Viscounts - a device that is not very wide, but applied in cars. For example, they work on "PARCATHTS" with automatically connected full drive, are used in some cooling systems. Therefore, to have an idea of \u200b\u200btheir device, the principle of operation and verification in case of problems is useful to each motorist.

What is Viscounts?

Your name is a detail (derived from the Latin word Viscosus - viscous) or viscous coupling (vz) received, thanks to the main principle used in its work. It lies in the transfer of the pulse of the movement between the two elements of the system not at the expense of the mechanical connection available between them, but by viscous friction.

This principle allows you to put the depth of communication and the share of energy transmitted from the leading element to the slave, depending on the mismatch in motion. The energy transmission medium uses a liquid whose viscosity varies depending on the intensity of stirring and / or heating.

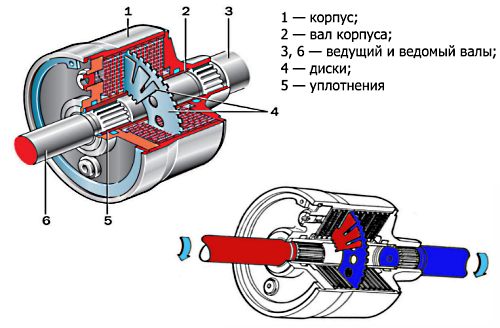

The work of the viscous clutch illustrates a simple example. Two disks are placed in a common hermetic case, one of which is associated with the leading shaft, and the other with the slave. There is enough distance between them, but there is no permanent connection. The space between the discs is filled with dilatated liquid (the viscosity of which grows is the stronger than intensively in it shift deformation, i.e. mixing),

So far, the shafts are moving consistently (at the same speed) the viscosity of the filling body of the liquid is small, the movement of the disks does not experience resistance and remains independent. When changing the speed of one of the shafts corner speeds Discs are changed relative to each other, the layers of fluid between them are shifted, mixing begins. At the same time, the viscosity of the substance increases, the process of friction of disks is increasing. Accordingly, the force from the drive shaft and the disk fixed on it (accelerating or braking) is transmitted to the drive of the slave shaft, due to which the rotation rates are aligned.

The viscosity of the substance increases the greater the more significant speed difference. With particularly strong mismatch, the shaft lock occurs due to the fact that the properties of dilatated fluid become similar to the properties of the solid body.

Video (basic principle of operation).

Viscouft species.

Currently, 2 types of devices are used in cars:

- with a constant volume of dilatant liquid;

- in which the working volume of the substance depends on external conditions.

The first are used in the so-called. self-locking differentials in car transmissions, including for automatic connection full drive.

Scope of the second - engine cooling systems, here they are used to control the fan.

Device and principle of viscous clutches for transmissions.

One of the main purpose items used today in the automotive industry is the automatic connection of the full drive.

The design of such a node includes two groups of round plates - disks with protrusions and holes. One group of plates is connected to the leading shaft, the other with the slave. Leading and driven discs alternate with each other, there is no mechanical connection between them. All this design is placed in a sealed body and is poured with silicone-based liquid.

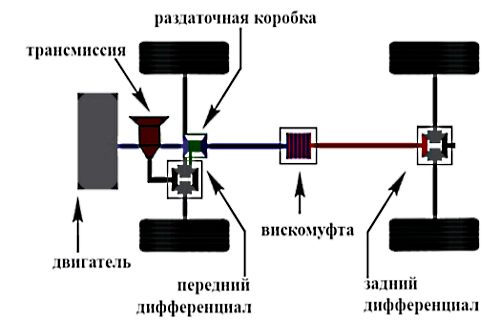

For use as self-locking inter-axis differential The Viscouft is located between the transfer box and one of the axes of the car. The second axis has a permanent connection with the engine.

Work details in the transmission.

When moving in normal mode on a normal coating, the angular velocities of the wheels of both axes are the same. Viscous clutch discs rotate with equal speeds, Transferring the moment from the engine to the slave axis is minimal. In fact, the car becomes completely front or rear-wheel drive.

When driving on ice, snow, dirt, irregular wheels, the synchronism of rotation of the wheels is broken, the viscosity of the fluid in the device increases, increasing the transmission of the torque on the second axis. Theoretically, such power transmission in some emergency modes can be up to 100%, although, as a rule, even partial connection of the second axis is sufficient to safely overcome the problem area.

Important! It should be understood that the viscous coupling in no way is not a full-fledged inter-axis differential, which ensures the redistribution of the engine torque on both leading axes.

The use of parts is justified on uneven coatings, with ice in the city or humid route. When driving, in terms of full off-road, the retardation of the operation of such self-locking differential is invalid. In addition, permanent loads can lead to fluid overheating in the device, loss of working properties and complete self-blocking, which is fraught with breakdowns of other car systems.

Currently, on vehicles with automatically connected full-wheel drive, the Viscounts are operated in the "sample mode". It is characterized by a constant transmission from 5% to 15% engine power to the slave axis, which significantly reduces the time of the reaction of the mechanism.

Video (operation of the device on Hyundai Tucson JM and Kia Sportage FQ).

Using the wicked for the wheels of one axis.

Another use of the coupling is possible - for the wheels of one axis. With this application, the device is installed between the axial differential and semi-axis. In this case, when passing the turns or slip of one of the wheels, the device contributes to the redistribution of the moment between them, ensuring the safe execution of the maneuver or the passage of the problem area.

There are decisions in which a pair of details are put on the wheels of one axis. This design allows you to refuse from axial (inter-track) differential. At the same time, the use of a pair of Vicility allows you to provide all modes - both differential rotation and locking wheels of the axis.

Pros and cons of the wicious drive.

Like any device, vz in all-wheel drive cars Have merits and disadvantages.

Advantages:

- Automatic connection of a full drive or mutual blocking of axis wheels, which significantly increases the permeability and safety of motion on complex coatings;

- Simplicity of technical solution and, accordingly, its cheapness and reliability - manufacturers, most often perform devices maintained, counting on the service life equal to the life of the car.

In practice, Mileage is 90-100 thousand km (in heavy conditions And less) becomes the limit due to the loss of liquid of its properties and faults in other car systems. With this mileage, it is recommended to replace the device.

Disadvantages:

- The delay and nonlinearity of the operation do not allow absolute control over the full drive;

- In most cases, on vehicles equipped with vessels, manual inclusion / shutdown of the second leading axis is not provided;

- Limited sizes make limit on the transmission of torque, as well as opportunities long work in a loaded condition (overheating and failure is possible);

- Joint work vz and electronic systems Type ABS, ESP and similar difficult, as they solve opposite tasks.

Viscounts in cooling systems.

In the cooling systems for controlling the fan, this is also used. It decides one of the important tasks - connecting the unit only in the case of engine warming up.

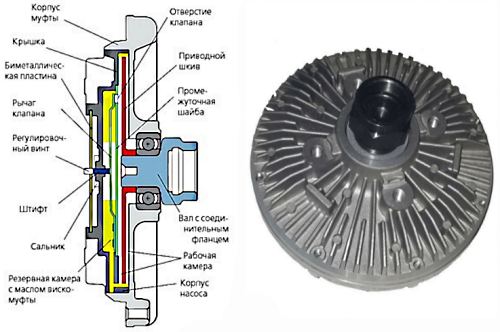

The design includes:

- The housing is rigidly connected to the fan;

- Disk with impeller (fin) associated with the shaft of the water pump;

- Reserve capacity;

- Valves for overflow substances and bimetallic plate or other temperature-dependent node for valve management.

How does the cooling fan (W) work?

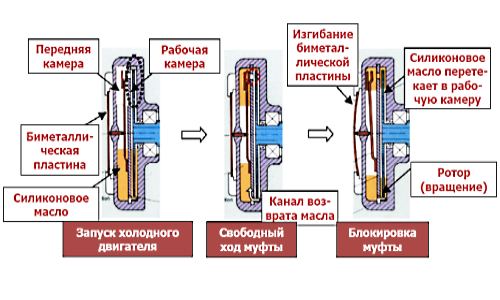

While the engine does not warm, the thermostat directs the flow of coolant for a small circle. In this mode, the substance in the Viscounts is squeezed with a rotating disk to a backup capacity. There is no gearing between the disk and the housing, the fan does not rotate.

The flow of coolant into the radiator causes the deformation of the bimetallic plate, the triggering of the valves and the accumulation of the liquid of the viscous clutch is not in the backup capacity, but in the space between the disk and the case. Due to the viscosity, the unit is blocked, which transmits power from the shaft. The fan comes in rotation, directing the air flow to the radiator, providing a decrease in the temperature of the coolant.

When cooled it up to the level of the threshold of the temperature-dependent node, paths for overflow of a liquid are opened, a viscous friction force between the disk and the body decreases, the fan stops.

Viscounts check.

Any suspicions of emergency work details require immediate check, since its malfunction can lead to serious breakdowns of the main systems.

How to check in transmissions?

The most accurate results gives checking removed from dispensing box Viscounts.

For this, enough:

- Remove the item;

- Turn the differential gear with a key with a dynamometer (or measure the force with a spring dynamometer).

The effort should not exceed the limits set by the manufacturer (you can find in technical writings on the device and reference books).

You can check the item and without removing it. This follows:

- post the wheel of the slave axis;

- try to turn it out by measuring with a dynamometer;

- moment Calculate on the well-known wheel diameter

If the resulting value does not exceed the limits specified by the manufacturer - the part is working. If the wheel could not be checked at all - the device must be urgently changed.

Video manual.

How to check the Viscuft in?

The test of the viscous clutch is not difficult:

- Start the engine "on the cold";

- After 30-60, the fan noise will decrease - it will switch to idle mode (at this point it can be stopped by any obstacle, for example, a rolled newspaper, but it does not recommend this safety);

- After some time, when driving the engine (monitored by temperature sensor), the viscous clutch will increase the speed of the aggregate;

- In this case, there must be a unambiguous reaction to an increase in engine speed - the engine rotates faster - fan rotates faster.

You can check the device in motion (more precisely, in the parking lot among the day). With increasing temperature on idling - Unambiguously we can talk about problems with viscous clutch.

Video (one of the methods of verification).

Viscosity clutch fan Nemphable part of the cooling system of any modern engine. For liquid cooling It sends the air through the radiator, and with air-serves this same air (here it acts as a coolant) to the heated parts of the engine. And we can say, from the moment the fans appear the engineers decide how to make it optimal drive. We will get acquainted with some results from efforts.

The simplest design of the fan drive is well known - a wedge strap from pulley installed on the sock crankshaft. But simple does not always mean the best. The fan works constantly, which means that it is constantly noise, consumes power, and considerable (3-6% of the engine power), and, most importantly, cools the engine regardless of its temperature mode. It is a large power consumption that prompted to abandon the belt drive in favor of gears on heavy engines. So that the drive does not experience large loads with a sharp change of motor operation modes (do not forget - the fan is also a kind of flywheel and the moment of inertia is not small), they set friction, hydraulic or elastic rubber couplings (Fig. 1).

Fig. 1. Fan drive with elastic coupling: 1 - fan; 2 - elastic coupling; 3 - pulley; 4 - fan drive gear.

Now about how to make the fan work in such a way to do not cool cold Engine, and intensively work when the motor is hot. One of the very first and simple regulatory systems was ... Replacing the fan. In the hot season of the year, the impeller was used for greater performance, the winter is smaller. Of course, the regulation was carried out very roughly - it is hardly possible to imagine a driver choosing fans in accordance with the weather forecast and changing them almost daily.

Such a system does not solve another important problem. It is clear that the design of the fan and its drive must provide sufficient cooling starting from the most low speed crankshaft. On the large turns with a tight mechanical connection, this will lead to a huge overflow of energy: say, for the machine of the middle class, such a fan on maximum turns "I eaten" about 8 kW of engine power, while sufficient in such conditions - does not exceed 3-3.5 kW. This is the reason that tough mechanical transmission Nowadays it is almost no applied.

As is known, devices transmitting and transforming torque are called transmissions, it means that the fan drive is also a transmission. Interestingly, many designs designed to solve the above problem of this drive have a certain similarity with a "large" vehicle transmission transmitting torque on its wheels. Here we can find both clutch, and hydromefta, and viscous coupling (viscous coupling, we will remind, now often use instead of the mid-sieve differential), and electric drive. Consider the most common of these systems.

Electromagnetic clutch (Fig. 2) automatically turns on the fan by reaching a certain temperature of the coolant.

Fig. 2. Electromagnetic inclusion coupling

Fan: 1 - pulley; 2 - contact ring; 3 - coal brush; 4 - Steel Ring; 5 - flat spring; 6 - fan; 7 - electromagnet.

Such a system was used on GAZ-24 Early Series and many contemporary foreign ones. In this system, a powerful ring solenoid was placed on the pulley. When the sensor is triggered, the solenoid chain is closed and the metal ring associated with the fan via plate springs is enjoyed to the pulley: the fan is turned on and operates until the temperature decreases and the control sensor does not remove power from the electromagnet. Similar principle is also implemented in cars with cross-location of the engine: the temperature sensor includes a fan electric motor.

Recently, two-speed electric motors have appeared, allowing to provide step regulation: the fan is disabled, works in partial mode or for full performance. There are cars and with two fans that are entered into operation sequentially. Along the way, we note that electrical fuel agents are rare on heavy freight cars and buses. Imagine the power of electrical equipment (generator, battery), which will be required to provide the necessary 10-12 kW fan. That is why it still reigns "clean" mechanics.

Popular buses "Ikarus" put friction clutch With a pneumatic reception - a kind of clutch, only a leg no leg is pressed on the conditional pedal here, but compressed air. Regulation of switching on-shutdown is carried out, naturally, depending on the temperature of the coolant.

The most complex systems can smoothly adjust the fan speed. On many passenger cars (As an example, we call most BMW, "Mercedes"), as well as on some trucks (including on domestic ZIL-4331), the fan drive is built into the Viscounts (Fig. 3).

Fig. 3. Viscounts of the fan: 1 - camera cover;

2 - petal valve; 3 - bimetallic thermostat; 4 - Coupling cover; 5 - coupling case; 6 - leading disk; A - reserve cavity.

Briefly introduce the work of such a device. As long as the motor warmed up, the working cavity of the coupling is empty - a special silicone fluid is in the reserve cavity. The engine warms, the thermoelastic plate is gradually opening the valve, the liquid enters the working cavity, and when it slips between the discs, its viscosity grows - the coupling starts to transmit the moment. With increasing temperature, the working cavity is filled with more and more, the fan turns increase. This is so smoothly adjustable fan performance. The Viscounts are designed so that on small speeds, its slipping is small, and at high - the fan is noticeably lagging behind. This, we repeat, allows you to noticeably save energy (and therefore fuel) at high speed when blowing the radiator is sufficient.

On heavy diesel engines For stepless regulation of revolutions in the actuator mechanics, a hydraulic coupling is often used (Fig. 4), similar to the one that works in automatic boxes Transmissions. The fan turns change here depending on the filling of the cavity between the leading and driven clutch wheels. The amount of oil that comes from the engine lubrication system is automatically adjusted by the coolant temperature.

Fig. 4. Fan drive hydraulicule: 1 - pulley; 2 - fan hub; 3 - leading wheel hydromeflues; 4 - Slave wheel hydromeflip; 5 - oil supply tubes into working cavity; 6 - presenter; A - working cavity.

Hydromefta is used on some air cooling engines, for example, for a long time, the diesel engines of the "Doyz", which were in the Magirus trucks. The coolant in the "air-term", understandable thing, no, and the oil supply in the coupling controls the thermostat, which takes into account the air temperature at the outlet of the cooling system and temperature exhaust gases. The operation of the system depends on the oil temperature: with increasing its viscosity of the latter decreases, which means that hot (and liquid) oil into the working caulter is income more. An interesting feature: the coupling housing simultaneously serves as a centrifuge for oil purification.

Completing the conversation about the actuator drives, we note: no matter how far many of these devices are perfect, they are still not able to save the engine of internal combustion from one of its serious disadvantages - up to 30% of the fuel energy, "leaving" into the cooling system are lost irretrievably.

Igor Soldunov "Driving" 1997-98

Owners of the UAZ SUV patriot know about such a problem vehicleWhen the engine is heated in hot weather and reaches 100 degrees Celsius. This, of course, an unpleasant sight, which is observed mainly in hot summer days, when the temperature overboard is +30 degrees and above. The reasons for the heating of the engine of the UAZ Patriot SUV is known - the fan does not cope with its properties. In this article, we will look at why the fan that is designed to cool the radiator of the engine of the UAZ SUV patriot does not cope with its functions, and will carry out insignificant repairs to eliminate this problem.

Let's start with the fact that the Ulyanovsky Automobile Engineer is equipped with SUVs UAZ Patriot fans for cooling radiator, which are powered by the Viscounts.

The Viscouft is a mechanism presented in the form of two flat disks. Viscounts allows you to transmit torque through special fluid Based on silicone.

The principle of operation lies in several plates struck on the slave and leading shafts. They rotate in a container with a liquid that changes its properties when heated. When the fluid is mixed when the drive shaft is rotated, it changes its properties (expands) and thereby creates pressure in the chamber. As a result, the disks of the slave shaft occurs, leading it in motion.

Such an ussociation and is a fan drive on the UAZ Patriot SUV. All of nothing, if it were not for such a minus, which gives impetus to the search for its elimination. This minus is that the viscosity of the fluid depends on the mixing rate. During the braking of the car UAZ Patriot and the engine work on idling The liquid loses its properties as a result of slowing the rotation of the drive shaft. This leads to the fact that the cooling fan slows down its rotational speed, and the temperature in the engine is gradually growing. Such a phenomenon is found when it falls in the summer heat stand in a traffic jam or move around rough terrain at low speed. Viscouft although it is an innovation, but its use on SUV UAZ Patriot is unsuccessful. To eliminate the engine overheating problem, we will consider below, but for now we will list the cons of use of the Viscounts.

Scattered blades of imperts

Cons Viscounts

By minuses of use, the Viscounts on the SUV of UAZ Patriot include the following factors:

- Instability of the engine temperature, which varies depending on the rotation of the crankshaft.

- Difficult access to rollers and belts.

- There is no possibility of enforcing the engine cooling fan.

- Fan rotation frequency. Possible separation of the blades of the fan, which is fraught with the breaking of the radiator. As a result, it becomes necessary to replace the radiator and installing a new fan.

There is no possibility to repair it. If the product does not function, then the repair is already inappropriate, and it is required to replace it with a new one.

Theoretically, the repair of the product is impossible to carry out, but it is practically possible. For this purpose, two holes are drilled in the opening, through which the bolts are tracked and fixed to the drive disc. This repair allows the fan to rotate regardless of changing the viscosity of the fluid.

To get rid of this problem, it is necessary to install an electric fan instead of the Viscuft. Such a system is much more reliable, more efficient, and, most importantly, rational. The advantages of such a system, consider further.

Electroventant instead of Viscounts: Advantages

The advantages of the installation of the electric fan instead of the Viscounts are:

- Maintain a constant engine temperature.

- When stopping the car and work at idle does not heat the motor.

- Disposable access to the belt and rollers, which simplifies their replacement.

- The ability to manually turn on the engine cooling electric fan.

- In addition, if one fan does not cope or it fails, then in this case two units are set, which compensate for each other's work if necessary.

So, we found out that instead of the SUV engine cooling, the engine is rationally install the electric fan. To do this, it is necessary to extract the Viscuft from the UAZ Patriot SUV.

Removal of the Viscounts

The removal of the Viscouft does not constitute special difficulties and is performed with their own hands in the presence of required tool. But still you need to know the process of removing the product and some important moments. So, the removal of the product is carried out in the following order:

The removal of the Viscouft is much simpler, as it is necessary to unscrew the four fastening bolts around the perimeter of the product and remove them. After that, you can remove the viscous coupling and proceed to the next stage of the work.

Installation

Installation or replacement of the Union of Electrical fans is carried out at home. To begin with, it will be necessary to find a frame with electric fan, which are suitable for installation under the radiator of the cooling radiator of the UAZ Patriot. There are several options, and every driver chooses the one that will like more, or the one that can get.

Therefore, as a foundation, you can take a Toyota car electric fan. The video below shows full information About the design of construction.

So, for this you need to perform the following steps:

- Remove the terminal "Minus" with battery.

- It is necessary to remove the radiator casing.

- Place the electric fan before the cooling radiator.

- Fixing the design is carried out in regular holes.

- Laying of feed wires of products is carried out. The video shows their placement.

- The cable connects to the car control system through the thermostat.

- It will be necessary to replace the thermostat for a new one and do not forget about the new seal.

- In conclusion, the casing is put on the radiator, and proceed to check the system.

We start the engine and check how the system heats up. When the sensor has a mark of 90 degrees, then the first electric fan must work. Previously, it is necessary to set the first and second product of the response. The second should be triggered at a temperature of 93-95 degrees.

On this replacement, the viscous coupling on the radiator cooling electric agent is complete.

Appointment of casing

The casing of the Viscuft on SUVs UAZ patriot of different years of release has different designs. Some installed steel and massive casing, which becomes a real obstacle to access the belt and rollers. Later models in the design have plastic casing. The main purpose of this element is to protect the parts of the engine from the possible separation of the blades. Therefore, the casing must be present both on the fans with the Viscounts and electrical devices.

This should be summarized and noted that after an electric fan was installed, cardinal changes were observed. In particular, now the engine works when permanent temperaturethat extends the life of its components of the details.

How often does your patriot break?

In the engine engines UAZ installed standard water cooling. The whole design has a small and large outline. The large contour system consists of water shirt, heater radiators and cooling, thermostat; The system of the small contour is from the total listed, except for the cooling radiator. These contours are separated by a thermostat, depending on the temperature of the coolant by opening or overlapping the radiator.

Although the cooling system of UAZ cars and is considered to be classic, it still has its own features in it. Before the radiator of the UAZ engine, special blinds are installed, adjusting air flow. There is a lever with which you can control the shutters, thereby changing the engine temperature.

The following fan drives are installed on UAZ cars:

- constant;

- through hydromeflua;

- through the electromagnetic coupling.

Permanent drive engines are no longer equipped, but they can be seen in some old models, for example, UAZ-469B. Permanent drive by the end of the 20th century began to be replaced by hydromefta. Some engines are equipped electromagnetic clutchBut it is not yet so popular. Another solution is to use the fan electrical drive, but it is already the revision of the car operators outside the production of UAZ.

Purpose and role Hydromefta UAZ

Represents pretty simple but effective solutionthat makes it possible to simplify the mechanism of driving the UAZ car fan. This is a single block of compact sizes, for which you do not need to connect. electric current or connections with other engine parts and parts. It turns out that his work is completely autonomous.

The main and only function of the car hydrauliculeuft is adjusting the speed of rotation of the fan impeller, depending on the temperature of the engine. The principle of operation is very simple: if the temperature of the motor increases, then the torque on the impeller increases to reduce the temperature, and vice versa. Another feature of the hydromefta UAZ is its smooth operation. This means that the change of modes occurs steplessly.

Hydromefta is best suited for high-pass vehicles, such as UAZ. It has many advantages: for example, automatic hydromefta makes practically no manual blinds, which were described above. But cars UAZ with permanent drive Require the use of blinds in difficult conditions. In addition, when driving on the water, you do not need to turn off the fan. When the car is immersed in water, then the hydromefta is cooled and the fan turns off as unrequisite. It ceases to work also in cases of greater driving resistance, and in direct or electrical drive engines, it can lead to belt wear. The use of hydromefta significantly simplifies the fan mechanism itself, it even reduces fuel consumption and the noise of the fan, which is especially noticeable at idle.

Maintenance Hydromefta UAZ

No special maintenance Hydromuft is not necessary, in most cases it can be operated without any particular problems until full resource generation. But that the quality of work does not suffer, it is necessary to clean its surface from time to time, namely, remove pollution and droplets of oil. The contaminated mechanism will turn on / off earlier / later, which will affect the engine temperature.

Sometimes it happens that the hydromule does not work without visible reasons. To repair it, you need:

- Remove the hydromule and its impeller;

- After unscrewing the stuffing of the fastening pour liquid;

- Rinse the internal mechanism of the coupling, the bay of gasoline there;

- Pour gasoline and dry it;

- Pour the composition of the PMS-10000;

- Install the hydromefluette back.

If after these operations of the hydromefta does not work, it is easier to purchase a new one, because its value is not so high. Many UAZ car owners complain to the work of the hydromefet. But it often happens only because of her incorrect operation and untimely cleaning. Some even change it on an electrical drive, which is a big mistake. Also, the firm of the coupling is of great importance, because domestic and foreign samples differ in terms of work, and in cost.

Each car owner should thoroughly know the design of his car. Perhaps most people only abstractly understand what the Vussft is, and the ways to repair it. This tool is greater importance for the car, so it is important to understand its technology.

Principle of operation of the device

It was invented in the United States in 1917 by an engineer Melvin North. This product did not immediately find their application, so for a long time was not recognized. In 1964, the Viscuft was installed in the Interceptor FF car, where it served as an automatic blocker for differential. Only in 1965 this mechanism took his place.

The Viscouft is a device that is responsible for rotating a special fan, which cools the system due to the special fluid. It has the form of a circular mechanism made of silicone base and filled with a lubricant. The Viscuft provides smooth fan adjustment.

Flat discs are located inside the body. Some of them are connected to the leading shaft, and others with the slave. There are various protrusions and holes on their surface. Features of the design have these items in close proximity to each other. Silicone fluid, located inside, has the property to thicken with strong stirring. It also expands when heated, so it creates big Pressure On the discs when operating the engine and compresses them together.

Features of the mechanism

At first glance, the principle of operation Viskorsfit fan cooling seems difficult, but it is not. Movable is driven into rotation and transfers its energy clutch. From this, its silicone base becomes softer and viscous. The coupling begins to blocked, which is due to the rotation of the second disk with the fan.

In almost every engine there is a Viscounts. This is due to the importance of its functions and the quality of the device, because it is at a sufficiently high level. In the Viscounts, the safety mechanism is perfectly implemented: when a person on his own carelessness shoves his hand to a moving element, he will stop to prevent injury.

Checking the cooling fan

It is not always possible to regularly use the car, so it turns out to be in idle state. Viscouft at this time requires checking its performance. It will help prevent breakdown from wear.

It is not easy in regular conditions, but there are methods how to check the fan viscous coupling. To inspect the mechanism, you need to check the condition of the turnover of the product when the heated and cold engine is enabled. With a cooled motor, no extraneous sounds should not occur, and the turns must match the norm. The hot engine can often provoke various noises and failures in the frequency of revolutions.

Such problems may arise due to faults in bearings or undime replacement Oil. Also, the sealing glands and the leakage of silicone fluid can cause breakage.

Solving the problem with your own hands

If defects were found in the work, the viscous fees should not be conducted. These problems can often be solved with their own hands. One of the most frequent problems arising in this device is the leakage of silicone fluid. To fill the lack, you need to perform the following actions:

- Disassemble VcKamuft by removing it from the water pump.

- It is necessary to look at the product disk. On its surface there is a special plate with a spring under which there is a silicone hole. It is necessary to remove the pin with extreme caution and pour into the lubricant with a special syringe. During this process, the part itself should be put in a horizontal position.

- It will be enough to fill in a syringe of 15 milliliters of fluid.

- It is necessary to wait a few minutes until the substance checks the viscous coupling inside without removing the syringe.

- After checking the correctness of the procedure performed and there is no silicone surplus, the item can be installed back.

Those who do not consider themselves experienced motorist, it is better not to engage in such works, because it can cause complete breakdown of the device. As a rule, the greatest difficulty is back assembly All elements.

Other problems

Often the bearings can cause the failure of the Union. This is evidenced by the emergence of unusual noise in the cooling zone. But it can also be repaired independently:

- To fix the product, it needs to be removed from the main engine design. For this, 3 bolts are unscrewed on which bearings are attached.

- Replacing these elements should be carried out only after it was merged oil fluid And disassembled a node. To simplify the process, you can use special tool - Demand. It is not necessary to use fir-handed appliances, as they can finally damage the details.

- After installing the bearing can be carried out in the mechanisms of the motor. Before that, you need to pour fresh silicone, which was merged before replacing parts.

Note: Not always the wrong behavior of parts requires their ambulance. Often you can do and simple repairwhich does not require special skills.

A frequent problem when checking the Viscuft or replacing bearing is to search for a suitable tool. Such a removator is not always easy to find in the car shop, so the repair can be difficult.

Features of repair work

As some motorists could notice, not always on the Viscounts there is a hole for filling the silicone fluid. In this case, it is done independently, but you should not make it novice to not harm the product. It is better to refer to the masters that make a neat drilling.

Repair of the Viskors Fan should be carried out without a thoughts underworse. The main material of the device is aluminum, which is easy enough to bend and finally deal with the Viscuft.

The work of the car depends on many mechanisms that should work as a whole. At the failure of at least one element, the serviceability of the entire vehicle is disturbed. Viscounts are necessary for normal work Cooling fan. This depends on the safety of the trip, so you need to monitor its performance.

Repair of the cooling fan uniform should be carried out only by specialists. Of course, you can do it yourself, but any error can derive a device. You need to take care of the service work in advance.

The best prices and conditions for the purchase of new cars

Credit 4.5% / installments / Trade-in / 95% approval / salon giftsMas Motors