› How tire pressure sensors work

The first tire patent was obtained in 1846, and since then the wheels are constantly punctured. It is clear to anyone that a flat tire does not bode well. And the drop in pressure can be very dangerous: it is not for nothing that in the section "Daily maintenance" of the vehicle operating instructions, the item "Checking tire pressure" is one of the first.

When the tire gives off its breath, rolling resistance is greatly increased. Where does this lead? To an increase in fuel consumption, increased tire wear and, of course, to side drift of the vehicle. Moreover, such a slight sideways shift can be attributed to the slope of the road or track. So the driver, by mistake or inexperience, can keep driving for a long time. And the most dangerous thing about this is that when emergency situation, for example, during a sharp maneuver or braking, a lowered tire may break off the disc or turn over. And here it is not far from the accident.

Therefore, this outrage must be fought with all forces. The sooner the driver notices the loss of pressure, the better. Of course, the easiest way is to check the pressure before driving by connecting a pump or a pressure gauge to each wheel in turn. But you and I are lazy and forgetful people. And the pleasure of poking around in the cold or in the rain with some kind of devices is not great. Moreover, there is already a whole heap of systems that can check this very pressure.

The caps made in China indicate a drop in pressure by changing color. The information content is good, the accuracy is questionable.

The simplest of them is special caps with color indicators, which are installed instead of the standard ones on the pump valves. The pressure has dropped below, say, two atmospheres - a warning yellow (orange, purple) strip will appear under the transparent lid of such a miraculous cap. Yeah, of course, there is something wrong with the wheel, we need to check. The pressure dropped even lower - the cap will “turn into” another, usually red color, which will indicate the criticality of what is happening. The advantage of this approach is simplicity. Minus - not good enough information content. After all, the caps can only be seen during a stop. And still, going around the car before driving, looking at the cap colors, is much easier than measuring the pressure every time.

Another drawback is that the caps begin to inform about a change in pressure only when it falls below some certain values, which, by the way, for your car and your wheels may be quite normal. This means that you need to select them specifically for your car.

Radio sensors of many electronic monitoring systems are mounted on a disk using special clamps.

And in order to notice something was wrong while driving, it would be nice to have an electronic system on board that would automatically notify you of dangerous drops in pressure. And she would not just notify, but would do it on time (so that there was time to orient herself) and without false positives.

In this case, the installed control system will warn the driver at the right time about a change in the corresponding parameter and give him enough time to safely stop the car. It is clear that in cases of a serious puncture or explosion of a tire, such systems will not help, since the driver will feel the car being pulled away without any sensors. But with a "slow" puncture, such electronics are simply irreplaceable.

There are, for example, systems that transmit data on the pressure and temperature of the tires to the central unit using radio communication. And there are those that can transmit this data via Bluetooth communication to phones or communicators. And that is very convenient.

X-Pressure pressure monitoring system developed by Pirelli. In its simplest version, Optic, it consists of four caps that are installed on the standard valves. And they signal a drop in pressure by a color change.

But there are more cunning systems that work without "real" pressure sensors, but through ABS. It is they who are usually placed in standard equipment cars. How do they work?

The electronics using sensors at each moment of time determines the wheel speed and their relative difference. As you know, when the pressure drops, the tire profile height becomes lower. Consequently, the speed of rotation of the wheel with the "sick" tire increases, therefore, the difference in the rotation frequencies of the wheels on the same axle also increases. As a result, the system fixes these changes - and gives an alarm signal.

X-Pressure System by Acoustic. The caps have built-in sensors that register the pressure, and radio transmitters that provide communication with the central unit. As soon as the pressure has dropped, a corresponding indication appears on the display of this unit and a warning sound signal... The batteries in the caps last for about 5 thousand hours of operation, which corresponds to five years of operation. Replacement of the batteries in the caps is not provided, therefore, at the end of the service life, the kit must be completely replaced.

Why is such an indirect method of determining tire pressure bad? Such systems can be triggered, for example, in long bends, when over a relatively long time the system fixes a large difference in the rotational speeds of the wheels of different sides (after all, the outer wheels rotate with more speedrather than internal). And these are still flowers.

One of the most sophisticated X-Pressure options - AcousticBlue is able to transmit pressure data via the Bluetooth port to mobile phone... Such a thing costs from 160 euros.

In some cases, such systems are useless at all. For example, when the vehicle is fitted with run-flat tires. Recall that tires with this technology even with a complete loss of pressure, the profile height decreases slightly - by about 30-40%. There is no pressure in the tire, and the reinforced sidewalls continue to "hold", and not just hold, but allow you to continue driving at a very decent speed for quite a long time.

Many cars themselves warn their owner about a drop in tire pressure.

And yet, this system can be very helpful, especially on a long journey, timely warning that there are problems with the wheels. But you shouldn't rely on "helpers" completely. Therefore, instead of a conclusion, we will write only two, no, three words. Watch out for the pressure, comrades! At least once a week, and if you notice that the wheel is lowered, do not be lazy, pump up.

Tire pressure monitoring is important both in terms of fuel economy and long term service, and from the position of ensuring safety when moving. Modern devices such as different kinds pressure sensors provide convenient and effective control over the tire inflation rate. Working on the principle of visual and sound notification in case of deviations from the norm, these devices make it easier to control the vehicle.

Pressure sensors with a monitor are one of the most convenient solutions. Photo: fis.ru

Why are pressure sensors needed

The deviation of tire pressure has a lot of negative consequences, both with an increase and a decrease from the nominal values \u200b\u200bof this value. Pumping up to 2 atm is considered optimal.

If there are deviations from the norm downward:

- If the indicator changes downwards, the possible consequences are an increase in fuel consumption, which can be up to 1.5 liters per 100 km with a pressure decrease of 0.5 atm.

- With insufficiently inflated wheels, contact with the roadway occurs along the line of the side surfaces, as a result of which their wear is accelerated.

Upward:

- If the tires are over-inflated, the contact area between the wheel and the road changes. This is due to the fact that due to the shape of its surface, the adhesion of the central part increases with insufficient contact with the side surfaces. This leads to accelerated wear of these areas.

- A tire with an increased pressure reduces the life of the body and suspension, as it has a low ability to cushion the shock transmitted by the wheel. In addition to a less comfortable ride, the heating of the tire, which occurs in this case, can provoke an explosion of the tube.

Tire inflation indicators make it easy to maintain the tire inflation rate within optimal performance limits.

How the tire pressure sensor works

Changing the degree of inflation of the wheels, depending on the type of installed indicator, either changes the color of the built-in cap, or transmit an electronic signal to the monitor of the tracking system when using radio sensors. Photo: kazan.compax.ru

Capsequipped with color indicators that change color depending on the degree of tire inflation from normal (green) to critical (red). Inside the cap, mounted on the wheel nipple, contains a piston, the indicator of which changes color depending on the pressure level. The principle of operation of the tire pressure sensor is that when it decreases by 0.3 atm at a nominal value of 2 atm, the color changes to yellow, and when it falls by another 0.4 atm, the color of the sensor acquires a red tint.

Cap manufacturers offer a wide range of transducers with nominal pressures ranging from 1.8-3.6 atm, which allows them to be used on different types mobile devices.

Among the advantages of such indicators:

- ease of installation, in which it is not necessary to balance tires and disassemble the wheel to install structures of low weight (5g);

- ease of replacement of indicators that have exhausted their resource.

Disadvantages of cap sensors:

- low degree of protection against thieves;

- lack of control of the degree of tire inflation during the movement;

- low susceptibility of the system to pressure fluctuations.

A variety of cap-type sensors is known, which are driven by a miniature battery. The disadvantages of this design, in addition to the disadvantages listed above, include the low tightness of the system, since the installation and operation of such a system provide for the open position of the nipple. The advantages include higher measurement accuracy due to the use of an electronic signal instead of mechanical piston pulses.

Among motorists good reviews indicators of the degree of inflation of tires are used, using an autonomous battery as a drive, while pulses are transmitted from the receiving device to the tracking systems by means of radio signals.

The set includes one sensor for each wheel, a temperature control system, an information receiving system and a block for reading signals coming from it. Photo: data.jc9.ru

The indicators are recorded at intervals of once every quarter of an hour during parking or once every 5 minutes when the car is moving. Such systems require an installation in which the sensor is mounted under the surface of the nipple after the wheel has been disassembled. In addition, such systems are subject to mandatory balancing taking into account the weight (30g) of the installed indicator. The complexity of the installation is one of the negative properties of such a system.

The design provides many advantages, including:

- High tightness ensured by nipple closure and retention with a cap.

- Accuracy that provides low time readings while detecting rapid changes in tire inflation.

Theft protection

An even more complex design in comparison with the one described above is a tire pressure monitoring sensor made in the form of a microchip. This system contains the entire database of the optimal values \u200b\u200bof speed, pressure and temperature; type of device; its dimensions and release date. The disadvantage of the design is the impossibility of installation outside the manufacturer. In addition, the accuracy of the indicators can be affected by the driving mode, the presence of obstacles on the road, and uneven surface relief. The signal from the microchip built into the bus structure can go both to the tracking devices in the car, for example, a monitor, and to the driver's mobile phone or gadget.

You can learn about other features of tire pressure sensors from this video:

Possible malfunctions

The operation of any of the described devices includes the possibility of breakdowns, some of which can be eliminated during service at a service station. Among the main malfunctions of pressure control sensors:

- In the event of a malfunction, the device is re-flashed to coordinate the operation of the indicators on different wheels. This operation can be performed by a driver who has the skills to install software on a car or a specialist from a service station.

- Mismatch in the operation of monitoring devices, which with a high probability can occur when replacing or restoring a punctured tire. In this case, their readings may be overestimated, the repair consists in zeroing the reader.

- Mechanical damage associated with the failure of the nipple or other structural elements systems are eliminated by contacting a specialized service center.

- One of the faults is an error electronic system TPMS. To eliminate the error message, you can use a method such as turning off the tire pressure sensor or turning off the warning light. This can be done by physically deactivating the tire pressure monitoring system or by removing the indicator light from dashboard car.

The most common flaw automatic systems is the battery discharge on the indicator drive device. In this case, after the expiration of the service life, which, depending on climatic conditions is up to 5 years, the battery must be changed.

To replace the battery in the tire pressure sensor, proceed as follows:

- dismantle the indicator, after which in the area with a rounded surface it is necessary to make cuts along the contour of the element;

- there is a battery under the filling, soldered to the contacts using micro-welding, you can check its serviceability using a tester, the discharge phase is characterized by zero readings of the device;

- replace the battery, ensuring a tight fit of the battery to the contacts, for which it is necessary to fix the device, using a needle to deepen the indicator body into the filling;

- degrease the surface above the battery and fill with silicone filler to the level of the body.

Outcome

A variety of designs for pressure control provides wide variability in the choice of price-performance ratio acceptable to the driver. Some manufacturers practice the production of tires in which the pressure is controlled by the deviation from the norm of the contact area of \u200b\u200bthe tire with the ground. In any case, the use of these devices will not only greatly facilitate operation vehicle, but will also make the movement on it safer.

Such systems can be using sensors and a radio signal, to determine the change in the radius of the wheels, etc.

using a special control device (Easy Control caps). The simplest and cheapest way to constantly monitor the pressure in is to install a special control device on the wheel instead of the standard nipple cap. For example, the use of Easy Control caps from the Belgian company Environix allows you to quickly find out if the pressure in the wheel has dropped: just look at the cap color. If it remains green, then the pressure is normal, it turns yellow - a more accurate check is needed, and if it turns red, then the tires need to be pumped up urgently.using radio signal consists of air pressure sensors screwed onto metal bodies of valves, from which a radio signal is transmitted to the receiving system, transmitters usually installed in the wheel arches, an electronic control unit. The receiving antenna for the pressure monitoring system is located in the roof. Some manufacturers install antennas in the wheel arches instead of transmitters.Figure: Easy Control caps for monitoring tire pressure.

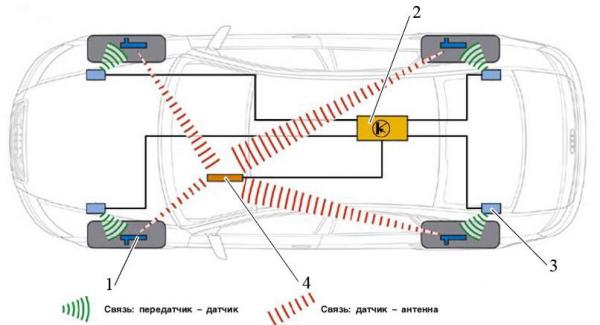

Figure: Tire pressure monitoring system:

1 - tire pressure sensor; 2 - the electronic unit tire pressure control; 3 - transmitters of the tire pressure monitoring system; 4 - receiving system for monitoring tire pressure

Figure: Tire pressure sensor:

1 - transmitting antenna; 2 - sensitive elements of sensors and temperature; 3 - electronic elements of measurement and control; 4 - battery

The pressure sensor measures the current (absolute) tire pressure. Sensitive elements of pressure and temperature sensors, as well as electronic measurement and control elements are combined in a common housing.

Pressure sensors can be reused when changing tires or.

A chip can be installed inside the wheel, in the memory of which all data about the tire are stored - its type, dimension, permissible load, recommended pressure, maximum speed, date of manufacture.

Figure: Bus with installed chip:

1 - valve; 2 - wheel rim; 3 - chip; 4 - bus

How the tire pressure monitoring system works

Tire pressure monitoring is carried out continuously both when the vehicle is moving and when it is stopped. Opening the driver's door or turning on the ignition switch starts the system initialization process. In this case, the control unit assigns a special address to each tire pressure monitoring system transmitter and the receiving antenna with a small time difference. At the end of the initialization, each transmitter successively receives a message from the control unit. Then the transmitter with the assigned address sends a single radio signal with a frequency of 125 kHz. Due to its small transmission radius, this radio signal can only be received by a suitable tire pressure monitoring system sensor. The sensor transmits the current measured values \u200b\u200bof pressure and temperature upon signal command. The antenna receives this signal and transmits it to the control unit via the LIN bus. After that, communication is terminated until the moment the vehicle starts moving. The temperature signal is used to correct the pressure value associated with changes in the air temperature in the tire, as well as a diagnosed parameter. The temperature correction is carried out by the tire pressure monitor control unit. The measured pressure values \u200b\u200bare then adjusted to a temperature of 20 ° C.

To detect movement, the sensors in the tire pressure monitoring system are equipped with centrifugal sensors to detect wheel rotation. When the movement starts, the sensors are bound to the wheel position within 2 minutes. Upon reaching a speed of 20 km / h and above, each sensor automatically and without a signal from the corresponding transmitter transmits the measured values. The sent radio signal contains information about the corresponding sensor. This allows the control unit to distinguish between the individual sensors and their location in the vehicle. In normal operation, each transmitter sends a signal every 30 seconds.

If the sensor detects a rapid change in pressure (\u003e 0.2 kgf / cm2), it automatically switches to the rapid measurement and data transmission mode and transmits the current measured values \u200b\u200bevery second.

Control and display of the tire pressure monitoring system

The system is controlled via the multimedia interface and is shown on a dedicated display in the driver information system.

The system can recognize the following conditions of air pressure in tires: a slow drop in pressure, about which the driver is informed in advance about the need to inflate the tire; a sharp drop in pressure, which is reported to the driver when the car is moving; excessive pressure drop during parking, which is reported to the driver immediately after turning on the ignition.

If the tire pressure has changed, for example, in the event of inflation, or in the case of rearrangement of wheels, it is necessary to enter the parameters of the nominal pressure.

Figure: Indication of indicators of air pressure and temperature in tires

If the pressure in the tires decreases by more than 0.5 kgf / cm2 (bar), the information on the display will light up, highlighted in red. When the pressure drops by 0.3 kgf / cm2, the information is highlighted in yellow.

Information about a decrease in pressure can be signaled by a warning lamp in the instrument cluster and by a single acoustic signal every time the ignition is switched on.

The principle of operation of the tire pressure monitoring system to determine the change in the radius of the wheels is as follows.

If air comes out of the tire, the distance covered by the tire in one revolution becomes less. Because of this, a tire with a reduced pressure will have to rotate more than a tire with normal pressure to travel a certain distance. The engine speed is recorded by a sensor and evaluated by the ESP control unit. This allows the control unit to recognize a decrease in tire pressure. The disadvantage of such a system is that under certain driving conditions, for example, when cornering quickly, driving on a bad road, starting and braking, the assessment of the measured pressure values \u200b\u200bis inaccurate.

Tire pressure sensors were originally installed on some vehicles, as additional option... The whole tire pressure monitoring system is called TPMS - Tires Pressure Monitoring System, and its purpose is to warn the driver about a critical change in air pressure in the wheels, and directly while the car is moving.

Now the car owner can independently equip the car with such a system.

How the tire pressure sensor works

The principle of operation of tire pressure sensors is to measure this very pressure and transmit a signal to a monitor or control lamp on the instrument panel. Moreover, the most "advanced" models allow monitoring the air pressure in motion (with an accuracy of 0.01 bar) in each tire.

Tire pressure sensor inside the wheel

The sensors are equipped with miniature accumulators designed for a service life of 5 - 7 years. Batteries are needed to transmit a signal from a sensor that directly senses air pressure and is equipped with a transmitter - transmitting device.

Modern models sensors allow you to monitor the air pressure in motion (with an accuracy of 0.01 bar) in each tire.

The antennas that receive the signal can be installed either in the wheel arches or directly in the TPMS control unit, which, in turn, can be integrated (in the case of a "standard" installation) or in the factory security system, either in .

To install them, you need to completely disassemble the wheels and remove the standard valve - a new one is mounted in the sensor housing. Replacing the battery in such tire pressure sensors is not provided, so when buying, pay, if possible, on the date of the product's release - this way you will insure against premature battery discharge.

Installation of such sensors is possible only on rims marked with TPMS. But installation of universal sensors is also possible. These products, sold complete with a monitor and receiver, can be called universal tire pressure sensors - they can be installed in any wheel.

Universal tire pressure sensors

External indicators cannot transmit a signal while driving, and to check it is necessary to leave the car.

A more simplified design is provided by the outer caps with tire pressure indicators, which are screwed directly onto the nipple thread - at a critical pressure drop, they change color, and there are three-color options showing a deviation of up to 1 bar and changing color when the pressure drops below. But they cannot transmit a signal while driving, and to check the wheels it is necessary to get out of the car. Therefore, such caps are nothing more than a toy that becomes the object of attention of petty thieves.

When asked which tire pressure sensors are better, one can answer that the most trustworthy are those devices that are adapted for installation in a standard "socket" wheel rim (from appropriate labeling TPMS), since the reliable fixation of the sensor is an additional "guarantor" of its reliability and the correctness of the data it produces.

The price of tire pressure sensors starts from 3000 rubles per set, in addition, if you wish, you can purchase a special programmer for activating and adjusting tire pressure sensors - for about 10,000 rubles.

Installing tire pressure sensors

As mentioned above, sensors are installed on the disassembled wheel - instead of the standard valve. But their installation is still not enough to start operation. After installation, the tire pressure sensors must be “registered” - enter their data into the control unit (ECU) and balance the wheels.

To program tire pressure sensors in a car with TPMS, you need to use the standard on-board computerby entering the vehicle maintenance system. But before that, it is imperative to write out or photograph the individual code printed on the body of each sensor.

External tire pressure indicator

After entering the code, the TPMS “finds” the sensors by itself, while the data of the old tire pressure sensors does not need to be reset - they are automatically deleted. The codes must be saved, otherwise the monitor will display incorrect data after changing the wheels. However, you can just make tags on the wheels, indicating the "address" on them - where which one stood.

After installing the internal tire pressure sensors.

To avoid incorrect reading of data by the TPMS control unit while driving, the order in which it is stored must be observed. As a rule, it is as follows: front left wheel - front right - rear left - rear right.

If lights up after entering data signal lamp tire pressure sensors, this does not mean that you have performed the procedure incorrectly. For the final setup of the system, you need to drive a car at a low, about 30 km / h, speed for a couple of minutes - after reading the information by the block, the lamp will go out.

You will, of course, make a decision on your own about the need to equip your car with a TPMS system. As a decisive argument or, on the contrary, a counterargument, you can use your driving experience. That is, if you are sensitive enough to any changes in the behavior of the car on the road, you will be able to feel without sensors which wheel "gave slack". But in order to gain such experience, you need to drive more than one hundred thousand kilometers. Considering the rather high cost of "rubber" (especially of large sizes), it is quite possible that the pressure sensor will pay off if at least one wheel is "saved".

Car tire pressure is a very important indicator. With a reduced tire pressure, the tread will wear out faster, due to the larger area of \u200b\u200bcontact of the tread to the surface road surface... Also, from a constant cyclic load while driving, the rubber will deteriorate faster on the tire rim. And of course, the well-known factor of low tire pressure is increased consumption gasoline.

High blood pressure in tires is also not allowed. In this case, there will be a feeling of stiffness in the suspension, since the tire with increased pressure will damp the resulting loads worse. As a result, this will affect the resource of the suspension and body. Increased pressure can also cause the tire to burst.

And so, we decided that the deviation from the nominal tire pressure is a negative factor. How to control tire pressure, with what?

The answer to this question is partly simple. Everyone is familiar with the classic pressure gauge, which can be assembled with a tire inflation pump, or it can be performed separately. But it is not always convenient to run after each trip to the tires, and there are at least 4 of them on the car, and check the pressure. Currently, the alternative would be tire pressure monitoring sensors. Their plus is the possibility of constant, if you like round-the-clock monitoring of tire pressure remotely. It is especially important to control the pressure while driving, when it is simply not possible to control the inflation pressure in the tire by conventional methods.

In this article we will talk about tire pressure monitoring sensors, their principle of operation, installation methods, standard systems of tire pressure monitoring sensors installed on expensive foreign cars.

The simplest version of the tire pressure monitoring sensor is the mechanical design of the sensors. Such sensors are made in the form of caps that are screwed onto the tire nipple. For example, sensors named Easy control

The principle of operation of the sensors is reduced to the mechanical movement of the piston, painted in green color, depending on the tire pressure. So, for example, at a nominal operating pressure of the sensor and tire of 2 bar, a green indicator should be visible, when the pressure drops to 1.7 bar, a yellow indicator appears, the red indicator starts to appear when the pressure drops to 1.3 bar.

When purchasing, the sensors must be matched to your nominal tire pressure. Only in this case, they will correctly display the situation with the pressure in your tires. So on the market you can find variations in the nominal working pressure of the sensors from 1.8 to 3.6 atmospheres (bar).

The advantages of such sensors are in the absence of supply voltage. In easy installation, without disassembling the tire and its balancing. Regular replacement of caps.

Cons: easy accessibility for theft, low measurement accuracy, inability to control pressure while driving, directly from the passenger compartment.

It is difficult to say anything about the reliability of such pressure control sensors, most likely all year they belong to the category of times at a time, that is, how lucky.

Such tire pressure monitoring sensors are more complex in their design and installation method, but also more accurate and reliable. In fact for passenger car This is a set of 4 sensors monitoring tire pressure, in some cases the temperature in them, and one receiving and information unit. They communicate with each other by means of radio communication, or rather the signal from the sensors on the wheels is systematically sent to the main unit, where the information is displayed. As a rule, the signal from the wheel sensors arrives at a significant frequency when the car is parked, for example, once every 15 minutes, while driving much more often, for example, once every 5 minutes. This is done to increase the battery life in the wheel pressure control sensors, since they are powered by an autonomous battery. Nevertheless, the battery life can be up to 5 years, of course, everything will depend on the intensity of use and weather conditions. In cold weather, the battery “sits down” much faster.

If the sensor detects a rapid change in pressure (\u003e 0.2 kgf / cm2) in a few seconds, then it automatically switches to the mode of intensive measurement and data transmission. In this case, the information can change every second. Of course, everything described above applies to certain models of sensors and versions, we have only given the possible options, and what they will be with you depends on what you choose. Although now you will be choosing sensors "armed" with the knowledge of what you would like to see on your car.

If with the principle of such electronic sensors everything is clear, but about the options for their execution there are alternatives, and it is on this, in our opinion, that it is worth focusing attention.

Disc mounted electrical pressure control sensors

![]()

A feature of such sensors is their installation on a disk. In this case, the tire is disassembled, the sensor is installed on the rim of the disc near the hole for the nipple. Then the tire is installed in place, the tire is now balanced taking into account the weight of the sensor. The weight is quite significant, about 30 grams, you cannot do without balancing. Sensors of this design are routinely used by world manufacturers WV, Audi, Toyota, Lexus, etc.

The downside of such pressure monitoring sensors is the complexity of installation. The advantage of the sensors is a higher security against theft, as well as a higher tightness of the system. The readings are taken from the sensor inside, while the tightness is ensured, firstly, by the nipple, and secondly, by the cap. Reusable

Electrical pressure control sensors - caps

These pressure sensors replace the standard caps. You unscrew the normal caps and replace the pressure control sensors. The plus is obvious, minimal difficulties with installation, no balancing is required, the weight is about 5 grams with the battery.

The disadvantages in this case are the continuation of the advantages of the sensors. As you easily install them, so the thief can easily remove them. Some manufacturers say that their sensors are installed using a special key, yes, it is very difficult to unscrew them manually, but with pliers it is still not difficult. Lower tightness, since the sensors control the pressure when the nipple is open, in fact, the sealing is provided only by the cap, the nipple does not work.

Electric pressure sensors - microchips (used in conjunction with standard vehicle systems)

In fact, these are complex standard devices related to the installed bus. A chip is installed inside the tire, in the memory of which all data about the tire are stored - its type, dimension, permissible load, recommended pressure, maximum speed, date of manufacture. All this is naturally done at the factory.

The bus with the installed chip: 1 - valve; 2 - wheel rim; 3 - chip; 4 - bus.

The system can recognize the following changes in the tires: slow pressure drop, sudden pressure drop, excessive pressure drop during parking, which is reported to the driver immediately after turning on the ignition.

If the tire pressure has changed, for example, in the event of inflation, or in the event of a rearrangement of wheels, it is necessary to calibrate the reinstalled tires. To set the pressure that you had when installing the wheel is controlled by an external pressure gauge.

Indication of indicators of air pressure and temperature in tires

Control in this case occurs through calculation, and not direct measurement, this naturally suffers from the accuracy of the readings. The number of revolutions is calculated depending on the distance traveled by the machine. If the tire is deflated, it becomes smaller in diameter, and the distance covered by the tire in one revolution becomes shorter. A tire with a reduced pressure will have to rotate more than a tire with a rated pressure. The number of revolutions is recorded by an additional sensor installed on the vehicle, each to its nearest tire.

The disadvantage of such a system is that under certain driving conditions, for example, during fast cornering, driving over bumps, starting movement and braking, the assessment of the measured pressure values \u200b\u200bis inaccurate. Also, the possibility of only one-time use of such embedded microchips in the bus, which significantly increases its cost. The system is expensive and perhaps already "dying out".

Changes in the radius of the wheel when the air pressure in the tire changes: R1 - radius of the wheel at normal air pressure in the tire; R2 is the wheel radius at reduced pressure.