Today, most models of gas boilers are volatile devices. Statistics claim that the main reason for boiler breakdown is unstable power supply. The automatic part of heating devices suffers greatly from power surges. As a solution to the problem, you can establish a backup power supply to the boiler from a gas generator.

Which generator to choose

A gas generator is a device that runs on gasoline and generates electrical energy.

The design of the unit includes a two-stroke or four-stroke engine, as well as a generator, asynchronous or synchronous. It converts the mechanical energy transmitted by the motor into electrical energy.

The difference between synchronous and asynchronous generators is the presence of windings. They are at the anchor of the synchronous generator. Among its advantages are resistance to short-term loads and the ability to more accurately maintain the voltage in the mains. The disadvantage is that the brushes can overheat and burn out during operation.

An asynchronous generator dispenses with windings. The design of such a device is simpler, the case reliably protects the insides from dust. However, such a unit is susceptible to starting loads.

In comparison with analogues, both gas and diesel, the gas generator has several advantages:

- Low cost;

- Mobility. Due to its relatively low weight, the device is quite easy to transport from place to place;

- Ease of maintenance and operation;

- Low noise level during operation;

- Environmental friendliness.

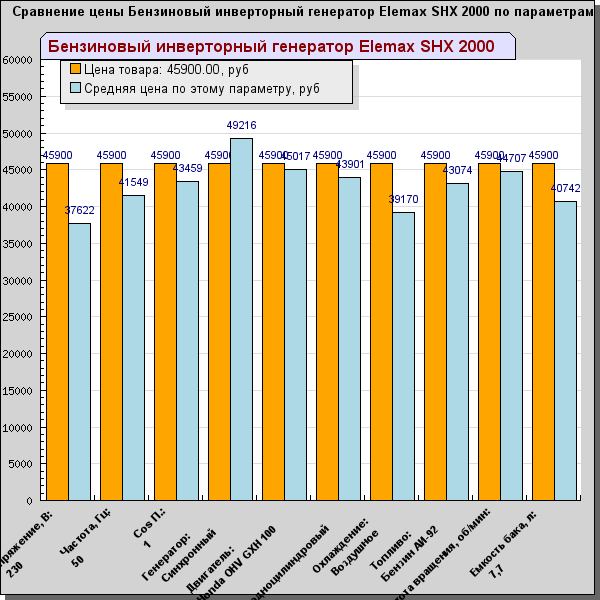

It is worth considering that the cost of such power plants is ten times higher than the price of a resonant filter. Therefore, the main criteria according to which a gas generator is selected are the level of output power, the level of quality, as well as the reliability of the device.

Recently, inverter power plants have gained significant popularity. The dimensions of such devices are about one and a half times smaller than those of standard models. A special inverter unit is included in the design. Using the method of pulse width modulation, it transforms an alternating electric current into a constant one.

After that, the wave oscillations are stabilized, after which d.C. goes to variable. For stabilization, capacitive filters are used.

With the help of an inverter, electricity can be generated significantly more high Quality... Due to the stabilized output voltage, as well as the current frequency, such generators will ensure the reliable operation of Baksi gas boilers. The choice of an inverter is ideal when high quality electrical power is required for low power applications.

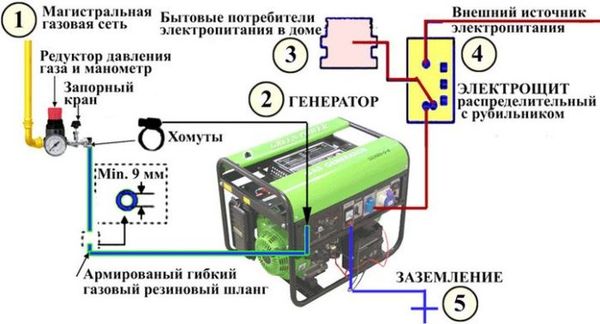

How to connect a generator

Incorrect connection of the gas boiler to the generator can lead to the inability of the ionisation electrode to distinguish the flame in the burner. The unit uses an ionisation flame sensor. When the air is ionized, the current begins to move between this flame sensor and the burner. A "zero" is required for a flame to be recognized correctly.

When connecting the gas generator to the boiler, the body is grounded. Based on the design features, most models exhibit "zero". Otherwise, one of the two contacts is taken as zero.

The boiler is grounded. This is necessary in order to achieve maximum electrical safety. In order to control the flame, the neutral wire must be connected to the protective ground. In the initial state, the network has a clear phase and zero. An insulated neutral generator has two equal leads. For safety reasons, the generator housing is also grounded. It is enough to connect it to a common conductor.

When any of the equal outputs of the generator are combined with a special grounding conductor, pronounced zero and phase conductors appear on the unit.

If the boiler does not start from the generator, it is necessary to check whether the gas generator is correctly connected to the mains. In addition, you need to check the serviceability of the operated gas boiler. Also, the voltage in the network should not be allowed to exceed 250 volts. In some cases, the external power grid is normalized using a special stabilizer. In this case, the gasoline generator is most often connected directly to the network, bypassing the stabilizer.

If the level of the voltage generated by the gas generator is not enough for the functioning of the gas boiler, you need to contact a service workshop. Very often, a built-in automatic voltage regulator is included in the design of a gasoline unit. It should be borne in mind that when an external stabilizer is connected immediately behind the gas generator, a conflict of both stabilizing systems is possible. This conflict must be avoided.

The centralized power grid always has a grounded zero. Thanks to this, the gas generator can be used without carrying out work on its grounding.

The manual phase switch can be replaced with automation. Automatic control the system can provide complete automation of both the procedure for turning on the electric generator, and a number of other functions. In this case, the opposite inclusion is completely excluded.

Before connecting the gasoline generator to the boiler, it is necessary to read the installation instructions. It is best to entrust the determination of the scope, connection and further maintenance of the device to persons with the necessary qualifications.

Modern gas boilers - this is a rather complex equipment equipped with control electronics. If earlier the gas boiler had as a maximum a piezo ignition system and an emergency valve controlled by a thermocouple to shut off the gas after the flame went out, now the boiler control electronics not only regulates the gas supply to the burner, but also when the flame goes out reignites it using the electrode connected to the voltage multiplier.

Using electronic control made it possible to make gas boilers completely autonomous, not requiring human intervention to regulate and maintain combustion. But at the same time, the boilers became volatile - if there is a power outage in the network, the boiler will also turn off.

To maintain the operability of wall-mounted and floor-standing gas boilers, either powerful uninterruptible power supplies or stand-alone generators are used.

We offer you to look at useful material on this topic

Types and selection of generators

Modern generators differ, first of all, in the fuel used.

Modern generators differ, first of all, in the fuel used.

- they are cheap and with a small size of the engine, they can develop sufficient power.

- the device is not much different from gasoline. The engine can be used the same, but instead of the carburetor it will be powered by a gas mixer. More powerful ones use a turbine instead of piston engine... Most gas installations with piston engines are either dual-fuel (that is, they can run on gasoline), or are completely improved from purely gasoline ones. When choosing a generator for a gas boiler, you should pay close attention to this class of equipment, since using the same fuel as the boiler is not only economical, but also convenient to use: you do not need to replenish the supply of gasoline in the tank and monitor its freshness. In addition, the resource of a piston engine when operating on gas for a number of reasons is greater than when using gasoline: the lubrication of the cylinder walls is not disturbed (the gas is unable to wash off the oil film), and soot is practically not formed.

- reveal their potential only in powerful installations long-term use, since a diesel engine is much more complicated and more expensive than gasoline and gas engines.

Itself generator set it can work both in a synchronous and asynchronous scheme.

Itself generator set it can work both in a synchronous and asynchronous scheme.

- Rotor synchronous generator has a field winding, the current in which regulates the degree of its magnetization and, accordingly, the voltage at the generator output. An important advantage of synchronous generators is the ease of voltage regulation and their quick response to sudden load surges. Resource problems due to the presence of collector rings on the rotor, which are worn out by brush friction, and the need to replace the brushes themselves, are now solved by the invention of brushless synchronous generators, although they are significantly more expensive than conventional ones.

- have a permanently magnetized stator, which means they have less stability of the output voltage. With sudden load surges, they give a noticeable and prolonged voltage drop. When providing a gas boiler and circulation pumps of the heating system, this is unacceptable - the simultaneous activation of the boiler and the pumps will lead to the fact that the voltage at the generator output will drop below the boiler operability threshold and it will not ignite.

It should also be noted that they are gaining popularity. Their advantage is less noise when operating at low loads and lower fuel consumption, since, unlike conventional generators, where, to maintain a given frequency alternating current the motor must rotate at a strictly defined frequency, in inverter generators the current they give out is rectified, and then stabilized and the final stage of the inverter is converted again into an alternating one, with a given voltage and frequency. But, in addition to the higher price compared to the devices of the traditional circuit, inverter ones in our case have the following disadvantages:

It should also be noted that they are gaining popularity. Their advantage is less noise when operating at low loads and lower fuel consumption, since, unlike conventional generators, where, to maintain a given frequency alternating current the motor must rotate at a strictly defined frequency, in inverter generators the current they give out is rectified, and then stabilized and the final stage of the inverter is converted again into an alternating one, with a given voltage and frequency. But, in addition to the higher price compared to the devices of the traditional circuit, inverter ones in our case have the following disadvantages:

- The electronics of gas boilers are sensitive to the shape and frequency of the supply voltage. Cheap inverters give a signal that is noticeably different from the ideal sinusoid, which can cause malfunction of the boiler.

- Even more, the accuracy of the output signal affects the performance of the electric motors of circulation pumps - their high inductance will immediately make it possible to see the deviation of the supply voltage form with a hum during operation and overheating of both the inverter and the motors, with a simultaneous increase in electricity consumption.

- Thirdly, the pumps have a significant and prolonged starting current, since they turn on immediately under load. This will require choosing an expensive inverter generator with a large margin of power, since the less powerful inverter will automatically shut down in case of overload.

Therefore, we can conclude: when choosing an autonomous generator that ensures the continuous operation of a gas boiler and heating circulation pumps, first of all, it is worth considering gas or dual-fuel generators with classic synchronous generators.

We offer you to watch the device review from the Russian Engineering Group, which will be discussed below in the text

Noteworthy are such common models as:

An overview of the above in the video

Installation and operation

The autonomy of a gas boiler pushes to buy a generator with an auto-start device - in this case, when the power is turned off, the restoration of operability heating system will happen automatically, although such an installation will be more expensive. In this case, the connection is as simple as possible: the input of the automatic transfer switch (automatic transfer switch) is connected to the power grid, circulation pumps and the boiler are connected to the outputs of the automatic transfer switch. The functioning of the system is completely autonomous.

The autonomy of a gas boiler pushes to buy a generator with an auto-start device - in this case, when the power is turned off, the restoration of operability heating system will happen automatically, although such an installation will be more expensive. In this case, the connection is as simple as possible: the input of the automatic transfer switch (automatic transfer switch) is connected to the power grid, circulation pumps and the boiler are connected to the outputs of the automatic transfer switch. The functioning of the system is completely autonomous.

When starting the generator manually, it will be most convenient to place two rows of sockets on the wall near the boiler: connect the upper row to the mains, the second to the output of the generator, and after starting and warming up the engine, simply reconnect the load from one row to another. Moreover, the pumps must be turned on first, and turned off last, since this causes strong voltage surges that are harmful to the control electronics of the boiler.

Do not connect additional voltage stabilizers between the generator output and the boiler - this can lead to inadequate performance a regulating device built into the generator.

Possible malfunctions

When connecting the boiler to the generator, problems often arise - incorrect operation or its going into protective mode. Why does this happen if the generator set is completely functional?

When connecting the boiler to the generator, problems often arise - incorrect operation or its going into protective mode. Why does this happen if the generator set is completely functional?

- Many modern gas boilers (Baxi Main Four, Baxi Slim HPS) are phase-dependent, that is, there must be strictly set phase and neutral in the power outlet. At the same time, at the outlet of the gas generator, both wires are phase. When using a synchronous generator, one of its outputs will only need to be grounded, while an inverter device will require an isolation transformer with a grounded secondary winding. The grounding of the outlet socket must match the position of the neutral on the boiler supply plug.

- In addition, the boiler control electronics may malfunction if the supply voltage and its frequency deviate from the specified ones. To minimize the influence of power surges, always connect the boiler after the pumps and disconnect first. If it stubbornly refuses to work even with a stable voltage, check the frequency that the generator set gives out - it may need to be adjusted using the engine speed controller of the gas generator.

Given the above nuances, the choice of a generator for a gas boiler should not cause much difficulty.

At the same time, during the purchase, it is worthwhile to immediately discuss with the seller or store manager the possibility of returning the generator if it cannot work correctly with your equipment (strong deviations in the signal shape and frequency, unstable voltage).

An inverter generator for a gas boiler is simply necessary in order to be sure that power outages will not in any way affect the operation of expensive equipment. Such generators are a guarantee smooth operation imported boilers, in which ultra-precise and sensitive automation is installed. Failure of this automatic system threatens to buy a new boiler.

The device and the specifics of the inverter generator for a gas boiler

The inverter generator for a gas boiler has a built-in unit - an electronic stabilizer, which is capable of producing an absolutely accurate sine wave. Due to this property, such generators are quite expensive. The special, exclusive property of inverter generators makes it possible to use them to work with various models of boilers, which can work properly only if the voltage is ideal for the operation of expensive equipment.

A generator for a heating boiler can be safely called a mini power plant, which has a good technical solution and does not create inconveniences for the inhabitants of the house. All these generators are compact, lightweight and capable of operating autonomously for a certain amount of time. A generator for a heating boiler is the best decision for those who want the equipment to work without interruption.

Buying an inverter generator for a gas boiler: selection difficulties

Before you buy a generator, you need to study it well. technical properties and characteristics, and it is best to consult a specialist. Exists distinctive feature of this type of generators from conventional gasoline, they do not have a flywheel, which is very voluminous and this makes it possible to significantly reduce the weight of the equipment. In terms of environmental functions, they are also ahead of other brands of current converters. They do not pose any danger to human health and are safe to use.

Electric generators for phase-dependent boilers must have a phasewhich is very clearly expressed. The boiler must be connected strictly according to the instructions. The generator can be used by phase-dependent equipment such as a boiler. For phase-dependent boilers, it is very important to connect "zero" to ground, without this the flame sensor will not work. If the generator is connected offline, then you need to know exactly where the zero of the boiler is and take care of its grounding. Electric generators for phase-dependent boilers do not require special maintenance, they are easy to operate. Without them, you will not have a guarantee that the gas boiler will work properly for many years.

By making your choice in favor of this product, you will protect yourself from damage to expensive gas equipment... Carefully consider the selection and installation of an inverter generator for a gas boiler and then the optimal functioning of the equipment is guaranteed to you.

Why do you need a gas generator for a gas heating boiler? After reading this material to the end, you will find the answer to this question, as well as find out what types of gasoline generators exist on the market, which one is better to buy and how to connect this unit.

What is a gas generator for?

The gas generator is designed to maintain the uninterrupted operation of the space heating system, hot water supply and, if necessary, power supply to other electrical appliances.

In view of the fact that modern gas boilers are completely dependent on an uninterrupted supply of electricity, a gasoline generator ensures stable operation of the boiler in case of unexpected interruptions of the main power supply. And also serves as the main source of power supply in cases where it is impossible to connect to the central network.

Types of gas generators for a gas boiler

By the number of engine strokes, generators are divided into:

- Two-stroke;

- Four-stroke;

The first type has a much smaller size and relatively low cost. And the second type is more economical and reliable.

The engine design distinguishes:

- Synchronous generators ... The disadvantage of this type is the short service life of the contact brushes (although the most modern models are already equipped with a brushless system). The advantages include resistance to starting loads and stable (without large drops) voltage in the network.

- Asynchronous generators ... Motors of this type have no windings, which ensures simplicity of design and reliability. disadvantages of this type: high sensitivity to inrush currents and voltage surges.

By way of inclusion:

- Gasoline generators with manual start. When the electricity supply from the main source is interrupted, it is required to manually start the generator, and after the main source of energy is restored, turn off the unit.

- Gas generators with automatic start... With the help of electronics, the gas generator will automatically turn on in case of malfunctions in the mains, and also turn off automatically if necessary.

Inverter gas generators for gas boiler

Today it is the most modern type of generator. Its main difference and advantage is the presence of an inverter, which provides an accurate sinusoidal voltage.

Advantages of inverter type gas generators:

- Small dimensions of the device. They have one and a half to two times smaller dimensions than models without inverters.

- Stable voltage. Thanks to the built-in voltage regulator, the output device produces electricity that is almost ideal in its characteristics (voltage of 220 volts at a frequency of 50 hertz). Therefore, manufacturers of expensive gas heating boilers recommend using this type of device with their equipment.

- Cost effective and energy efficient. Design feature inverters is the presence of a special module that controls the engine speed, which significantly increases the efficiency of the units.

The main disadvantages of inverters include their high cost.

Which is better to choose a gas generator

The main criteria for choosing gasoline generator are: power, price, dimensions, quality of the output current, noise level and the required duration of the unit's autonomous operation. Only after deciding on all the criteria, you can choose the optimal solution.

- Power... To select a generator for this parameter, you need to know the power consumption of the gas boiler, as well as other devices that are planned to be connected (if any). Add 20-30% to the resulting value (power reserve).

- Dimensions... Here everything rests on the area of \u200b\u200bthe room in which the unit will be installed. As a rule, the more compact the device, the higher its cost.

- Output current quality... Imported boilers are very sensitive to the quality of the supplied current, therefore for such models it is important to choose a generator that produces a stable voltage that has the desired parameters.

- Noise level... Conventional gasoline generators have a noise level of 50-80 decibels, while inverter generators have a slightly lower noise level.

- Battery life... You should decide what time the generator needs to run and choose the right model.

- Price... A very important indicator when choosing. You should not stop your choice on cheap and low-quality equipment - this can lead to failure of the gas boiler and other heating devices!

How to connect a gas generator to a gas boiler

First of all, when connecting a gasoline generator to the boiler, you need to carefully read the technical documentation of the generator and boiler and strictly follow it.

It is imperative to ground both the generator and the heating boiler. This is necessary not only to ensure electrical safety, but also so that a pronounced "zero" appears in the generator. Without this, the boiler flame detection system may not work.

For correct work of the boiler, the sine wave of the output current must be exactly 50 hertz, otherwise the boiler may not start. A voltage regulator or buying a high-quality inverter generator will help to cope with this task.

An important point in the water in the operation of a gasoline generator is the outlet exhaust gases from the premises. To do this, you need to equip a chimney or ventilation system in the room.

In many private houses, gas boilers are the main source of heat. However, for their effective work, the creation of certain conditions is required. Most of the models of modern gas units are volatile. Important for them is their uninterrupted power supply electricity.

According to statistics, in 85% of cases, the cause of boiler breakdown is unstable power supply. This is due to the fact that modern automation is extremely sensitive to significant voltage surges in the network. A stable voltage supply to heating equipment can be provided by a gas generator for a gas boiler.

Features of the design of gas generators

They are devices that use gasoline as fuel to generate electrical energy.

Definition! The principle of operation of the gas generator is based on the conversion of mechanical energy from the rotation of the engine shaft into electrical energy.

The design of such a device includes a 2-stroke or 4-stroke engine:

- from two-stroke engine have smaller dimensions, weight and low resource;

- with a four-stroke engine are designed for active and long-term use.

By design generators are divided into synchronous and asynchronous.

- Synchronous ones have windings on the armature, to which electricity... When its value changes, the magnetic field changes, and, consequently, the output voltage. The output is adjusted using a simple electrical circuit... The disadvantages of synchronous generators include the presence of brushes, which overheat and burn out during operation. Advantages - more accurate, in comparison with an induction motor, maintaining the voltage in the network and high resistance to short-term starting loads.

Attention! Modern models Generators of this type have brushless excitation systems on the rotor winding.

- Anchor asynchronous motor has no windings. This ensures simplicity of design, reliability, closeness and protection of the case from moisture and dust. But such equipment does not withstand starting loads.

Attention! In most cases, synchronous generators are used.

The units are easily wound by hand using the hand-starting rope. The launch can be made from battery or without human intervention - in automatic mode.

New generation of autonomous power supplies - inverter petrol generators

These backup power supply devices are capable of providing boiler automation, welding equipment, freezers, and power tools with high-quality power supply with a stable voltage.

The dimensions of inverter devices are approximately one and a half times smaller than those of traditional models.

Definition! In the design of inverter-type gas generators, there is an additional element - an inverter, the task of which is to gradually convert the current using capacitive filters.

The principle of operation of the inverter unit:

- an alternating current is supplied from the generator;

- passing the rectification circuit;

- a smoothing circuit is used to stabilize the current;

- transformation into sinusoidal current - conversion circuit;

- generation of alternating current with a stable voltage.

Definition! In inverter gasoline generators, an alternating current with an unstable voltage is transformed into a direct current. Further, the DC current is converted into AC with a stable voltage value of 220 V. At the same time, power losses are only about 2%.

For petrol mini-power plants of the inverter type, a reduced noise level is characteristic - 50-60 dB. The sound of operating equipment is audible, but does not cause irritation or deterioration of well-being.

Another important advantage of such power plants is their efficiency. The power can reach 2 kW and with intensive use only 20 liters of fuel are consumed within a week.

Petrol mini-power plant of inverter type Elemax SHX (1000)

If you want to purchase a high-quality and reliable portable power source for the boiler, then you should pay attention to the 1 kW Elemax SHX inverter gas generator (made in Japan). The cost of this model is approximately $ 800.

An innovative control system was used in the production of this mini-generator. throttle... With its help, the engine speed is automatically corrected depending on the load. The presence of this function allows you to save gas mileage.

An important advantage is the low noise level and the absence of vibrations due to a high-quality sound absorption system.

Attention! The unit is also attractive for its small size and low weight, which makes it convenient for use in summer cottages and country cottages.

Advantages of the Kipor IG 1000 petrol generator

The Kipor IG 1000 (1 kW) model has a number of advantageous characteristics similar to the Elemax SHX mini-power plant - compact dimensions, low level noise, lack of vibration. However, the cost of the Chinese product is slightly lower - about $ 500.

The Chinese gas generator for the boiler is easy to start up, economical, and gives a guaranteed stable frequency at the output.

The equipment is equipped with an emergency stop function in the event of a sharp drop in the oil level. The package includes a single-phase socket with grounding.

Attention! It is most difficult to unequivocally answer the question about the magnitude of the motor resource of a gas generator, since it depends on many factors: the quality of fuel, oil, and the intensity of use of the unit.