Are a type of engine internal combustion... These engines have external mixture formation and autonomous ignition. In the engine of this type itself, a ready-made fuel-air mixture will be sent to its cylinders, which is prepared in the carburetor device, which is why, in fact, such an engine received the same name. In addition, such a preform process can take place by means of fuel injection, in a gas-air mixer, etc.

Regardless of the method of forming the mixture, as well as the number of strokes into which the working cycle is divided, the carburetor engine has one single principle of operation. Directly the combustible mixture, which is compressed in the combustion chamber, is ignited by the ignition system at a certain moment, often by means of an electric spark system. In addition, ignition from a glow tube can be used, which in modern times are found in small-sized internal combustion engines. At the present time, plasma and laser ignition is also used, albeit at an experimental level.

All carburetor engines will have an order of magnitude higher fuel consumption than the engine To reduce this parameter there are many design solutions, one of which is the carburetor solenoid valve. Many motorists do not see any benefit in this device and believe that it is not necessary, although in fact, in urban conditions, the fuel consumption of the “seven” can be reduced by 5, or even 7%. In the context of the eternal rise in the price of gasoline, this positive can significantly raise the mood of a car enthusiast. The solenoid valve device is electromechanical device, which is designed to regulate the flow of all gases and liquids. This element consists of a solenoid with a core, a body, a piston and a regulating flow.

Electric voltage is applied directly to the solenoid coil of the valve, as a result of which the magnetic core begins to be drawn into the solenoid. This procedure will cause the system valve to close or open. The core itself moves inside the solenoid coil tube, which is necessary to increase the sealed composite solenoid valve. This device is similar to a conventional check valve. The only difference is that in such a device, the closing and opening of the valve does not use any mechanical forces, since it occurs by means of an electromagnetic coil by applying an electric voltage to it.

1. Due to what is the excess consumption of gasoline?

During those periods when the vehicle is operated on idling, the carburetor will not supply air-fuel elements directly to the internal combustion engine, since this is incorporated into the feed mechanism itself. However, in order to avoid stalling the engine, you need to consume a certain amount of gasoline and air, precisely for the combustion of this mixture.

During those periods when the vehicle is operated on idling, the carburetor will not supply air-fuel elements directly to the internal combustion engine, since this is incorporated into the feed mechanism itself. However, in order to avoid stalling the engine, you need to consume a certain amount of gasoline and air, precisely for the combustion of this mixture.

Air enters the device through the idle valve, as a result of which this element is mixed with gasoline and sent directly to the internal combustion engine. With a system of this kind, there will be a continuous supply of fuel. And the need for the fuel itself is always the same, since the operation vehicle can be produced in all kinds of conditions.

So, for example, at the moments of engine braking, fuel consumption decreases and rises, and due to the fact that the supply of gasoline itself is not regulated by anything, its overrun will occur. The same can be said about when the car is coasting down a hill. In order to save fuel, there is a similar device - an electromagnetic gasoline valve.

2. What does the carburetor solenoid valve do?

The solenoid valve device is installed in order to reduce the fuel consumption of the vehicle. This is done through the fact that this device can regulate its supply. It all depends on the need, since the valve can block the channel through which the supply occurs air-fuel mixture and air in the carburetor. In addition, this device contributes to the fact that the engine will burn exactly as much fuel as required, and the pistons and the combustion chamber will not exceed the norm in the pressure of the ignited gases. This is what can serve to reduce the wear of all parts of the internal combustion engine. In addition, this device will serve to reduce emissions exhaust gases in atmosphere.

The solenoid valve device is installed in order to reduce the fuel consumption of the vehicle. This is done through the fact that this device can regulate its supply. It all depends on the need, since the valve can block the channel through which the supply occurs air-fuel mixture and air in the carburetor. In addition, this device contributes to the fact that the engine will burn exactly as much fuel as required, and the pistons and the combustion chamber will not exceed the norm in the pressure of the ignited gases. This is what can serve to reduce the wear of all parts of the internal combustion engine. In addition, this device will serve to reduce emissions exhaust gases in atmosphere.

3. How is the VAZ 2107 solenoid valve arranged?

An elementary valve in the "seven" is installed in the carburetor device. The operating mode of this system is controlled by a special forced idle economizer. Closing the air channel, in such a device, is facilitated by the upper working valve part. As a result of the opening, the air itself will be directed directly into the chamber, where it is mixed with gasoline. With all this, another channel will be blocked, through the lower working part of the valve, which leads out of the chamber, while not allowing the released mixture to enter the engine.

In the second stroke of the engine operation, the air channel will overlap, as a result of which the lower one will also open, which contributes to the ingress of the fuel-air mixture directly into the internal combustion engine. At first glance, it may seem that the system is quite simple, as a result of which there is no particular need for it. However, there is one small caveat. Both the opening process and the closing process of the valves will occur at a uniform frequency, and how much they open will be controlled by the forced idle economizer. It is through this clearance that the level of fuel supply directly to the internal combustion engine will be regulated.

In the second stroke of the engine operation, the air channel will overlap, as a result of which the lower one will also open, which contributes to the ingress of the fuel-air mixture directly into the internal combustion engine. At first glance, it may seem that the system is quite simple, as a result of which there is no particular need for it. However, there is one small caveat. Both the opening process and the closing process of the valves will occur at a uniform frequency, and how much they open will be controlled by the forced idle economizer. It is through this clearance that the level of fuel supply directly to the internal combustion engine will be regulated.

The valve stroke itself will provide itself with power supply, which has a voltage of 12V. If the food is higher than the indicated one, then it will open air valve, which will block the channel for the air-fuel mixture. If the power supplied through the forced idle economizer is not supplied, the valve will be closed by means of the installed spring at the bottom of the device. Therefore, when the vehicle's ignition is inactive, no fuel will be supplied. Motorists are advised not to remove the solenoid valve device.

Many car owners who have had a fairly long experience do not know the purpose of installing a solenoid valve in the carburetor. In case of failure this device they might make a mistake: instead of buying a new device, they block it from working. This is done by breaking off the locking mechanism, leaving it in the open position. As a result, you can get a huge excessive fuel consumption.

Subscribe to our feeds in

An electromagnetic valve is installed on carburetor VAZ models. Like any other part, the solenoid valve of the VAZ 2107 carburetor may stop working and require cleaning or replacement. You can do this yourself. No special tools, fixtures or skills are required.

Solenoid valve device VAZ 2107

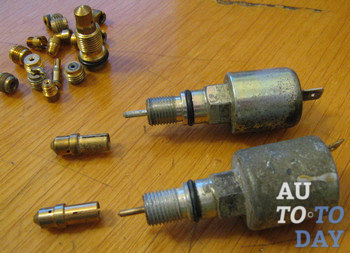

Solenoid valve VAZ 2107 is an electromechanical device that regulates the flow of a mixture of gasoline and air to the carburetor jet at idle speed. The valve is installed in the carburetor itself and consists of the following parts:

- body;

- solenoid;

- jet;

- spring;

- piston.

When current flows through the solenoid, a magnetic field is created that displaces the piston. As a result, the fuel-air mixture is able to flow through the jet into the car's carburetor.

The idle solenoid valve VAZ 2107 is designed to reduce fuel consumption. This is achieved due to the fact that when the engine is braking, the flow of fuel into the engine stops. The valve is controlled by special device - economizer. It works as follows:

opens the idle valve when the engine speed decreases to the rated idle speed;

closes the valve if the engine speed is high and the gas pedal is not depressed.

This approach can reduce fuel consumption in the urban cycle by 5-7%. On a track where engine braking is less frequent, the economy is more modest.

Signs of a malfunction of the idle speed valve VAZ 2107

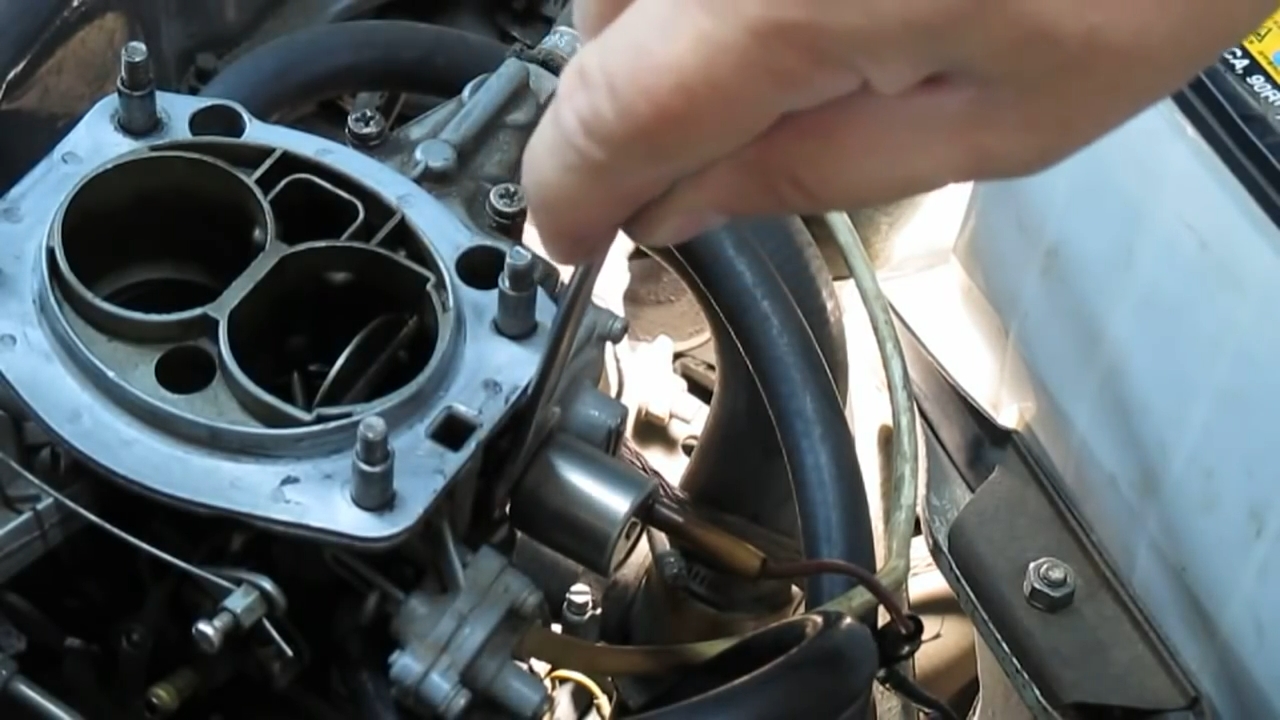

The valve is controlled by means of a special unit - forced idle economizer (EPHH). A valve malfunction usually manifests itself in the fact that the engine stops idling or its speed “floats”. Given that the operation of the valve and the carburetor depends on the health of many parts and assemblies, it is rather difficult to unequivocally determine the valve malfunction. The test should begin with diagnosing the connection of the VAZ 2107 solenoid valve to the EPHH. Check with a voltmeter or tester if voltage is supplied to the valve when the ignition is on. If there is power, the problem may be both in the valve itself and in the clogged nozzles of the carburetor. The jets must be cleaned, for which the carburetor must be disassembled.

Tip: you can find out exactly whether the idle valve is working properly by screwing in a similar valve instead, in which the needle (piston) has been removed. If with such a valve emulator the engine runs unstable or stalls at idle, the problem is not in the valve. Simpler but less reliable way - apply 12 volt power to the valve power output. A working valve should make a loud click.

A defective idle valve cannot be repaired. It needs to be replaced with a new one.

Replacing the solenoid valve VAZ 2107

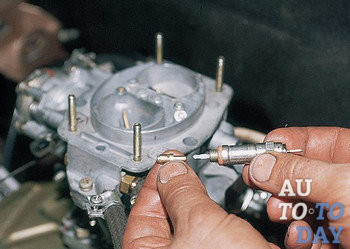

To replace the valve, you only need a 13 spanner and a new valve.

Replacing the solenoid valve VAZ 2107 is done as follows:

This completes the replacement of the VAZ 2107 solenoid valve. If the engine continues to run unstable, the carburetor jets and ignition system should be checked.

100 101 102 103 104 105 106 107 108 109 ..Checking the EPHH system without special devices VAZ-2108

Diagram of the control system for the solenoid valve of the VAZ-2108 carburetor

1 - ignition coil;

2 - electromagnetic valve;

3 - control unit;

4 - carburetor limit switch;

5 – mounting block;

6 - ignition switch;

7 - ignition relay

PERFORMANCE ORDER

In the absence of a voltmeter and tachometer, it is possible to determine the malfunction of the solenoid valve and the control unit using a piece of insulated wire about a meter long.

We perform troubleshooting by the elimination method.

In the absence of idling, remove the wire tip from the output of the solenoid valve. Turn on the ignition without starting the engine

We connect the tip to the valve outlet.

At the moment of connection, a click should be clearly heard. If this does not happen, check the serviceability of the solenoid valve. To do this, again remove the tip of the wire from the valve terminal and, using a piece of wire, apply voltage to it directly from the "positive" terminal battery... If the valve has worked with a characteristic click, it means that the control unit is faulty or there is no supply voltage to it. It is also possible to damage the connecting wires or their connectors. If the valve does not work when energized, it must be replaced.

When the engine is idling, you can make sure that the solenoid valve is working properly. To do this, with the engine running, remove the wire tip from the valve outlet. If the valve is good, the engine should stall.

You can check the operation of the control unit using a known good solenoid valve. To do this, turn on the ignition and put the tip of its wire on the valve output.

With a working control unit, a characteristic click should be heard at the moment the valve body is closed to ground.

It should be borne in mind that by the indicated methods it is impossible to make sure of the correct moment of switching on and off the EPHC system. If the car is equipped with a tachometer, then the functioning of the system can be checked with sufficient accuracy, using a test lamp instead of a voltmeter. For this, a car lamp with a power of no more than 3 W and a voltage of 12 V is suitable, for example, an instrument illumination lamp. We solder two pieces of insulated wire about 0.5 m long to its contacts. It is more convenient to use a lamp with a cartridge, then the wires are connected to the terminals of the cartridge.

To check, connect the test lamp to the tip of the solenoid valve wire. We connect the output of the solenoid valve with a piece of wire to the "plus" terminal of the battery. The procedure for testing with a lamp is the same as for testing with a voltmeter.

With help control lamp you can find faults in the tip of the "quantity" screw and its wire.

To check, connect one wire of the test lamp to the tip of the screw wire, and the other to the "plus" terminal of the battery. When closed throttle the first chamber, the lamp should be on, and when open, it should go out.

In the same way, you can check the condition of the wire by removing its tip from the screw tip and closing it to the carburetor body.

This is what the murzilka writes ...

you probably have a sin in the control unit of this valve, so read here how to check itThe solenoid valve is an EPCH actuator, the shut-off needle of which cuts off the fuel supply through the carburetor idle jet. The valve is turned on and off by the electronic unit management.

It is very important to correctly install the valve on the carburetor.

Hand tightening the valve is often one of the causes of erratic idle speed. Such a loosely tightened valve causes air leaks and, as a result, depletion of the mixture. If you overtighten the solenoid valve, you can damage the valve itself, the seat (it is very delicate), or rip off the thread in the carburetor cover.

The valve must be tightened with a torque of 0.4 kgf-m (3.68 N-m).

If there is no torque wrench, then:

Remove the rubber seal from the solenoid valve;

Without effort, screw it in by hand until it stops, counting the revolutions (in this case, you need to remember in what position the contact was);

Put on the seal and tighten first by hand, and then with a 13 key to the same contact position;

With the engine running, the valve can be turned off (no more than 120 degrees), achieving maximum speed.

Performance monitoring and typical malfunction solenoid valve

The functionality of the solenoid valve can be checked with the engine off with the ignition on by removing and putting on the wire that goes to its contact. In this case, a characteristic click should be heard. If there are no clicks, remove the wire from the control unit from the installed valve carburetor and connect the valve contact with another wire directly to the positive terminal of the battery. The appearance of clicks indicates either a wire break in the harness between the valve and the control unit, or a poor contact in the connector, or a malfunction in the control unit. The absence of clicks indicates a malfunction of the solenoid valve, a winding breakage is possible (the resistance of the valve winding should be within 70 - 80 Ohm - for valves with a tail section diameter of 20 mm and 30-40 Ohm for valves with a tail section diameter of 13 mm). (idle) when removing the wire from the valve contact, the engine should stall. If this does not happen, you must repeat the procedure for installing the carburetor valve. It happens that there are clicks, and the needle does not fully exit the electromagnet. It is also possible that the carburetor is incorrectly adjusted, and the engine is powered at idle speed bypassing the idle speed - due to the slightly open damper of the first chamber. This is also indicated by the lack of reaction (change in speed XX) when the screws of the quality and quantity of the mixture rotate.

A clogged idle jet may be the culprit for erratic XX rpm.

It is also necessary to monitor the condition of the valve shut-off needle. If burrs are found on it, it is necessary to grind the needle to the valve nozzle seat (using lapping paste).

The condition of the rubber seal can also affect the performance of the EPHC system. When the sealant delaminates, air leaks and the mixture becomes leaner. This manifests itself in a drop in idle speed and may be accompanied by a "floating" of revolutions by XX.

Damage to the rubber seal can cause the smell of gasoline when driving.

In rare cases, air leaks can be caused by the solenoid valve itself (cracks in the epoxy joint around the valve terminal).

Checking the solenoid valve removed from the car is carried out according to the diagram shown in Fig. ?. when the power supply is switched on, the valve should click and the ammeter should register a current not exceeding 0.3 - 0.4 A at a supply voltage of 14 V for valves with a tail section of 20 mm and 15 A for valves with a tail section of 13 mm.

In case of failure of the solenoid valve on the way, if it is not possible to replace it with a new one, you can remove the shut-off needle of the valve by pulling it out with pliers or breaking off its plastic tip. After that, you need to install the valve in place.

And the purpose of this valve is to reduce gasoline consumption by xx .. like so ...

The presence or on the engines of cars VAZ 2108, 2109, 21099 with carburetors 2108, 21081, 21083 Solex often depends on the serviceability of the solenoid valve of the carburetor. If any problems arise with the idle speed of the engine, first of all, we check the solenoid valve.

Checking the solenoid valve

1. Turn on the ignition, but do not start the engine.

2. Remove the wire end from the solenoid valve lead.

Thus, we de-energize it. Its locking needle is in the forward position and closes the feed hole fuel mixture into the idle system of the fuel jet of the idle system.

3. We put the tip of the wire on the output of the solenoid valve.

That is, we apply voltage to it. A click should be heard. This shutoff needle retracted into the inside of the valve body and opened the fuel supply port to the idle system. This means that the valve is working properly.

If there is no click, we check that it is faulty - the solenoid valve itself or its electrical circuit (EPHH system).

4. Connect a piece of wire plus the battery and the output of the solenoid valve.

A click appeared - the electrical circuit is faulty. We check it further. There is no click - we change the valve.

In addition, we check the idle system fuel jet inserted into the tip of the solenoid valve. To do this, turn the valve out of the carburetor. We take out the jet with pliers and visually inspect it. The jet should not be deformed, we wash and blow through its holes from contamination.

We check the integrity and presence of a sealing ring on the valve. Worn out, can be a source of "suction" of extraneous air and depletion of the fuel mixture and, as a result, the engine triple structure.

Notes and additions

- If the electrical circuit of the solenoid valve of the carburetor 2108, 21081, 21083 Solex is faulty, you can supply current from the terminal plus the ignition coil to its terminal by pulling the wire directly. Thus, it is possible to restore the idle speed of the car engine that was lost through the fault of the EPHH system of the carburetor. It is not worth driving in this way for a long time, since the valve will be constantly energized, which discharges the battery, and it is also possible to short circuit this electrical circuit that is not protected by a fuse.

- The following check is an indicator of the correct operation of the Solex carburetor solenoid valve. With the engine idling, remove the tip of the wire from the terminal on the valve. The engine should stall. That is, the valve in this case is de-energized, and its needle blocked the access of the fuel mixture to the idle system.

- A new valve, ready to fit into the carburetor, is best checked first. We connect its output with a piece of wire with the plus of the battery and touch the valve body to the minus of the battery. The needle should retract. If this does not happen, the valve is faulty, or its needle sticks when moving, which is also not good.