Did you grow up, loose or collapsed the suspension bearing? In this article I will describe how to change the suspension bearing cardanian Vala on gazelles.

Intermediate support is installed in the junction of the front and rear parts of the cardan shaft. Meet trucks With a large wheelbase, where two intermediate supports are installed at once. In our case, with a conventional elongated gazelle with a body of 4 meters, such a bearing one.

Noise, rustling from the bearing?

To identify the bearing malfunction, you can hang one of rear wheels (Or both) and turning on the transmission on the engine manager, to listen from where there is noise. Observe care and security measures with such checks. Perhaps you have noise reducer rear bridge or gearbox. If the culprit is the bearing prom. Supports, then remove it.

The sound of the worn bearing on the removed cardan, look in the video, in the cabin it will be heard, if you move in rolling (it is well auditioned when moving along the wall or fence on the road).

We disassemble the cardan shaft

Before disassembling, in the book it is proposed to marvel the position of the shaft relative to the gearbox extension cable and the flange of the rear axle gear. We turn around the four cardan attachment bolts to the rear axle flange and two bolts of the intermediate support bolt to the crossbar. We take out the entire shaft from the extension crankcase gearbox. We mark the mutual position of the parts of the cardan to put them in their place and not to break the balancing. Next, you need to bend the mustache of the lock washer - free access to the head of the tightening bolt. Unscrew it or twisting into several revolutions, get a P-shaped plate. Applying shocks with a hammer along a fork, disconnect half on the slots of the shaft. We bring up or tighten the bearings of the support from the landing site.

Before disassembling, in the book it is proposed to marvel the position of the shaft relative to the gearbox extension cable and the flange of the rear axle gear. We turn around the four cardan attachment bolts to the rear axle flange and two bolts of the intermediate support bolt to the crossbar. We take out the entire shaft from the extension crankcase gearbox. We mark the mutual position of the parts of the cardan to put them in their place and not to break the balancing. Next, you need to bend the mustache of the lock washer - free access to the head of the tightening bolt. Unscrew it or twisting into several revolutions, get a P-shaped plate. Applying shocks with a hammer along a fork, disconnect half on the slots of the shaft. We bring up or tighten the bearings of the support from the landing site.

Cleaning the shaft slot, threading a tightening bolt. Planting place Bearings inspect for wear. If the bearing has long been noisy, he could twisted and turn in his place. In this case, it is easily removed from the shaft and when replacing the latitude does not sit down. How to do with this wear to solve you (replacement of the entire shaft or repair). Personally, I welded several points around the circumference and finishing them achieved a dense bearing planting.

Cleaning the shaft slot, threading a tightening bolt. Planting place Bearings inspect for wear. If the bearing has long been noisy, he could twisted and turn in his place. In this case, it is easily removed from the shaft and when replacing the latitude does not sit down. How to do with this wear to solve you (replacement of the entire shaft or repair). Personally, I welded several points around the circumference and finishing them achieved a dense bearing planting.

If a rubber frame of supporting a whole can be replaced by the bearing itself. It is the same for the support of the new and old sample - the marking 6206 RS. Its value in the store - from 90 rubles. Imported analogue, for example, the NSK company (6206 DU) cost 420 rubles (cost as of summer 2014). The bearing is pressed into the metal glass (for the support of the new sample) or in the rubberized sleeve (for the support of the old sample).

Assembling Kardana

Assembling Kardana

When assembling, we put the dirt-shielding washers on the bearing, the lubricants of the shaft, correctly combine parts of the cardan, we put the sealant on the bolt thread and wrap it by installing the P-shaped plate in place. Beaging the assholes of the lock washer on the bolt hat. We set the entire shaft in accordance with the labels in the checkpoint and to the flange of the rear axle.

Import or ours. That in the end

How much is very different quality of imported bearings from our domestic ... maybe not in all nodes so!? For example, the hubes in front and rear are completely walking and do not deliver concerns, but the same attempts to replace bearings in the generator lead only to their next replacement, but already on imports.

How much is very different quality of imported bearings from our domestic ... maybe not in all nodes so!? For example, the hubes in front and rear are completely walking and do not deliver concerns, but the same attempts to replace bearings in the generator lead only to their next replacement, but already on imports.

After replacing the bearing suspended support, the gazelle in cargo transportation has already passed 80 thousand km and the check on the removed Cardan showed that it is in excellent condition. At the time, before I had to change it every 20-30 thousand.

The "KARANDARPROFO" technical center provides a wide range of services in the field of car service. Experts successfully perform the renovation of the sided bearing of the cardan shaft. Characteristic signs of such a malfunction:

- deep hum from under the car, even at a minimum speed (from 10 kilometers per hour);

- sharp knock in the cabin vehicle When driving.

It is important to note that this detail may fail even on relatively new cars. In most cases, wear is due to the effects of water on the suspended bearing. The reason can also be natural wear - cracks and mechanical defects appear on the details.

Why is it worth ordering the replacement of the pendant bearing of the cardan shaft?

Specialists "KARANDARPROFI" professionally perform the repair of the sided bearing of the cardan shaft on the vehicle of various brands and models. We are focused on politics affordable prices. At the first stage, careful diagnosis is carried out. Only after that the repair scheme is developed, which will achieve the perfect result and will require minimal financial costs.

Suspended bearing This size is mounted on the support of the cardan shaft of the VAZ models from 2101 to 2107. More common nodes, where it is used, perhaps, no. However, it is enough for the bearing that the bearing is "popular", as a result of which problems in order to buy it should not. It is produced in the following factories: SPZ-4, KZUP (Kursk plant of thrust bearings - 20 GPZ), VBF (Vologda - 23 GPZ) and 8 GPZ (now - HARP, Ukraine). It is not recommended to take a hanging bearing with another labeling, as it can be a camouflaged Chinese product that can be broken at any time. Approximate price (When buying wholesale) to a less acceptable product for the quality of the production of SPZ-4 - from 55 rubles, I do not recommend buying cheaper Bearing.

You can order such a bearing in where the manufacturer's plant (SPZ-4) of this suspension bearing is located and if the order amount is large, it will be much more profitable than the company in your city.

Bearing is closed with rubber plugs, lubricant is made in advance, it does not need care.

Analogue of imported production has a number 62205 2RS (2RS1, 2RSR). Additional designation thermal clearance - C3 (62205-2RS / C3 - analogue of our 76-180505). The best import brands - FAG (Germany), SKF (Sweden), SNR (Japan - France) and some others. These brands are much more expensive and more reliable than others and stand from 400 rubles and higher (the price depends on the manufacturer and modification). The cheapest of the import bearings (the quality of them is appropriate), FBJ has a price of about 100 rubles. Prices are taking into account the choice of the optimal supplier! That is, most often, they will be slightly higher. If you offer a "imported" bearing substantially cheaper, then it is most likely a product of Chinese production or illiquid (the last version is unacceptable, since with time the lubricant thickens).

Sizes and specifications

Internal diameter - 25 mm;

Outer diameter - 52 mm;

Width - 18 mm;

Weight - 0.14 kg;

Number of balls - 9 pcs.;

The diameter of the ball is 7.938 mm;

Rated speed of rotation - 7,500 rpm;

Load capacity dynamic - 14 k / n.

The product is installed on the drive shaft of VAZ cars (2101, 2102, 2103, 2104, 2105, 2106, 2107, 21213 and some others), tension roller Tractors T-151K, HTZ-120, HTZ-121, other nodes, above all, agricultural machinery.

180505 bearing diagram (62205-2RS)

Where can one buy

To find a quality product, especially if you want to buy bearings in bulk, it follows to official representatives of manufacturers (). Where to purchase imported bearings can be viewed in (for each brand, representatives in our country are indicated, where prices are below all, and quality is guaranteed).

Replacing the suspension bearing on classic rear-wheel drive vehicles may be required on any machine, after a certain mileage. And this mileage directly depends not only on the quality of this bearing, but also from how this repair will be produced. In this article and will be described how to make a competent repair, which will significantly increase the bearing resource and what will be required for this.

Worn bearing usually declares hersal hum, especially when moving on high speed. And the wear of its rubber shell is manifested by increased vibration of the cardan shaft. Make sure that the bearing is worn, you can if we are holding hands for the cardan shaft, shake it from side to side. The flavor of the worn bearing is perfectly felt.

But as a rule, it does not reach the back of the bearing itself, since the quality and resource of the bearing itself exceeds the outer rubber shell resource in which it is concluded. And the rubber is much earlier than the bearing itself fails (cracks and in the end rushes). Therefore, most often the suspension bearing is changed only because of the damage of the rubber shell.

If it does not replace the worn outboard bearing on time, then it is possible to quickly fail the crossings and problems during repair will be much larger. But before repaid to repair, it should be purchased new.

When buying a new bearing, if you do not understand the firms of manufacturers (it is useful yet to study the forums of this topic, who set it out), always try from the two-three options offered by the seller in the store, choose the most expensive. As good qualityIn most cases, it may not be cheap (there are exceptions, but rarely).

Well, when viewing the bearing, scroll through its inner clip with your fingers and if you feel at least the slightest jealous or backlash, then return it to the seller. Also inspect the outer shell rubber and how it is docked with the outer metal rope.

In the mette of docking rubber and metal there should be no detachal of rubber, and the rubber itself should not be oak as plastic. If the rubber is too hard, then the body from the cardan will be transmitted at high speed, and the oak rubber cracks much faster than elastic.

By choosing the bearing for your car model, you can start repairing. What instrument will need in the work it makes no sense to list, as it will be much clearer to write about it in the process of work.

Sequence of work when replacing the suspension bearing.

Work is more convenient on the lifting, but there are few people he is, but everything can be done with looking Jama or overpass. Heading the machine as convenient, spray penetrating fluid (for example, WD-40) bolts (nuts) of mounting the suspended bearing to the body, and also nuts attaching the cardan shaft to the rear axle flange.

Before removing the cardan shaft, mark the hell like it stood (the cardan flange relative to the flange of the rear axle gearbox), to then install it in place as it stood before the removal. Next, we unscrew the fastened fastener and carefully remove the drive shaft from the gearbox of the gearbox (the slots are visible in the photo).

It is useful to inspect the gearbox gland and if it leaks, it does not hurt to replace it until the drive shaft is removed. Now the drive shaft should be removed from the machine and put it on the workbench for further work.

And further work lies in the correct removal of the Kardan Cross, as it is not yet to remove the cross, the bearing can not be pulled out from the shaft. And if you do not want to spoil the full-time creston, and together with the new released Bearing spend money also to a new cross, I advise you to read here. There I described very details, as well as with the help of something to remove (or disassemble) the crossbar and how to install it correctly in place (assemble) so that it is then without any problems "retired" the resource put it.

There are certainly some imported cars, which, instead there are a ball hinge, as in the photo on the left, which is easier to disassemble than the crossbar (it is enough to remove lock rings), but most rear-wheel drive cars have cardan hinge With a cross.

After breaking the cross, then you should unscrew the nut with the help of the cape head (see photo on the left), holding the creston fork on the cardan shaft.

After breaking the cross, then you should unscrew the nut with the help of the cape head (see photo on the left), holding the creston fork on the cardan shaft.

At the same time, the cardan shaft, through cardboard pads, clamp in vice, and further it is desirable to check whether this nut is fixed, holding the fork of crosses. In 99 cases out of 100, it is connected and preferably with the help of the borders to undermine the opened place, otherwise unscrew the nut will be quite hard and possible when unscrewed to spoil the thread nut.

By revealing the nut, we mark the plug of the crossens relative to the cardan shaft and remove it from the shaft using the film, as in the photo on the left.

By revealing the nut, we mark the plug of the crossens relative to the cardan shaft and remove it from the shaft using the film, as in the photo on the left.

Such a removal is easy to make with your own hands from the plates of the sheet metal (side plates with a thickness of 4-5 mm, and the central plate with a thickness of 10-12 mm, in the center of which is cut into the thread M12 ıti M14). From the tool you will need drill, Bulgarian and taps. Side plates to the central can also be welded, and can be connected using M6 bolts, as in the photo.

The shock technology here is applicable here only for a slight tapping in a circle to reduce the effort for the filler.

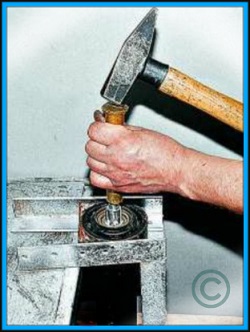

For tightening from the bearing shaft, the removal will not work, as it is possible to break the rubber of the elastic pillow. Therefore, it is better to put a cardan shaft into two corners, as in the photo on the left, and sending a brass flipper on the shaft, knock out the shaft from the bearing.

For tightening from the bearing shaft, the removal will not work, as it is possible to break the rubber of the elastic pillow. Therefore, it is better to put a cardan shaft into two corners, as in the photo on the left, and sending a brass flipper on the shaft, knock out the shaft from the bearing.

It remains to press the new bearing on the shaft along with the case. If the rubber does not have cracks and breaks and still has normal elasticity, then you can leave the rubber shell with the case and replace only the bearing. But still it is not known how much a rubber shell will stretch, so it is better to buy a bearing assembly with the case.

When pressing a new bearing onto a cardan shaft, you should instruct the spacer (tube) only on the internal bearing clip, but in no case is not an outdoor clip. And the diameter of the spacer sleeve (tube) should be the same as the diameter of the inner bearing rope.

If you change only the bearing, and the body with a rubber pillow leave the old one, then when pressing the new bearing into the housing, the exhaust on which you punish or press the press, should be pressed only on the outer clip and be the same diameter. After pressing the bearing into the housing, then press it into the cardan shaft, as described above (with pressure only on the inner bearing clip).

By saving a new bearing on the shaft, we all collect in the reverse order and all the details must be assembled according to previously marked labels, that is, as they stood before disassembly. And then there will be no problems with balancing the cardan shaft. All bolts on the flanges of the cardan shaft are desirable to degrease and their threads are treated with a thread retainer. This will prevent their unscrewing at high speed.

That's it seems to be all. After the suspension bearing will be replaced, light noise from under the car will be replaced, but then the lubricant will warm up and distributes between the bearing balls and the noise will disappear, all success.