Gimbalis called a transmission that carries out the power connection of vehicle mechanisms, the shafts of which are not aligned or located at an angle. The cardan drive is used to transfer torque between the shafts of mechanisms. Depending on the type, layout and design of the car, the cardan gear can transmit torque from the gearbox to the transfer case or to the main gear of the driving axle, from transfer case to the main gears of the driving axles, between the main gears of the middle and rear driving axles, from the axle shafts to the front driving and steered wheels, from the main gear to the driving wheels with independent suspension... The cardan drive can also be used in the drive from the power take-off to auxiliary mechanisms (winch, etc.) and to link the steering wheel with the steering gear. In addition to the general requirements for systems, units and mechanisms of a car, special requirements are imposed on the cardan transmission, in accordance with which it must provide:

Transmission of torque and uniform rotation of the shafts of the connected mechanisms, regardless of the angle between the shafts;

Transmission of torque without creating a transmission in the vehicle additional loads;

High efficiency;

Quiet operation.

To connect the mechanisms of the car, cardan drives of various types are used.

Single-shaft cardan transmission applied on passenger cars with a short base (base is the distance between the front and rear wheels) and wheel arrangement 4x2 for connecting the gearbox with the rear driving axle . Such a cardan transmission consists of cardan shaft3 and two cardan joints .

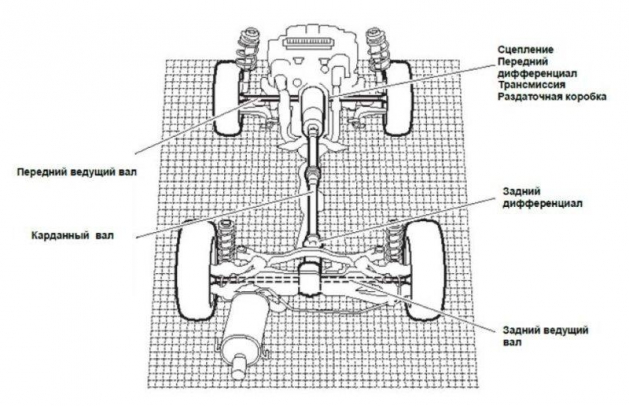

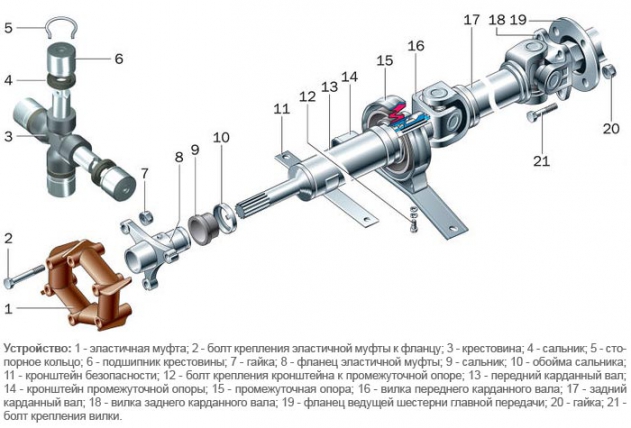

The two-shaft cardan transmission is used on cars with a long base and a 4x2 wheel arrangement to link the gearbox to the rear driving axle. The transmission includes two cardan shafts, three cardan joints and an intermediate support. This cardan transmission is most widespread in cars, trucks and buses of limited cross-country ability. By cars high cross-country ability with a 4x4 wheel arrangement, three single-shaft cardan drives are used to connect the gearbox to the transfer case, respectively, and the transfer case to the rear and front drive axles. By cars high cross-country ability with 6x6 wheel arrangement and individual drive axles, the transfer case is connected to the rear drive axle by a two-shaft cardan transmission with an intermediate support . The connection of the gearbox with the transfer case with the front and middle drive axles of these cars is carried out by single-shaft cardan gears. In cross-country vehicles with a wheel arrangement of 6 x 6 and with a medium through drive axle, single-shaft cardan drives are used to connect the gearbox with the transfer case and the transfer case with the drive axles. This ensures the drive of the additional gearbox of the middle axle.

Single-shaft and double-shaft cardan drives used to connect the gearbox, transfer case and drive axles of cars have cardan joints of unequal angular velocities.- Cardan drives with hinges of equal angular speeds on cars are used to drive the front steered and driving wheels at the same time.

Cardan joints.Cardan joint or cardan joint is called a movable joint that transfers rotation between shafts whose axes intersect at an angle. In cars, cardan joints of unequal and equal angular speeds are used. The former are called asynchronous hinges, and the latter are called synchronous.

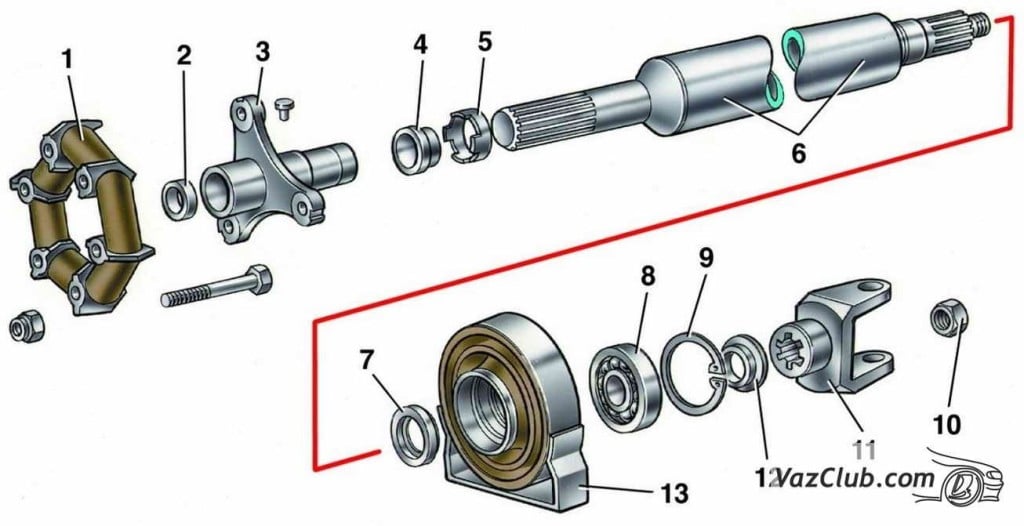

The cardan joint of unequal angular velocities consists of a fork of a drive shaft, a fork of a driven shaft and a cross connecting the forks with needle bearings. Single-shaft, double-joint, with cardan shafts of unequal angular speeds, the cardan drive consists of a tubular cardan shaft, to one end of which a fork is welded , and to the other - a tip with slots. The tip is connected to an axially movable splined sleeve , welded to the cardan joint fork. Such a movable spline connection is called a compensating device. It provides a change in the length of the driveline when moving the drive axle relative to the gearbox while driving. The spline joint is lubricated through an oiler. It is sealed with a cuff and protected from dirt by a rubber bellows.

The shaft forks are connected to the universal joint forks with crosses and needle bearings, which are lubricated through an oiler in the cross. Each bearing consists of a steel cup with needles, secured in the yoke eyelet and sealed with a collar to hold lubricant and protection from water and dirt. The universal joint forks are bolted through their flanges to the flanges, which are installed at the ends of the universal joint and final drive shafts, connected by the universal joint. With such a flange mount of the cardan transmission, it is very convenient to install and dismantle it on a car.

“Listen, your cardan knocks. Hand it over for repairs, otherwise it will end badly, ”her lover said to the main character of the film“ Moscow Does Not Believe in Tears ”. About what a cardan shaft is, why is it needed, what malfunctions are typical for it, and how to repair them - in our today's article.

From the history of the cardan

If you remember, the car that the characters in the film drove was a VAZ 2103 - with rear wheel drive. Cardan shaft, about which the hero-lover speaks, is the transmission unit of the "troika", which was also installed on cars with four-wheel drive... For front-wheel drive cars, such a transmission unit is not needed - the torque from the engine to the front axle is transmitted through main gear and that are located in the gearbox housing.

A car cannot do without a propeller shaft: with its help, the torque from the gearbox or (for all-wheel drive) to the front and rear axle... For the first time, the principle of operation of this mechanism was described by the Italian Girolamo Cardano, after whom the shaft was named. In the automotive industry, the cardan began to be used at the end of the 19th century. For example, one of the pioneers in installing a driveshaft on a car was the founder of the French company of the same name, Louis Renault. On his machines, the cardan has established itself from the very better side: thanks to the introduction of this unit into the transmission, the engineers managed to solve an important problem - without failures to transmit torque from the gearbox to the rear axle while driving on uneven roads, thereby ensuring a smooth ride. Since then, the propeller shaft has evolved slightly - the torque transmission mechanism has remained the same, but the design of the unit has improved depending on which particular car model it was installed on.

What does the cardan shaft consist of and how does it work?

In the device of the propeller shaft, it is customary to distinguish between five main components:

Central shaft... It is a hollow (to reduce the weight of the unit) steel pipe.

Crosspieces with tips... These are cross-shaped hinges, the function of which is to ensure that all rotating transmission elements operate at a certain variable angle (from 0 to 20 degrees) for smooth transmission of torque - in this case, the efficiency of the crosses is highest. If the angle of rotation during the movement of the car exceeds 20 degrees, the crosspiece begins to work under heavy load, which affects the balance of the propeller shaft.

Sliding fork... It is a unit responsible for connecting the splined ends of the intermediate and propeller shafts. Together with the splines, it compensates for the change in the height distance between the intermediate shaft and the propeller shaft when driving over rough terrain.

Intermediate bearing... Performs the function of supporting the main shaft, allowing it to rotate freely along its axis. Depending on the number of propeller shaft sections, there are two, three, or more intermediate bearings.

In addition to these, the main parts, the propeller shaft includes various mounts, seals and an elastic coupling, which absorbs the shocks that occur when the clutch is engaged.

A distinction is made between single-section and multi-section cardan shafts. Single-section cardan shafts are used in the design of rear-wheel and all-wheel drive transmissions sports carswho need maximum fast transfer torque to the driving wheels. Multi-section universal joint shafts are used in standard cars and trucks.

Pros and cons of cardan

The design of the propeller shaft has one significant advantage - it can withstand the enormous loads that fall on the vehicle's transmission when driving on high-quality roads and rough terrain.

There is also one drawback of the driveshaft - its large mass, which adds extra pounds to the curb weight of the car, which affects its dynamic characteristics and fuel consumption. In addition, the installation of a propeller shaft on a car requires equipment under its bottom of a special tunnel, the convex side of which protrudes into the passenger compartment and brings inconvenience to the rear row passengers. The rotating mechanism of the propeller shaft serves as a source of noise and vibration, which in modern cars has practically been reduced to naught through the installation of high-quality noise and vibration insulation materials.

Cardan broke: how to diagnose and repair

The strongest element of a propeller shaft is the shaft (s) itself, made of high-load steel. The estimated resource of this part is 500 thousand kilometers. But this part can also be damaged during operation - for example, bend when the car hits an obstacle or fails (breaks) of its elements (hinges).

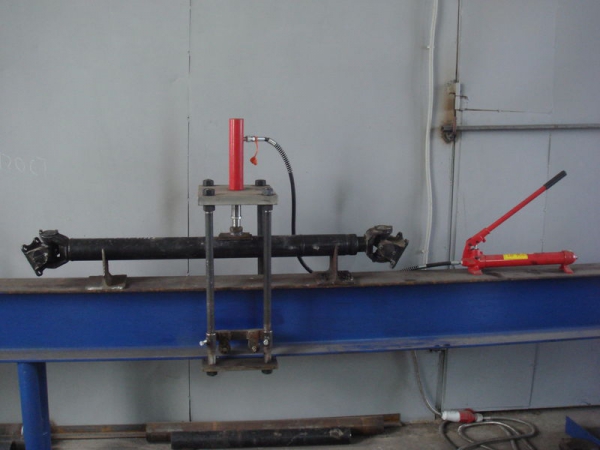

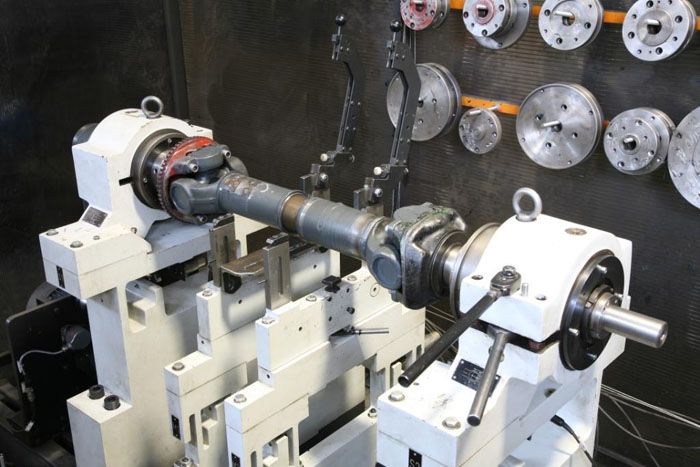

When this trouble occurs, it is possible to diagnose a breakdown by the increased vibration that comes from under the bottom of the body during driving. Some craftsmen say that in this case the cardan shaft can be "cured" by tapping it with a sledgehammer and aligning the bends. We recommend replacing the bent shaft with a new one. Since incorrect editing of the propeller shaft geometry can lead to rapid failure of the crosspieces. When replacing the propeller shaft, it is important to properly balance it, otherwise the unbalanced shaft, producing vibrations, will destroy not only the crosses, but also other transmission parts. It is impossible to balance the driveshaft on your own - this operation will require special balancing equipment, which is available in repair shops cardan shafts.

The most susceptible to breakage are such elements of the cardan shaft as hinges, crosses, bearings. These parts wear out during long-term operation and cannot perform their functions. The service life of the hinges, depending on the type of drive and the design of the transmission of the car, is 60 - 70 thousand kilometers, the same amount is taken care of by crosses and bearings. However, they may wear out earlier - it depends on the quality of the parts themselves, the driver's driving style and the conditions in which the car is operated.

It is possible to diagnose the failure of hinges, bearings and crosses by knocking, clicks when shifting gears or starting a movement, which are uncharacteristic for normal work cardan transmission to noise or vibration. We strongly recommend that you do not "treat" these worn parts. It would be best to replace them with new ones: they are relatively inexpensive, they are installed quite easily. Replacing hinges, crosses and bearings can be done by yourself, with certain skills. If you do not possess such skills, then it will be correct to contact a service station.

Another breakdown characteristic of the cardan transmission is the loss of tightness protective covers ball joints. When the cover wears out, a gap appears in it through which it oozes transmission fluid... If this fluid drains out completely, the joints will no longer be lubricated and can quickly wear out from increased friction.

You can diagnose this malfunction by looking under the bottom standing car... If you notice drops of oil under the gimbal in the places where the ball joints are located, then the cover has torn. In this case, we advise you to install new covers.

To extend the service life of all elements of the propeller shaft, we recommend adhering to the following simple rules:

- move away smoothly when starting to move;

- do not allow long-term wheel slip in deep ruts;

- do not accelerate sharply;

- refrain from cross-country driving.

Driver, take care of the cardan from your youth!

Title

A full drive system always has this element available. This is not an intermediate piece!

A propeller shaft is a part that is part of a car's transmission, which has a rear or all-wheel drive device. This mechanism transfers rotation to the gearbox of the front or rear axle from the gearbox, thus the propeller shaft deserves the right to be called "intermediate link-part". Also, it can be called nothing other than the support of the machine!

Classification

Below will be a classification of cardan transmissions, which form a mechanism, the role of which is intermediate.

The central device can be classified according to several criteria:

- Appointment;

- In the presence of a compensating device.

By the purpose of the mechanism, the transmission (it is also the support of the main mechanism and the intermediate link) can be classified:

- Basic - the basic ones work as a support for the drive wheel drive mechanisms;

- Auxiliary - used for mechanisms of auxiliary mechanisms, for example, winches or pumps, transmission mechanisms, can be an intermediate mechanism, in some device.

The type of cardan depends on what kind of construction it has and its location:

- Closed transmission - when it is enclosed in one of the elements of the vehicle;

- Open - when it is independent of other parts of the machine.

Classification by the presence of compensation that the device has:

- Availability of compensation. If it provides options for compensating large axial movements, then the shaft is called universal;

- Otherwise, the intermediate mechanism is called simple.

Work principles

The cardan shaft contains:

- Propeller shaft suspension bearing;

- Double hinge of the same name;

- Sliding fork;

- All kinds of intermediate seals;

- Fastening elements.

The propeller shaft itself can be of several sections. It is also a support for many parts of the machine. Its weight depends on the vehicle and its features. The design of this part of the car depends on the size. Usually it is composite and the base is made of steel pipe, to save metal and weight, and cross tips are attached to it. Only a small gimbal can be made solid and solid. So its intermediate role is enhanced.

The solid piece is a support for sports cars, since some of the weight is held on it, so it is made solid.

This part of the machine (its support) is one of the most suitable for repair. The process itself is simple, as is the removal of the mechanism from the car. The peculiarity is to replace the double cardan joint and outboard bearing. This is the part class "intermediate".

The implementation of an intermediate gear is a function that is provided by articulated mechanisms based on crosses. Allows two shafts to support each other without interrupting rotation, while being at a variable angle. Moreover, the highest efficiency is achieved when the shafts are supported on each other from 0 to 20 degrees. In this case, they work as a support. If this indicator is exceeded, then the intermediate part begins to experience very high loads. Which leads to the fact that the support of the parts is lost, the shaft is unbalanced and the body vibrates.

The outboard bearing is nothing more than supporting the split shaft, keeping it in place even while rotating. It is also an intermediate part of a common element.

Pros and cons of using cardan gears

Description of the advantages of using a part such as a double universal joint:

- The device is capable of withstanding enormous loads:

This parameter is very important in vehicle, since there is no other way to transfer rotation in a car with a large mass. As an example, limousines are always rear wheel drive for this reason (they need support). Since this is the most in a reliable way transfer rotation. Another example is the weight, the weight of the Belaz propeller shaft is 105 kg. And the sports cardan weighs 1.8 kg.

- Maintainability:

This property helps not to change the unit, but to repair only the part, which makes life easier for all car owners. Since replacing an expensive unit can be critical. Thus, keeping in good condition propeller shaft and changing only consumables, you can extend the operating time of the car.

Disadvantages:

The presence of a cardan in the car increases the weight, and also reduces the dimensions of the cabin.

- Vibration: The presence of an additional unit that a device may have increases noise and vibration, which leads to the destruction of parts.

A cardan drive is an integral part of a car that transmits torque between shafts located at a certain angle relative to each other. It is difficult to imagine a modern car without a cardan transmission of one type or another. The driveline is usually used in the transmission and steering. The name comes from D. Cardano, who described the device in the 16th century. However, the scientist only described the device of the cardan shaft, but it cannot be ranked among the inventors of the cardan transmission. They realized what was described much later, several centuries later. And Cardano's name is now immortalized for centuries.

The following elements are connected using a cardan gear:

- power unit and checkpoint;

- Checkpoint and razdatka;

- Gearbox and main gear;

- transfer case and main gear;

- differential and driving pair of wheels.

The main element of the cardan transmission must be called the cardan joint. It comes in various modifications:

- equal angular velocities;

- unequal angular velocities;

- semi-cardan elastic hinge;

- semi-cardan inelastic hinge.

This type of transmission can be found on vehicles with rear wheel drive or four-wheel drive cars... The device of such a transmission is as follows: on cardan shafts hinges of unequal angular velocities are located. There are connecting elements at the ends of the transmission. A connecting support is used if necessary.

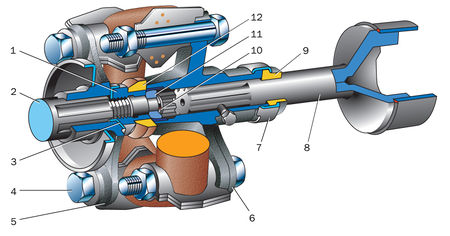

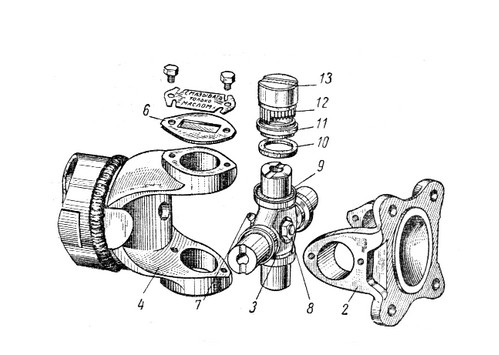

The hinge brings together a pair of forks, a crosspiece and locking devices. In the eyes of the forks, needle bearings are installed in which the crosspiece rotates.

Copy-paste:

Steel cups 13 with needle bearings 12 are installed on the carefully machined pins of the crosspiece 3. The bearing needles from the inner end rest on the support washer 11. The bowl is sealed on the crosspiece with a rubber gland 10 installed in the metal body 9, which is put on the crosspiece. The crosspiece with glasses is fixed in the ears of the forks 2 and 4 with retaining rings or plates 6 with screws. The cross-piece bearings are lubricated through the central oiler 7, from which the oil goes to the bearings through the channels in the cross-piece. To eliminate excessive oil pressure, a body with a safety valve 8 is threaded into the crosspiece.

The bearings cannot be repaired or serviced. Oil is poured into them during installation.

The peculiarity of the hinge is that it transmits an unequal torque. The additional shaft periodically overtakes and lags behind the main shaft. To compensate for this disadvantage, multiple joints are used in the transmission. Opposite hinge forks are in the same plane.

Depending on the distance to which the torque must be transmitted, one or two shafts are used in the cardan transmission. When the number of shafts is equal to two, one of them is called intermediate, the second - rear. To fix the shafts, an intermediate support is installed, which is attached to the car body.

The cardan transmission is connected to other elements of the car using flanges, couplings and other connecting elements.

It is safe to say that unequal angular velocity joints have low reliability and a relatively short service life. In modern conditions, cardan transmissions with hinges of equal angular speeds are used.

Cardan transmission with constant velocity joint

This type of transmission is widely used in front wheel drive vehicles. It connects the differential and the drive wheel hub.

The transmission has two joints - internal and external, connected by a shaft. CV joints are often used in cars with rear wheel drive, in all-wheel drive cars. The fact is that constant velocity joints are more modern and practical, besides, the noise level from them is much lower than from the SNUS.

The most common of the existing ones is the ball-type constant velocity joint. CV joint transmits torque from the driving shaft to the driven shaft. The angular rate of transmission of torque is constant. It does not depend on the angle of inclination of the shafts.

CV joint, or as it is popularly called "grenade" is a spherical body in which the holder is located. Balls rotate between them. They move along special grooves.

As a result, torque is evenly transmitted from the drive shaft to the driven shaft under the condition of changing the angle. The separator holds the balls in position. The "grenade" is protected from the external environment by a "boot" - a protective casing.

A prerequisite long service life of CV joints is the presence of grease in them. And the presence of lubricant, in turn, is ensured by the tightness of the hinge itself.

Separately, it should be said about the safety of CV joints. If a crack or noise is heard in the "grenade", then it must be changed immediately. Operation of a car with a faulty CV joint is extremely dangerous. Simply put, a wheel can fall off. The reason why the cardan shaft becomes unusable is most often the wrong choice of speed and poor road surface.

Cardan transmission with elastic semi-cardan joint

The elastic semi-cardan joint facilitates the transmission of torque between shafts located at a slight angle. This happens due to the deformation of the elastic link.

1 - nut; 2 - the driven shaft of the gearbox; 3 - lock washer; 4 - bolt (3 pcs.); 5, 6 - coupling flanges; 7 - clip; 8 - cardan shaft; 9 - oil seal; 10 - retaining ring; 11 - centering ring; 12 - sealant

An example is the elastic Guibault coupling. It is a hexagonal compressed elastic element. The flanges of the driving and driven shafts are attached to it and the torque is transmitted.

Conclusion

It is worth noting that most often under the cardan transmission is understood, of course, the cardan of a rear-wheel drive car. As for the universal joint with CV joints in front-wheel drive cars, this is, rather, a successful application of the development for SUVs and rear-wheel drive cars. This opinion is debatable, but it is widespread among the masses.

As noted above, such an invention as a cardan transmission is difficult to overestimate. Without it, the pleasure of driving a car would not be so great. And more likely modern cars without a cardan gear they would not be able to move at all.

If you remember, the car that the characters in the film drove was a VAZ 2103 - with rear wheel drive. The propeller shaft, about which the hero-lover speaks, is the transmission unit of the "troika", which was also installed on cars with all-wheel drive. For front-wheel drive cars, such a transmission unit is not needed - the torque from the engine to the front axle is transmitted through the main gear and differential, which are located in the gearbox housing.

Rear- and all-wheel drive vehicles cannot do without a cardan shaft: with its help, the torque from the gearbox or transfer case (for all-wheel drive vehicles) to the gearboxes of the front and rear axles. For the first time, the principle of operation of this mechanism was described by the Italian Girolamo Cardano, after whom the shaft was named. In the automotive industry, the cardan began to be used at the end of the 19th century. For example, one of the pioneers in installing a driveshaft on a car was the founder of the French company of the same name, Louis Renault. On his machines, the cardan has proven itself from the best side: thanks to the introduction of this unit into the transmission, the engineers managed to solve an important problem - without failures to transmit torque from the checkpoint to the rear axle while driving on uneven roads, thereby ensuring a smooth ride. Since then, the cardan shaft has evolved slightly - the torque transmission mechanism has remained the same, but the design of the unit has improved depending on which particular car model it was installed on.

What is a driveshaft in and what function does it perform?

The car's transmission performs important function - transfers the rotation of the crankshaft to the wheels. The main elements of the transmission: the clutch - we talked about it on Vodi.su, it connects and disconnects the gearbox and the flywheel crankshaft; gearbox - allows you to transform the uniform rotation of the crankshaft into a specific driving mode; cardan or cardan drive - used on cars with rear or all-wheel drive, serves to transfer the moment of movement to the drive axle; differential - distributes the moment of movement between the driving wheels; gearbox - to increase or decrease torque, provides a constant angular speed. If we take an ordinary mechanical box gears, then we will see three shafts in its composition: primary or leading - connects the gearbox to the flywheel through the clutch; secondary - rigidly connected to the cardan, it is he who is designed to transfer the torque to the cardan, and from it to the drive wheels; intermediate - transfers rotation from input shaft secondary.

The purpose of the cardan transmission

Any driver who has driven RWD or four-wheel drive car, and even more so on the GAZon or ZIL-130, I saw a driveshaft - a long hollow tube consisting of two segments - a longer and a shorter one, they are connected to each other by an intermediate support and a cross, forming a hinge. At the front and rear of the propeller shaft, flanges can be seen for rigid connection to the rear axle and the output shaft exiting the gearbox. The main task of the cardan is not only to transfer rotation from the gearbox to the rear axle gearbox, but also to ensure that this work is transmitted with variable coaxiality of the articulated units, or, in simple articulate language, a rigid connection of the driving wheels with the secondary shaft of the gearbox is provided while not interfering with the independent movement of the wheels and suspension relative to the body. Also, the device of the car is such, especially when it comes to trucks, that the box is located higher in relation to the surface than the rear axle gearbox. Accordingly, the moment of movement must be transmitted at a certain angle, and thanks to the gimbal's hinge device, this is quite possible. Moreover, in the process of driving, the car's frame may deform slightly - literally by millimeters, but the cardan device makes it possible to ignore these minor changes.

REMOVAL AND INSTALLATION OF PROPELLER SHAFT

Removing the shaft is straightforward. It is necessary to unscrew the bolts and nuts connecting the flanges of the propeller shaft and the axle gearbox, remove the cardan flange from the gearbox and lower it down. Then unscrew the bolts securing the elastic coupling and take the universal joint away from the gearbox. Unscrew the mounting bolts last. outboard bearing... Installation is in the reverse order.

CHECKING PROPELLER SHAFT CONDITION

The condition of the cardan is checked if vibration appears when driving on high speed, hum, noise, knocks, which were not there before. To check the propeller shaft, a hoist, overpass or inspection pit... If the check is carried out on a pit or overpass, it is necessary to raise the rear (if checking the front propeller shaft, then the front) side of the car so that the wheels rotate freely. Read about how to safely lift the car in the article (Replacement and restoration of shock absorbers).

The check is carried out in several stages:

- Checking the tightness of the connecting elements (fastening of the elastic coupling, flange connection and outboard bearing). All connections should consist of a bolt, a lock washer and a nut. If somewhere there is no lock washer, then there is a high probability that under the influence of vibration the nut will unscrew and the bolt will fall out. The tightening torque must correspond to that specified in the instruction manual.

- Checking the condition of the elastic coupling. To do this, slowly turn the propeller shaft and carefully inspect the condition of the coupling. If ruptures, cracks or other damage are found, the coupling must be replaced.

- Checking the condition of the spline connection. To check the connection, hold the shaft with one hand, with the other try to rotate elastic coupling in different directions. If even a slight play is found, the gimbal and joint must be replaced.

- Checking the hinges. Insert a powerful screwdriver between the hinge forks and wiggle. If you find play, replace the crosses.

- Checking the condition of the outboard bearing. To check the bearing, grasp the shaft with one hand before it, with the other after it, and pull it in different directions. If you find even a slight play, replace the crosses.

- If all this does not help, you need to check the balancing using a special stand. To carry out this operation, contact a large car service that has the appropriate equipment.

Advantages and disadvantages of cardan drives

The main advantages in the operation of cardan shafts is their ability to withstand heavy loads, which is especially important for vehicles with large mass... It is no coincidence that all limousine and stretch cars are rear-wheel drive. Weighing several tons and powerful engine transmission of torque by a cardan shaft is the most reliable way.

The propeller shaft of the BelAZ dump truck weighs 105 kilograms. Sports gimbal for BMW made of carbon fiber - 1.8 kilograms

The main disadvantage is the own weight of the cardan, which increases the total weight of the car. The need for a special tunnel under the cardan in the floor of the body reduces the volume of the passenger compartment, increases the level of noise and vibration. In addition, the cardan shaft is a rather expensive and complicated part.

To extend the service life of the universal joint shaft, it is recommended to service the crosses and the splined joint after every ten thousand mileage, if, of course, their maintenance is provided by the manufacturer. The serviced crosses are equipped with grease fittings, into which it is necessary to pump thick oil of the Litol type. Most modern cars cardan shafts are maintenance-free and only need to be replaced when a backlash appears. By the way, after each repair, the shaft must be balanced, and this can be done only with specialized equipment. When extraneous noise, knocking when the car is running, contact the station maintenance for the diagnosis of the cross.

Reverse is only available on motorcycles with cardan gear

Services of specialized services for the repair of cardan shafts are expensive. It is worth taking care of the cardan, be careful and do not allow it to work for wear.

Cardan transmission with constant velocity joint

This type of transmission is widely used in front wheel drive vehicles. It connects the differential and the drive wheel hub. The transmission has two joints - internal and external, connected by a shaft. CV joints are often used in cars with rear wheel drive, in all-wheel drive cars. The fact is that constant velocity joints are more modern and practical, besides, the noise level from them is much lower than from the SNUS.

The most common of the existing ones is a ball-type constant velocity joint. CV joint transmits torque from the driving shaft to the driven shaft. The angular rate of transmission of torque is constant. It does not depend on the angle of inclination of the shafts. CV joint, or as it is popularly called "grenade" is a spherical body in which the holder is located. Balls rotate between them.

They move along special grooves. As a result, torque is evenly transmitted from the drive shaft to the driven shaft under the condition of changing the angle. The separator holds the balls in position. The "grenade" is protected from the external environment by a "boot" - a protective casing. A prerequisite for the long service life of the CV joints is the presence of grease in them. And the presence of lubricant, in turn, is ensured by the tightness of the hinge itself. Separately, it should be said about the safety of CV joints. If a crack or noise is heard in the "grenade", then it must be changed immediately. Operation of a car with a faulty CV joint is extremely dangerous. Simply put, a wheel can fall off. The reason why the cardan shaft becomes unusable is most often the wrong choice of speed and poor road surface.

Cardan transmission with a hinge of unequal angular speeds

This type of transmission can be found on rear-wheel drive or all-wheel drive vehicles. The device of such a transmission is as follows: joints of unequal angular speeds are located on the driveshafts. There are connecting elements at the ends of the transmission. A connecting support is used if necessary. The hinge brings together a pair of forks, a crosspiece and locking devices. Needle bearings are installed in the eyes of the forks, in which the crosspiece rotates.

Copy-paste: Steel cups 13 with needle bearings 12 are installed on the carefully processed pins of the cross 3. The bearing needles from the inner end rest on the support washer 11. The cup is sealed on the cross with a rubber gland 10 installed in the metal case 9, which is put on the cross. The crosspiece with glasses is fixed in the ears of the forks 2 and 4 with retaining rings or plates 6 with screws. The cross-piece bearings are lubricated through the central oiler 7, from which the oil goes to the bearings through the channels in the cross-piece. To eliminate excessive oil pressure, a body with a safety valve 8 is threaded into the cross-piece. The bearings cannot be repaired or serviced. Oil is poured into them during installation. The peculiarity of the hinge is that it transmits an unequal torque. The auxiliary shaft periodically overtakes and lags behind the main shaft.

To compensate for this disadvantage, several hinges are used in the transmission. Opposite hinge forks are in the same plane. Depending on the distance to which the torque must be transmitted, one or two shafts are used in the cardan transmission. When the number of shafts is equal to two, one of them is called intermediate, the second - rear. To fix the shafts, an intermediate support is installed, which is attached to the car body. The cardan drive is connected to other elements of the car using flanges, couplings and other connecting elements.

It is safe to say that unequal angular velocity joints have low reliability and a relatively short service life. In modern conditions, cardan transmissions with hinges of equal angular speeds are used.