At the moment, the Russian market has most of the world's well-known manufacturers of automotive glass, many of which are suppliers of glass for conveyors car factories (original glass) and to the secondary market. All glasses from these manufacturers comply with international quality standards and are certified in the Russian Federation.

SAINT-GOBAIN was founded in 1665 in France by the order of Louis XIV as a royal mirror manufactory. The campaign was named after the French village in which one of the first factories of the company was located, founded in 1692. Initially, SAINT-GOBAIN was engaged in the production of mirrors and glass. The first order of the manufactory was the decoration of the mirror hall of the Versailles Palace. In the 19th century, the company's production expanded. Now sekurit autoglasses are products of the transnational concern SAINT-GOBAIN. The concern is one of the world's largest manufacturers of building and finishing materials, including glass for various industries. And his auto glass comes out under the SAINT-GOBAIN SEKURIT brand. Every second car leaving the assembly line of a European manufacturer is equipped with SAINT-GOBAIN SEKURIT autoglasses. Today SAINT-GOBUIN is one of the world's top 100 industrial corporations, it owns more than 1400 companies in 64 countries. Around the world, the concern employs about 200 thousand people. 5 SAINT-GOBAIN research centers are constantly working to improve the technology and production and quality of auto glass construction. SAINT-GOBAIN SEKURIT autoglasses are supplied to the conveyors of the largest automobile concerns, as: Alfa romeo, AUDI, BMW, Chrysler, Citroen, Daewoo, FIAT, Ford, Honda, Hyundai, Jaguar, Kia, Lancia, MAN, Mazda, Mercedes-Benz, Mitsubishi, NISSAN, Opel, Peugeot, Renault, SAAB, SEAT, Skoda, Subaru , Suzuki, Toyota, VOLVO, VW

Pilkington was founded in 1826 in Great Britain and is now one of the leading glass manufacturers in the world, with headquarters in the North West of England. In 2006 Pilkington became part of the Nippon Sheet Glass group. In turn, the NSG Group is one of the world's largest manufacturers of glass products for the construction, automotive and special application... Glasses are produced on 49 lines in 29 countries of the world on four continents, and sales are carried out in 130 countries. PILKINGTON's autoglasses are supplied to the world's leading automobile conveyors, such as Land Rover, Toyota, Honda, Jaguar, Nissan, Mercedes and others. Pilkington is also known for supplying glass to the buildings of the Reichstag in Berlin and the Strasbourg Court of Human Rights. Her regular customers include Toyota and Volkswagen.

Pilkington was founded in 1826 in Great Britain and is now one of the leading glass manufacturers in the world, with headquarters in the North West of England. In 2006 Pilkington became part of the Nippon Sheet Glass group. In turn, the NSG Group is one of the world's largest manufacturers of glass products for the construction, automotive and special application... Glasses are produced on 49 lines in 29 countries of the world on four continents, and sales are carried out in 130 countries. PILKINGTON's autoglasses are supplied to the world's leading automobile conveyors, such as Land Rover, Toyota, Honda, Jaguar, Nissan, Mercedes and others. Pilkington is also known for supplying glass to the buildings of the Reichstag in Berlin and the Strasbourg Court of Human Rights. Her regular customers include Toyota and Volkswagen.

The Polish company JAAN, which has at its disposal 29 factories in Poland, is engaged in the production of automotive glass under the brand "NordGlass". Established in 1991, a still very young company has already quite firmly established itself as a very worthy competitor in its market segment and is one of the leaders in production and sales car glass... Raw materials for the production of its auto glass "NordGlass" buys from such worldwide renowned manufacturers, like Saint-Gobain, Pilkington, Du-Pont, Guardian, NordGlass's production capacities significantly exceed the needs of Polish car enthusiasts, the company produces more than 1,200,000 car glasses per year and owns the largest wholesale warehouse for car glasses in Central and Eastern Europe, from where then more than half of they are exported. Glass production is carried out exclusively on modern Finnish equipment and meets all European requirements and standards, and special design bending furnaces installed by Glassrobots allow glass to be produced in small batches, which allows NordGlass auto glass to achieve the highest qualityrequired by the market original spare parts... Through the use modern technologies, innovation and research work, as well as relying on the personal experience of their installation centers, JAAN is constantly improving the quality of its products. In 2002, the British Standards Institution (BSI) awarded NordGlass the ISO 9001: 2000 quality management certificate. Also, the products manufactured by this company meet all the requirements for the level of quality and safety, which is confirmed by certificates obtained in accordance with UN Regulations No. 43 and the American standard ANSI / SAE Z26.1-1996.JAAN. NordGlass today produces autoglasses for more than 550 models of popular autos, coming off the assembly line of the European automotive industry, and the windshields of this company are very popular and in demand among bus owners and trucks... Among other things, it is worth noting that NordGlass windshields are supplied to the conveyors of manufacturers such as LAMBORGHINI, MASERATI and WIESMANN.

The Polish company JAAN, which has at its disposal 29 factories in Poland, is engaged in the production of automotive glass under the brand "NordGlass". Established in 1991, a still very young company has already quite firmly established itself as a very worthy competitor in its market segment and is one of the leaders in production and sales car glass... Raw materials for the production of its auto glass "NordGlass" buys from such worldwide renowned manufacturers, like Saint-Gobain, Pilkington, Du-Pont, Guardian, NordGlass's production capacities significantly exceed the needs of Polish car enthusiasts, the company produces more than 1,200,000 car glasses per year and owns the largest wholesale warehouse for car glasses in Central and Eastern Europe, from where then more than half of they are exported. Glass production is carried out exclusively on modern Finnish equipment and meets all European requirements and standards, and special design bending furnaces installed by Glassrobots allow glass to be produced in small batches, which allows NordGlass auto glass to achieve the highest qualityrequired by the market original spare parts... Through the use modern technologies, innovation and research work, as well as relying on the personal experience of their installation centers, JAAN is constantly improving the quality of its products. In 2002, the British Standards Institution (BSI) awarded NordGlass the ISO 9001: 2000 quality management certificate. Also, the products manufactured by this company meet all the requirements for the level of quality and safety, which is confirmed by certificates obtained in accordance with UN Regulations No. 43 and the American standard ANSI / SAE Z26.1-1996.JAAN. NordGlass today produces autoglasses for more than 550 models of popular autos, coming off the assembly line of the European automotive industry, and the windshields of this company are very popular and in demand among bus owners and trucks... Among other things, it is worth noting that NordGlass windshields are supplied to the conveyors of manufacturers such as LAMBORGHINI, MASERATI and WIESMANN.

FUYAO GLASS is a subsidiary of SAINT-GOBAIN SEKURIT with offices in America, Japan, Korea, Australia, Russia, Germany, Western Europe and Eastern Europe, etc. FUYAO GLASS Corporation is largest manufacturer auto glass in China and ranks 4th in this segment in the world. FUYAO's central factory and headquarters is located in Fuqing Province, Fuqing, and covers an area of \u200b\u200bover one million m2. FUYAO factories are equipped with modern equipment made in Finland, USA, Japan, Italy, Switzerland and France. Human labor is minimized - most of the processes in the manufacture of auto glass are automated, thanks to the widespread use of robotics. On domestic market FUYAO Group supplies auto glass to conveyors for more than 50% of car manufacturers, including Audi, Bentley, GM, Ford, DaimlerChrysler, Volkswagen, Volvo, PSA Peugeot Citroen Group, Toyota, Honda, Suzuki, Isuzu, Nissan, Mazda, Mitsubishi, Hyundai. Export of component glass to England for Land rover, in the USA for Ford, in Germany for Audi and Volkswagen, in South Korea for Hyundai, to Japan for Mitsubishi, to Europe Volvo, as well as to Russia for the factories "VAZ" and "TaGAZ". FUYAO Group supplies over 20 million sets of car glass for sale annually, all glass pass strict control quality in several stages, and meet the requirements: ISO 9002, QS-9000, VDA6.1, ISO 14000 and TS16949. Produced on FYG production lines car glass not only are comparable in quality characteristics with the products of such manufacturers as GUARDIAN and SPLINTEX, but also surpass the products of these companies in some characteristics. In 2000, Fuyao Glass was awarded the Gold Award from fordas the world's best supplier, and at a ceremony held in the USA in April 2008, FUYAO received the General Motors' Best Supplier of the Year award.

FUYAO GLASS is a subsidiary of SAINT-GOBAIN SEKURIT with offices in America, Japan, Korea, Australia, Russia, Germany, Western Europe and Eastern Europe, etc. FUYAO GLASS Corporation is largest manufacturer auto glass in China and ranks 4th in this segment in the world. FUYAO's central factory and headquarters is located in Fuqing Province, Fuqing, and covers an area of \u200b\u200bover one million m2. FUYAO factories are equipped with modern equipment made in Finland, USA, Japan, Italy, Switzerland and France. Human labor is minimized - most of the processes in the manufacture of auto glass are automated, thanks to the widespread use of robotics. On domestic market FUYAO Group supplies auto glass to conveyors for more than 50% of car manufacturers, including Audi, Bentley, GM, Ford, DaimlerChrysler, Volkswagen, Volvo, PSA Peugeot Citroen Group, Toyota, Honda, Suzuki, Isuzu, Nissan, Mazda, Mitsubishi, Hyundai. Export of component glass to England for Land rover, in the USA for Ford, in Germany for Audi and Volkswagen, in South Korea for Hyundai, to Japan for Mitsubishi, to Europe Volvo, as well as to Russia for the factories "VAZ" and "TaGAZ". FUYAO Group supplies over 20 million sets of car glass for sale annually, all glass pass strict control quality in several stages, and meet the requirements: ISO 9002, QS-9000, VDA6.1, ISO 14000 and TS16949. Produced on FYG production lines car glass not only are comparable in quality characteristics with the products of such manufacturers as GUARDIAN and SPLINTEX, but also surpass the products of these companies in some characteristics. In 2000, Fuyao Glass was awarded the Gold Award from fordas the world's best supplier, and at a ceremony held in the USA in April 2008, FUYAO received the General Motors' Best Supplier of the Year award.

AGC (Asahi Glass Company) was founded in 1907 in Japan by the young Toshiya Iwasaki, the second son of the second president of Mitsubishi Corporation. Before him, not one Japanese company failed to achieve success in the production of flat glass. 26-year-old Iwasaki prudently did not use the name Mitsubishi, so that in case of failure, he would not cast a shadow on the famous corporation and his family. Perseverance and dedication in the spirit of a pioneer helped the young entrepreneur to found the Asahi Glass Company, Japan's first flat glass company. Glass for automotive industry the company began manufacturing in 1956. Today Asahi Glass Company is the undisputed leader in the production and supply of auto glass for almost the entire auto industry in Japan, and every third car leaving conveyors around the world is equipped with AGC glasses, and under the logos belonging to this company you can find glasses from the following manufacturers: AGC Automotive, Asahi, AP Tech , Asahimas, Lamisafe, Splintex, Temperlite, Bor. The company owns 130 enterprises worldwide, has 350 subsidiaries, and the number of employees, despite the extensive use of robotics, is more than 54,000 people. The global nature of this company today allows it to occupy 30% of the world and 70% Russian market... In 1997, the Bor Glass Factory also became part of the AGC company. The largest auto glass warehouses in Russia belong to AGC, the largest glass melting furnace in the world, with a capacity of 1000 tons of sheet glass per day, installed at the Klin plant in 2010 belongs to AGC.

AGC (Asahi Glass Company) was founded in 1907 in Japan by the young Toshiya Iwasaki, the second son of the second president of Mitsubishi Corporation. Before him, not one Japanese company failed to achieve success in the production of flat glass. 26-year-old Iwasaki prudently did not use the name Mitsubishi, so that in case of failure, he would not cast a shadow on the famous corporation and his family. Perseverance and dedication in the spirit of a pioneer helped the young entrepreneur to found the Asahi Glass Company, Japan's first flat glass company. Glass for automotive industry the company began manufacturing in 1956. Today Asahi Glass Company is the undisputed leader in the production and supply of auto glass for almost the entire auto industry in Japan, and every third car leaving conveyors around the world is equipped with AGC glasses, and under the logos belonging to this company you can find glasses from the following manufacturers: AGC Automotive, Asahi, AP Tech , Asahimas, Lamisafe, Splintex, Temperlite, Bor. The company owns 130 enterprises worldwide, has 350 subsidiaries, and the number of employees, despite the extensive use of robotics, is more than 54,000 people. The global nature of this company today allows it to occupy 30% of the world and 70% Russian market... In 1997, the Bor Glass Factory also became part of the AGC company. The largest auto glass warehouses in Russia belong to AGC, the largest glass melting furnace in the world, with a capacity of 1000 tons of sheet glass per day, installed at the Klin plant in 2010 belongs to AGC.

Guardian Glass Company was founded in the USA in 1932 in Detroit, Michigan. Initially, it was a small glass processing plant for the needs of the American car industry, and in the 80s the company already began to enter the European market, acquiring large factories in several European countries. It is now a transnational company called Guardian Industries with 19 factories in different countries on 5 continents and manufactures auto glass for more than 240 car brands and models. The products of this company are supplied to the assembly lines of such manufacturers as: Audi, Bmw, Peugeot, Opel, Chrysler, Jaguar and others. famous companies car manufacturers. In the United States, the company produces most of the auto glass for General Motors. Buick, Cadillac, Chevrolet, Saturn, Geo, Oldsmobile and others are equipped with these glasses. The most famous Guardian factories are located in Spain and Luxembourg. The factory in Luxembourg is focused on the primary glass (OEM) market - these glasses are supplied to the assembly lines of renowned car manufacturers. The Spanish factory is mainly focused on the production of glass for secondary market, which in no way affects the quality of Guardian products. The Russian car market receives mostly windshield guardian of Spanish production. The company pays special attention to the innovative development of production and invests considerable capital in innovation, annually introducing new products to the market. Today Guardian is a leading manufacturer of products for the construction and automotive industries. Today the Guardian company ranks first in the world in the field of production of nano-sputters of various characteristics and mirrors, the priority today is the production of magnetron sputtering. These are special sprays that allow to reduce heat loss of premises in winter and prevent overheating of buildings in summer, reducing exposure to ultraviolet radiation, which in turn significantly increases the life of the product as a whole, and Guardian also ranks second in terms of float glass production.

Guardian Glass Company was founded in the USA in 1932 in Detroit, Michigan. Initially, it was a small glass processing plant for the needs of the American car industry, and in the 80s the company already began to enter the European market, acquiring large factories in several European countries. It is now a transnational company called Guardian Industries with 19 factories in different countries on 5 continents and manufactures auto glass for more than 240 car brands and models. The products of this company are supplied to the assembly lines of such manufacturers as: Audi, Bmw, Peugeot, Opel, Chrysler, Jaguar and others. famous companies car manufacturers. In the United States, the company produces most of the auto glass for General Motors. Buick, Cadillac, Chevrolet, Saturn, Geo, Oldsmobile and others are equipped with these glasses. The most famous Guardian factories are located in Spain and Luxembourg. The factory in Luxembourg is focused on the primary glass (OEM) market - these glasses are supplied to the assembly lines of renowned car manufacturers. The Spanish factory is mainly focused on the production of glass for secondary market, which in no way affects the quality of Guardian products. The Russian car market receives mostly windshield guardian of Spanish production. The company pays special attention to the innovative development of production and invests considerable capital in innovation, annually introducing new products to the market. Today Guardian is a leading manufacturer of products for the construction and automotive industries. Today the Guardian company ranks first in the world in the field of production of nano-sputters of various characteristics and mirrors, the priority today is the production of magnetron sputtering. These are special sprays that allow to reduce heat loss of premises in winter and prevent overheating of buildings in summer, reducing exposure to ultraviolet radiation, which in turn significantly increases the life of the product as a whole, and Guardian also ranks second in terms of float glass production.

Modern cars are equipped with reliable and durable windshields that can last almost unlimited time. Unfortunately, there are often cases when you have to face the problem of replacing them, a stone hit, an accident, and so on. Which windshield to choose in this case? First, let's figure out what types of windshields are supplied to the market today.

Types of glasses

From the beginning of the invention of the automobile, ordinary glass was installed on them. When a stone hit, such glazing instantly collapsed into a mass of fragments, which could seriously injure passengers and the driver. Later on cars began to install tempered glass, "Stalinite". Since the end of the twenties of the last century, "triplexes" have appeared, which are a combination of two layers of glass and a polymer film.

Stalinite ("kalyonka") It is produced by heating ordinary glass in special ovens to a temperature of +680 ° C, followed by cooling with cold air. As a result of this crystal hardening, heat resistance tempered glass increases by at least two, and the mechanical strength is improved 5 times. When destroyed, the stalinite crumbles into small fragments with blunt edges. Stalinite windshield is practically no longer produced today. However, sometimes on sale you can still find windshields made of "red-hot" for old car models. As a rule, stalinite is used as the rear and side windows.

Triplexin comparison with Stalinite it is characterized by increased strength, and most importantly, safety. When such glass is destroyed, a polymer film located between the layers keeps the fragments from flying apart, thus ensuring the safety of the driver and passengers. Almost all modern cars are completed with triplex windshields.

The windshield manufacturing technology is rather complicated and time consuming. All processes are fully automated. First, on the flat glass, two templates are trimmed around the perimeter of the desired size. Then the incision line is heated with a high-temperature burner. After that, the glass breaks exactly along the cutting line. At the next stage, the edges of flat workpieces are processed with abrasive belts.

After abrasive processing, the smallest dust particles are removed from the workpieces by washing in a soapy solution. Then the glass surface is covered with a special compound that prevents the templates from sticking together. The workpieces processed in this way are stacked on top of each other. Next, the size of the windshield is adjusted using high-precision equipment. Then the blanks are sent to the bending machine.

A specific shape is created for each car model. Flat workpieces are placed on it, after which they are heated to a temperature of +759 ° C in a special oven. The heated glasses become elastic and take the curvature of the bending machine, after which they cool slowly.

After the glasses have hardened, a polymer film is laid between them. Then air is removed between the layers using a special machine and an autoclave. Silk-screen printing is applied along the perimeter of the edge of the triplex, which will ensure reliable retention of the glazing in the body opening.

At the final stage of manufacturing the windshield, multilevel quality control and selective testing for strength by simulating impact are performed.

Which windshield to install?

What is the best windshield to install? Considering the above, you need to choose only triplex. Now we will consider in detail how to choose it from what is on the market today. First of all, the main criterion when choosing a windshield is the manufacturer. Conventionally, all windshields that go on sale can be divided into several categories:

1. Original frontal glasses are of excellent quality. They are durable, easily resist low-force impacts and practically do not scratch. The main disadvantage of such glasses is their higher cost compared to other analogs.

2. European triplexes... Glass made european manufacturers, are in no way inferior to the original. Such glazing does not distort the environment and is well-sized. The polymer film retains its original color for a long time. At the same time, the cost of a windshield made in Europe is lower compared to the original analogue.

3. Domestic frontal glasses can be either good or bad. It all depends on the specific manufacturer, quality of raw materials and manufacturing technology. There are cases when glasses with irregular geometry are found on the market. Therefore, you should be very careful when choosing a windshield.

4. Asian triplexes... This category includes windshields from Chinese and Turkish manufacturers. The cost of such glazing is the lowest, therefore the quality is significantly inferior to the above categories. As a rule, in the manufacture of triplexes, Asian manufacturers use ordinary glass without special additives and simplified technology. Such windshields are short-lived. They are characterized by low mechanical strength, scratch and quickly become cloudy. Quite often, Asian windshields do not match the required dimensions and distort objects. These and other defects are quite difficult to identify visually when buying. As a rule, they appear during installation or during operation. Therefore, experts do not recommend buying triplexes of Chinese or Turkish production.

5. Fake... It's no secret that today there are a lot of fakes on the market that imitate well-known manufacturers. The disadvantages of such windshields are the same as those of Asian triplexes. To avoid counterfeiting, pay attention to the quality of the glass edge processing, as well as its marking and the presence of additional elements.

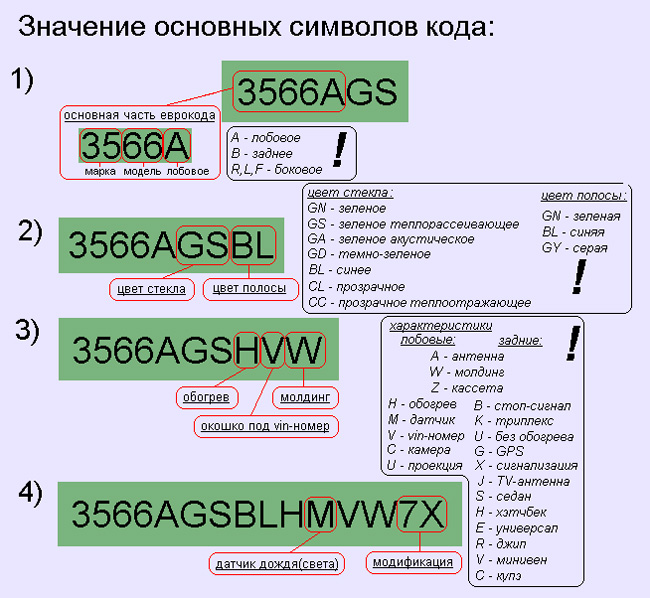

Absolutely all car glasses made in a production environment have a special windshield marking in the form of a stamp located in one of the corners. The upper inscription, in large letters, identifies the trademark. Below and to the left should be Roman numerals, which indicate the type of glass:

... "I" - increased strength windshield (windshield);

... "II" - laminated windshield (windshield) of standard strength;

... "III" - processed laminated windshield (windshield);

... "IV" - plastic glass;

... "V-VI" - not windshields, throughput the light of which is less than 70%.

In the left corner, in a circle, the code of the country in which this glass was certified is written. Below the manufacturer's name is the standard and date of manufacture.

In addition to the markings on the windshields, there may be additional elements:

Manufacturer's logo (trade mark);

... silkscreen printing - a black strip around the perimeter that protects the glue and fasteners;

. VIN number;

... transparency coefficient;

... molding;

... rain sensor;

... top tinted strip.

Knowing the markings and additional elements that should be on the windshield, you can always distinguish original products from a counterfeit made by handicraft.

Original - the best optionhowever, its cost in some cases is very high, so many motorists prefer to buy cheaper analogs that look very similar to the original. There are other options as well car glass, which are produced by world manufacturers.

When choosing glass, you need to pay special attention to whether the goods are certified by a particular seller. According to some motorists, alternative windshield options are sometimes absolutely not inferior in quality to the original. The cost of the alternative is much less, which actually makes it attractive to motorists.

A few tips on how to do it right choose windshield

In order not to be mistaken with the choice, it is necessary to take into account some important pointsBesides, you shouldn't assume that big-name brands are incapable of making mistakes and making defects. Therefore, before the final choice of glass, it is necessary to carry out several verification procedures.

First of all, you should make a visual inspection of the auto glass, in case of scuffs, chips, cracks or scratches on its surface. If you find at least one of the above defects, please refuse to purchase this product. Qualitative car glass must have smooth, well-finished edges. You also need to take a closer look at whether the glass is distorting. This type of marriage is quite common among glass products. Windshield should not be muddy, everything should be perfectly visible through it.

High-quality auto glass is produced by serious manufacturers in the factory in compliance with complex technologies. As a rule, the main work in the production of auto glass is performed by automated equipment practically without human intervention. When buying glass, pay attention to its size, it must be strictly observed, in addition, the correct high-quality models must have an indication of the type and model of the windshield as well as the brand or name of its manufacturer. Take a closer look at the inscriptions, they should be clear and even if you find some kind of "mud" or errors in the brand name or in other words - bypass such a product.

Also avoid various generic or non-standard windshields, which, according to the seller, look much better or give the car a different look. Buy only those that are approved by the automaker, for orientation, you can rewrite the parameters from your glass or check the dimensions and characteristics with the dealers of your car manufacturer.