The fuel level sensor is a device that is necessary to determine the degree of filling of the fuel tank (on a car - fuel tank). As well as indirect control of the consumption of gasoline, diesel or another type of fuel, which are one of the main operational parameters of the car. A visualized representation of the sensor readings is displayed with a corresponding pointer, both of which are linked.

Operating principle

The sensor transmits a signal corresponding to a certain level of fuel in the tank to the indicator. Depending on the type of signal, analog and digital sensors are distinguished. The first type of sensors is not widely used today due to the high degree of their unreliability. A digital fuel level sensor converts analog data into digital format, and then gives an output value, taking into account the correction for the uneven distribution of fuel in the tank, as well as for the geometric features of the tank. Compared to analog, this device has a much lower measurement error.

Float measuring devices

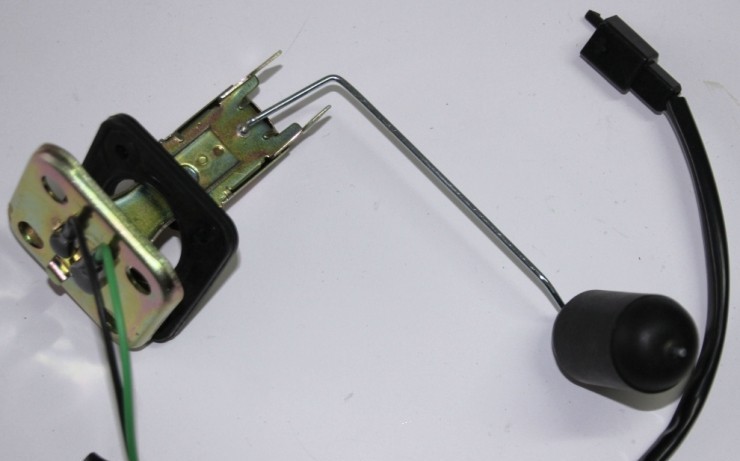

IN modern cars gasoline level or diesel fuel measured with digital potentiometric (float) devices. In such systems, the position of the float, made of foam, light metal, or plastic, determines the level of fuel in the fuel tank.

This scheme has a number of advantages:

- simplicity of the device;

- operational reliability;

- low cost.

The disadvantages include the mobility of the contacts, which can lead to their oxidation and wear.

By design, there are two types of float sensors:

- lever;

- tubular.

Features of the device

In the lever version, the float is connected to a rheostat through a metal lever. When the fuel level in the tank changes, the float moves. This leads to a rotation of the lever associated with the moving contact of the rheostat. The resistance of the latter changes, which entails a change in the value displayed on the fuel gauge. The linkage design is versatile and can be used in fuel tanks of any geometric shape.

The tubular fuel level sensor works as follows. The float moves along a guide located inside the tube. Parallel to the direction of movement of the float, wires with slip rings are laid, by closing which the float fixes the corresponding value of the fuel level.

The main advantage of such a scheme is the stability of its readings during the ascents, descents and turns of the car, when the fuel level fluctuates.

However, its use is limited by the geometry of the fuel tank.

Alternative fuels

As already noted, lever and tubular systems can be used for gasoline or diesel, but, for example, for ethanol, methanol, biodiesel, they are completely unsuitable. The contact of these types of fuel with sensor elements leads to a rapid failure of the latter. In such cases, contactless fuel level sensors are used, for example, inactive magnetic position sensors, in which structural elements are hermetically isolated from external aggressive influences. They also use a float connected to a magnet. The magnet moves over a sector on which metal plates of various lengths are located. Depending on the value of the transmitted signal, the value of the fuel level in the tank is determined.

Most common faults

Obviously, the malfunction of the fuel level sensor can only be determined indirectly - through malfunctions of the fuel level indicator. The most common faults are:

Withdrawal

In many of the cases described above, to check or repair the fuel level sensor, it must be removed and then reinstalled. The removal procedure is carried out in the following order.

- For gasoline car be sure to remove the negative terminal of the battery.

- Provide access to the sensor, depending on where it is installed - unload the contents and remove the luggage compartment trim or dismantle the rear seat cushion.

- If a safety plate is installed on top of the sensor, unscrew the fixing bolts and remove it.

- Clean the fuel level sensor and the surface of the tank near it from dust and dirt.

- Disconnect suitable electrical wires (it is recommended to pre-mark them).

- Unscrew the bolts securing the fuel sensor to the tank and carefully remove it to avoid damage to the structural elements. In some cases, you will need to unscrew the plastic cover before removing it.

Installation

Before reinstalling the fuel level sensor, you must perform the following operations.

- Clean the seat from the old sealant.

- If there is a new gasket, install it on seatby aligning the holes for the mounting bolts. For older vehicles (10 years or more) with a new gasket, it is recommended to use a sealant.

- Assembly is carried out in the reverse order of removal.

- After assembly, check the readings on the fuel level indicator.

- Drive 30-50 km, re-access the fuel gauge and check for fuel odors and leaks.

Fuel level sensors must meet the requirements fire safety... They work in an explosive environment, so the slightest spark can cause a fire. Float fuel level sensors are widely used in cars. They are easy to manufacture and operate, relatively cheap, and have a relatively small measurement error.

Float level sensors

There are two main designs of float fuel level sensors:

- lever type;

- tubular type.

And the principle of their work is the same. The first level sensors use a resistor connected in a circuit with an indicator of the amount of fuel in the tank. A resistor is a plate with a nichrome wire wound on it. On the lever at one end there is a float, and at the other there is a slider, the output of which is connected to the level indicator circuit.

The fuel level indicator itself in the tank is a voltmeter or ammeter. Depends on what parameter is being monitored. The same operation scheme is exactly the same for tubular level sensors. The basis of the structure is a cylindrical pipe, inside which a float is located. It closes the turns of the wire wound along inside pipes. The accuracy of such sensors is quite high, since there are practically no oscillations of the float when moving on an uneven surface.

In some designs, reed switches are sometimes used. The float is located around the tube and has a magnetic strip on it that acts on the reed switches. The reed switches are located in the tube body. The more reed switches there are, the higher the accuracy of this type of level sensor. Most likely, it is for this reason that sensors have not been widely used. Their production is too expensive.

Fuel level sensor installation

On cars with injection engines the fuel level sensor is integrated into one unit with the fuel pump. This makes sense as it saves a lot of space and you don't need to make separate holes in the tank for each node. On cars with carburetor system power supply level sensor is installed in a special hole in the tank.

Using the example of a car with an injection engine, it is best to consider the process of installing a level sensor. After all, carburetors are not used in the manufacture of cars, because they are outdated for a long time. On most machines, the tank is under back seat... Therefore, the lower part of the seat must be raised. Approximately in the center is a viewing window covered with upholstery.

Removing the cover from the sight glass reveals the top of the tank and fuel pump with level sensor. Remove the entire assembly and disconnect the level sensor from the pump. Put a new one in its place, just make sure that all the wires going to it are correctly connected. It remains only to assemble the entire assembly and, turning on the ignition, control the operation of the sensor. Calibration is not required when replacing a sensor with the same model.

quickly and accurately measures the fuel level

measures in liters and millimeters

fixes the date and time of measurements

stores information across the entire fleet

uploads measurement data to a PC

The FZ-500 device is designed for fast and accurate measurement of the level (volume) of fuel in the tanks of vehicles.

This device was created, first of all, for organizations that have their own fleet of vehicles and are faced with the problem of accurately measuring the amount of fuel in car tanks at different times.

Description of the device

To date, the fuel level in the vehicle tank is determined either by the readings of a standard vehicle level sensor (error is about 10-12%), or<на глаз> with the help of various improvised means ("twig", ruler, etc.), and most often it is generally recorded from the words of the driver. The result of such measurements is a constantly accumulating error, which gives ample opportunities for fuel write-off or theft. For enterprises with a large fleet of vehicles, these write-offs result in a colossal amount. The company incurs huge, completely unjustified losses, and money usually ends up in the pockets of enterprising drivers. The fuel theft business in trucking businesses is well established and well established.

\u003e\u003e The existing picture can be easily changed using the FZ-500. It can be used to measure the fuel level in liters or mm with an accuracy of + 1.5%. The simplicity of the design and measurement methods allow you to effectively monitor the fuel level in the car tank during the working day and overnight stops. It is enough to measure the fuel level at the beginning and at the end of the work shift and, knowing the amount of fuel filled, calculate its consumption per shift. Comparing the readings of the device in the morning with the measurements of the previous day, you can easily fix the fact of fuel draining during off-hours, especially since this type of fraud is practiced quite often.

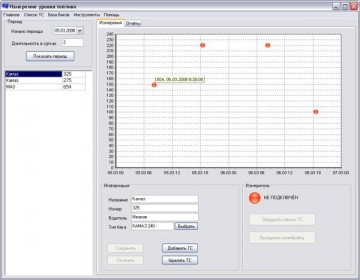

The FZ-500 level meter can be connected to the personal computer of the dispatcher, chief mechanic or logistician of the enterprise to view information about the measurements made visually on a timeline, which is very convenient for perception. The data can be viewed and printed for a specific vehicle for any period of time or presented as a table of measurements for all vehicles in the fleet.

Thus, the appearance of the FZ-500 device in the organization will allow persons responsible for the use of vehicles to have a complete picture of the current expenses of fuels and lubricants.

\u003e\u003e In addition, based on the results of measurements of fuel consumption on one car for different shifts, it is possible to analyze the driving economy of each driver, as well as to draw a conclusion about technical condition car.

As with any control device, the use of the FZ-500 level meter when the right approach to the point, will inevitably lead to optimization of the logistic and organizational scheme of the use of vehicles, and as a result to a decrease in the total costs of the enterprise for fuel and lubricants.

\u003e\u003e However, no control and accounting will allow to achieve an increase in the efficiency of the use of the vehicle fleet and fuel resources, if the head of the enterprise or department does not analyze the data received and make adequate, possibly tough decisions with respect to violators.

Control plus work with personnel is the key to success!

The FZ-500 level meter can be used to calibrate the readings of standard or additional fuel level sensors when configuring the vehicle monitoring system "AutoScan ASK-1" or "AutoScan GPS".

Have information - cut costs !!!

Benefits

\u003e\u003e\u003e Availability of non-volatile memoryThe device memory can store information about all vehicles in the fleet and the capacitive characteristics of their tanks. There is no need to write down the measurement result on paper, all readings are stored in memory until they are read into a computer.

\u003e\u003e Possibility to form your own database of fuel tank characteristics.

You can independently enter the calibration characteristics of the tanks of any vehicle into the memory of the device, make adjustments for non-standard tanks (deformed standard or homemade tank), and also edit calibration tables according to the records made earlier.

\u003e\u003e Quick search for vehicles by registration number or type of fuel tank.

The digital keyboard of the device allows you to select the desired car from the list of all vehicles of the company in a matter of seconds.\u003e

>> High speed measurements

It only takes a few seconds for measurements per vehicle.

\u003e\u003e High measurement accuracy

The amount of fuel in the vehicle tank is measured with an error of about 1.5%

\u003e\u003e Convenience of information display

The measurement result is immediately displayed on the LCD display of the device in liters. In addition, information can be viewed on a dispatcher's or logistician's PC for any period of time for any vehicle. Measurement data in the form of a report can be printed.

\u003e\u003e Availability of autonomous power supply

The device has an autonomous power supply from 4 AA batteries.

\u003e\u003e Convenient storage and transportation

The measuring probe is easily detached from the instrument and can be stored separately

\u003e\u003e Confidentiality of measurement data

There is no possibility of falsification and distortion of facts. Information about measurements is stored on a computer in a special format that excludes any changes.

Composition and principle of action

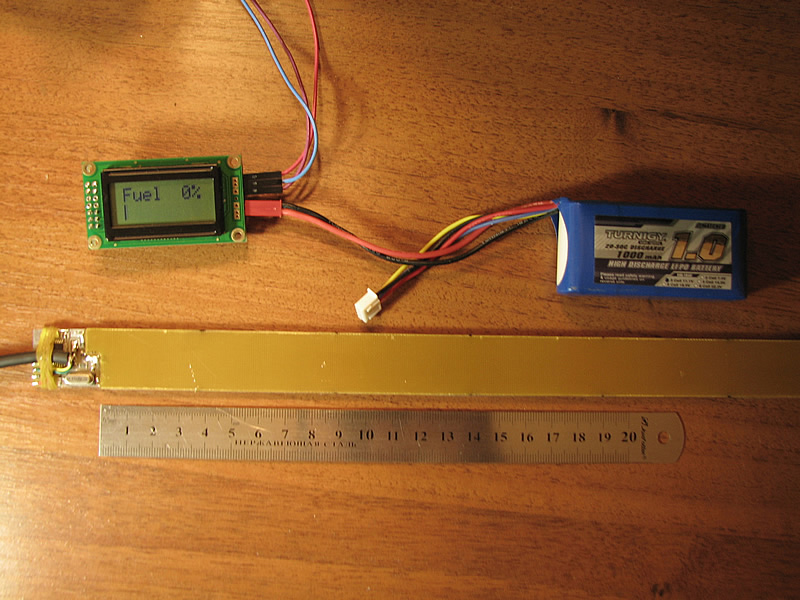

The system consists of three main components: a measuring unit with an LCD display, a measuring probe and a PC program.

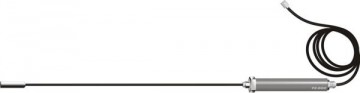

Fig. 1 Measuring unit FZ-500

Fig. 2 Measuring probe FZ-500

Fig. 3 FZ-500 program

The measurement unit is made in a single housing. It includes: a controller that performs all calculations, a real-time clock with its own power supply, an LCD display that allows you to view the measurement results, a control keyboard, and a memory for storing the database and measurement results.

The measuring probe consists of two hollow tubes of different diameters, hermetically connected through a fitting. One of them (made in the form of a handle) accommodates a measuring sensor, and the other (a flexible metal tube) is directly the measuring element itself - a probe and has a length of 1000 mm.

The software required to connect the meter to a PC and work with the system allows you to view the measurement results, edit the lists of fleet vehicles, fuel tank parameters, and transfer data to and load the measurement unit from it. To connect the Measuring Unit to a computer, use the USB cable supplied.

Operating principle

The device "FZ-500" is designed for accurate and operational measurement of the current fuel level in the tanks vehicles... The measurement result (both level in mm and volume in l.) Is displayed on the built-in indicator and entered into the internal memory of the device. After connecting the meter to the PC of a dispatcher, mechanic or logistician, the results of all measurements are transferred to the memory of a personal computer for storage. They can be analyzed, statistic, and reports generated.

Before starting the operation of the device, it is necessary to create a list of the enterprise vehicles in its memory and assign them the characteristics of fuel tanks based on the data obtained during the calibration of fuel tanks (performed by the user).

1. Mode of measuring the amount of fuel in the tank

To identify a vehicle from the entire list of vehicles in the park, use quick search by state registration number. After selecting the desired number on the meter display, the device automatically determines the capacitive characteristics of its tank.

Then the measuring probe is lowered into the vehicle tank to the very bottom. It is very important to really rest the probe against the bottom of the tank, since the beginning of the tube is taken as the zero level. According to the sensor readings, the device determines the fuel level in mm. and, according to the calibration tables stored in its memory, calculates the volume of fuel. This result saved in the device memory. The time and date of measurement are indicated.

2. Fuel tank calibration mode

It is used when the characteristics of the measured fuel tank are not in the memory of the device. In this case, it is necessary:

* Determine the capacity of the vehicle's fuel tank

* Drain fuel completely\u003e

* Determine the volume of refilled portions of fuel based on no more than 20 control points

* Sequentially fill in portions of fuel, keeping each value, until the vehicle tank is full

To view the measurement results, their subsequent accumulation and storage, it is necessary to transfer them from the device to the computer. To do this, the measuring unit is connected to the USB port of the computer using a special cable from the kit. The computer must have special software installed, also included in the package. At the command of the program "Load data from the device" information about the measurements made is read into the computer, and the device memory is cleared.

Capabilities software

* view the results of measurements for any period of time, customizable by the user, for each vehicle in the fleet.

* create, edit, upload lists of vehicles of the company

* create, edit, load types of fuel tanks

Operating procedure

Fuel level measurement in millimeters

To work in this mode, no additional device settings are required.

1. In the menu of the measuring unit, select the item "Measure in mm."

2. Insert the measuring probe into the neck of the fuel tank so that the probe touches its bottom (this is very important because the level at which the end of the measuring probe is located is taken as the zero fuel level)

3. The fuel level in millimeters will be displayed on the display of the measuring unit (it is not recorded in the device memory)

Fuel level measurement in liters

Since the fuel tanks different cars have different sizes, the same fuel level in different types tanks correspond to different amounts of fuel.

To measure the amount of fuel in liters on any type of tanks, it is necessary to preset the meter, which is done on a personal computer using the program. The essence of the setting comes down to storing various configurations of fuel tanks in the meter's memory.

Fuel gauge electromagnetic principle action consists of a receiver, located in the instrument cluster, and a sensor (petrol resistor) BM134-A, installed in the upper part of the fuel tank. The device and diagram of the fuel level indicator are shown in the figure.

The pointer sensor is a rheostat 3, one end of the winding of which is connected to ground, and the other - to the windings of the pointer coils. Moving contact 4 (brush) slides along the rheostat winding, which is fixed on the axis of the float arm 5 floating on the fuel surface.

The receiver consists of two coils 7 and 10, located at an angle of 90 ° to one another. At the point of intersection of the geometric axes of the coils, an iron armature 8 with an arrow 11 is installed on the axis. The winding of the left coil is connected in series to the battery - rheostat circuit, and the winding of the right coil is parallel to the rheostat. The direction of the turns of the windings is made so that the poles of the same name of both coils are located at the top and bottom, respectively.

The fuel level indicator receiver has a scale with a graduation equal to V4 of the fuel tank capacity. The scale contains the designations: 0 (empty tank), 0.5 (half of the tank capacity) and the letter P (full tank).

Figure: Fuel level indicator diagram Moskvich-408:

1 - accumulator battery; 2 - sensor; 3 - rheostat; 4 - movable contact; 5 - float; 6 - receiver for the gasoline level indicator; 7 - right coil; 8 - anchor; 9 - counterweight; 10 - left coil; 11 - arrow; 12 - ignition lock

The fuel level indicator works as follows.

When the tank is empty, the float is lowered and the rheostat brush is in the extreme left position (the rheostat resistance is zero). In this case, the current through the winding of the right coil almost does not go, since the coil is connected to ground by the rheostat brush; therefore, almost all the current passes through the winding of the left coil, as a result of which the armature under the influence of the magnetic field turns towards the left coil, and the pointer arrow is opposite the number 0 of the instrument scale.

When the tank is full, the float is in the uppermost position, and the brush turns on all the resistance of the rheostat. The current passes through the winding of the right coil, creates a magnetic field, under the action of which the armature rotates, and the pointer arrow is opposite the letter P.

When the tank is partially filled with fuel, a part of the resistance of the rheostat is included in the circuit, and the current simultaneously flows into the windings of both coils. In this case, the position of the armature, and hence the pointer arrow, is determined by the combined action of the magnetic fields of both coils.

Depending on the ratio of the magnetic fields of the coils and determined by the level of fuel in the tank, the pointer arrow takes intermediate positions between the divisions 0 and P of the instrument scale. The pointer works only when the ignition is on. With the ignition off, the instrument arrow is at zero. The indicator serves for approximate control of fuel consumption and is not suitable for determining the exact consumption, since the accuracy of its readings is insufficient.

In order not to burn out the winding of the rheostat when repairing electrical wiring or when changing devices, you must not allow the receiver terminals to close and confuse the ends of the wires connected to the terminals.

A serviceable and properly adjusted device at a voltage of 12.5 V and a temperature of 20 ° C provides an accuracy of readings at the 1/4 and 1/2 scale points of about 7% of the tank capacity, and at the P (full) point - about 10%. In this case, the shift of the arrow from the axis of the scale division by the width of the arrow is taken as an error equal to 7%. In other points of the scale, the accuracy of the instrument readings is not standardized. When the voltage in the device circuit changes, as well as when the temperature changes environment the instrument error may increase slightly.

What to do if it incorrectly shows, is buggy or lies the fuel level sensor in the tank? Of course, immediately repair it or replace it with a new one, since this device not only predicts our fuel costs, but also saves the family budget by controlling its consumption.

Main functions of the device

All capacitive fuel level sensors are designed to measure the amount of liquid in a container, or rather, in a gas tank. They are connected to the monitoring system vehicle, to which they transmit the corresponding signals. Basically, these are high-precision universal devices, which can be used not only for cars, but also for other equipment, as well as stationary objects.

Today there are several types this mechanism... And it doesn't matter at all which fuel level sensor (float, electronic, digital, ultrasonic, universal) was chosen, its main function still remains unchanged - definition. But it is fuel costs that are the most constant and tangible for the pocket. The gasoline level sensor will also allow you to control such moments as fuel draining (this function is especially important for businesses, taxi services, etc.), and, of course, will not let you fool you at the gas station.

For more detailed monitoring of the fuel level, you need to install more sensitive devices with the smallest error on your car.

The principle of the device

Basically, the device of the fuel level sensor assumes the presence of a float. Most often, it is made from plastic, foam or other lightweight material. The presence of a potentiometer is also important, its role is played by a resistor, on the surface of which metal strips are applied, and its movable contact creates a variable resistance to the current that passes through it.

Today, the most popular are tubular or lever-type potentiometric sensors. The principle of operation of the fuel level sensor of the first type is reduced to the fact that the float placed in the tube moves depending on the position of the liquid and closes the wires parallel to the guides. In the second case, the movable contact of the potentiometer is connected to the float by means of a metal lever.

Possible malfunctions of the petrol level sensor

Problems with the fuel level sensor are of a different nature. The most common problems are related to the fact that the device shows invalid data, for example, its arrow indicates that the tank is empty, but in fact there is still plenty of fuel in it. And there are quite a few reasons for this behavior, for example, the panel itself may fail, and it is possible that the arrow is out of order, or the float is jammed.

When the readings of the device jump: let's say, at the beginning of the movement, it indicates the minimum fuel level, but then this value increases by itself, then this also indicates that the device does not work, but how to check and repair the fuel level sensor in such a situation , we will describe below. If the light on the panel stopped lighting up, warning of the minimum amount of fuel in the tank, or if it works, but malfunctioning, then the whole point is in the thermistor, which must be replaced immediately.

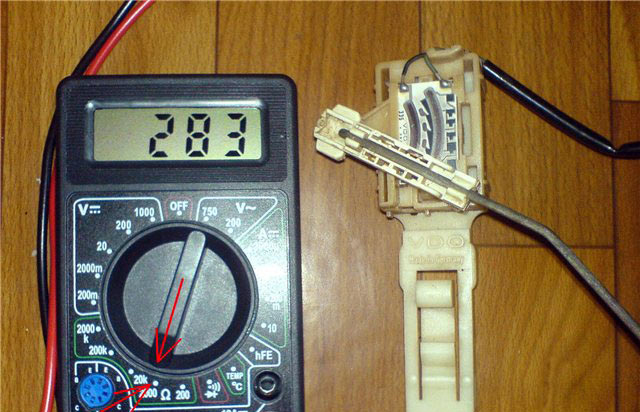

We repair the fuel level sensor ourselves

But before proceeding directly to the replacement or repair work, you need to know where it is, how to remove and repair the sensor low level fuel. It is attached to the bottom of the gas tank, and therefore, in order to remove it, it is advisable to raise the car on a jack and disconnect the contacts. First of all, we pay attention to the condition of the tracks, since they are often erased from the impact of the slider. If the defect is small, then you can bend the slider so that it is above the damaged area. If this cannot be done, the entire device should be replaced.

Also, checking the malfunction of the fuel level sensor involves diagnosing the contacts and "ground" (especially under). To get to the contacts, you need to remove the panel and then tighten all the nuts, through which the closure is created. If the arrow showing the fuel level is out of order, then you must press the button daily run, and then start the engine.

But besides information on how to repair or replace this device, someone may be interested in how to trick the fuel level indicator sensor. One of the ways to drain gasoline imperceptibly is to put a so-called dropper, because this device records only those drains that occur in a very short time interval. But if the liquid drips on the sly, then such a scam will not be detected. In general, the repair and replacement of the fuel level sensor are simple operations, so it is not at all necessary to contact specialists for this, but you can do most of the activities yourself. It is much more important to choose a really high-quality device.