Author racer

A car battery is an expensive part. vehicle... Therefore, it is necessary to properly operate it, and, if necessary, carry out competent repairs. Then the battery will last for many more years. You can entrust complex recovery operations only to an experienced battery operator, and you can try to eliminate simple malfunctions with your own hands.

The main types of damage and repair options

There are several major car battery malfunctions most commonly encountered. Some of them can only be eliminated on collapsible battery models.

Internal break... Most often there is a separation of the plate from the output in any bank. Repair is only carried out in the case of a collapsible battery design You should immediately saw through the jumpers that connect this jar with the neighboring ones, remove the mastic from the jar lid, remove the block of plates from the jar. The plates must be rinsed with distilled water, and the unit must be visually inspected to detect breakage. To restore the connection, you need a soldering iron with a power of 0.1-0.2 kW. Previously, the places that will be soldered are cleaned to a shine and treated with an alcohol solution of rosin or stearin. Soldering should only be done with pure lead solder.

Observing the polarity, the plate block returns to its place. The jumpers are sealed, and the gaps between the body and the lid are filled with liquid mastic.

Damage to cans... Damage of this type is repaired by replacing the cans or filling the crack in an accessible way (soldering, gluing, sealing).

Blocking Blocks, warpage of plates. These types of damage can be repaired by completely replacing blocks or plates.

Sulfation of plates... Often the cause of this malfunction of the battery is electrolyte contamination, the use of technical water, a long-term presence of the battery in a discharged state. To eliminate sulfation, it is necessary to perform desulfation charge-discharge cycles and replace the electrolyte. The number of cycles depends on the nature of the fault. If foam appears, it must be constantly removed.

Terminal repair... The most common terminal faults are cracks and chips. The damage can be eliminated by welding, soldering, as well as using suitable hardware (self-tapping screws, screws, screws).

Features of repair of acid, alkaline, lead, traction batteries

Every year there are more and more modern batteries, differing from classical models by the material of the plates and the composition of the electrolyte. Therefore, when repairing each type of battery, you should take into account their features and differences.

Acid Batteries... This type of battery is well known to both motorists and repair specialists. The main trouble with maintenance and repair lies in the aggressiveness of sulfuric acid, which is in the battery. Special care is required when draining and refilling electrolyte, and good system ventilation in the room where repairs and charging are performed.

Depending on the material used for the manufacture of plates, acid batteries can be:

- lead (low antimony),

- calcium, designated by the marking "Ca / Ca". Both the positive and negative plates contain calcium in their composition.

- hybrid, positive plates are made of lead with added antimony, and negative plates are made of calcium. Such batteries are designated "Ca +".

Gel and AGM models... Instead of a liquid electrolyte, a gel-like substance is used. These batteries can be tilted, they have a low self-discharge rate and are not afraid of overcharging. But gel batteries must be charged with a very low current, which requires special devices.

Alkaline batteries... A solution of caustic potassium is used as an electrolyte. Plates are made from nickel alloys with cadmium or iron. The peculiarity of this type of batteries is that no electrolyte is consumed during the course of an electrochemical reaction. They can work at low temperatures, they are not afraid of overcharging, they do not emit harmful vapors, they give out electric current longer.

Traction batteries... They are used as a source of energy in self-propelled devices powered by electric traction. They are distinguished by their large size and capacity to ensure the functioning of the transport during the working shift. The most popular and widespread types of traction batteries are alkaline models. Difficulties in maintenance and repair are associated with the danger of alkali to human skin. Any wrong action by the repairman can lead to the impossibility of further repair. Therefore, maintenance is carried out only by highly qualified specialists.

DIY repair

The battery is considered one of the most unrepairable parts of a car. The presence of an aggressive electrolyte and a complex electrochemical reaction occurring in the battery require a battery specialist to have good knowledge of chemistry, soldering skills, and the ability to use load fork, hydrometer and charger.

You can clean the battery and terminals yourself, check the state of charge and electrolyte level, charge the battery. In some cases, with certain skills, it is possible to close up a small crack in the case, repair a broken terminal, and eliminate sulfation. But all this is best done after consulting an experienced battery operator.

The crack can be eliminated by soldering, gluing, processing the damaged area with heated mastic. To repair the terminal, ordinary self-tapping screws are suitable, which connect the broken pieces. First you need to drill a hole, screw in a self-tapping screw, and at the end of the repair, solder the crack along the contour. To eliminate sulfation, several full charge and full discharge cycles are required. In some cases, you have to completely change the electrolyte.

Currently, most of the batteries are manufactured in a maintenance-free design, so the car owner can only perform timely maintenance.

Battery maintenance

Clear and trouble-free operation of the car battery is possible only with regular and full maintenance... All basic procedures are available to every motorist.

1. Cleaning the battery case... It is made with a piece of rags soaked in detergent solution. As detergent fit:

- 5-10% soda ash solution,

- 5-10% solution of ammonia,

- car shampoo,

- household detergents.

After wet cleaning, dry wipe with a cloth. Now you should perform a visual inspection of the integrity of the battery case.

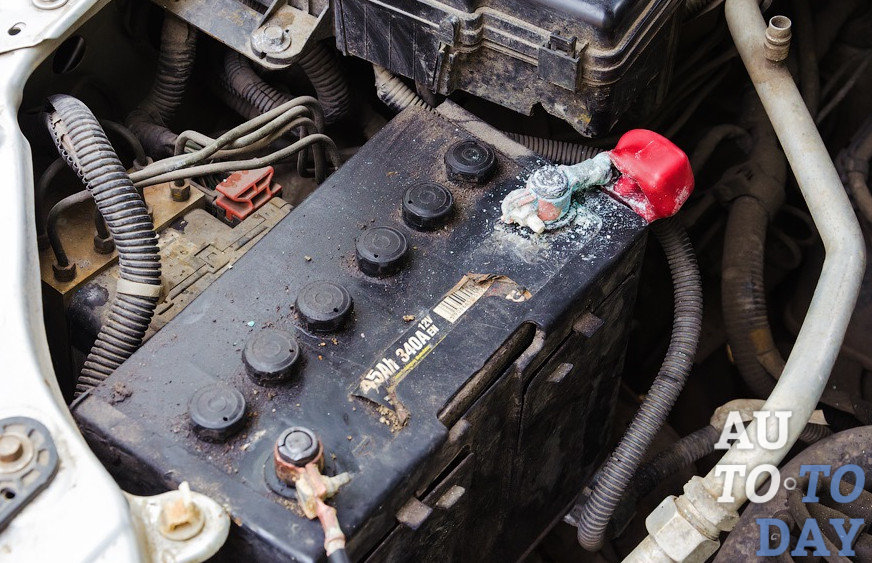

2. Checking the status of the terminals... In the presence of an oxide coating, the terminals are cleaned with metal clear or fine-grained sandpaper. The ends of the wires must be securely fastened to the battery terminals and grease the upper part with technical vaseline.

3. Checking the reliability of fastening the battery in the socket... The appearance of a backlash and displacement of the battery relative to the mounting socket often leads to mechanical damage to the case, as well as to the formation of cracks near the battery terminals.

4. Checking the electrolyte level (on serviced models)... It can be checked visually, but it is better to use a glass tube. The electrolyte level in each can should be 5-20 mm higher than the safety plate, depending on the type of battery.

5. Determination of the state of charge... For maintenance-free batteries, in addition to the existing "eye", you will need to measure the voltage with a load plug (in extreme cases, with a conventional electronic tester). Serviced batteries can be additionally tested with a hydrometer by measuring the density in each can.

6. Monthly battery charging... To restore the battery capacity, you must use a charger. After fully charged, check for density or voltage.

Summary

Sooner or later, every car owner has to deal with a non-working battery. Someone will be able to solve the problem on their own by performing simple repair and maintenance operations. But it is best to contact a professional battery specialist who will assess the degree of damage and make the final verdict on the battery.

Car enthusiasts handle batteries that have lost their performance in different ways. Some people decide to immediately get rid of the unnecessary element, going to the store for a new battery. Others, in order to save money, still try to restore a faulty battery, testing all possible methods. In both cases, actions can be justified, since battery repair is not so easy, and the presence of toxic liquids in it becomes a warning for inexperienced motorists. And yet, if you follow the safety rules and follow the practical experience of experienced craftsmen, then the battery life can be extended by at least six months.

The reasons for the "death" of the battery

How to restore the volume of the battery?

The most affordable car / battery repair is to repeatedly charge a faulty battery with short interruptions. A series of such charges increases the voltage of the cell, after which it no longer perceives the effect of current. On the other hand, in the intervals between operations, the process of equalizing the electrode potentials is started. Normalization of the state of the plates promotes the transition of dense electrolyte into the space between the electrodes from the pores on the surface of the plates. Thus, during the breaks, the voltage on the battery decreases and as the charges are made, the battery gradually gains volume.

This technique allows not only repairing car batteries, but also recovering batteries with a similar composition from other equipment and even electronic devices... In the course of simple manipulations with the charges, the density of the electrolyte increases, acquiring a state normal for operation. The charging time is determined by the specific battery model and is usually 6-8 hours. The breaks between them vary from 8 to 16 hours.

Complete battery disulfation

It is not so common that the battery has completely lost its volume as a result of development and damage by sulfate. Usually, up to this point, the batteries are either repaired or thrown away, since it is impractical to use them in this state. Despite the severity of the lesion, in this case it is quite possible to repair the battery with your own hands using the disulfation method. The essence of recovery is the supply and long-term retention of high voltage to the battery. But here, too, one cannot do without small pauses, since an increase in voltage contributes to the intensity of gas evolution, which is undesirable from a safety point of view.

So, disulfation is performed according to the following instructions:

- Water is poured into the battery.

- A current is connected to the power supply.

- Initially, approximately 14.4 V is supplied in two 13-minute cycles.

- Then two more cycles are performed, but already with a voltage of 14.6 V.

Subsequent voltage build-up should be done until a clear increase in capacity appears. In this way, you can repair any type of battery. But, if the recovery operation does not give any results, then all that remains is to dispose of the device.

Fast battery recovery

This technique allows you to restore the battery within an hour. A fully discharged battery must be charged. After that, the entire electrolyte is drained from it, and the cavity is washed several times with distilled water. Further used ammonia solution, therefore, such a repair of car batteries should be carried out with maximum body isolation from possible contact with the substance.

The composition used should include 2% (w / w) trilon and 5% ammonia. The chemical mixture will act as an activator of the disulfation process, which on average takes from 40 to 60 minutes. A quick repair of the battery with the help of a solution should be accompanied by the release of gas and the appearance of small splashes. When gas evolution stops, the procedure can be completed.

Battery repair with constant voltage

This method is a little similar to exposure to a high voltage battery, but has its own characteristics. A discharged battery is supplied with a stable charge of about 15 V. You cannot increase it, but you should not decrease it either. The battery should remain in this state for 12-13 hours, after which it must be slightly discharged. Under constant voltage, battery repair gives almost 100% results in volume recovery. This procedure can be repeated two times, and then the voltage in the battery can be measured. If it is approximately 13 V, this means that the element is working properly and can be used. If this figure does not exceed 10 V, then the battery can be thrown away. The battery is mechanically defective and no other repair method will help it.

Prevention of battery malfunctions

First of all, it is necessary to monitor the level and condition of the electrolyte in the battery sections. In addition, it is necessary to maintain the tightness of the case and the integrity of its service elements, including the battery terminal - the quality of the current supply largely depends on it. You should also protect the battery from external influences, especially from low temperatures. AT winter time it is advisable not to leave the unit in the car, but to take it to a garage or house overnight (if it is possible to isolate it from living quarters). Much in the quality of work and longevity of the battery also depends on how correctly the charging procedure is performed. Compliance with operational standards will extend the battery life to several years.

Almost every driver is interested in the question of how to restore the battery. After all, buying a new one is not at all profitable, but because of misuse or for other reasons, native batteries very often fail. Fortunately, DIY car battery repair is not a difficult task. For its implementation, it is necessary to understand only what exactly could cause the failure of the battery, and make the necessary repairs in accordance with the breakdown.

Car battery repair: the most common malfunctions and their causes

To understand how to repair a car battery, you first need to understand why it does not work, and what led to the breakdown. Below we will consider the most common battery malfunctions.

Self-discharge

Important! As soon as the battery in the car is discharged, it should be charged immediately. It is strictly prohibited to store the battery in a discharged state.

Important! As soon as the battery in the car is discharged, it should be charged immediately. It is strictly prohibited to store the battery in a discharged state.

So that self-discharge does not lead to a complete failure of the battery, even during storage, it should be recharged at least once every 2 months by using small currents. But if the battery discharges more than 3% during the day, it means that it also has others. faults:

the presence of contaminants in the electrolyte;

Use of low-quality components in the battery manufacturing process;

Ingress of foreign objects inside the battery;

Contamination of the outer surface of the battery;

Destruction of separators.

If you continue to use a battery with similar disadvantages, it can be completely discharged even in one day. Such a car battery is unlikely to be repaired.

The appearance of oxidation on the lead pins

A similar malfunction is caused either by electrolyte contact with the pins and copper terminals of the battery, or by electrolyte vapors. In any case, the contact between the pins and terminals deteriorates, which is why you have to resort to self-cleaning of oxidized elements with fine-grain sandpaper. After completing the car battery repair procedure, the pins and terminals must be covered with special technical Vaseline, which will prevent the occurrence of oxidations in the future.

Short circuits

Short circuits of opposite-pole plates of a car battery can occur either as a result of the destruction of separators, or due to the residual active mass settling at the bottom of the battery cans. Other reasons for a short circuit include:

excessive shaking of the battery, which is poorly fixed in the engine compartment;

Using a high density electrolyte;

Warping of the plates resulting from the supply of too high a current;

Long battery life.

Repair of car batteries with short circuit damage is possible only if the battery itself is serviceable. Otherwise, the battery, inside which short circuits periodically occur, must be disposed of.

Repair of car batteries with short circuit damage is possible only if the battery itself is serviceable. Otherwise, the battery, inside which short circuits periodically occur, must be disposed of.

Hull damage

If the case is damaged, the car battery can also be repaired with your own hands, however, the possibility of such restoration always depends on the degree of damage. Often the situation can be corrected with an adhesive that is suitable for fixing the material of damaged areas. During operation, the electrolyte from the car battery case is necessarily poured out and the tank is dried. After repairing the damage to the case, a new electrolyte is poured into the battery.

This is a very common reason for car battery failure, which, however, is subject to self-elimination... To understand how to repair a car battery with a "diagnosis" of plate sulfation, you need to understand what is the cause of such a malfunction:

long-term storage of the battery without recharging;

Reducing the amount of electrolyte in battery banks;

Use of electrolyte with increased density for the battery;

Driving a vehicle with an over-discharged battery.

A characteristic sign of plate sulfation is the formation of lead sulfate crystals on their surface. This substance is unable to dissolve in the electrolyte and, when accumulated on the plates, does not allow liquid to penetrate into their active mass. The result is a dramatic decrease in battery capacity.

Important!If the sulfation slightly damaged the battery plates, then you can still save the device. If the crystals have almost completely covered the plates, it is cheaper to replace such a car battery.

Important!If the sulfation slightly damaged the battery plates, then you can still save the device. If the crystals have almost completely covered the plates, it is cheaper to replace such a car battery.

Every driver should take good care of the vehicle's battery and avoid situations that can lead to sulfation.

Broken internal network

A similar malfunction is more likely to be characteristic of older battery models. However, if you are "lucky" to encounter such a battery problem, fixing it is not only easy, but also cheap. As a result of the breakage, the plates are simply disconnected from the output terminals of the battery. To make it work again, this connection will need to be restored.

DIY car battery repair: a list of necessary actions

Car battery repair can take a lot of time, so it is worth preparing for such a procedure in advance. At the same time, it is most rational to restore the battery only in the case of sulfation of its plates. In almost all other cases, the battery will need to be replaced. In order to desulfate the plates, you must:

1. Drain the old electrolyte from the battery, as a result of which the plates are covered with lead sulfate.

2. In a new electrolyte, dilute a special desulfating additive liquid. It is recommended to use an electrolyte with a density of 1.28 g / cm3. The amount of electrolyte to be poured into the battery, check with the instructions for the device.

3. Pour the resulting electrolyte into a non-working battery.

4. Unscrew on car battery plugs for connecting to charging with a small current. It is very important that during this process the battery does not start to heat up and boil. If the voltage at the terminals rises to 13.8 V, the current will need to be reduced a little more and measure the density of the electrolyte. Re-measurement will need to be carried out after another 2 hours, and if the results obtained are identical, the battery is charged.

5. In order for the density of the electrolyte to reach 1.28 g / cm3, it is necessary either to add more electrolyte with a higher density to it, or to dilute it with distilled water.

Important!To restore the original capacity of a car battery that has been “stolen” by the sulfation process, it must be completely discharged. Limit the current supply and connect a light bulb to the recovered battery. A complete discharge will be evidenced by the voltage at the terminals of 10.2 V. Next, calculate the battery capacity by multiplying the time of its discharge by the current with which the discharge was carried out. If the capacity is insufficient, the battery charge / discharge procedure is repeated.

After the repair of the car battery is completed and its capacity is restored, a little more desulfation additive must be added to the electrolyte. The battery can then be installed and connected to the vehicle.

How to quickly restore a dead battery

Before fixing a dead battery, you need to check it for other breakdowns. If there are none, and the battery has sat down solely due to sulfation, it can be restored in another simple and, most importantly, quick way:

1. Produce full charge car battery.

2. Drain the electrolyte and rinse the car battery with distilled water. It is better to repeat the procedure several times.

3. Fill the battery capacity special liquid for cleaning, which includes ammonia and trilon. Leave it in the container for about 40-50 minutes.

4. Drain the liquid and flush the battery again with distilled water.

6. Discharge to restore capacity.

This completes the car battery recovery process. It is only important to take into account the fact that you will have to work with aggressive liquids, therefore it is necessary to pour and pour them out carefully, after putting on latex gloves.

Do-it-yourself car battery repair: is it worth getting to work?

Now you know how to repair a car battery, but still do not forget that in some cases such an operation is not advisable. This may be due to such a feature of modern batteries as the lack of serviceability. In such a case, the only recovery procedures applicable to the car battery would be recharging and topping up with distilled water.

But if the battery is of an older model and is subject to maintenance, it is really worth repairing it. However, if you also need to replace its main components, it will be cheaper to buy a new battery, since it is not entirely advisable to invest in an old battery.

Therefore, before starting to repair a car battery with your own hands, it is worth assessing the severity of the malfunction. If in monetary terms it will cost you less to buy a new battery - do so. If you yourself cannot make such a decision, seek advice from auto repairmen.

Subscribe to our feeds in

Batteries are a stable source constant voltage, they are irreplaceable in individual designs and devices. But of course there are no eternal things on earth, and with batteries, time passes and they are no longer suitable for use, what to do? Throw away and buy a new one? You can, of course, but it's better to try to repair them. You can find a sea of \u200b\u200bbatteries on the market different types capacities and voltages. They mainly use acid alkaline and lithium batteries. Today we will talk about how to repair such types of batteries as lead. Acid batteries - more commonly referred to as lead-helium batteries. Two lead plates are immersed in sulfuric acid, one plate is positive and the other negative. Such batteries are most often used in automotive engineering and in pocket flashlights. They have a relatively short service life. They can be repaired (restored) in several ways.

The first way multiple charging small current rating with small temporary interruptions between charges. By the end of the first and subsequent charges, the voltage on the battery gradually rises, and it stops accepting a charge. During the break, the electrode potentials on the surface and in the depth of the mass of the plates equalize, while the denser electrolyte from the pores of the plates flows into the interelectrode space and reduces the voltage on the battery during temporary breaks. During a cyclic charge, as the battery accumulates capacity, the density of the electrolyte begins to increase. When the density becomes normal, and the voltage on one section reaches 2.5-2.7 volts (the nominal value of each can is 2 volts), the charge is stopped. This cycle is repeated 5-8 times. Charging current ten times less than the battery capacity, let's say the battery has a capacity of 1000 ma / hour, then the charge current should be from 80 to 100 milliamperes.

Second recovery method acid batteries - electrolyte replacement. We drain the electrolyte from the battery and rinse the battery with hot water several times. Next, take 3 teaspoons of baking soda and dilute with 100 ml of water. We boil water and immediately pour boiling water into the battery, wait 20 minutes and drain. We repeat this process several times. Then we rinse the battery 3 times with hot water. This recovery method is very convenient for car batteries. At the last stage of work, pour a new electrolyte and charge the battery for 24 hours, the repaired battery is charged once a day for 10 days, the charge lasts 6 hours, the charger parameters are 14-16 volts, the charge current is 10 amperes (no more).

The third way is reverse charge... To do this, you need a powerful voltage source (a welding machine, for example), the charger voltage is 20 volts, and the current strength is 80 amperes or more, we open the cans' plugs and charge them only back - we attach the plus of the power source to the minus of the battery, and the minus of the power source to the plus battery. In this case, the battery will boil, but do not pay attention, we charge for 30 minutes, then drain the electrolyte, rinse with hot water and pour in new electrolyte. We take an ordinary charger with a current of 10-15 amperes and charge the repaired battery for 24 hours, just do not confuse the polarity, since the factory positive pole will already be negative, and the negative positive one, we will talk about repair and lithium batteries in the next article, stay with us - Arthur Kasyan (AKA).

Discuss the article REPAIR OF AUTOMOTIVE BATTERIES

When is it necessary and how to repair a battery on a car

Car owners use their batteries in different ways. Someone watches them and serves them, while others simply "kill" them and put a new one. Accordingly, the service life in these cases will be different. But sooner or later there is a need to repair a car battery. For those with free money, this is not a problem. They go out and buy a new battery pack. And those who are strained with money are trying in every possible way to extend the life of a car battery.

The main reasons for battery failure are as follows:

- damage to the battery case, plates for various reasons;

- short circuit of battery plates of different polarity for various reasons;

- break in the internal battery circuit;

- sulfation of plates.

Damage to the battery case and plates

One of the main causes of such damage is mechanical impact on the battery. It can be a hard blow, a fall, and so on. In addition, freezing of the electrolyte in the battery can lead to destruction of the case and damage to the plates (reference to material). As freezing expands, it causes cracks in the housing and warpage of the plates.

In case of mechanical damage to the case, if the plates are not affected, repair is possible. It boils down to the fact that the polypropylene case will need to be repaired. This repair can be done by hand. If the freezing of the electrolyte led to the destruction of the case and plates, then here it is already necessary to evaluate the consequences in each specific case. If, as a result of freezing, the plates did not warp, and a short circuit did not occur, then you got off easily. And if there is a short circuit in one or more banks, then the battery can be sent to and purchased a new one.

Today on the forums you can find questions about how to disassemble car battery... Modern low-maintenance or disassemble it will not work. More precisely, it is possible to disassemble, but this is an irreversible process that destroys the battery. Only serviced old-style batteries, which are now not produced, can be disassembled for repair and replacement of cans.

Closing the plates

Shorted plates can be caused by the following reasons:

- manufacturing defects;

- mechanical deformation or freezing of the electrolyte;

- shedding the active mass of the electrodes;

- damage to the separator.

In the case of a factory defect exists. This is definitely a warranty case, which usually appears in the first six months of battery operation. Everything else is out of warranty and in most cases beyond repair.

Open circuit of the internal battery

If this happened during normal operation of the battery, then the battery can be returned under warranty. At the same time, it should not have any damage (traces of impacts, cracks, melting, etc.). If the battery is used correctly, such a malfunction is in most cases a manufacturing defect. Repairing this malfunction is either impossible or very problematic. So, in this case, you will have to exchange the battery under warranty or buy a new one.

Sulfation of plates

Plate sulfation is the process of deposition of lead sulfate (PbSO 4) on the surface of positive and negative electrodes. As it accumulates, this substance clogs the surface of the active mass of the plates, which leads to a strong decrease in the battery capacity.

Lead sulfate is formed during battery discharge and dissolves when charged, but the process is not complete. As a result, part of it remains on the electrodes in the form of a white coating.

This kind of battery malfunction can be corrected. But it should be said right away that sulfation in most cases is successfully "treated" in the early stages. If the battery has already worked for several years and has lost a significant part of its own, then it is easier to buy a new one. In such advanced cases, in addition to sulfation, corrosion of plates and connecting bridges, significant shedding of the active mass, and so on are also added. By restoring such a battery, you will simply waste time.

Car battery repair methods

As you already understood from the above, car battery repair is possible only when mechanical damage body (if they are moderate) and sulfation (if it is not in an advanced stage).

Battery repair in case of mechanical damage

Here again you can often come across the question, but how to disassemble a car battery during repair. There is no need to disassemble it. The electrolyte must be drained from the battery with the punctured case and dried.

Attention! The electrolyte is an aqueous solution of sulfuric acid, which is corrosive. Therefore, when working with electrolyte, rubber gloves and goggles must be worn to protect the skin and eyes. Keep an aqueous solution of baking soda (10%) with you to neutralize the acid.

Next, arm yourself with a soldering iron and pieces of plastic. Seal holes and cracks in the case. For better sealing, mastics that are acid resistant can be used. After repairing the case, fresh electrolyte is poured into the battery and charging is carried out.

Battery repair with sulfation

Anti-sulfation of battery plates or desulfation is mainly carried out in two ways:

- using electric current;

- using chemical reagents.

All methods belonging to these groups are aimed at lead sulfate. Let's take a quick look at some of them.

Desulfation using electric current

Below are the main ways to reduce sulfation on battery plates using chargers and other devices:

- carrying out several charge-discharge cycles, called. The battery is first charged and then discharged for 10 or 20 hours. The actual time will be less. Simply, depending on this value, the battery discharge current is selected. We discharge the battery until the voltage drops to 10.2 volts. Then we charge the battery again and so on for several cycles. The method is suitable in cases where sulfation is at an early stage;

- the next method is a sufficiently long dissolution of lead sulfate in distilled water. The battery is charged, then the electrolyte is drained and distilled water is poured into it. After that, it is put on charging with a current of 0.1 of the nominal capacity. This process can take 2 to 3 weeks. The density of the solution is measured periodically. If all goes well, then it should slowly rise. After a couple of weeks, the resulting electrolyte is again drained and distilled water is poured. The rechargeable battery is put on charge for another couple of weeks. After that, the resulting sulfuric acid solution is drained and a fresh electrolyte with a density of 1.27 g / cm 3 is poured. Then the battery needs to be charged and it is ready for use;

- use of various devices. Recently, more and more examples of the use of such devices have appeared on the Internet. Usually ordered from China or the USA. They are designed to supply impulse current to the battery terminals. The point here is that through alternating current knock lead sulfate off the plates. However, if the battery is sufficiently worn out, there is a risk that the active mass will crumble together with the lead sulfate. And there are such examples. In some cases, after using such devices, the battery capacity only decreased. Therefore, such "tricks" should be used with caution.