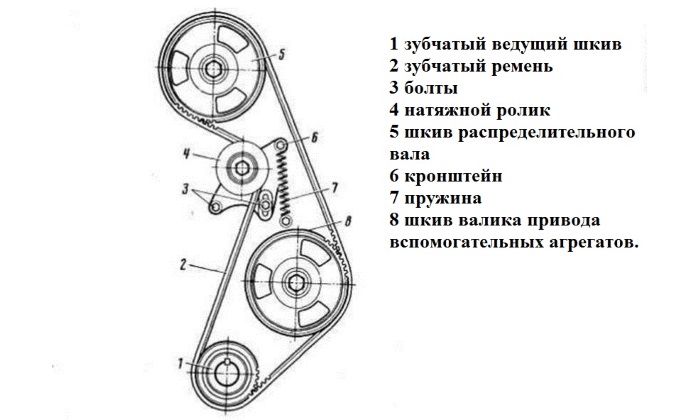

The complexity of such a defect is in its multitasking. The functional dependence of many units of the VAZ 2114 car does not allow us to immediately name only one single reason. Low or unstable voltage of the on-board network can be caused both by the failure of the generator units and by defects battery (Battery). A break is possible drive belt or at least loosening its tension.

This article is intended to understand all the intricacies of such a defect.

What could be the reason

On modern cars there are 2 sources of electricity. This is, first of all, the generator of the car and its indispensable companion (the initiator of his labor exploits) - the battery. Working in pairs - they represent an automatic power plant in miniature. Such a station supplies energy to all consumers of the car.

Can they work independently? They can, but with disabilities:

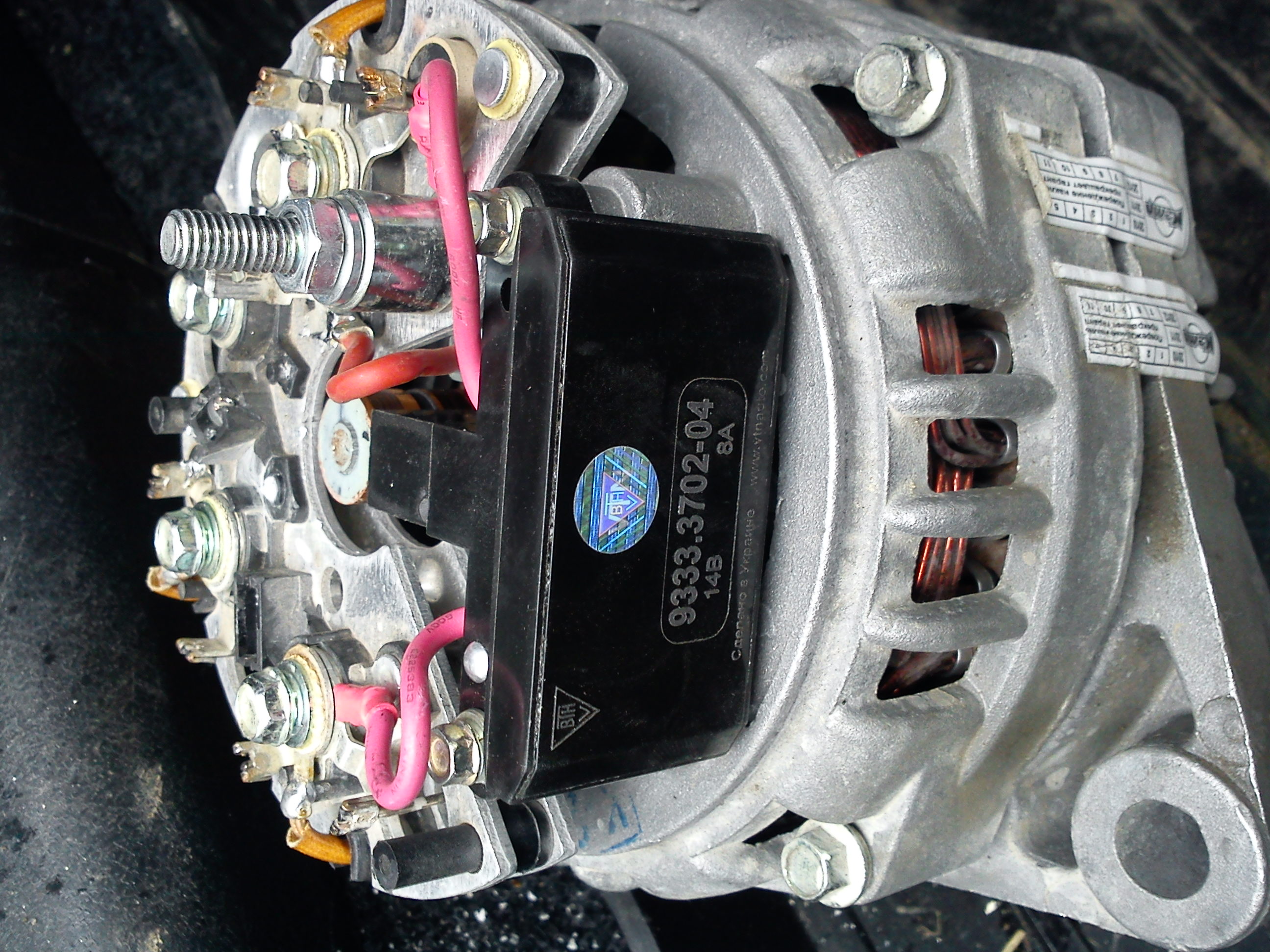

- generator (model 94.3701) - before the first shutdown of the engine, after starting from an external source;

- Battery - for about an hour. No powerful consumers;

- it is possible completely without this duet - on a tow truck;

- but they should not work with faults. More precisely, they can, but with unpredictable consequences. This will be a roulette wheel with all sorts of accidents, which are, as the basic law of the auto mechanic says, an unknown pattern.

The operation of such a power plant is stable and produces about 14 V. When connected to a full load, it cannot drop by more than 1 V. Otherwise, it will be necessary to deal with the causes of deviations from the norm:

- the drive belt is broken and the engine torque is not transmitted. The engine is operated from the battery, which gradually discharges with a drop in voltage to extremely low values \u200b\u200band the engine stops;

- its tension has weakened - the indicators of the on-board network are unstable. The consequences are similar, up to stopping the car;

- faulty condition of the rectifier unit (staples, horseshoes).

- there is a decrease in the supplied energy or its complete absence. The consequences are the same, with the possible failure of all electrical equipment of the machine;

- the voltage regulator (tablet, chocolate) does not work (model 611.3702-14);

- both high and low voltage, which is significantly different from the optimal;

- the regulator itself cannot be repaired - it must be replaced with a similar model;

- replacement or cleaning of brushes is possible;

- due to the constriction of the drive belt, there are frequent cases of failure of the front bearing assembly;

- an extraneous rumble is heard;

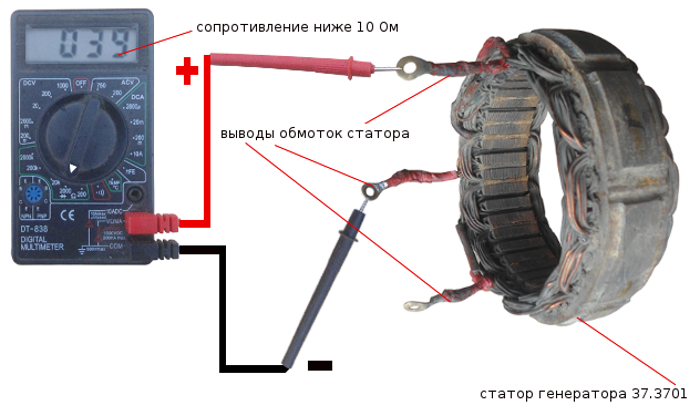

- short circuit in the stator or rotor windings;

- replacement of the entire electrical installation.

If the performance of the battery is not in doubt, and on-board computer gives information about the lack of battery charging and when the load changes, the network indicators drop, which means it is time to diagnose the state of the car's electrical installation.

Do-it-yourself troubleshooting

It is better to start diagnostics of cars of the VAZ 2114 model with the most accessible and simple reasons possible problems... It is necessary to adjust the tension of the drive belt, make sure that its brush mechanism is in good condition (including the general condition of the holder). Tighten the power cable fixings. The worries about dismantling the entire unit and its revision should be carried out after all the previous versions of the results have not yielded.

As in the previous case, you need to start from a simple case to a complex one:

- checking the status of the regulator;

- make sure again that there is less than 14.6 V on a cold motor;

- turn off the engine, disconnect the battery terminals;

- disconnect all electrical wiring from the unit being repaired;

- remove the plastic protection of the electrical contact assembly;

- remove the wiring block and unscrew the 2 fixing screws;

- remove the regulator;

- make sure of good condition brushes and brush holder, otherwise - replace;

- using a battery, a 12V bulb and 2 finger batteries check the functionality of the "tablet". By alternately supplying 12 V and then 15 V, make sure that the light on the brushes is on;

- otherwise, replace the tablet with a similar model;

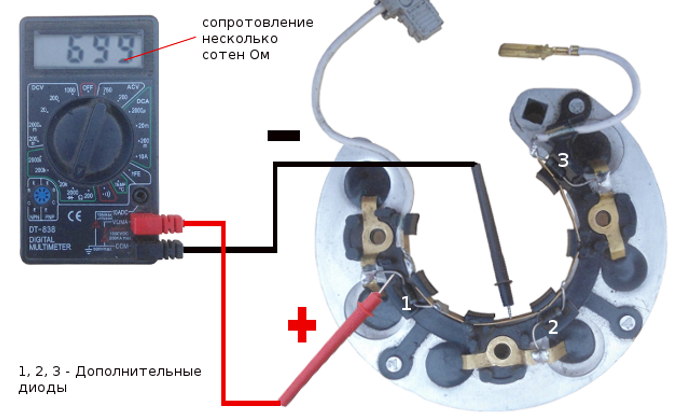

- checking and replacing the diode bridge (horseshoe), for this purpose it is better to remove the generator from the car;

- unscrew 3 fastening nuts and 2 fastening nuts for spacer sleeves with a ring or socket wrench;

- disconnect the supply wires (soldering) and remove the "horseshoe";

- in this state, you can check the suitability of all 6- and power and 3-additional diodes, if you have a multimeter and certain skills of an electrician;

- replace faulty diodes or purchase a new unit entirely;

- at the same time you can check for breakdown and the windings of the generator itself;

- its replacement without removing protection;

- select the right tool - various 13 mm wrenches. and 10 mm, socket heads 13,17 and 19 with a ratchet, lever (mount);

- disconnect the battery;

- loosen the excessive tension of the drive belt; remove it, together with the adjustment unit;

- remove the battery connection wire;

- using the “13” head, unscrew both bolts of the adjusting bracket to the vehicle block, one of them is longer than the other;

- after that, by turning the generator clockwise, it will be possible to remove its attachment axis to the bracket;

- do not miss the opportunity to check the condition of the front bearing assembly;

Having thus removed the electrical installation, you can tackle the solution of all both mechanical and electrical problems associated with the performance of this unit. However, it should be assumed that if the replacement of the "pill" and adjustment tension belt - operations are quite affordable for an ordinary car enthusiast, then manipulations are still better done in specialized car services.

Having thus removed the electrical installation, you can tackle the solution of all both mechanical and electrical problems associated with the performance of this unit. However, it should be assumed that if the replacement of the "pill" and adjustment tension belt - operations are quite affordable for an ordinary car enthusiast, then manipulations are still better done in specialized car services.

Why does the voltage drop in the on-board network of the VAZ-2114? For the same reason as in any vehicle with a battery-operated electrical system. The generator does not supply (or does not provide enough) current to charge the battery and power consumers. There can be several reasons for a generator failure:

- Mechanical faults.

- Electrical faults.

- Voltage regulator malfunction.

- Faulty wiring.

In turn, each item on the list includes more than one reason why there may be a low voltage in the network.

Mechanical problems

- Generator bearings are seized or destroyed.

- The belt is broken or excessively stretched (worn out).

- A mounting bracket or belt tensioner has collapsed.

Any of these faults can also be eliminated mechanically. It is unlikely that it will be possible to change bearings on the road, but a broken belt can be replaced with women's tights tied with a ring. They, or a piece of wire, can help out in the event of a breakdown of the bracket or belt tensioner, performing the function of stretching.

Electrical problems

These problems are much more complicated than mechanical ones, since they cannot be detected with the naked eye, unless the wire or terminal is burned out in a conspicuous place. Instruments are needed here. And the search space for breakdowns is much wider, and there are more of them. Here are the most likely ones:

- There is no current supply to the field winding.

- Broken brush assembly.

- Violation of the geometry of the slip rings.

- Excitation winding defective.

- Open or short circuit in the stator winding.

- Breakdown of the diode bridge.

Let's sort them out in order. Why can't the excitation current be supplied to the winding?

- The fuse has blown.

- Broken or shorted to ground wire from the fuse to the generator.

A malfunction of the brush assembly manifests itself in wear or destruction of the brushes.

On many modern generators, the brush assembly takes on the functions of a voltage regulator, since an electronic valve is mounted on it.

The rings on the generator rotor are very often the reason for the lack of "charging" or low voltage in the on-board network. Even a small output on them with fast rotation of the rotor does not allow the brushes to adhere tightly to the surface of the rings. As a result, the contact resistance between the brush and the ring increases and, accordingly, the excitation current decreases. The grooves on the rings, machined with brushes, are eliminated by grinding on a lathe with fine emery paper.

The serviceability of the excitation winding is expressed in the absence of short circuits and breaks. Often a break occurs at the soldering points of the winding wire with slip rings. The malfunction is eliminated by carefully soldering the defective place. It is important to ensure that the solder does not leak onto the surface of the ring.

The stator winding rarely fails, but it still happens. You can check with a tester on a disassembled generator.

And finally, the diode bridge. Generators modern cars generate 3-phase alternating current, and all consumers are powered by direct current. Therefore, a current rectifier is mounted in the generator, consisting of 6 diodes, 2 for each phase.

The diode bridge (rectifier) \u200b\u200bconverts the alternating current into a pulsating constant, the capacitor connected to the output terminal smooths out the ripple, the regulator maintains the output voltage level within the specified limits - this is how it is generated d.C. in the vehicle generator to charge the battery and power consumers.

In conclusion, I would like to give a recommendation to those who wish to minimize the likelihood of such malfunctions on the road: regularly (every 15-20 thousand km of run) diagnose the generator of your car. Thus, you will avoid many troubles associated with a voltage drop in the on-board network of the VAZ-2114.

I didn’t know any particular problems, but as one guy in the service said, with these cars on average every two months, something happens, something breaks down.

In the morning I am going to go to work, as usual I start it, turn on the tumanki, and I see in the reflection of the fence at which it was parked that the right tumanka flickers feverishly like a straboscope (there is xenon). Since there is already little experience in this, I concluded that there was not enough power, clicked on the voltmeter on the tidy and was stunned, it sank to 10 volts when the turn signals were turned on, especially for some reason. My bulbs there are a little not standard, tk. white turn signals in the back, stuck in there yellow lampsperhaps because of them. In general, I had to go to work on the battery. After reading various forums, I decided to purchase a three-level voltage regulator.

The three-level voltage regulator is installed directly on the side of the car, and the brush unit or panel (depending on the version) is installed in the generator. Switching of regulated voltage levels is performed by a three-position toggle switch built into the regulator, depending on the following conditions: “minimum” level - 13.6 Volts for vehicle operation at air temperatures above +20 ºС, long climbs, etc .; The "norm" level is 14.2 Volts for the operation of cars in temperature conditions 0 ºС - +20 ºС; The "maximum" level is 14.7 Volts for vehicle operation at negative air temperatures; when numerous additional current consumers are switched on; after long-term parking; after a significant battery discharge caused by connecting devices (radio tape recorder, TV, refrigerator, etc.) while the engine is not running. The use of three-level voltage regulators allows you to solve the problems of charging the battery and extend its life. The standard voltage regulator built into the generator, although it has a negative temperature compensation, that is, when the air temperature drops, it increases, and when the temperature rises, it decreases adjustable voltage, but in reality it is not able to monitor the air temperature outside the generator, since the air temperature inside the generator quickly reaches high values, sometimes exceeding +100 ºС. In addition, the inclusion additional loads (glass heaters, headlights, stoves, etc.) leads to the discharge of the battery even when the engine is running with a working standard voltage regulator. All these problems are solved by installing three-level voltage regulators. Tens of thousands of three-level voltage regulators are already in operation at different cars and have proven to be effective and reliable. These products are covered by the Energomash brand warranty - 2 years from the date of sale. Three-level regulators are provided with personal branded packaging and detailed instructions... Installation of a three-level regulator is quick and does not require any special knowledge and tools.

For comparison, the old PH. The brushes were noticeably worn off there, although as it turned out, as a spare, it still fit.

Replacing the PH did not give any result, so a diode bridge was also bought.

Replacing the bridge, however, also did not lead to the desired result)) In general, I moved, cleaned all the contacts, threw a minus on the battery terminal into another hole, and to my surprise it helped. Finally everything worked as it should. I didn't take pictures of the old bridge, because I was too lazy, and I forgot) It's getting dark now early, I don't have a garage, I tried to do everything as quickly as possible. If anyone is interested in a previous record about music, there is a video showing the voltage before replacing the PH with a three-level one (there was about 13v there). Now the picture is much nicer.

Let's see how long this pribluda will last.