In order to save materials and reduce the cost of new cars, manufacturers have stopped installing a washer check valve. windshield... A penny item, in comparison with the cost of a car, does not affect the pricing at all, but adds a lot of trouble to car owners. Why? The rubber bands of the wipers quickly lose their elasticity, and abrasive debris accumulates under them. With the inclusion of glass cleaning, water begins to flow from the tank with a great delay and have time to "cut" the unfortunate scratches.

How and where to find the washer valve on the car?

Check valve designed to retain water in the immediate vicinity of the nozzles. This allows, after turning on the pump drive, to immediately supply water to. Car owners are trying to eliminate this flaw by installing a windshield washer valve with their own hands. You don't need any special knowledge or complicated tools to install the device.

In order to exclude the return flow of air, water or fuel, devices that are very simple in design are used - petal or spool valves. The flow tube has a separate chamber that houses the valve itself. Liquid or gaseous substance only goes in one direction.

As soon as the direction of flow changes, the valve closes the channel lumen and prevents reverse movement. In washers, such a device keeps water in the tubes in the immediate vicinity of the spray nozzles and allows you to immediately open its supply when the water tank pump is turned on.

Finding the washer valve is very easy. To do this, it is necessary to trace the route of the tube from the outlet fitting of the water pump installed on a plastic tank in engine compartment... A thin polymer tube runs along the walls and, depending on the design of the machine, enters the hood or into the air duct under the lower part of the windshield frame. It is in these places that the nozzles are installed.

For cars with washers and rear windows the device is more complicated, because a tube must go from the tank through the interior, which also ends with a nozzle. Washer check valve rear windows is also important, since the route for the liquid is longer and it will take much longer to wait for it to appear on the glass.

If on the way from the tank to the nozzles additional devices cylindrical shapes are not found, which means that there is no valve, and you will have to install it. If there is such a valve, then it should be checked regularly. To do this, remove it and blow it in two directions. If the valve does not allow air to pass through or, on the contrary, does not retain it simultaneously in one and the opposite direction, it should be replaced.

Where to get and how to install a washer check valve?

The valve in question is a fairly common subject. Finding one is not at all difficult in anyone. Even if it was not possible to buy a special one for car washers, the valve that is used for fuel system some cars.

The selection criterion should be the diameter of the fittings. By the way, as an option: it is useful to visit a store that sells aquariums and accessories for them. Valve devices are mandatory in air supply systems. It has been noticed that elastic tubes that come with aquarium systems are more practical, as they retain their elasticity longer.

To upgrade and install a glass washer check valve (front or rear), you will need:

- the valve itself;

- flexible polymer tubes of suitable diameter;

- plastic clamps.

The place of installation of the valve is not of fundamental importance to ensure the operability of the system. In any case, the top point of the network will be the nozzle, so the outflow of water held by the valve is impossible. It is necessary to introduce the device where it is more convenient and the possibility of its damage is excluded.

On some cars, couplings can be found in the highway. It is not at all clear why they were installed, but it is better to insert a valve instead of such a connecting tube than to make an extra cut in the tube.

Installation technology consists of the following stages:

- the tube is cut at the installation site;

- after determining the direction of valve opening, the ends of the cut tube are put on its fittings;

- a new part with tubes is attached to the body elements with clamps;

- after turning on the ignition, the washer is turned on and fluid is pumped into the system.

Winter is a time of special attention for car windows

As soon as water is pumped into the washing systems, it should be remembered that it will always be there. the network can be thawed, which will lead to the need to replace it. In this regard, you should carefully monitor the weather forecasts and in a timely manner fill instead of ordinary water or summer washer fluid, "anti-freeze" with the appropriate temperature for your area.

Stained glass is a common sight in modern travel. So, an emergency stop, which occurs due to the "invisibility" of the road by a motorist, can occur in any periods of weather conditions. Of course, the most common such situations occur during the winter period. In the rain, it would be much easier, since the dirt can be brushed off with ordinary wiper brushes if the washer is inoperative.

Nevertheless, if the sun and winter are outside, and car glass is enriched with colorful dirt and splashes from under the wheels of other cars, then problems already arise, since ordinary washing with brushes can lead to many scratches, as a result of which the glass will deteriorate.

The reasons for a washer breakdown are very different: from your own oversight to a failure of the system itself. If you do not go into details design features washer devices, then you need to turn your gaze to several recommendations that will help the motorist avoid many problems. The driver should remember to add water to the tank, as it tends to run out. IN winter periods you should replace ordinary water with non-freezing liquids washer. In addition, when choosing such a fluid, you need to pay attention to the maximum operating temperature.

There is a small detail that can be either a necessity or an unnecessary item. This part is called check valvewhich adapts to the windshield washer. Lots of car manufacturers stopped installing such a device in new cars in order to save materials and reduce the cost of the car. Although, if you look at it, then in comparison with the cost vehicle this detail is a monetary minuscule, but it can cause a lot of trouble for the motorist. This is due to the wear of the rubber bands of the brushes, which lose their elasticity and can scratch the windshield due to the long flow of water from the tank.

There is a small detail that can be either a necessity or an unnecessary item. This part is called check valvewhich adapts to the windshield washer. Lots of car manufacturers stopped installing such a device in new cars in order to save materials and reduce the cost of the car. Although, if you look at it, then in comparison with the cost vehicle this detail is a monetary minuscule, but it can cause a lot of trouble for the motorist. This is due to the wear of the rubber bands of the brushes, which lose their elasticity and can scratch the windshield due to the long flow of water from the tank.

As for the liquid, it must first be mixed with water in the appropriate proportions indicated on the label. You should not just add liquid to the tank, in the hope that there is still water there, since it is not known how much water there is. So, if the concentrate is weak enough, then all the effectiveness of the liquid will disappear and it will simply freeze with the onset of frost. Therefore, it is better to purchase a ready-made mixture in general, having previously checked its authenticity using a home freezer.

It is imperative to check the condition before filling with new fluid. The fact is that not all motorists have time to replace the fluid in time, as a result of which it may already freeze together with the motor. Refilling the concentrate in this case will not provide a positive result, but will only worsen the current situation.

The problem is that the cold time that the motorist missed could have formed a piece of ice in the tank. No one will guarantee that the ice has thawed at the time of adding concentrate. So, the concentrate will hang on top of the tank without mixing with water.

The problem is that the cold time that the motorist missed could have formed a piece of ice in the tank. No one will guarantee that the ice has thawed at the time of adding concentrate. So, the concentrate will hang on top of the tank without mixing with water.

1. How and where to find the washer valve on the car?

The washer check valve device is designed to keep water close enough to the nozzles. This will serve as an instant water supply to the car windshield when the pump drive is turned on. Motorists are trying to change this kind of flaw on their own by installing a windshield washer valve. Complex tools and special knowledge are not needed for this process.

To prevent backflow of water, air or fuel, spool or petal valves must be used. The flow tube device contains a separate chamber where the valve device itself is installed. A gaseous or liquid substance in this case can only pass in one single direction. After changing the direction of flow, the valve will close the valve lumen, thus eliminating the reverse movement of the fluid. In the washer itself, this device will retain water in the tubes, next to the spray nozzles, which will allow it to immediately open when the water tank pump is activated.

Finding a washer valve device will not be difficult. So, for this you need to trace where the tube goes from the water outlet, which is installed in the engine compartment on a plastic tank. This thin pipe will run along the walls and, directly in the way of constructing the car, will fall into the air duct or on the hood of the car. This is where they will be installed

Finding a washer valve device will not be difficult. So, for this you need to trace where the tube goes from the water outlet, which is installed in the engine compartment on a plastic tank. This thin pipe will run along the walls and, directly in the way of constructing the car, will fall into the air duct or on the hood of the car. This is where they will be installed

2. Where to get and how to install a washer check valve?

This kind of washer check valve is a fairly common device. It will not be difficult for a motorist to find it in any car store or service. Even in cases where the car enthusiast cannot find and purchase a special valve for the washer, then you can take the valve that is used for the fuel system in selected models Vehicle. In this case, you need to look directly at the size and diameter of the fittings. Alternatively, you can consider stores that sell accessories and aquariums for them. All valve devices will necessarily be present in air supply systems. All elastic tubes that are part of the design of aquarium systems are much more practical, since they are able to maintain their elasticity for a much longer period.

In order to upgrade and install the washer check valve device, you need to have several parts in your arsenal:

- valve device;

Elastic polymer tubes of the required size;

Plastic clamps.

The location of the valve being installed is almost irrelevant. In all cases, the top of such a network will be a nozzle, therefore, the outflow of water that is held by the valve is impossible. The device itself must be implemented where it will be most convenient, as well as where the possibility of damage to the device is completely eradicated.

The location of the valve being installed is almost irrelevant. In all cases, the top of such a network will be a nozzle, therefore, the outflow of water that is held by the valve is impossible. The device itself must be implemented where it will be most convenient, as well as where the possibility of damage to the device is completely eradicated.

On special car models, there are certain couplings that cannot speak for themselves about their purpose. So, instead this device it is better to install the valve than to make an extra cut on the tube itself. The technology for installing a new washer valve is quite simple and consists of several stages. As already mentioned, first you need to cut the tube in the place where the device will be installed. After the motorist has determined the direction of opening the valve, you need to put both ends of the already cut tube directly onto the fittings. Then you need to install new part with tubes to body elements by means of clamps. After the motorist turns on the ignition, the washer will also turn on, and at the same time, the injection of fluid into the system will begin.

3. Winter is a time of special attention for car windows.

It is very important to remember one simple detail: if water has already been pumped into the washing system once, then it will be there all the time. With the onset of cold snaps and winter, you can unfreeze the entire network, which will be fraught with the need to replace it. Consequently, the motorist needs to be very careful about all time changes and the weather forecast. In addition, it is necessary to regularly and in a timely manner replace ordinary water or summer washer fluid with a winter "anti-freeze", which is intended for a certain temperature in certain regions.

It is very important to remember one simple detail: if water has already been pumped into the washing system once, then it will be there all the time. With the onset of cold snaps and winter, you can unfreeze the entire network, which will be fraught with the need to replace it. Consequently, the motorist needs to be very careful about all time changes and the weather forecast. In addition, it is necessary to regularly and in a timely manner replace ordinary water or summer washer fluid with a winter "anti-freeze", which is intended for a certain temperature in certain regions.

Subscribe to our feeds in

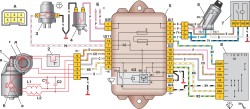

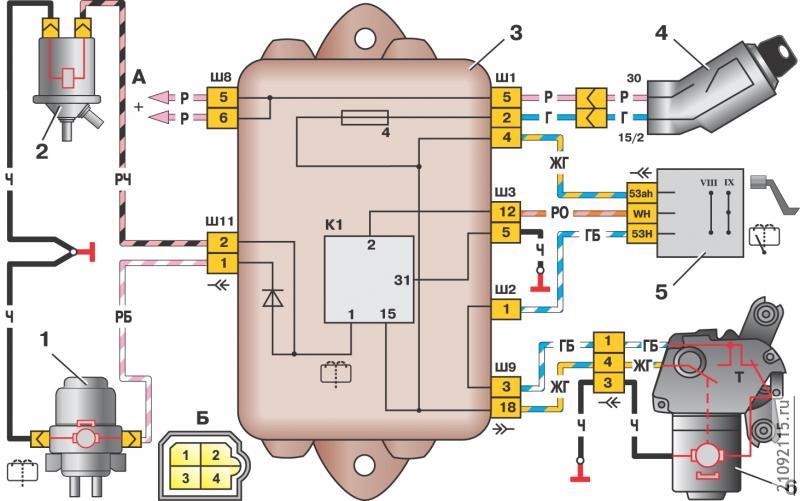

Figure: 7.41. Cleaner and washer connection diagram windscreen: 1 - windshield wiper motor; 2 - thermobimetallic fuse; 3 - washer pump electric motor; 4 - windshield washer solenoid valve; 5 - mounting block; 6 - ignition switch; 7 - ignition relay; 8 - switch of cleaners and glass washers; K3 - windshield wiper relay; A - the order of the conditional numbering of the plugs in the block of the cleaner; B - to terminal "30" of the generator; a - brush of the 2nd speed of the cleaner; b - brush of the 1st speed of the cleaner; c - spring plate of the limit switch; d, e - contact posts of the limit switch; C1, C2 - noise suppression capacitors; L1, L2 - chokes

Windshield wiper kit type 33.5205 consists of electric drive, levers and brushes. The movement of the brushes is parallel. The purifier connection diagram is shown in.

Windshield wipers can be either domestic production, or made in Hungary. They are interchangeable in connection and mounting dimensions. The gear motors (electric motors with gears) of these cleaners are also interchangeable, although they have some design differences.

The cleaner has three operating modes: 1st and 2nd constant (but with different speeds of the brush movement), and the 3rd mode - with intermittent movement of the brushes.

The electric motor of the cleaner is excited by permanent magnets, three-brush, with two rotation speeds. The 1st speed (low) is provided by supplying a supply voltage to the brush "b" (see), and the 2nd speed (high) - by supplying a supply voltage to the brush "a".

To protect the electric motor from overloads when the brushes freeze to the glass, have a high resistance to their movement, or when the wiper mechanism is jammed, a reusable thermo-bimetallic fuse is installed in the wiper. For Hungarian-made geared motors, the fuse is installed under the gear cover on the limit switch panel, while for domestic geared motors the fuse is placed on the cleaner drive bracket.

Intermittent operation of the cleaner is provided by an electronic relay type 52.3747 installed in mounting block... This relay also activates the wiper motor (low speed) when the windshield washer is activated.

The mounting block 2114-3722010 is equipped with a 526.3747 relay without the "R" terminal. Its characteristics are the same as for relay 52.3747. This relay can also be installed in the old mounting block.

Figure: 7.43. Scheme of switching on the headlight cleaner and washer: 1 - headlight cleaners; 2 - solenoid valve for headlight washer; 3 - washer motor; 4 - mounting block; 5 - ignition switch; 6 - outdoor lighting switch; 7 - switch for cleaners and glass washers;

K6 - relay for turning on headlight cleaners; A - the order of the conditional numbering of the plugs in the headlight and rear window wiper pads; B - to terminal "30" of the generator

Figure: 7.45. Rear window wiper switching circuit: 1 - washer pump electric motor;

2 - solenoid valve for enabling rear window washer; 3 - mounting block; 4 - ignition switch; 5 - switch for cleaners and glass washers; 6 - rear window cleaner; A - to terminal "30" of the generator; B - the order of the conditional numbering of the plugs in the rear window wiper block

The washer pump is integrated into one unit with an electric motor. The fluid supply line for washing the windshield is closed by solenoid valve 4 (see), the fluid supply to the headlights is closed by valve 2 (see), and to rear window - valve 2 (see). When you turn on the washer of any of the glasses, voltage is applied to the corresponding valve and it opens the fluid supply in the required direction.

1 - cleaner electric motor;

2 - washer motor;

3 - solenoid valve for switching on the windshield washer;

4 - mounting block;

5 - wiper relay;

6 - ignition switch;

7 - ignition relay;

8 - switch for cleaners and washer.

Windshield cleaner type 32.5205 consists of a gear motor, levers and brushes. The electric motor of the cleaner is three-brush, with excitation from permanent magnets, two-speed. To protect against overloads, a thermo-bimetallic fuse is installed in it.

Technical characteristics of the geared motor:

The cleaner has three modes of operation, they are included with the right steering column switch. Intermittent operation is provided by an electronic relay type 52.3747 or 525.3747 installed in the mounting block. The relay also turns on the low speed of the wiper gear motor when the windshield washer is turned on. The relay must ensure that the electric motor is switched on with a frequency of 14 ± 4 cycles per minute at a speed of rotation of the gear motor shaft of at least 20 min – 1, a temperature of (20 ± 5) ° С and a supply voltage of 14 ± 0.2 V.

When the cleaner operates at low speed in a constant mode, the supply voltage is applied to diametrically opposite brushes. When using the cleaner on maximum speed The "+" supply is supplied to the side brush.

The windshield washer consists of a plastic reservoir with an electric pump installed on the right in the engine compartment, washer nozzles located on the bonnet, and flexible connecting hoses.

The washer is turned on by the right steering column switch, while power is supplied to the pump motor and the windshield wiper relay, which turns the wiper on at low speed if it was turned off or worked in intermittent mode. If the pump fails, it is replaced. Clogged nozzles can be blown backwards or cleaned with line.

Solenoid valve of the washer in a vertical position (with the fittings down) should operate at a voltage of no more than 8.5 V. The resistance of its winding at 25 ° C should be (95 ± 6) ohms.