The personal computer we use in our daily life and the car computer work in a similar way. The computer receives some initial data, processes it according to a given program and displays it on the screen in a form understandable to any user.

INITIAL DATA

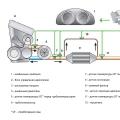

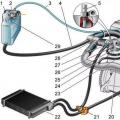

In the case of a personal computer, everything is quite transparent. Data is entered from the keyboard, scanner or read from storage media: hard disk, eg. Where does the information come from onboard carmobile computer, and what is it? Everything is very simple. A modern car is simply teeming with all sorts of sensors and control units. The on-board computer reads information from the controller, and, if necessary, connects to the gap of the fuel level sensor, to the speed sensor, to the ignition circuit, to the diagnostic block, to the fuel consumption sensor and others standard systems... That is, all the information that operates on-board computer, was in the car before it appeared. But we could see only a small part of it. Thus, "route book" is a universal translator from the language of your car. Moreover, new generation models are able to determine the type of controller installed in your car themselves.

DATA PROCESSING

Here is a 100% analogy with a regular computer. In the memory of the car BC there is a certain program that processes the received data. For example, having received information from the level sensor and the fuel consumption sensor, the computer divides one value by another and makes it possible to predict the mileage on the remaining fuel. The same is true for a number of other parameters. The on-board computer program allows you to adjust the readings for fuel consumption, calculation of speed and mileage, etc.

DISPLAY INFORMATION

An important role is played by the way the received and calculated information is displayed. And this directly depends on the type of display installed. The display can be digital, three-, four- or six-digit. And also a liquid crystal (LCD), similar to those that are installed in cell phones and handheld computers. A number of BCs have LCDs capable of displaying information not only in text format, but also in graphic design. Fashion trends, ease of use, information content, led to the fact that LCDs have become the main visual carriers of modern route guides. In the latest versions of BC, the multi-display function has become the norm - the simultaneous display of several parameters. Graphic displays are used with information output in the form of graphic pictures. BK with such displays also allow displaying a larger number of parameters simultaneously.

List of used displays

LCD 8-bit (RGB-selection of the color spectrum by the user), the ability to display 4 parameters simultaneously

-LCD MAGNUM 16-bit (blue background / light text, green background / black text or RGB-selection of the color spectrum by the user, light filter-improvement of contrast when exposed to direct sunlight), the ability to display 6 parameters simultaneously

-LCD Graphic (blue background / light text, green background / black text), the ability to display simultaneously 4 parameters and a graphic image

-LCD 24-bit (blue background / light text, green background / black text or RGB-selection of the color spectrum by the user), the ability to display simultaneously 8 parameters

-P-LED 8-digit (black background / green letters, high contrast / non-freezing - up to minus 40 degrees), the ability to display 6 parameters simultaneously

-P-LED 16-bit (black background / green letters, high-contrast / non-freezing - up to minus 40 degrees), the ability to display 6 parameters simultaneously

-P-LED Graphic (black background / turquoise letters, black background / yellow letters, high-contrast / non-freezing - up to minus 40 degrees), the ability to display simultaneously 11 parameters and a graphic image

- Segment digital indicator (green / red digits), 3/4/6 digit

VOICE SUPPORT FUNCTION

Technological advances have allowed on-board computers to become "talking". Alarm annunciator will instantly draw your attention to overheating in the cooling system, to problems in on-board network... A pleasant female (or male-in bc with two-voice accompaniment) voice will notify you of the need for various kinds of maintenance... Warns about the minimum amount of fuel in the tank. And, simply, wishes you a pleasant journey.

Facilitate design and manufacture

Existing communication standards have made the design and manufacture of an automobile a little easier. A good example of this is the simplification of vehicle instrumentation.

The instrument cluster collects and displays data from various parts of the vehicle. Most of this data is already in use by other modules in the machine. For example, the on-board computer knows the coolant temperature and the engine speed. The controller knows the vehicle speed. Anti-lock controller brake system (ABS) knows if there is a problem with ABS.

All these modules can simply send data to the communication bus. Several times per second, the ECU will send an information packet consisting of a header and data. In the header, it is simply a number that identifies the packet, either the speed or temperature reading, and the data of the number corresponding to that speed or temperature. The dashboard contains another module that knows to look for certain packages - whenever it sees it, it updates the corresponding gauge or indicator with a new value.

Most car makers buy a fully assembled device that is designed to fit the car maker's specifications. This makes the dashboard design job much easier for both the automaker and suppliers. It is easier to tell the automaker which supplier each sensor will be. Instead of saying that a particular wire supplier will give a speed signal and it will be a different voltage between 0 and 5 V and 1.1 V corresponds to 30 mph, the automaker can simply provide a list of data packets. It is then the responsibility of the automaker to ensure that the correct data is output to the communication bus.

It is easier for a supplier to design a dashboard because he does not have to know any details about how the speed signal is generated, or where it goes. Instead, the Dashboard simply monitors the communication bus and updates the sensors when new data is received.

These types of communication standards make it very easy for carmakers to outsource the development and production of components: the carmaker doesn't have to worry about the details of how each sensor or light bulb is wired by the actuator, and the supplier who does dashboard don't worry about what signals are coming from and where.

Intelligent sensors

Clusters are currently used on a smaller scale for sensors. For example, a conventional pressure sensor includes a device that outputs different voltages depending on the pressure applied to the device. Typically, the output voltage is non-linear, temperature dependent and low level voltage that requires amplification. Several sensor manufacturers provide a smart sensor that is integrated with all electronics, along with a microprocessor that allows it to read voltages, calibration using temperature compensation curves, and digital bus pressure outputs.

This saves the automaker from having to know all the details of the sensor and also saves the processing power in the module that these calculations would otherwise have to do. This is done by the supplier, who is responsible for providing accurate information. Another advantage of the smart sensor is that the digital signal passing through the communication bus is less sensitive to electrical noise. Analog voltage passing through a wire can be distorted when it passes certain electrical components, or even from overhead power lines. Communication buses and microprocessors also facilitate multiplexing wiring. Let's take a closer look at how they do it.

The main operating modes of the RSBN equipment are:

- navigation, i.e. flight along a programmed route;

- return to a programmed or unprogrammed aerodrome;

- landing;

- re-approach:

- interplane navigation.

In the "Navigation" mode, the RSBN on-board equipment measures slant range I to radio beacon and azimuth 0 regarding himand also calculated range and set course f e to the selected route point.

The "Navigation" mode assumes flight along a pre-programmed route. To do this, the equipment preliminarily enters the coordinates of airfields, free-standing radio beacons and intermediate route points (MRP).

For aerodromes such parameters are set as:

- orthodromic or geodesic coordinates x, at or X;

- lateral offsets of ADRM relative to the runway center Z m;

- landing courses runway f runway;

- angles of convergence of meridians A (in the equipment, where the geodetic coordinates of aerodromes are programmed f, X, this parameter automatically calculated in the processor).

The onboard equipment also specifies the CCC of ground radio beacons and their type (directional or non-directional).

For MRP, only coordinates are programmed.

The flight along the route using the RSBN is performed by the course method. For this, in the processor of the RSBN onboard equipment, based on the programmed coordinates of the PPM or airfields and the aircraft coordinates calculated according to the data of the onboard autonomous means, target range and set course by formulas

where /? z \u003d 6371 km -

radius of the Earth; from $

^ sun

Correction for the sphericity of the Earth.

In this case, the navigation problem is solved in the orthodromic coordinate system.

The calculated values \u200b\u200bof the parameters are fed to the indicator devices. The pilot's task is to fly the aircraft in such a way that the true heading coincides with the given one.

When the aircraft is in the coverage area of \u200b\u200bthe programmed ADRM, the range and azimuth of the aircraft relative to it are measured and the calculated coordinates are corrected.

For operation in the "Navigation" mode, 88 (non-directional radio beacon) or 176 (directional radio beacon) CHKK are provided.

In the "Return" mode, a distinction is made between "Return to a programmed aerodrome" and "Return to an unprogrammed aerodrome".

Return to programmed airfield mode is similar to the "Navigation" operating mode, except that from a distance of 250 km to the airfield, if there is a radio contact with the ADRM, the "Radio return" submode is switched on in the onboard equipment. In this case, the processor calculates aircraft descent trajectory and signals of trajectory control in the vertical plane are issued, for example, to the ACS. The calculation of the flight trajectory in the horizontal plane (a given course) is carried out taking into account the programmed lateral offset of the ADRM and the angle of convergence of the meridians. As a result, the aircraft is withdrawn at the stage of pre-landing maneuvering to the point of descent initiation (TNS).

Definition set course in mode "Return to unprogrammed aerodrome" at the stage before entering the coverage area, the ADRM is performed by the pilot using a flight chart and aircraft coordinates data obtained from onboard navigation aids, for example, a number system. After entering the ADRM coverage area, if there is a radio contact with it (for this, the pilot must manually set the appropriate CCCs of the RSBN radio beacons of the landing aerodrome) are measured and displayed aircraft azimuth relative to RM and slant range. The pilot performs the pre-landing maneuver before entering the TNS in the aircraft manual piloting mode.

In the "Landing" mode, the onboard equipment switches to work with the PRMG radio beacons. At the same time, the transfer of the equipment from the "Return to the programmed airfield" mode to the "Landing" mode occurs automatically when the aircraft enters the zone of confident reception of the KRM and timing signals according to the readiness signals of the course and glide path channels "Goth. K "and" Goth. Г ", respectively. The pilot manually transfers the equipment from the "Return to an unprogrammed airfield" mode to the "Landing" mode.

In the "Landing" mode, the onboard equipment determines aircraft deviation from the course and planning planes set by the landing beacons, and runway distance (interacting with the RPD).

Information about deviations from the course and glide path, as well as the distance to the start of the runway, is issued to the appropriate indicator devices.

To work in the "Landing" mode, 40 CSC are used.

The "Inter-aircraft navigation" mode, provided in certain types of RSBN onboard equipment, is designed to assemble the aircraft into a group (submode "Meeting") and performing a flight in battle formations (sub-mode "OVK"),

In the "Inter-aircraft navigation" mode on the slave aircraft, bearing and range to the leading aircraft. In this case, the equipment of the distance-numbered channel of the leading aircraft operates in the mode of retransmission of range request signals. To work in this mode 28 CCCs are used.

The bearing to the leading aircraft is determined by the amplitude method - the minimum method when receiving a range response signal by spaced antennas.

An article about the work of an on-board computer in a car - types of computers, features of functioning. At the end of the article - a video about an on-board computer for carburetor machines.

The content of the article:

A modern car, "stuffed" with all kinds of electronics, with complete confidence can be called a "computer on wheels." Various microprocessors, programs and sensors are designed to minimize the so-called “human factor” (human driver errors) and to make the vehicle operation as convenient and comfortable as possible.

And the main role in electronic control the car is assigned to the "on-board computer", which is a computing device for reading and processing data on the operation of the main systems and components of the car with the subsequent display of the results on the monitor screen (or LCD).

There was a time when on-board computers were only equipped expensive cars premium class. But technical progress does not stand still, and such devices are already being installed serially even in inexpensive cars... In addition, in some models where the "onboard" is not installed by the manufacturer, it can be installed additionally. Below we will look at what kind of on-board computers are, what they are capable of and how they work.

When dividing automobile "bortoviks" into types, their purpose and functionality are taken into account, which improves the operation of the car's systems, and the comfort during its operation.

Accordingly, on-board car computers can be:

- Universal (carputers).

- Service.

- By route.

- Managers.

Functionality and principle of functioning of autocomputers

This on-board computer (carputer) is a kind of hybrid and includes the following functionality:

- pC personal computer;

- GPS navigation via satellite;

- tV set;

- dVD player.

- sensor system with executive mechanics for parking sensors;

- a system for adjusting injectors and ignition timing (for power control and fuel economy);

- management of two-way radio communication.

At the moment, the designs of on-board carputers are not standardized (with the exception of LCD monitors: 1DIN, 2DIN, 1 / 2DIN). As a result, the design of the carputer system units may vary. Most often, a universal "bortovik" is designed in the same way as a regular personal computer, with the same basic components.

The only difference is that in "bortoviks" the system drive consists of electromechanical hard drives in the 2.5-inch format. They also use solid state drives or electronic flash memory chips (in older models).

The carputer removed from its car cell can be used like a regular PC, from a 12V power supply.

On-board car computers universal type (carputers) are poorly integrated into the electrical network of the vehicle and are offered separately as an additional option. On the positive side, if such a computer breaks down, the overall electronic functionality of the car will not be affected.

The universal "bortovik" is easy to operate and can be easily installed both in a simple injection vehicle and in a diesel engine, as well as with a turbocharger. Another plus of this universal device is that when changing a car, you do not need to purchase a new on-board computer, and to successfully reinstall the old "on-board" you only need to update the software.

Highly specialized (with minimal set functions) "bortovik-marshals" appeared much earlier than the serial car computers "CarPC" from the American firm "Tracer", which entered the market in 2000. While highly specialized "minibuses" began to be installed on rally cars back in the 70s of the last century, in the 90s they have already firmly taken their place in the serial standard configuration many passenger cars.

The main duty of the route on-board autocomputer is to calculate the necessary parameters and track the coordinates of the car. In the basic configuration, the route "bortovik" is not interconnected with the navigation satellite system GPS, however in modern models cars, it is capable of working together with a satellite navigator.

In addition, the "route book" is equipped with a graphic display with the ability to display on it not only route data, but also a geographic map indicating the location of the car. In this case, the number of parameters displayed on the display can be increased.

The trip computer reads, processes and displays the following data:

- average speed indicator for a specific time of movement and for the entire journey;

- average fuel consumption;

- the length of the path;

- planned time of arrival at the specified point;

- how many kilometers the car has traveled during the entire trip;

- downtime;

- the cost of fuel that was consumed for travel;

- fuel consumption in various modes of travel (speed gain, coasting, braking) and other parameters.

Quite often, a service on-board autocomputer is called "diagnostic". This "bortovik" is a client block of the general diagnostic systemidentifying system and nodal malfunctions, which greatly facilitates their elimination in service repair centers.

The service "bortovik" is rarely used as an independent device. As a rule, the diagnostic functions are performed by the system computer, which controls the components and mechanisms of the car (according to the principle of the trip autocomputer).

The service "bortovik" performs the following work:

- diagnoses the engine and saves the detected error code in the electronic memory;

- monitors the condition of the brakes;

- controls the presence of oil in the main systems and assemblies;

- diagnoses the electrical network of the car.

The control "bortovik" is the main unit in the electronic system control. The most common configuration of a control on-board computer is a single system with multiple branches and digital specialized functionality. Less common are options with several independent digital computing units, with sensors and executive mechanics.

The main job of the “bortovik” manager is to manage:

- nozzles;

- ignition;

- brake anti-lock;

- automatic transmission;

- high-speed mode (cruise control);

- climate control.

The control "bortovik" is installed in cars with gasoline engines injection type, as well as with diesel units, except for internal combustion engines with carburetors.

Conclusion

An on-board car computer is, first of all, a useful necessity that increases safety and enables the driver to timely identify problems and abnormal situations. Utility this device It is difficult to overestimate, since it allows you to avoid multiple chain breakages of several parts and assemblies, which will save not only money, but also time.

As for the complexity of working with car computers, then, of course, it will be much easier for those who are familiar with the work of an ordinary home personal computer. Other drivers who do not have experience with a PC will have to work a little and spend some time studying the "hardware".

Video about on-board computer for carburetor machines:

Computers have become commonplace in everyone modern car... On-board computers keep under control the significant nuances of the car's functioning, including braking and steering.

They are also responsible for the suspension, instrumentation, and engine performance. The driver and passengers cannot operate the computers installed in the car; their programs are stored in ROM (permanent memory devices) and cannot be changed.

Computers were initially installed in cars to reduce air pollution after the [US] government passed laws setting emission standards exhaust gases in atmosphere. Detectors in exhaust pipe analyze emissions and transfer information to the processor. The processor, in turn, adjusts the combustion efficiency to reduce harmful emissions.

Detectors, wherever they are installed, collect information about the condition of the wheels, brakes and attachment system to ensure a safe soft ride. Computers can make dozens of small fixes per second, constantly adapting to changing conditions. They prevent the wheels from slipping before braking. The computer adjusts the brake water level to keep the wheels spinning. Computers help to mitigate shaking on rough roads by directing pressure to the springs. In addition, computers allow you to improve car through innovations such as four-wheel steering and on-board navigation, which informs the driver of the eft) position and offers the shortest route to the destination.

Renault. On-board computer... How it works after activation.

Renault-Logan, Renault_Sandero, Renault-Duster, Lada-Largus, Trip computer, On-board computer,

What shows on-board computer?

Petrovsky Autocentre in the heading " useful tips"talks about what information is shown onboard…

Engine monitoring

To make a car engine work, air and fuel are mixed in the cylinder, and then the mixture is burned under pressure, releasing energy. The computer, using data on air flow, fuel, temperature in the engine and exhaust, determines the most effective mixture and the amount of fuel. The spark plugs are also controlled by a computer that ensures correct timing. The computer makes constant adjustments for each spark plug and cylinder to ensure maximum engine efficiency.

Slip control

When the driver applies the brake when slippery road, unexpected brake pressure can cause one or two wheels to lock, meaning they stop turning while the machine continues to move. Traction stops and the driver may lose control. A rotation sensor detects when the wheels should stall. A computer with the help of a pump, presses on the brakes at a speed of 10 times per second, which relieves pressure and allows the wheels to rotate, thereby preventing slipping.

Shock absorption

The weight of the machine is supported by wheels, springs and shock absorbers. The car shakes while driving, and the more uneven the terrain, the stronger the shocks and impacts. Sensors detect movement of the shock absorbers and adjust pressure to ensure a smooth ride. When the load in the car is unbalanced, for example, the trunk is overloaded, the computer supplies air to where it is needed to keep the chassis level.

Control Panel

Computer gauge displays give the car a jet-like appearance. Dial gauges gave way to liquid crystal displays. These displays project data directly onto windshield, freeing the driver from the need to look away from the road.