Manual or parking brake, or as it is called by the people, just a handbrake, capable of playing a cruel joke for many who are learning to drive when passing the exam in the traffic police. Here the student gets into the car, adjusts the seat, mirrors, squeezes the clutch, turns on the first gear, correctly wraps his hands around the steering wheel, presses on the gas pedal ...

Reducing pressure by passing vehicle in a vehicle leads to an increase in the propagation speed. Valve exhaust valve serves to facilitate braking maneuver, avoiding any inconvenience that may arise when braking is not carried out with great care. In order for the brakes to function regularly, depression in general behavior must be continuous. It is also necessary that the drain does not close once if you want to avoid the drum hitting.

The goal is achieved by the interconnection between the pipeline and the atmosphere of the small tank, which guarantees gradual release into the air. Vacuum continuous brake can also be achieved. The strain strain is created by atmospheric pressure on the lower surface of a movable plunger in a vertical cylinder, from which air is sucked out through an ejector. This consists essentially of two coaxial cones, which leave between them a very close conical crown through which the steam taken from the locomotive passes through the side tube.

In general, he does everything right, but the car still does not go. This is where the student's exam ends. And the reason for this is the usual forgetfulness and the unlocked parking brake. It would seem a very funny situation. But not for the one who failed the exam. Agree, it will be rather embarrassing to answer the question of friends why I didn't pass it.

The steam gains excellent speed by exercising in the cone at the bottom, communicating through the common drive with the brake cylinders, strong suction air. The vacuum you get is about 50 inches of mercury. An automatic valve closes the pipeline as soon as steam stops exiting the ejector and prevents air from entering the pipe, losing suction. To dissolve using air check valve, let it enter again the air in the general direction, the plunger for its weight falls, melting the wheels.

The ejector is usually double, one acts on the locomotive and the tender track, and the other acts on the vehicles. Smith's vacuum was perfected by Hardy, Clayton, Curting, etc. The most important prerequisite for continuous braking for railway trains is automaticity. This object lacks both the first type of compressed air brake and the previously described vacuum brake, and it belongs to the triple valve brake; but it can also be obtained with another system using compressed air or vacuum.

The purpose of the parking brake

but hand brake is necessary not only for obtaining a driver's license, it is really needed.

You should make it a rule to always put the car on the handbrake when there is no driver in it, because everything happens in life.

A car can simply move out of place and hit another car or a pole, it can provoke a larger accident. So the handbrake is a pretty useful thing and in some cases will save your car from all sorts of troubles.

Then there are dual chamber or differential brakes. Double-chamber brakes consist of a cylinder in which compressed air can be sent out of the pipe at all. Plunger stem is in a suitable stop position; plunger came half way, can't go any further. Now, if we open the channel, the air that entered the second chamber was unable to escape through the plunger seal because this, so as to allow only the entrance, pushes the plunger back onto the braking application. it will be enough to send compressed air into the pipeline and then into the cylinders.

If you leave your car on the side of the road, even for a few minutes, auto instructors always advise you to use the handbrake, as it will be very difficult to catch up with the car that has gone.

It is better for beginners not to go here. To begin with, you need to carefully work out the process of moving uphill in a calm atmosphere, away from bridges.

This brake is automatic, since braking occurs whenever there is continuity in the pipeline. Likewise, a double chamber vacuum brake can be created by extracting air from the cylinder with an ejector, but ensuring that the air extracted from both rooms can no longer be returned to the first chamber results in braking. The latter is especially useful during a long descent, when it is necessary to follow with the deformation pressure changes to a more or less slope and, thus, to get the train speed unchanged.

After all, here the cars move very slowly, and the cars stand close to each other. You simply cannot do without a parking brake, so it is important to work out all the actions in advance.

We get under way from the parking brake

So, you stopped at an overpass, put the car on the hand brake. How can you get under way without hitting the car behind?

So far we have talked about the part of the brake that rises to the first moving body. From this point on, the belts that are pressed against the wheels have a series of levers that make up the wheelhouse and serve to multiply the initial force from the first stroke onto the belts. Called multiplies the brake link obtained through wheel, between the pressure against deformation and the force applied to the first movable. This applies to both brakes and handbrake brakes. In order for the hand brake to limit the initial force, its multiplication by the same braking force must be much higher than in brakes with mechanical force.

It is necessary to start driving as usual, but when releasing the parking brake, it is recommended to do the following manipulations.

Press the lock button, while the handbrake is in the upper position.

As soon as you feel that the car can already start moving, you need to quickly lower the handbrake down.

The car should go forward without rolling back.

On the other hand, high speed brakes are very slow and therefore spend a significant interval between the brakes when the maneuver starts and the pressure at which the pressure reaches the stresses. At this stage, there is no difference between the parking brake and the fluid, but the superiority of the latter is obvious, since by quickly touching the phase of application of deformation to deformations, they minimize the distance traveled by the train from the moment in which the braking action began from the one in which the brake is actually applied.

For heavy railway cars, applying the hand brake requires about 10 seconds, and for a compressed air compressor - one and a half to two. With continuous braking, the speed of propagation of the initial force, also carried out at the end of the train. If the propagation is slow, the braking action reaches the following vehicles at a time interval, so that the vehicles cling to each other by tightening the bumper springs. When the entire train comes to a stop, the compression action is released, but the uncompressed springs react to relaxation until the attachment organs break, this danger is eliminated if spreading occurs quickly. around the speed of sound, but never reaches it in the case of compressed air, surpassing it in the case of vacuum, which, from this point of view, is the most convenient form of transmission.

The most important thing here is to correctly determine when the handbrake is released.

Signs of this are a decrease in speed. crankshaft, changing the tonality of engine noise, the appearance of new vibrations. We strongly advise you to learn this not in traffic jams or on highways, but outside the city, where no one puts you, or rather you, anyone ...

Finally, must be described brake wheel... The continuous brake wheelhouse does not differ, with the exception of the drive end, from the wheelhouse. In this last command, the command is screwed, in hydraulic brakes, the command is started from the piston brake cylinder... The magazines are equal to four per wheel, and the transmission levers are proportioned so as to produce the same voltage on each strain. FIG. 13 shows the application of a brake to a vehicle.

One main tie transfers the force from the cylinder to four logs of each axle, but the triangular arrangement divides the force so that they are equal on both sides or from another vehicle. Axial compressors are also used, that is, they move on an automobile axle.

Good luck with your driving training and handbrake starting.

The article uses an image from the site www.volga-gaz.nnov.ru

The functional purpose of the parking brake, as its name implies, is to prevent the spontaneous movement of a stationary vehicle under the influence of extraneous forces. As a rule, the handbrake is applied when stopping (parking) a vehicle on surfaces with a certain slope (approaches to overpasses, bridges, railway crossings etc.).

For trams, there are brakes that follow the same principles as above, with simpler bodies. An important innovation is the innovative quick pad change system, which allows mechanics to easily and quickly change worn pads.

The gripper is also prone to use a sensor to check for pad wear while racing. Derived from new crude oil, this disc has been engineered with a different air duct ranging from the current 17mm and 18mm sizes and with an innovative design of inner fenders to provide a significant improvement in heat dissipation efficiency - reducing the weight of the disc itself.

Hand brake device

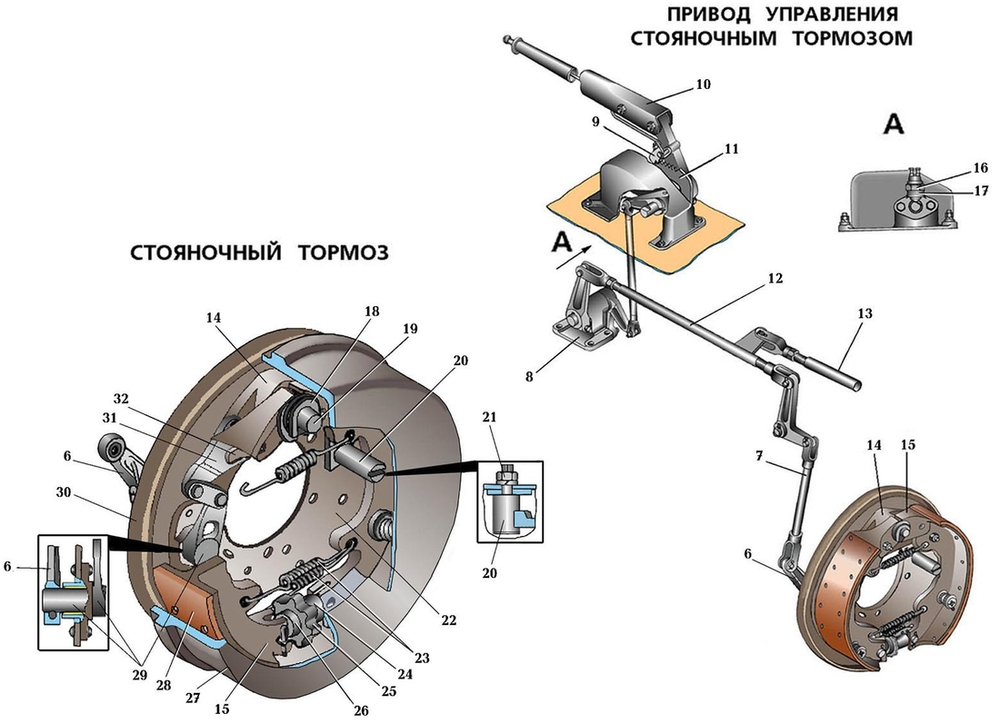

The design of the hand brake will be considered on the example of the most common model from the "classic" of the Volga Automobile Plant - "VAZ 2106", the rear wheelset, which is equipped with drum-type brakes.

The main structural elements given brake mechanism are:

Cross-flow measurement data with pressure and temperature data allow for more accurate analysis of brake performance. The remarkable heat sinking allows for more aggressive compound pads that guarantee a larger bite and a higher coefficient of friction, thereby moving the release point while avoiding excessive overheating of the pliers.

New 4-piston piston with liquid cooled Fully manufactured and particularly lightweight in accordance with the design of standard pliers with the addition of some accessories such as reservoirs and radiators for circulating the liquid required for this type of cooling.

Parking brake lever located in the passenger compartment of the vehicle.

An adjusting unit, consisting of an equalizer, a rod, adjusting and fixing nuts, a rubber boot.

Parking brake drive cable made of a steel cable enclosed in a flexible twisted winding and connecting the adjusting unit with the rear brakes of the vehicle.

This structure allows the weight gain to be limited to only 0.2 kg, which together with the significant thermal gain leads to a significant improvement in plant performance. It is a lightweight cast iron plate of about 20%, with completely redesigned ventilation compared to the past, which allows for significantly improved air circulation during cooling. The disc is available with a diameter of 300 mm or 355 mm.

Each of the two options has a different thickness depending on the application. More conservative, 28 mm for 300 mm disc and 32 for 355 mm disc - more extreme, 25, 4 mm and 30 mm respectively for 300 mm and 355 mm diameters. To provide even more complete equipment, Brembo studied a handbrake exclusively designed for four-wheel drive vehicles rally. The chassis mounting bracket is made of aluminum and is made entirely of fully. The mechanics of this system allows the operation of the brake pump to be delayed relative to the release of the differential.

In addition, in the braking mechanisms of the rear wheelset, there are elements that provide the performance of the parking brake functions.

This is the drive lever (item 9), one arm of which is rigidly fixed to the metal pin (item 11), and the other, capable of moving, is connected to the handbrake drive cable (item 8).

This guarantees blocking rear wheel only when disconnected from the transmission. The structure has a floor mount bracket and the 3 pedals are divided into two groups, also available separately: brake clutch and accelerator. The accelerator unit has a chassis separate from the brake pedal - a clutch that allows disassembly and optimization of installation. The accelerator has two electronic sensorso that it can work even when the main sensor breaks.

The total weight of the pedal is only 3.25 kg. As an option for the brake clutch unit, you can request two different remote controller lengths for active brake balancing. This tool allows the pilot to swap out the subwoofer with brake split between front and rear, thereby altering the balance of the vehicle. The gripper also provides the ability to attach the air duct to supply the cooling air flow; All this makes it extremely efficient at cooling the system.

Do-it-yourself parking brake adjustment

The process of adjusting the hand (parking) brake is not complicated and does not require complex technical support, since its essence lies in changing the length of the drive cables. The operational wear of the elements that ensure the operation of the system is extremely insignificant, which allows for a long time to do without replacing them.

The vertical mounting and the ability to assemble in both rear and main configurations make it extremely versatile and allow the team to freely choose the trim that best suits their car's layout. The main components of an amibromide brake are two curved logs coated with friction material and attached to a plate attached to a stationary part of the vehicle, and a rotary cast iron roller called a drum. On the plate between the two logs there are also one or two hydraulic cylinders with relative pistons, but only on rear brakes - mechanical control device controlled by the parking brake lever. The latter is pushed onto the drum, which, resisting strong dynamic friction, slows down the rotation of the wheel. In other words, the brake "clip" is an integral part of the chassis and is the seat in which the "brake pads" are located. During braking, the mechanism presses the pads against the disc, thereby creating a force that is directly proportional to the pressure. As a result, the wheel receives a torque that counteracts its rotation, that is, braking. Disc brake consists of a solid steel cast iron disc on the wheel, which is fired by a clamping system that rolls up a pair of pads composted with a mud-like material, which, while pressing on the milky liquid, causes it to slow down along with the wheel of the wheel. The thrust rod pressure is generated by hydraulic or mechanical device.

- Distinguish different types brakes, both by their drive and by the principle of operation.

- On the other hand, the plate holder is attached to the suspension and cannot rotate.

The effectiveness of the "handbrake" is determined by the stability of the vehicle on surfaces with a slope, with a certain degree of lever lifting (the number of clicks). If we are talking about "six", then, as a rule, four is enough. Otherwise, the brake is adjusted. Another indication for the performance of adjustment measures is the increased travel of the handbrake lever.

In addition, the handbrake adjustment is performed after some repair and restoration work:

Replacement brake pads and disks.

Replacing the drive cables.

Replacing the brake calipers (for disc brakes).

Attention! The adjustment is carried out exclusively on a serviceable brake system, the moving elements of which are easy to move, and adjustment work has been performed on the brakes of the rear wheelset.

Adjusting the "handbrake" on cars equipped with rear drum brakes:

We release (turn off) the parking brake by lowering the lever.

Use the “b” wrench to release the locking nut.

Use the "a" wrench to tighten the adjusting nut until the pads come in contact with the brake drum (determined by turning the rear wheels).

We unscrew the adjusting nut 1.5-2 turns, which allows the brake pads to be removed from contact with the drum.

Raise the parking brake lever two clicks, which corresponds to the second tooth of the ratchet, and turn the wheel again. It should be inhibited.

Tighten the fixing nut.

We check the freedom and smoothness of the drive cable.

In order to prevent the occurrence of corrosion processes, we cover threaded connection traction with a thin layer of grease (for example "Litol").

After completing the adjustment measures, be sure to check the operation of the parking brake system. To do this, place the vehicle on a surface with a slope (up to 250) and turn on the handbrake (on the 4th - 6th ratchet teeth). If there is even the slightest movement of the vehicle, the parking brake is not sufficiently applied. The appearance of a squeak in the mechanism of the rear wheelset and a difficult start of the car's movement are symptoms of an overtightened "handbrake". In these cases, the parking brake adjustment is repeated.

When brake adjustment is necessary

Often, motorists with little practical experience in car repairs ask the question: "How often do you need to adjust the parking brake?" If the car was not performed renovation work, which we talked about above, the "handbrake" is subject to adjustment only when the lever, installed on the 4-6 teeth of the ratchet mechanism, cannot cope with fixing the vehicle on an inclined surface. Why is this happening? The material from which the drive cable is made is capable of stretching during operation; accordingly, the degree of its tension decreases. However, the rope cannot be pulled up indefinitely. Experts recommend performing no more than four tensioning of the drive cable with one set of brake pads, after which it is necessary to replace them (pads) with new ones.