Introduction

1. Literary review

3. Kinematic Analysis mechanism

4. Kinetostatic analysis of the mechanism

Conclusion

Design and research of the crank-slider mechanism of the screen

The volume of the explanatory note was 37 sheets, 4 illustrations, 10 tables, 2 annexes, 3 sources used.

The object of course design is a crank-slider mechanism. IN term paper the study of the crank-slider mechanism was carried out. Structural, kinematic, kinetostatic analyzes were carried out.

In the structural analysis, the composition of the crank-slide mechanism was determined. In the kinematic analysis, the speeds and accelerations of the points of the mechanism are determined by the methods of plans and kinematic diagrams. In kinetostatic analysis, a force calculation was carried out using the force plan method and the Zhukovsky method.

Introduction

The purpose of the course work is to consolidate and systematize, expand theoretical knowledge, and develop the calculation and graphic skills of students.

The development of modern science and technology is inextricably linked with the creation of new machines. In this regard, the requirements for new developments are becoming more and more stringent. The main ones are: high performance, reliability, manufacturability, minimal dimensions and weight, ease of use and efficiency.

A rationally designed machine must meet social requirements - safety of service and creation best conditions for service personnel, as well as operational, economic, technological and production requirements. These requirements represent a complex set of tasks that must be solved in the process of designing a new machine.

The design object of this course work is a crank-slider mechanism.

The theory of mechanisms and machines is a science that studies the structure (structure), kinematics and dynamics of mechanisms in connection with their analysis and synthesis.

The aim of the theory of mechanisms and machines is the analysis and synthesis of typical mechanisms and their systems.

The problems of the theory of mechanisms and machines are diverse, the most important of them can be grouped into three sections: analysis of mechanisms, synthesis of mechanisms and the theory of automatic machines.

The analysis of the mechanism consists in the study of the kinematic and dynamic properties of the mechanism according to its given scheme, and the synthesis of the mechanism consists in designing the scheme of the mechanism according to its given properties.

From all of the above, it follows that the theory of mechanisms and machines, in conjunction with courses in theoretical mechanics, machine parts, engineering technology, strength of materials, is a discipline directly dealing with the problems set forth earlier. These disciplines are fundamental in the training of specialists working in the field of mechanical engineering.

When solving problems of designing kinematic schemes of mechanisms, it is necessary to take into account structural, metric, kinematic and dynamic conditionsensuring the reproduction of a given law of motion by the designed mechanism.

Modern methods of kinematic and kinetostatic analyzes are linked to their structure, i.e., the method of formation.

Structural and kinematic analyzes of mechanisms are aimed at studying the theory of the structure of mechanisms, studying the movement of bodies that form them, from a geometric point of view, regardless of the forces causing the movement of these bodies.

The dynamic analysis of mechanisms aims to study the methods of determining the forces acting on the bodies that form the mechanism, during the movement of these bodies, the forces acting on them, and the masses that these bodies possess.

1. Literary review

When studying the mechanism, methods of calculation and design of modern automated and high-performance machines are used. A rationally designed machine must meet the requirements for safe maintenance and the creation of the best conditions for the operating personnel, as well as operational, economic, technological and production requirements. These requirements represent a complex set of tasks that must be solved in the process of designing a new machine.

The solution to these problems at the initial design stage consists in the analysis and synthesis of the designed machine, as well as in the development of its kinematic scheme, which ensures the reproduction of the required law of motion with sufficient approximation.

To perform these tasks, it is necessary to first study the basic provisions of the theory of machines and general methods kinematic and dynamic analysis and synthesis of mechanisms, as well as acquire skills in applying these methods to the study and design of kinematic schemes of mechanisms and machines different types.

A machine is a device created by man for the study and use of the laws of nature in order to facilitate physical and mental labor, increase its productivity and facilitate it by partial or complete replacement a person in his labor and physiological functions.

In terms of the functions performed by machines, machines can be divided into the following groups:

a) power machines (motors and generators);

b) working machines (transport and technological machines);

c) information machines (mathematical and control machines);

d) cybernetic machines.

With the development of modern science and technology, systems of automatic machines are increasingly used. A set of automatic machines, interconnected and designed to perform a certain technological processis called an automatic line. Modern advanced and perfect machines usually represent a collection of many devices, in the operation of which the principles of mechanics, thermal physics, electrical engineering and electronics are put.

A mechanism is an artificially created system of bodies designed to transform the movement of one or more bodies into the required movements of other bodies. According to their functional purpose, the mechanisms of the machine are usually divided into mechanisms of motors and converters; transmission mechanisms; executive mechanisms; mechanisms of management, control and regulation; mechanisms for feeding, transporting, feeding and sorting the processed media and objects; mechanisms for automatic counting, weighing and packaging of finished products.

Despite the difference in the functional purpose of the mechanisms of certain types, there is much in common in their structure, kinematics and dynamics. Therefore, it is possible to apply general methods based on the basic principles of modern mechanics in the study of mechanisms with different functional purposes.

The main types of mechanisms:

1) rod mechanisms are used to transform motion or transfer of force in machines;

2) in many cases there is a need to design mechanisms, which include elastic links in the form of springs, springs, elastic beams, etc .;

3) gear mechanisms are used to transfer rotary motion between shafts with parallel or non-parallel axes;

4) cam mechanisms are used to communicate periodic or limited episodic movement to the slave link of the mechanism at a given

specific or chosen law;

5) as flexible links transmitting motion from one rigid body in the mechanism to another, are practically used various shapes cross-section belts, ropes, chains, threads, etc .;

6) frictional mechanisms - mechanisms in which the transfer of motion between contacting bodies is carried out due to friction;

7) movement mechanisms with stops;

8) wedge and screw mechanisms are used in of various kinds clamping devices or in devices in which it is required to create large forces on the output side with limited forces acting on the input side;

9) wider possibilities in terms of reproducing the laws of motion of the driven links in comparison with purely lever, gear or other mechanisms are given by the so-called combined mechanisms, in which lever, gear, cam and other mechanisms are combined in various combinations;

10) mechanisms of variable structure are used, if necessary: \u200b\u200bto protect the links of mechanisms from accidental overloads; carry out the required movements of the driven links, depending on the presence or absence of payloads; change the speed or direction of movement of the driven link of the mechanism without stopping the engine and in many other cases;

11) mechanisms with a given relative movement of the links;

12) hydraulic mechanisms - a set of translational or rotary mechanisms, a source of injection working fluid, control and regulating equipment;

13) pneumatic mechanisms are piston or rotary mechanisms in which movement is carried out by energy compressed air, i.e. gas in these mechanisms is used as an energy carrier;

The most important stage in the design of machines is the development of the structural and kinematic schemes of the machine, which largely determine the design of individual units and parts, as well as performance cars .

In this course work, the crank-slider mechanism will be considered.

The crank mechanism is one of the most common. It is the basic mechanism in all piston (engines internal combustion, compressors, pumps, gas expansion machines), agricultural (mowers, cutters, combines) and forging machines and presses.

For each functional purpose, the design must take into account the specific requirements for the mechanism. However, the mathematical relationships describing the structure, geometry, kinematics and dynamics of the mechanism will be practically the same for all different applications. The main or main difference between TMM and academic disciplines that study design methods special machines, in that TMM focuses on the study of methods of synthesis and analysis, common for a given type of mechanism, independent of its specific functional purpose.

The rocker crank-slider mechanism is a crank-slider mechanism with an infinitely long connecting rod, which has structurally turned into a slider-stone. Its guide, the curtain, is one piece with the slider making a harmonious movement. Therefore, the movement of the slider is proportional to the cosine of the crank angle. This mechanism, also called a yoke sinus mechanism, is used in small piston pumps and compressors, devices for the harmonious movement of the slider or for determining the values \u200b\u200bproportional to the sine or cosine of the crank angle, etc.

Depending on the purpose and operating conditions, mechanisms with higher pairs can be divided into a number of types, of which the main ones are cam, gear, friction, Maltese and ratchet.

The cam mechanism is a mechanism, the upper pair of which is formed by links called - cam and pusher. They differ in the shape of their elements. The shape of the pusher element can be arbitrary, and the shape of the cam element is chosen such that, for a given pusher element, the required law of motion of the driven link is provided. The simplest cam mechanism is three-link, consisting of a cam, a pusher and a rack; its leading link is usually the cam.

Gear mechanism, i.e. the mechanism, the upper pair of which is formed by toothed links, can be considered a special case of a cam mechanism, since a toothed link is like a multiple cam. Gear mechanisms are mainly used to transfer rotary motion between any two axes with a change in the angular speed of the driven shaft.

A frictional mechanism is a mechanism in which the transfer of rotational motion between the links that form the upper pair is carried out due to friction between them. A simple friction mechanism consists of three links - two rotating circular cylinders and a rack.

Friction mechanisms are often used in continuously variable transmissions. With a constant angular speed of the disc, by moving the wheel-roller along its axis of rotation, you can smoothly change not only its angular speed, but even the direction of rotation.

The Maltese mechanism converts the continuous rotation of the driving link - a crank with a pin into the intermittent rotation of the slave - "cross".

The ratchet mechanism with a leading pawl is used to convert the reciprocating movement into an intermittent rotary one in one direction. The leading rocker with a pawl gradually turns the ratchet wheel. The dog prevents the wheel from turning in back side... The top pair here is formed by a dog and a ratchet wheel.

Maltese and ratchet mechanisms are widely used in machine tools and appliances.

2. Structural Analysis mechanism

The roar mechanism (Figure 1) consists of five links: 1 - OA crank, making a rotational movement; 2 - slider A, performing a reciprocating motion along the wings; 3 - rocker arm ABC, making a rocking motion around the hinge B; 4 - connecting rod CD; 5 - slider D, performing a reciprocating motion; as well as seven kinematic pairs.

Figure 1 - Diagram of the linkage mechanism

Determination of the degree of mobility of the mechanism

The degree of mobility of the mechanism is determined by the Chebyshev formula:

W \u003d 3n - 2P 5 - P 4, (2.1)

Where n is the number of moving links for the mechanism, n \u003d 5;

Р 5 - the number of kinematic pairs of the V class, Р 5 \u003d 7;

Р 4 - the number of kinematic pairs of class IV, Р 4 \u003d 0.

Substituting numeric values, we get:

W \u003d 3 5 - 2 7 - 0 \u003d 1.

Consequently, the degree of mobility of the mechanism, showing the number of leading links in the investigated mechanism, is equal to 1. This means that one leading link is sufficient for the operation of the mechanism.

Breakdown of the mechanism into structural groups

According to I.I.Artobolevsky's classification, we divide the mechanism under study into structural groups. The screening mechanism (Figure 1) consists of a leading link 1 and two structural groups of II class of order 2.

Both structural groups belong to the third type: the first - (links 2 and 3), and the second - (links 4 and 5). Structural groups consist of 2 links and 3 kinematic pairs. The formula for the structure of the mechanism is:

3. Kinematic analysis gear transmission

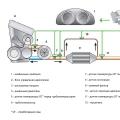

The drive of the linkage mechanism of the screen, consisting of a planetary gearbox and a gear train, is shown in Figure 2. The planetary gearbox, consisting of a carrier and four wheels with external gear, has gear ratio i H3 \u003d 10. The gears installed after the planetary gear have the following numbers of teeth: z 4 \u003d 12, z 5 \u003d 28.

Figure 2 - Drive linkage

Gear ratio gear wheels 4 and 5 is determined by the formula

![]()

The total gear ratio of the entire drive is determined by the formula

Here are some parameters of the gear and planetary gear: m I \u003d 3.5 mm; m II \u003d 2.5 mm; the center distance of the gears - a w \u003d 72 mm; angular speed of the drive shaft (motor shaft) - ω d \u003d 150.00 rad / s. Let us determine the angular velocity of the driving link of the screening mechanism - ω 1 by the formula:

ω 1 \u003d ω d / i 15, (3.3)

ω 1 \u003d 150 / 23.33 \u003d 6.43 rad / s.

4. Kinematic analysis of the linkage

The purpose of the kinematic analysis is to determine the speeds and accelerations of the characteristic points of the lever-slide mechanism of the screen.

Building plans for the provisions of the mechanism

The parameters of the investigated mechanism (Figure 1) are shown in Table 1.

Table 1 - Mechanism parameters

| ω 1, rad / s |

||||||

The scale of the mechanism plan is determined by the formula

where l OA is the true length of the OA crank, m;

OA - the length of the OA crank in the drawing, mm.

Substituting the data, we get

m l \u003d ![]()

The procedure for constructing a plan of provisions this mechanism:

- we mark on the drawing the position of the centers of rotation of the crank t. O and the rocker mechanism t. C;

- outline the trajectories of points A and O of these parts;

- we will divide the trajectory of movement of the OA crank into 12 equal parts;

- from the obtained points A 0, A 1, A 2, ..., A 12 draw lines to point B;

- from point B we draw perpendiculars, taking the angle ABC equal to 90◦;

- we determine the position of point C at certain positions of the OA crank;

- we postpone the segment of the CD on a scale in such a way that the point D lies on the ATS straight line;

- using the serif method, we determine the position of point D at certain positions of the crank OA;

- clockwise put the crank OA in a new position and repeat the construction;

- we designate in the drawing the trajectories of the extreme points of the links and the position of the centers of mass of the links.

Building a diagram of the displacement of the working link

To construct kinematic diagrams using the method of graphic differentiation, 12 positions of the movement of the mechanism (along the crank OA) are considered.

Consider the movement of the output link. We will take the zero position as the starting point (it is also the last one). The abscissa axis is divided into 12 equal parts. Along the ordinate, we plot the distance traveled by point D in a straight line (on link 5) from the leftmost position to the rightmost position corresponding to a given moment in time. Using the obtained points, we construct a displacement diagram φ \u003d φ (t) of the output link.

Determine the scale of displacement from the angle of rotation and in time:

where l is the distance in the drawing full turnover crank ОА, mm;

n is the number of revolutions per minute of rotation of the OA crank, rpm, determined by the formula

![]()

Taking the length of a full turn in the drawing 180 mm, we determine the scale

![]()

Let's take the scale of displacements a little smaller.

m s \u003d

Graphical differentiation of speed and acceleration diagrams of the output link. Choosing an arbitrary pole distance H v \u003d (40 ... 60 mm) \u003d 50 mm, we calculate the scale of the velocity diagram m V

(4.5)

(4.5)

We replace the displacement curve with a set of chords, select the pole distance and build a coordinate system. To do this, on the graph of velocities parallel to the chords, we build straight lines passing through the pole. From the point of intersection of a straight line with the S axis, draw a straight line parallel to the t axis to the desired position. We connect the obtained points in series, resulting in a graph of the speeds of the output link. Similarly to the velocity diagram, choosing arbitrarily the value of the pole distance H A equal to 40 mm, we calculate the scale of the acceleration diagram m A

(4.6)

(4.6)

Plotting an acceleration diagram is similar to plotting a velocity diagram.

Building speed plans for three positions

To plot, you need to know the speed of point A in the rotating motion of the link OA. Let's define it from the formula:

V A 1 \u003d ![]()

To build plans of speeds, we will choose the positions of the mechanism: the first, seventh and tenth. For all positions, the construction is similar, so we describe the construction algorithm. Let's define the characteristic points for construction: pivot points - A1, B6, D6, C3; and basic - A3, D4. Let's compose the vector equations of the velocities of these points:

(4.8)

(4.8)

(4.9)

(4.9)

We build a speed plan. The OA crank moves at a constant speed. From the pole - P of the plan of speeds in the direction of rotation of the crank perpendicular to OA, we postpone the velocity vector (Pa 1), conventionally taking its length equal to 80 mm. Then we determine the scale of the speed plan:

m V \u003d ![]()

In accordance with the system of equations (4.8), we make the corresponding constructions. To do this, draw a straight line parallel to BA through point a 1, and draw a straight line perpendicular to AB from the pole P, since the speed B6 is zero. Thus, we get point a 3. Since point C belongs to the ABC link, then on the plan of velocities it can be found using the similarity theorem. We determine its location by the ratio of the lengths of the ABC lever and the ratio of the lengths of the speeds a 3 to 6 c 3. Then, we use the system of vector equations (4.9). Having found a point with 3, we set aside from it the perpendicular to the SD connecting rod. Draw a straight line parallel to the VD line from the pole; since the speed of the point b 6 is equal to zero, we thereby obtain the point d 4. The positions of the velocity vectors of the centers of mass are determined from the similarity theorem. Since the center of mass of the link OA is located at point O, then on the plan of velocities it will be at point P. The position of the center S 4 on the plan of velocities is determined on the line with 3 d 4, in the middle of the segment. On the segment b 6 a 3, we find from the proportion (4.11) the position of the point S 3:

For all three positions, we will calculate the velocities from the graphical construction, taking into account their recalculation to their full size, measuring the length of the vectors corresponding to the velocities and multiplying them by the scale of the velocity plan:

Table 2 - Actual values \u200b\u200bof the speeds of the characteristic points of the linkage mechanism in three positions

| Mechanism position |

Point speed |

Vector length from the plan (pn), mm |

||

Building acceleration plans for three positions

Let us compose systems of vector equations for the acceleration of the linkage mechanism by analogy with the vector equations of velocities:

(4.13)

(4.13)

(4.14)

(4.14)

Let's define the normal acceleration of point A of the link OA. Since the link rotates at a constant speed, there is no tangential acceleration. Then we have:

Let us give an algorithm for constructing a plan of acceleration analogs using the example of the first position. We carry out the rest of the construction in the same way.

We begin the construction of the plan by constructing the acceleration of point A. Let us postpone it on a scale from the pole P, and the direction of the vector from A to O. Determine the scale of accelerations, taking arbitrarily in the drawing the length of the acceleration a 1 \u003d 80 mm:

m a \u003d ![]()

Let us determine the angular velocities of the ABC and SD links. We find their values \u200b\u200bby the formula (4.17), and are directed parallel to the corresponding links from the base point.

(4.17)

(4.17)

We find the angular velocity for each link from the velocity plan. Let's summarize the obtained values \u200b\u200bin Table 3.

Table 3 - Angular speeds of links and normal accelerations

| Position |

Speed |

Value, m / s |

Normal acceleration |

Value, |

Scale value, mm |

The construction is carried out using a system of vector equations. The tangential accelerations are directed perpendicular to the links. Considering all this, we will construct a plan of accelerations for the positions of the mechanism: 1, 7, 10. Point with 3 is found by analogy with the plan of speeds. We find the Coriolis acceleration by the formula:

![]() (4.18)

(4.18)

![]() (4.19)

(4.19)

We will summarize the obtained values \u200b\u200bin Table 4. It is deposited in the direction of rotation 90 o from the velocity vector. The relative velocity has a direction parallel to the motion, putting the vectors in order. Find point a 3 and d 4.

Table 4 - Calculation of Coriolis acceleration

The results of all calculations by the graphical method and differentiation are summarized in Table 5.

Table 5 - Convergence table

We find the discrepancies in the values \u200b\u200bof speeds and accelerations by the formulas:

![]() (4.20)

(4.20)

![]() (4.21)

(4.21)

where is the value of the acceleration from the plan, m / s 2;

- value of acceleration from the diagram, m / s 2;

V D4 - the value of the speed from the plan, m / s;

V pp D4 - the value of the speed from the diagram, m / s.

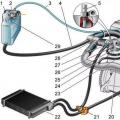

5. Kinetostatic analysis of the mechanism

The purpose kinetostatic analysis is the finding of inertial forces and the determination of reactions in kinematic pairs.

From the first sheet of drawings, we transfer the plan of the mechanism in the first position, and also transfer the plan of accelerations of this position and the plan of speeds turned 90 0 counterclockwise.

Determination of the weight of the links of the mechanism

The weight of the links is determined by the formula

G i \u003d m i ∙ g, (5.1)

where g is the acceleration due to gravity, g \u003d 9.81 m / s 2.

The obtained values \u200b\u200bare summarized in table 6.

Table 6 - Weight and mass of links

| Parameter |

|||||

| Weight, kg |

|||||

Determination of moments of inertia forces and inertia forces of links

Let's find the force of inertia of each link separately.

Force Ф И is directed opposite to the full acceleration of point S and can be determined by the formula

where m is the mass of the link, kg;

and S is the acceleration of the center of mass of the link, m / s 2.

Substituting numerical values, we get Ф 1 \u003d Ф 2 \u003d 0,

The moment of inertia M And a pair of inertial forces is directed opposite to the angular acceleration e of the link and can be determined by the formula

where is the moment of inertia of the link relative to the axis passing through the center of mass S and perpendicular to the plane of the link movement, kg ∙ m 2,

Determine the angular acceleration by the formula

Substituting the numerical values \u200b\u200bin the formulas (5.3-5.4), we get the values \u200b\u200bthat we will enter in table 6.

Table 6 - Moments of inertia forces and inertia forces of links

| The quantities |

|||||

Determination of points of application of forces

Consider the groups of asura separately each to find reactions. The calculation will be carried out with the latter. For rotational pairs, the reactions are decomposed into two - parallel and perpendicular. We direct the force of useful resistance against the forces of inertia.

Determination of reactions in a kinematic pair

We start the calculation with the last structural group. We draw a group of links 4 and 5, we transfer all external loads and reactions to this group. We consider this group to be in equilibrium and compose the equilibrium equation

The value is decomposed into two components: normal and tangential.

![]() (5.6)

(5.6)

We find the value from the equilibrium condition relative to the point D for the fourth link.

where, h 1, are the shoulders of forces to point D, determined from the drawing m.

(5.8)

(5.8)

We build a plan of forces, from where we determine the values,. We obtain the following values, taking into account the scale of forces m F \u003d 10 N / mm:

![]()

![]()

Considering that the slider can also be considered separately, we get that the force is applied in t.D, since the distance b \u003d 0. We determine the directions.

Similarly, we compose the equilibrium equation for the second Asura group.

We are not looking for the reaction of the slider 2 to the rocker arm, because it is not so important.

We build a power polygon, from where we determine the unknown reactions. We get the following values, taking into account the scale of forces:

Determination of the balancing force

We draw the leading link and apply the acting loads. To keep the system in equilibrium, we introduce a balancing force, which is applied at point A perpendicular to the link AO. The diagram shows that the balancing force is equal to the reaction

Determination of the balancing force by the Zhukovsky method

We rotate the speed plan of the mechanism by 90 ° and apply acting forces and inertial forces to it. Then we compose the equilibrium equation, considering the velocity plan as a rigid body, relative to the pole.

Substituting numerical values, we get

Determine the error in calculating the balancing force using the plan of forces method and Zhukovsky's method using the formula

(5.11)

(5.11)

Substituting numerical values, we get

![]()

Conclusion

In this course work, the analysis of the crank-slider mechanism was carried out.

In the literature review, we got acquainted with the principles of operation of various mechanisms. As a result of the analysis, the following types of research were carried out: structural, kinematic, kinetostatic and the synthesis of gearing.

During the structural analysis, the structure and degree of mobility of the mechanism were determined.

In kinematic analysis, velocities and accelerations were determined using two methods: the method of plans and the method of graphical differentiation. The velocities and accelerations of point D for the first position turned out to be equal to 0.28 m / s, 0.27 m / s and 5.89 m / s 2, 5.9 m / s 2, respectively, errors - 2.1% and 1, 2%. For the seventh position, the speeds and accelerations are equal to 0.5 m / s, 0.5 m / s and 8.6 m / s 2, 8.5 m / s 2, the errors were 0% and 2.3%. For the tenth position, the speed and acceleration turned out to be 2.05 m / s, 1.98 m / s and 3.6 m / s 2, 3.7 m / s 2, the errors are 2.3% and 2.6%. It can be argued that the calculations were performed correctly, since the error for speeds does not exceed 5%, and for accelerations less than 10%.

In kinetostatic analysis, a force calculation was carried out by two methods. We used the method of plans of forces and the method of Zhukovsky. According to the method of plans of forces F UR turned out to be equal to 910 N, and according to the method of Zhukovsky - 906 N, the error was 2.3%, which does not exceed the permissible norms. It can be concluded that the force plans method is more laborious than the Zhukovsky method.

List of sources used

1 Artobolevsky I.I. Theory of mechanisms and machines: Tutorial.- 4th ed., Add. pererab.-M.: Nauka, 1988.-640 p.

2 Korenyako A.S. Course design on the theory of mechanisms and machines: -5th ed., revised. - Kiev: Vishcha school, 1970. - 332 p.

3 Kozhevnikov S.N. Theory of mechanisms and machines: Textbook.- 4th ed., Revised.-M.: Mechanical engineering, 1973.-592 p.

4 Marchenko S.I. Theory of mechanisms and machines: Lecture notes. - Rostov n \\ D: Phoenix, 2003 .-- 256 p.

5 Kulbachny OI .. The theory of mechanisms and machines design: Textbook.-M .: Higher school, 1970.-228

1. Structural Analysis mechanism

The crank-slider mechanism is presented.

The number of degrees of the mechanism under study is determined by the Chebyshev formula:

(1)

where n - the number of moving links in the studied kinematic chain; p 4 and p 5 - respectively, the number of pairs of the fourth and fifth class.

To determine the value of the coefficient n let's analyze the block diagram of the mechanism (Figure 1):

Picture 1 - Structural scheme mechanism

The structural diagram of the mechanism consists of four links:

1 - crank,

2 - connecting rod AB,

3 - slider B,

0 - rack,

wherein links 1 - 3 are movable links, and rack 0 is a fixed link. It is represented as part of a structural diagram with two hinged fixed supports and a slide guide 3.

Hence, n \u003d 3.

To determine the values \u200b\u200bof the coefficients p 4 and p 5 we will find all the kinematic pairs that are part of the considered kinematic chain. We enter the results of the study in table 1.

Table 1 - Kinematic pairs

| № | Kinematic pair (KP) | Kinema diagram tic pair |

Kinema class tic pair |

The degree of mobility |

||||||

| 1 | 0 – 1 | rotational |

||||||||

| 2 | 1 – 2 |  |

rotational |

1 | ||||||

| 3 | 2 – 3 |  |

rotational |

1 | ||||||

| 4 | 3 – 0 |  |

rotational |

1 | ||||||

From the analysis of the data in Table 1, it follows that the investigated iCE mechanism with an increased piston stroke consists of seven pairs of the fifth class and forms a closed kinematic chain. Hence, p 5 \u003d 4, a p 4 \u003d 0.

Substituting the found values \u200b\u200bof the coefficients n, p 5 and p 4 into expression (1), we get:

To identify the structural composition of the mechanism, we divide the scheme under consideration into Assur structural groups.

The first group of links 0-3-2 (Figure 2).

Figure 2 - Structural group of Assur

This group consists of two moving links:

connecting rod 2 and slider 3;

two leashes:

and three kinematic pairs:

1-2 - rotational pair of the fifth grade;

2-3 - rotational pair of the fifth class;

3-0 - forward pair of the fifth grade;

then n \u003d 2; p 5 \u003d 3, a p 4 \u003d 0.

Substituting the revealed values \u200b\u200bof the coefficients into expression (1),

Consequently, the group of links 4-5 is an Assur structural group 2 of class 2 of order 2 of the type.

The second group of links 0-1 (Figure 3).

Figure 3 - Primary mechanism

This group of links consists of a movable link - crank 1, rack 0 and one kinematic pair:

0 - 1 - rotational pair of the fifth class;

then n \u003d 1; p 5 \u003d 1, a p 4 \u003d 0.

Substituting the found values \u200b\u200binto expression (1), we get:

Consequently, the group of links 1 - 2 is indeed the primary mechanism with mobility 1.

Structural formula of the mechanism

MECHANISM \u003d PM (W \u003d 1) + SGA (class 2, order 2, type 2)

2. Synthesis of the kinematic scheme

For the synthesis of the kinematic scheme, it is first necessary to set the scale factor of the lengths μ ℓ. To find μ ℓ, it is necessary to take the natural size of the crank OС and divide it by the size of a segment of arbitrary length │OС│:

After that, using the scale factor of the lengths, we translate all natural dimensions of the links into segments, with the help of which we will build the kinematic diagram:

After calculating the dimensions, we proceed to constructing one position of the mechanism (Figure 4) using the serif method.

To do this, first draw a rack 0 on which the crank is fixed. Then we draw a horizontal line XX through the center of the circle, which was drawn to build the rack. It is necessary for the subsequent finding of the center of the slider 3. Further, from the center of the same circle, draw two other radii

and. Then, from there, we draw a segment of length at an angle to the horizontal line XX. The intersection points of this segment with the constructed circles will be points A and C, respectively. Then from point A we build a circle with a radius.The point of intersection of this circle with line XX will be point B. Draw a guide for the slider, which will coincide with line XX. We build the slider and all the other details of the drawing are needed. We designate all points. The synthesis of the kinematic scheme has been completed.

3. Kinematic analysis of a plane mechanism

We proceed to building a speed plan for the position of the mechanism. To simplify the calculations, you should calculate the speeds and directions for all points of the mechanism position, and then build a speed plan.

Figure 4 - One of the positions of the mechanism

Let us analyze the scheme of the crank-slider mechanism: point O and O 1 are fixed points, therefore, the moduli of the speeds of these points are equal to zero (

).The velocity vector of point A is the geometric sum of the velocity vector of point O and the speed of the relative rotational motion of point A around point O:

Velocity vector action line

is perpendicular to the axis of the crank 1, and the direction of action of this vector coincides with the direction of rotation of the crank.Speed \u200b\u200bmodule point A:

Angular velocity

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists using the knowledge base in their studies and work will be very grateful to you.

Posted on Allbest.ru

Introduction

2.1.1 Marking the mechanism

2.1.2 Calculation of speeds

2.1.3 Calculation of accelerations

Conclusion

Introduction

The theory of mechanisms solves the problems of structure, kinematics and dynamics of machines in connection with their synthesis and analysis.

In this work, an analysis is carried out, since the existing mechanism is being investigated.

The course project in the discipline "Theory of Mechanisms and Machines" provides for the calculation of the mechanism in three main sections:

1. Structural analysis.

2. Kinematic analysis.

3. Kinetostatic analysis.

In each section, a certain set of calculations is performed that are necessary to study this mechanism.

Structural analysis gives general idea about the structure of the investigated mechanism. This section does not provide for a large amount of calculations, but only provides initial information about the parts and about the entire mechanism as a whole. This information will be needed later when calculating the mechanism.

Kinematic analysis is based on the results of structural analysis and provides for the calculation of kinematic characteristics. In this section, the positions of the mechanism at different times are built, the speeds, accelerations, displacements of points and links of the mechanism are calculated. Calculations are carried out by various methods, in particular, the method of plans (that is, the solution of equations by the vector method), the method of kinematic diagrams, in which diagrams of kinematic characteristics are constructed, and the mechanism is studied using them.

Kinetostatic analysis or force calculation allows you to calculate the forces and reactions that act on the mechanism, and not only external forces such as gravity, but also forces of an exclusively internal nature. These are forces - the reactions of bonds that are formed when any links are excluded. In the force calculation, the same methods are partially used as in the kinematic analysis, but in addition to them, the method of N.E. Zhukovsky, allowing you to check the correctness of the work.

All methods used in the work are simple and accurate enough, which is not unimportant in engineering calculations of this kind.

Section 1. Structural analysis of the mechanism

Structural analysis allows you to understand the structure of the mechanism. The main objectives to be achieved in this section are:

1) Determination of the structure of the mechanism;

2) Calculation of the mobility of the mechanism;

3) Determination of the class of the mechanism;

Sliding crank mechanism working machine shown in Fig. 1.1, it consists of: 0 - rack; 1 - crank; 2 - connecting rod; 3 - slider.

The total number of links in the mechanism is N \u003d 4.

Let's determine the mobility of the mechanism according to the Chebyshev formula:

W \u003d 3n - 2P 5 - P 4, (1.1)

where n is the number of moving links (n \u003d 3), Р 5 is the number of pairs of the fifth class, Р 4 is the number of pairs of the fourth class.

Let's depict the block diagram of the mechanism:

Figure: 1.2 Block diagram

The number of pairs of the fifth class Р 5: (0; 1), (1; 2), (2; 3),

The number of pairs of the fourth class P 4 \u003d 0.

Mobility mechanism (1.1):

Let's write down the formula for the structure of the mechanism:

Mechanism class - II.

Section 2. Kinematic analysis of the mechanism

crank slider kinematic lever

In this section, the tasks of the kinematic analysis of the crank-slider mechanism of the working machine are solved, namely: the marking of the mechanism is constructed for its twelve positions; the positions of the centers of mass of the links are determined; plans for speeds and accelerations are made; the values \u200b\u200bof speed, acceleration and displacement of the output link are determined; the extreme positions of the mechanism are determined; kinematic diagrams are built.

2.1 Kinematic analysis by the method of plans

The kinematic analysis by the method of plans (graphic-analytical method) is quite simple, visual and has sufficient accuracy for engineering calculations. Its essence is that the relationship between speeds and accelerations is described by vector equations, which are solved graphically.

2.2.1 Marking the mechanism

The movement marking is a movement in twelve positions at specific points in time. The layout of the mechanism is built based on the initial data. When constructing a markup, the main task is to maintain the proportions of the dimensions of the links and the overall design of the mechanism.

To build the markup, it is necessary to calculate the scale factor, which allows you to maintain all proportions and relate the actual dimensions of the mechanism to the dimensions used in the graphic part. The scale factor is determined from the ratio of the actual size of the mechanism (expressed in meters) to the size on the sheet in the graphic part (expressed in millimeters). Let's find the value of the scale factor using the actual size of the crank, equal to 0.280 m, and the size of the crank on the sheet in the graphic part, which we take 70 mm

where is the real size of the crank.

Using the resulting scale factor, we calculate the remaining dimensions of the links of the mechanism.

The same for all other sizes. The size calculation results are shown in Table 1.

Table 1

Based on the dimensions obtained, we build twelve positions of the mechanism, strictly observing all proportions and the basic structure. The markup of the mechanism is built on the first sheet of the graphic part of the course project. In fig. 2.1.1 presents the mechanism in twelve positions.

Figure: 2.1.1 Mechanism in twelve positions

2.1.2 Calculation of speeds

The calculation of speeds is made for all twelve positions of the mechanism. Linear and angular velocities of all links are calculated, as well as the velocities of the centers of mass.

Calculation of speeds and construction of plans will be carried out for position No. 2 of the mechanism.

Angular crank speed:

Using the value of the angular speed of the crank, we determine the speed of point A:

where is the length of the OA link.

Let us write down the vector equation for the speed of point B:

In this equation, we know the directions of the velocity vectors V B, V A, V AB. The speed of point B is directed along the t-t rail, the speed of point A is directed perpendicular to the crank OA, and the speed of link AB is directed perpendicular to this link. Knowing the direction of the speeds and the value of the speed of point A, we solve equation (2.1) graphically (Figure 2.1.2). To do this, we will initially determine the value of the scale factor, which is necessary for constructions. It is determined similarly to the scale factor found in clause 2.1.1:

where pa is a segment representing the speed of point A on the plan of speeds (pa is chosen arbitrarily).

After determining the scale factor, we solve the vector equation (2.1) (Fig. 2.1.2). To do this, mark the point p v - a pole, from it we draw a segment p v a equal to the value of the speed of point A and directed perpendicular to the crank OA. From the end of the constructed segment, we draw a line of action of the relative velocity, which is directed perpendicular to AB, at the point of intersection of this vector with the t-t direction, there will be point b. The vector p v b determines the speed of point B, it is directed from the pole p v.

We determine the numerical value of the speeds by measuring the obtained segments and multiplying them by the scale factor:

We calculate the angular velocities by the formulas:

where is the length of the connecting rod (m).

The position of the centers of mass on the plane of velocities will be determined by the similarity property:

The speed of the center of mass of the connecting rod is:

This work calculates the speeds for all twelve positions. The calculation is carried out similarly to the considered provision. The vectors of all speeds come out of the same pole. Calculation results (full speed plan) are presented on the first sheet of the graphic part of the project. The values \u200b\u200bof all speeds of the links of the mechanism and points of the links are presented in table 2.

table 2

2.1.3 Calculation of accelerations

The calculation of accelerations is carried out for two positions of the working stroke of the mechanism, in which the force of the useful resistance is not equal to zero. Accelerations are determined similarly to the speeds, the calculation of which was done above (Section 2.1.2).

Initially, we determine the acceleration of point A of the crank. It is constant and equal to the product of the squared angular velocity of the crank and its length:

We will find accelerations by the method of plans, for this we write down the vector equation for the acceleration of point B:

where and are the normal and tangential components of the AB link acceleration, respectively.

Let us solve equation (2.10) graphically. To do this, we take the scale factor of the acceleration plan, equal to:

We build the acceleration plan according to the direction of the vectors:

Directed from point A to point O 1;

Directed from point B to point A;

Directed perpendicular to the AB link;

The direction is given by the t - t rail.

Let us determine the normal component of the acceleration of the AB link:

To build an acceleration plan:

· Choose the pole pa;

· Build the vector of acceleration of point A;

· From the end of the vector we build a ray parallel to the link AB, and on this ray we lay off the segment an equal to:;

· Draw a straight line perpendicular to AB through point n, mark the point of its intersection with the t-t guide - point b;

· Segment p and b - acceleration of point B on the plane of accelerations.

The acceleration of the centers of mass is determined by the principle of similarity:

The acceleration plan for position # 2 is shown in Fig. 2.1.4

Figure: 2.1.4 Acceleration plan for position # 2

The numerical values \u200b\u200bof the accelerations are calculated by the formulas:

The obtained values \u200b\u200bof all accelerations for the positions of the mechanism No. 8 and No. 10 are shown in Table 3.

Table 3

2.2 Kinematic analysis by the method of diagrams

The method of kinematic diagrams allows you to visually see how the movement, speed and acceleration change during the cycle of the mechanism.

Let's take the scale factor equal.

To build the charts, we need a time scale factor and a rotation angle scale factor. We calculate these coefficients using the formulas:

where t c - cycle time,; L \u003d 180 mm.

The displacement diagram is shown in Fig. 2.2.1

Fig 2.2.1. Displacement diagram

We transfer the speeds of the output link to the speed diagram taking into account the obtained scale factors. We connect the obtained values \u200b\u200bof speeds with a line, and as a result we have a diagram for the speed of the output link in twelve positions of the mechanism (Fig. 2.2.2).

The speed diagram is built on the first sheet of the graphic part.

Figure: 2.2.2. Speed \u200b\u200bchart

The acceleration diagram is constructed using the graphical differentiation method. For this:

· The diagram of velocities is approximated by a broken line;

Transfer the abscissa axis from the velocity diagram to the acceleration diagram and continue it beyond the origin (to the left);

· Set aside the segment H \u003d 20 mm;

On the velocity diagram, define the point 1 /, then connect it to point O with a straight line:

· From point P we draw a ray parallel to the chord O1 /. Get point 1 //;

Segment O1 // depicts the average acceleration in the time interval (0; 1);

· To find the point of the acceleration diagram, it is necessary to restore the perpendicular from the middle of the time interval (0; 1) and project point 1 // onto this perpendicular;

· These constructions are repeated for the entire time interval.

Let's define the scale factor of the acceleration diagram:

Figure: 2.2.3. Acceleration diagram

Section 3. Kinetostatic analysis of the mechanism

Objectives of kinetostatic analysis:

· Determination of the force of useful resistance in the considered positions of the mechanism;

· Determination of reactions in kinematic pairs;

· Determination of the balancing moment by the method of plans;

· Determination of the balancing moment by the “rigid lever” method N.Ye. Zhukovsky

3.1 Force analysis by the plan method

Force calculation by the plan method allows you to determine the reactions in kinematic pairs and the balancing moment. This method is simple, intuitive, and accurate enough for engineering calculations.

3.1.1 Determination of the useful resistance force

The order of construction of markings for the force calculation of the mechanism does not differ from its construction in the section of kinematic analysis, therefore, no additional explanations are required here. After building the markup, we turn to the power diagram, which must be transferred from the source data to the sheet. In doing so, it is important to define. the magnitude of the resistance forces in each position of the marking and establish their compliance with these provisions. On the marking of the mechanism there are marks of the position of point B of the slider. Let us direct the ordinate axis of the desired graph parallel to the trajectory of point B from its zero position towards the other extreme position. Let us direct the abscissa axis perpendicular to this axis. In this case, along the ordinate axis, in essence, the movement of point B is plotted, along the abscissa, the same as on the original graph, the resistance force P is plotted.

In the selected coordinate system, it is necessary to apply scales along both axes and then a coordinate grid in the same way as it was done on the original graph in the assignment for the course project. Having read the coordinates of a number of characteristic points of the original graph, we build these points in the coordinate system prepared for this, and then we connect the plotted points sequentially with each other, which gives the desired graph.

Lowering the perpendiculars from the trajectory marks onto the ordinate axis of the graph, we obtain the abscissas P in the desired positions of the marking of the working stroke of the mechanism. Note that the scale along the ordinate of the graph is equal to the marking scale (Figure 3.1.1 a)

Let's find the resistance forces:

for the 2nd position:

P s_ 2 \u003d 1809 N,

For the 4th position:

P s_ 4 \u003d 1298 N.

Fig 3.1.1а Determination of the useful resistance force

3.1.2 Force analysis of the structural group

We transfer link AB from the marking of the mechanism and, at point A, free it from links, discarding link 1 and replacing the action of this link with a reaction, which, in turn, has normal and tangential components.

We apply the forces of gravity, inertia, useful resistance, and bond reactions to the links of the group. In the loading diagram (Fig. 3.1.1), the forces are depicted by segments of arbitrary magnitude, but strictly maintaining the directions of these forces. We direct the forces of inertia in the direction opposite to the acceleration of the corresponding points. The force of useful resistance is directed in the direction opposite to the direction of the speed of the slider in the selected position.

Figure: 3.1.1. Loading scheme of the structural group for position No. 2

Determine the force of inertia of the slider in position No. 7:

Inertia forces of the AB link:

Let us write the sum of the moments relative to the slider B:

From equation (3.3) we express:

Let's write down the sum of all forces acting on the group:

Let's solve equation (3.5) graphically (Fig. 3.1.4). Let's choose a scale factor. We select a pole through which we draw a straight line parallel to the loading scheme and lay on it the segment depicting. We sequentially construct the vectors of all forces in accordance with equation (3.5) so that the unknown reactions are constructed in the last turn. The intersection of the lines of action of these two vectors will give the solution to this equation. In fig. 3.1.2 shows the plan of forces for the trailed group in position No. 2 of the mechanism.

Figure: 3.1.2. Force plan for the trailed group

To determine the numerical values \u200b\u200bof the unknown reactions and it is necessary to measure the segments that denote the reaction data on the plan of forces and multiply them by the scale factor.

The obtained values \u200b\u200bof calculations and constructions are entered into the table.

3.1.3 Force calculation of the initial mechanism

The power calculation of the crank allows you to determine the balancing moment.

For the calculation, we transfer the initial link from the marking, discard the stand and replace it with an unknown reaction R 01. Let's load the crank by gravity and link reactions (Fig. 3.1.3).

The balancing moment M ur is determined from the equilibrium equation of the crank in the form of moments relative to the point O 1.

From equation (3.6) we express the moment M ur and find its numerical value:

To find the unknown reaction R 01, we will compose the equation of all forces acting on the link, and solve it by the method of plans:

Figure: 3.1.4. Initial Mechanism Force Plan

Reaction R 01:

3.2 Force calculation by the "rigid lever" method N.Ye. Zhukovsky

The main task of the force calculation by the Zhukovsky "rigid lever" method is to check the correctness of constructing plans of forces and determining the reactions in kinematic pairs.

From an arbitrary point taken as a pole P, we build a plan of accelerations for position No. 8 and rotate it 90 0 clockwise relative to its normal position. The speed plan for position # 8 was built in section 2.1.2. We transfer these forces to the ends of the velocity vectors of the points at which the forces applied to the mechanism act, keeping their exact directions.

We determine the direction and value of the moments of inertia acting on the mechanism. Since ab and on the plan of speeds coincide with AB on the marking of the mechanism, then

Figure: 3.2.1. "Rigid lever"

We compose the equilibrium equations of the plan of speeds as a conditional rigid lever in the form of moments of forces relative to the pole of the plan of speeds. The shoulders of the forces are taken directly from the lever without any transformation:

We define:

Balancing moment:

Let's define the error:

Therefore, it can be concluded that the calculation was correct.

Force calculation for position No. 4 is carried out in the same way.

Power calculation of the trailed structural group in position No. 4

The power calculation of the mechanism in the 10th position is carried out in the same way. As a result of calculations, we get:

Conclusion

In this course project, the tasks of the kinematic and kinetostatic analysis of the mechanism were solved. In the course of the project, the following goals were achieved:

· Complete kinematic calculation of the mechanism has been performed;

· The values \u200b\u200bof speeds, accelerations and displacements of links and points of the mechanism are determined;

· Positions of the working stroke of the mechanism are found;

· Determined the forces and reactions acting on the mechanism;

The values \u200b\u200bobtained in calculations and calculations were checked by the Zhukovsky method. According to this, the methods determined the error in position No. 2 () and in position No. 4 (), which turned out to be less than the permissible one, which indicates the correct constructions and calculations.

Bibliography

1. N.N. Fedorov. Design and kinematics of flat mechanisms. Tutorial. Omsk, publishing house OmSTU, 2010.

2. N.N. Fedorov. Kinetostatics of flat mechanisms and dynamics of machines. Tutorial. Omsk, publishing house OmSTU, 2009.

3. Artobolevsky I. I. Theory of mechanisms and machines. Textbook for universities - Moscow: Nauka, 1988.

4. Kozhevnikov S.N. The theory of mechanisms and machines. -M .: Nauka, 2012.

Posted on Allbest.ru

Similar documents

Kinematic and kinetostatic study of the working machine mechanism. Calculation of speeds by the method of plans. Power calculation of the structural group and the leading link by the method of plans. Determination of the balancing force by the "rigid lever" method N.Ye. Zhukovsky.

term paper added on 05/04/2016

Structural analysis of the crank mechanism. Building plans of position, speeds, accelerations and kinematic diagrams. Determination of the resulting forces of inertia and balancing force. Flywheel moment of inertia calculation. Cam mechanism synthesis.

term paper, added 01/23/2013

Structural analysis of the lever mechanism of the working machine, its kinematic and dynamic study. Sliding crank mechanism, its movable joints. Building plans of the mechanism, speeds and accelerations. Power calculation of the lever mechanism.

term paper added 05/27/2015

Structural analysis of the crank-slider mechanism, identification of its structural composition. Synthesis of the kinematic scheme. Kinematic analysis of a flat mechanism. Determination of the forces acting on the links of the mechanism. Kinetostatic method of force analysis.

laboratory work, added 12/13/2010

Determination of positions, speeds and accelerations of the links of the linkage mechanism and their various points. Study of the movement of links by the method of diagrams, the method of plans or coordinates Calculation of the forces acting on the links by the method of plans of forces and the Zhukovsky lever.

term paper added 09/28/2011

Structural and kinematic analysis of the mechanism of a forging and stamping machine using plans and diagrams. Determination of forces and reactions acting on links in kinematic pairs. Determination of the balancing force by the "rigid lever" method N. Zhukovsky.

term paper added on 11/01/2013

Structural and kinematic analysis of the crank-slider mechanism. Definition of linear and angular velocities and accelerations. Calculation of the greatest braking force in braking device; kinematic parameters of the gear drive, gear transmission and shafts.

test, added 03/22/2015

Structural and kinematic analysis of the linkage of the drawing press. Defining a class and decomposing it into Asura groups. Building plans for the position of mechanisms, speeds and accelerations. Determination of the balancing force by the Zhukovsky lever method.

term paper, added 05/17/2015

Kinematic diagram mechanism of the crank-balancing mechanism. The starting position of the leading link. Kinematic diagrams, plans of speeds and accelerations. Determination of the balancing moment on the driving crank, check by the Zhukovsky lever method.

test, added 07/27/2009

Fundamentals of kinematic and kinetostatic research of the crank-slider mechanism. Development of drawings of the plan of speeds, accelerations and statistical moments with the subsequent calculation of their values. Construction of the hodograph of the velocity of the kinematic pair.

slider mechanism

2.1. Block diagram of the mechanism

Fig 2.1 Block diagram of the crank-slider mechanism

2.2. Identifying complex and spaced kinematic pairs

There are no spaced-apart kinematic pairs in the crank-slider mechanism. Couple INcomplex, so we will consider it as two kinematic pairs.

2.3. Classification of kinematic pairs of the mechanism

Table 2.1

|

P / p No. |

The numbers of the links forming a pair |

Symbol |

Name |

Mobility |

Higher / Inferior |

Closure (Geometric / Power) |

Open / Closed |

|

|

Rotational |

||||||

|

Rotational |

|||||||

|

Rotational |

|||||||

|

Rotational |

|||||||

|

Rotational |

|||||||

|

|

Rotational |

||||||

|

|

Translational |

The investigated mechanism consists only of one-way kinematic pairs ( r 1 = 7, r\u003d 7), where r 1 - the number of one-moving kinematic pairs in the mechanism, r- the total number of kinematic pairs in the mechanism.

2. 4. Classification of links of the mechanism

Table 2.2

|

P / p No. |

Link numbers |

Symbol |

Name |

Traffic |

Number of vertices |

|

Is absent |

|||||

|

Crank |

Rotational |

||||

|

|

|||||

|

|

Rotational |

||||

|

|

|||||

|

|

Translational |

The mechanism has: four () two-vertex () linear links 1,2,4,5; one (n 3 \u003d 1) three vertex link, which is the base link; five () moving links.

Find the number of connections to the rack. The conveyor mechanism has three () attachments to the rack.

In the studied complex mechanism, one elementary mechanism can be distinguished

Figure: 2.4 Crank-slider mechanism.

There are no mechanisms with open kinematic chains in the investigated crank-slider mechanism.

The mechanism contains only simple stationary mechanisms.

There are no fixing links in the investigated mechanism. Link 3 is simultaneously included in two simple mechanisms - an articulated four-link mechanism and a crank-slider. Hence, for this link

We classify the mechanism. The investigated mechanism has a constant structure, is complex and of the same type. It consists of one elementary mechanism and two stationary simple ones, which contain only closed kinematic chains.

The mechanism exists in a three-movable space.

Formulas for determining the mobility of these mechanisms will take the form, respectively:

Let's define the mobility of the hinged four-link link. This mechanism has: three () movable links 1,2,3; four () one-way kinematic pairs O, A, B, C.

![]()

Let's find the mobility of the crank-sliding mechanism. It has: () movable links 3,4,5 and four () kinematic pairs C, B, D, K. Its mobility is determined in the same way:

![]()

We determine the mobility of a complex mechanism by the formula:

We analyze the structural model of the machine tool. We check whether the investigated mechanism corresponds to the structure of the mathematical model. The mechanism has: seven () single-moving kinematic pairs; five () movable two-vertex () links, the base is; three attachments to the rack () and no anchoring links ().

Mathematical model:

;

;

;

;

![]()

![]()

Since the equations of the model have turned into identities, the investigated device has the correct structure and is a mechanism.

Let's select and carry out the classification of structural groups. The elementary mechanism is conventionally classified as a class I mechanism.

|

|||

|

|||

The class of the structural group is determined by the number of kinematic pairs included in a closed loop formed by internal kinematic pairs. The group order is determined by the number of external kinematic pairs. The type of the group is determined depending on the location of rotational and translational kinematic pairs on it.

2-order

It can be seen that the identified structural groups are completely similar in species and quantitative composition of links and kinematic pairs. Each of the structural groups has: two movable links (), and the links are two-vertex () and, therefore, the base link also has two vertices (); three () one-way kinematic pairs, of which two are external ().

We check whether the selected structural groups correspond to mathematical models. Since the groups are similar, we check only one group, for example, OAB. Mathematical models of structural groups are as follows:

The crank-slider mechanism belongs to the II class.

3. Kinematic analysis of the mechanism

The kinematic analysis of any mechanism consists in determining: extreme (dead) positions of the machine, including the definition of the trajectories of individual points; the speeds and accelerations of the characteristic points of the links according to the well-known law of motion of the initial link (generalized coordinate).

3.1 Determination of extreme (dead) positions of the mechanism

The extreme (dead) positions of the mechanism can be determined analytically or graphically. Since analytics gives higher accuracy, it is preferred when determining extreme positions.

For a crank-slider and an articulated crank-rocker four-link, the extreme positions will be when the crank and the connecting rod are stretched (), then folded () in one line.

Figure: 3.1 Determination of extreme positions of the mechanism.

3.2 Determination of the positions of the links of the mechanism graphically.

Figure: 3.3 Construction of closed vector contours.

We place the structural diagram of the mechanism in a rectangular coordinate system, the origin of which is placed at point O. We connect the vectors with the links of the mechanism so that their sequence is two closed contours: OABCO and CBDC.

For the OABCO circuit:  (3.1)

(3.1)

We represent the equation in projections on the coordinate axes.