The trailer is chosen not only for its spaciousness, manufacturer and body color. The type of suspension is also important. Repairability depends on it field conditions and cross-country ability.

The independent suspension of a light trailer is the softest - each wheel moves separately from the other. In turn, independent suspensions are subdivided into torsion and spring. The leaf spring modification is dependent.

Types of suspensions and their key features

The spring suspension of a light trailer smooths out unevenness well, providing gentle transportation of the load. Its advantages:

- Suitability for road repair and service;

- Reliable protection against vibration and shock;

- Increased cross-country ability on country roads and off-road.

Each wheel in a spring suspension is supported by its own spring and rotates on a separate axle. Such a trailer is perfect for transporting not very heavy loads.

The leaf suspension of a light trailer is stiffer, but also more durable. Cars on such suspensions (for example, old Muscovites) can carry solid loads, withstanding any loads - a godsend for the countryside. The suspension of the light spring-type trailer is distinguished by its reliable design and the ability to cope with the transportation of heavy loads. These trailers are ideal for transporting building materials. They are also suitable for farm use.

Spring suspension - dependent, both wheels are planted on one axle. Due to the rigid springs, an empty trailer can bounce a little on bumps. But when loaded, it will ensure the reliable movement of heavy loads in all conditions. The suspension almost never breaks, it can travel tens of thousands of kilometers without knowing the repair. To do this, it must be regularly lubricated - this prolongs its service life and eliminates squeaks.

The torsion bar suspension of a light trailer consists of only a few parts. These are two levers that hold the wheels, torsion bars running along the axis and a protective tube. It is simply nowhere easier, which provides the suspension and the entire trailer with comparative cheapness. If something happens to the wheels, there will be no problems with the repair. But the breakdown of the torsion bars will lead to the need to completely change the suspension. Second name torsion bar suspension - rubber-cord.

Which suspension to choose

If you choose for reliability, leaf spring suspension will take the lead. It will serve for years without knowing any breakdowns. It will also provide a high carrying capacity. If the transported loads are not very heavy, you should choose an independent torsion bar or spring suspension.

Manufacturers light trailersadhering to the requirements of GOSTs, they are trying to make the "carts" universal. Automobile manufacturers approach them more individually, indicating the permissible total mass of towed trailers with and without brakes - "personally" for each model. Well, traffic rules regulate the safety of the road train. At first glance, it is clear and logical. But in life, a lot is done according to the principle "maybe it won't fall apart." In all honesty (and it would be better on the drawbar) - you, too, load the trailer by eye? And don't you limit the speed?

We set out to study what errors in loading and driving a road train lead to in this test. But the task suddenly became more difficult! At the Stupa enterprise "Trailer" we were offered two trailers with different suspension designs - spring and rubber-harness. Both of these schemes are widely used by many trailer manufacturers. Both applicants went to the Dmitrovsky training ground "sandwich", that is, immersed on top of each other.

BETWEEN WISHES AND OPPORTUNITIES

Recall: the total mass of a light single-axle trailer without brakes (the most affordable and therefore the most popular), as a rule, does not exceed 750 kg. This means that its actual carrying capacity is 500-540 kg, depending on the model. Agree, it is tempting, because with a platform length of 2–2.5 m, this design allows you to solve most everyday problems. Of course, there are options and "simpler", 150-350 kg, but against the background of the proposed 500 they look pale. To carry, so to carry. And after all, carried away, they almost got lucky! But someone just in time guessed to look into the instruction manual of our tractor - "Lada-Kalina". AvtoVAZ's recommendations turned out to be much more sobering - 490 kg with a trailer, and no more.

I had to reduce appetites and ballast - sandbags prepared in advance. Here is the first conclusion: you should first study the capabilities of the tractor and only then ask the price for the makeweight!

With the loads sorted out, it remains to correctly distribute the ballast on the platforms. After all, the essence of the proposed experiment is to compare the reliability of control of the road train and its braking qualities depending on the location of the load, linking this with the suspension structures. According to one of the requirements of the OST "Trailers for passenger cars", the vertical static load in the center of the ball joint at full weight should not be less than 240 N (25 kgf) and more than 980 N (100 kgf). The range is quite wide, although it is not clear how to measure it when there are no special scales or dynamometer at hand. Naturally, mistakes are possible. Therefore, we settled on three options for loading each of the trailers: "norm" - 50 kgf per ball joint, "all forward" - 110 kgf and "all backward" - 5 kgf per hitch, respectively. "Kalina", of course, also takes a portion of ballast, so to speak, "to full." You can start.

ON THE EDGE OF YUZA

Heavy acceleration, acceleration, stabilization of speed, and then, following the movement of the brake pedal, a powerful forward dive, accompanied by a downright physical sensation of the increased mass of the car. In the cabin, the smell of overheated brakes, burning rubber, on the instrument panel - the result.

After consultations with the traffic rules, the braking start speeds of 80 and 100 km / h were chosen as credits. With a small margin (as in real life), they cover the range permitted by the Rules for road trains - 70 km / h on normal roads, 90 km / h on highways. In addition, it is from 80 and 100 km / h that we usually brake in our standard tests - there is a starting point.

In principle, it is already clear that Kalina slows down equally with any of the trailers, without presenting any surprises. Moreover, contrary to expectations, even the redistribution of ballast does not affect the length braking distance... Only the nuances of the initial reactions of the tractor to pressing the pedal change. The car demonstrates the most stable result in the “all backward” variant, allowing the most accurate metering of the effort on the pedals. In other cases, it takes a little longer to adapt to the reactions of the machine. A little overwhelmed, and the front wheels are immediately blocked with all the ensuing consequences. We must pay tribute, the behavior of the road train, even with errors, is stable, and does not require any corrections. So the only but very significant drawback is a noticeable increase in the braking distance of a road train with a trailer against the background of a single car (see diagrams).

WITHOUT HARD MOVEMENT

"Rearrangement" is the next test of our wards. Being docile “driven” under normal conditions, both trailers react negatively to sudden movements of the steering wheel. It seems that the tractor is firmly holding on to the road, it is still far from the limit, and the trailer begins to write out such pirouettes, you just wonder. But it is precisely on the “rearrangement” that we have a leader. It turns out that the rubber-harness suspension is much more tolerant of such maneuvers. It makes it much easier to drive a road train in critical situationsand the trailer is less prone to abrupt stalls and vibrations. Of course, it unwinds at top speed, but winning more than three kilometers of speed over a brother is a significant advantage.

You have to be careful with the leaf spring suspension. Inaccurate steering, and already at 70 km / h, sliding rubber squealed from behind, and the trailer strives to fly out of the marked corridor.

The redistribution of the load also makes adjustments to the behavior of the road train, and our wards react to this in different ways. In the all-ahead version, the behavior of the trailer with leaf spring suspension becomes even more stable, the tendency to skid is noticeably reduced. Move the ballast back - again an early and sharp axle disruption and a tendency to oscillate.

The rubber-braided construction is also the most unstable in the “all-back” option. At a speed close to the limit, the trailer cannot calm down for a long time, dangling from side to side. An increase in the load on the hitch somewhat improves the situation, but the "follower" still breaks down earlier in sliding.

COMFORT FOR

When assessing the smoothness of the ride, the leader changes: this time the spring trailer is out of competition. “Leader” and “Follower” are so united in overcoming most of the irregularities that you simply forget about the “tail”. It reminds of itself with characteristic twitching only in case of overload of the coupling device ("all forward").

The situation is changing, it is worth catching the rubber-harness structure. Even relatively flat road tremors and twitching immediately become annoying. It is worth getting into serious potholes - sandbags bounce, dust is a column, and the wheels of the "follower" strive to fly over the road. Naturally, the forward ballast shift only aggravates the situation, once again making you think about which option to give preference to.

FOR EASY CAR TRAIN SPECIAL RIGHTS ARE NOT NECESSARY, BUT SPECIAL CARE, ACCURACY AND A CERTAIN SKILL ARE STRICTLY MANDATORY!

DRIVER REMINDER

The braking distance of a car with a trailer increases by 30-40% in the speed range from 80 to 100 km / h.

The controllability and stability of the trailer primarily depend on the correct positioning of the load on the platform, especially in emergency situations... The most dangerous option is overloading the rear of the "follower" when the load on the hitch is minimal.

Abrupt maneuvers for a road train are contraindicated. With a trailer, the speed of the "rearrangement" is reduced by 10-15 km / h; observe the regimes prescribed by the rules!

The choice of the type of trailer suspension directly depends on the operating conditions. In our case, the longer travel spring was clearly more comfortable, not only for the cargo being transported, but also from the point of view of the passengers of the towing vehicle. The rubber-band construction has the advantage of being simpler and better handling, but the suspension is not properly adapted for bad roads.

Automobile trailers have a structure, the main elements of which are the body, frame, drawbar and suspension. The main task of the suspension is to provide stability and stability of the trailer while driving. IN modern models trailers use the following types of suspension:

- spring;

- spring;

- lever-spring;

- rubber-cord;

- torsion bar.

The Avtopritsep company offers you a car trailer for passenger car buy by affordable price... Our catalog contains models with different kinds pendants. Let's consider each of them in more detail.

The main types of suspension for car trailers

The spring suspension gets its name because coil springs are used as elastic elements. This suspension is the most energy intensive.

The leaf suspension is based on longitudinal semi-elliptical leaf springs. In most cases, it is equipped with hydraulic shock absorbers.

Lever-spring suspension includes longitudinal and wishbones, coil springs and hydraulic shock absorbers.

Rubber harness suspension consists of profiled pipes, between which rubber harnesses are fixed. This type of suspension requires almost no maintenance.

The torsion bar suspension is based on elastic metal elements - torsion bars. Its advantages are low cost maintenance and preventive maintenance.

Car trailers for general and special purposes

In our company, you can transport various goods. If you need a trailer for transporting an ATV, for a boat or for a boat, you've come to the right place. There are devices of domestic and foreign production: Laker, MZSA, LAV, KRD, Flint. Automobiles are presented in a wide range.

You will find trailers for ATVs, boats and boats in our catalog. The price of our products is one of the lowest in Moscow and the Moscow region. We guarantee reliability, safety and high quality car trailers.

If you still have questions related to the purchase of light caravans, please call the phone number listed on the website. The consultants of the Avtopritsep company are always ready to answer all your questions.

Good day! You probably noticed that when studying , Trailer and various other designs, I often focused on what kind of suspension is installed on this or that model. But it turned out that I did not take the time to consider the structures themselves for the trailer. Therefore, today the situation will be corrected.

We have a rubber-harness suspension under consideration. Such an axis has its pros and cons, features of work, device and design. Whether to buy it or not is a moot point. To begin with, I propose to find out what it is, how it works, how it differs from a spring one.

Let me also remind you that the rubber-harness suspension (RZHP) is also called torsion bar. Therefore, if you see one or the other concept, they mean the same design option.

What it is?

Often people are interested in what is better, rubber-harness or leaf spring suspension in terms of its installation on a trailer. I'll start by saying that I've already considered. Therefore, you can read about it in the previous materials.

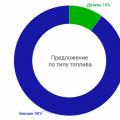

All offered on the markets are divided into 2 types:

- torsion (rubber-harness);

- spring.

RZhP consists of a hexagonal shaped tube. Inside it is another pipe, but smaller. This is necessary in order to place special rubber bands with high elasticity values \u200b\u200bbetween the metal elements, that is, pipes.

Due to this design, the inner tube does not rotate. The interior of the structure is directly connected to the levers to which the wheels are attached car trailer.

Since in the rubber-harness suspension all the moving components are hidden inside, this implies that there is no need for maintenance of the device as it is used.

The service life of such solutions is quite long, which makes it possible to count on long-term and trouble-free operation. But what if repairs are needed? In the event of a breakdown, you are essentially left without a suspension. Therefore, questions arise regarding the further operation of such a trailer.

In principle, you can fix the situation yourself. But it's better to contact a special ... There you will be provided qualified assistance in case of serious breakdowns.

Principle of operation

I have already told you about the construction. Despite the protection against cranking in the RHP due to harnesses, certain movements occur there. This allows it to damp on uneven surfaces and create a fairly smooth ride for the vehicle.

The smoothness of the movement largely depends on the profile of the pipe. Previously, square sections were used, where 4 bundles were located. This suspension was energy intensive but very stiff.

Therefore, manufacturers gradually switched to hexagonal versions. The stiffness indicators dropped significantly, but this did not play a cruel joke with the softness of the stroke. Trailers stopped jumping on bumps like abnormal ones when moving empty without load.

By understanding how the suspension works, you can roughly estimate future operating conditions. If you are going to regularly drive a car with a caravan, carry some things without exceeding the maximum permissible load, with a rubber-harness suspension, problems should not arise.

But there is always room for advantages and disadvantages. Let's talk about them further. In the meantime, you can view interesting photos and a video revealing the essence of the rubber-harness suspension and its appearance.

Advantages and disadvantages

If we talk about the strong and weak sides, which the rubber-harness device possesses, then very interesting and for many important details creep out here.

When choosing a domestic or imported trailer for your car, carefully weigh the pros and cons regarding the type of suspension.

For example, the spring options require reinforcement, therefore, usually, in addition to the spring sheets, shock absorbers are also installed. In the case of the rubber-harness version, this is not required. This is not an automotive spring suspension that is always under load. Sometimes you have to drive with an empty trailer, which reveals main drawback springs.

If we talk about RGP, then here I have identified the following strengths:

But do not rush to draw conclusions and buy yourself a new harness suspension for your trailer. , Trailer 82944С, or another model.

First, study the disadvantages that characterize the rubber-harness axles. Of the objective disadvantages, the following are worth highlighting:

If you decide to opt for the rubber-harness version, choose exclusively high-quality spare parts. Show yourself well .

There are strengths and weaknesses everywhere. Therefore, when choosing a suspension for your trailer, focus more on the conditions in which the main time will be used vehicle... Smart choice plays a key role in maintaining and extending the life of the structure.

Do not overload the vehicle, stick to , observe the recommended speed mode and service all structural elements on time. So you can guarantee yourself trouble-free and long work its trailed wheeled vehicle for the transport of goods.

For small trailers, as a rule, there are two types of suspension - spring and rubber-harness.

Despite the fact that from time immemorial all trailers in Russia were made spring-loaded, we have not observed any positive trends in this area. The matter has not gone further than using the suspension from Moskvich-412. Depending on the carrying capacity, only the number of sheets changes. Such a suspension is poorly adapted for trailers, since it is not designed for "empty" / "loaded" modes. Still, the car has a load constantly. And the trailer either has it (and almost complete), or it does not exist at all. And if a loaded trailer normally goes along the road, but empty it jumps to the envy of frogs and rattles like an artillery cannonade. Therefore, imported spring packages are used on the correct trailers. They have only one sheet working without load, and the rest are connected only after filling the trailer. In addition, although it is believed that the springs are good at dampening vertical vibrations due to inter-sheet friction, in fact, shock absorbers must still be installed with them. Hence the rather high cost and relatively expensive maintenance.

Rubber-harness suspension and cheaper than a spring one, and practically does not require maintenance. You just need to follow wheel bearings and change the lubricant in them in time. The first maintenance is carried out after running-in (1000 km), the subsequent ones - once either a year or in 10,000 km. The range of such suspensions is designed for different loads - from 500 kg to several tons, so that overpayment for "underload" does not threaten customers. Externally, the rubber-braided suspension is a complex section pipe, from which two curved levers stick out. In fact, this is a complex construction. Inside the outer tube, there are two “thinner” tube segments that act as “fingers” for pendulum levers with wheel hubs. Full turning of the inner pipes relative to the outer one excludes rubber bands located between their walls. At the same time, the "rubber bands" allow the fingers of the levers to rotate slightly inside the pipe, damping on irregularities. The smooth running of a trailer with such a suspension is influenced by ... the profile of the pipe. If it is square, then there are four harnesses inside, and the suspension is stiff, although energy-intensive. The design with a hexagonal pipe and three bundles is practically equal to it in the ability to withstand the blows of fate, but it works noticeably softer. The rubber-harness suspension has its drawbacks. So, it is repaired only at trailer manufacturing plants. A ready-made rubber-harness "bridge" can be bought only from regional dealers. So don't get carried away driving fast... Indeed, if the speed is exceeded, the manufacturer is not responsible for the breakdown. Meanwhile on high speeds a small hole is enough to damage the suspension.

By the way, the safe speed for our asphalt roads, according to manufacturers, is from 80 to 100 km / h, and according to traffic regulations you cannot accelerate faster than 70 km / h with a trailer on any road. But on unpaved roads, in order to exclude unplanned repairs, it is better not to exceed 30-40 km / h, and to move deep holes at all at the speed of a pedestrian.

So which is better - rubber or spring? It is difficult to answer this question unequivocally. A rubber-harness suspension is cheaper to purchase and easier to maintain, a trailer with such a “shock absorber” drives more smoothly, but in case of a breakdown, you can “hit it hard”. There are cases when a lever was pulled out of people (albeit at high speeds and on a rough road) near Astrakhan and they had to throw a trailer with contents from kind people and go to Moscow for spare parts. The spring is easier. The fastening could not stand - in almost any village there is a welder, spring sheets broke - I found similar ones or even planted a suitable sledge and got to the nearest auto shop. The spring also refers to overloads stoically. Well, the body lay on the bridge, well, it turned out to be a peasant cart of the nineteenth century, when no one had even heard of depreciation. But the inner tube at the harness suspension can turn. Especially if it is made poorly. But the rubber-harness suspension better passability... Indeed, in this case, the frame is the lowest point of the trailer, and the springs are almost always lowered below the frame.