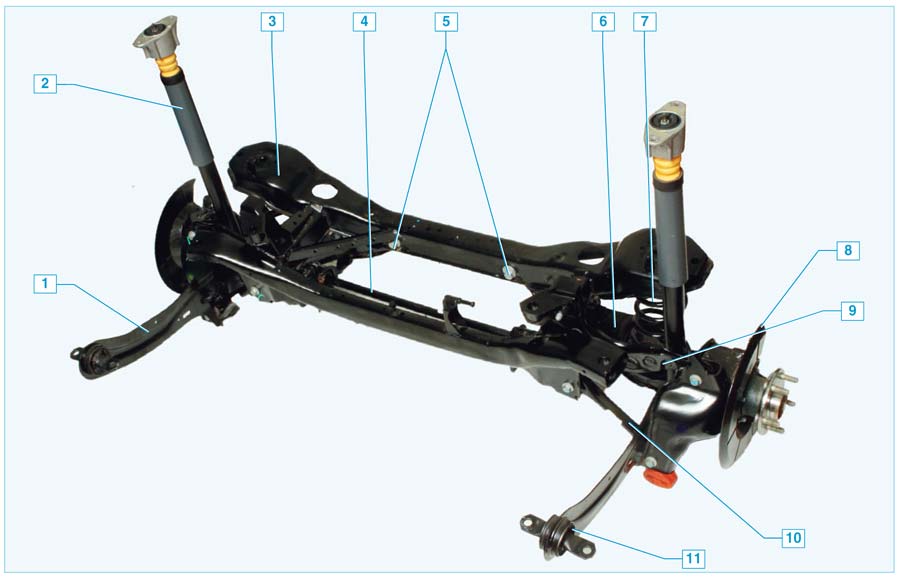

It consists of:

- trailing arm

- shock absorber

- stretcher

- stabilizer lateral stability

- adjusting bolt

- lower front arm

- bottom rear arm

- upper arm

- springs

- brake shield

- trailing arm silentblock

By itself, the rear suspension Ford Focus 2 is independent, has many levers, coil springs and double-acting hydraulic shock absorbers.

It's 92 hp. more than it started. Things can go horribly wrong if not done properly. It reacts the way you want it to when you press it and you can really push it hard. It requires a solid foundation and good suspension setup for all of the above functions.

Here we see that the lower control arm and rounded fist made of the same iron as the main car. Typically, in front vehicles, the steering system moves around its business in the background of the centerline of the axle. The front hinge stabilizer post up the top of the steering rack en route to its long, narrow cable, which in turn connects directly to the rack body for the most efficient driving ratio.

The bearing elements of the suspension include stamped trailing arms. Each of these arms is connected to the subframe via three wishbones. And these levers are attached through the silent blocks.

When you brake, the forces generated are taken over by the trailing arms. The transverse levers, on the other hand, perceive the forces acting when you hit an obstacle.

This is much shorter, which dramatically speeds up the control response. The variable portion comes from the ever-widening tooth spacing as you move away from center, but the overall increase in speed comes from this shorter arm. Most of this huge difference does come from the faster ratio, but some comes from the need to limit the amount of blocking somewhat so that the shorter hand doesn't get too close to its center overload point.

At the tip of the tie rod, this prominent bend is designed to clean the inner flange of the 18 '' by 8 '' wheel when steering completely blocked. It mounts up and down on two bushings when the suspension is compressed. Larger and more visible from the rear to the rear is primarily intended to handle acceleration and braking torque reactions, as well as the front component of pothole impact.

The trailing arms are attached to the body with two bolts. There is a silent block between them. The wheel hub assembly is attached to the rear of the trailing arm. It rests on four screws.

The hub assembly consists of a bearing, a hub and a wheel speed sensor, which is part anti-lock braking system.

Springs are installed on the lower arms. For them, support cups are made in the levers, in which rubber gaskets are placed. From above, the springs fit into the cups made in a stretcher.

This loading path at the entrance explains why the rear hub seems to hang to the side of the subframe, why the lower control arm slides into it from the front and isn't locked tightly at the back. The subframe fully corresponds to the internal direction of the forces to which it is subjected, by the way, it will be more even with the ground than we see here when the car is lifted up and the suspension is in a full fall.

Just past the point where this bushing meets the subframe is where the subframe is bolted to the chassis, and here we see the smallest subframe bushing tape. It is easier to see the subframe bushing material when we look at the front subframe attachment point. This white color gives this as a polymer material that is stiffer than the kinds of rubber bushings that are commonly used in front subframe mountings, and that means something to us because the stiffness of these bushings has a direct impact on steering precision and feel.

Shock absorbers are attached in this way:

- lower eyelet to trailing arm with bolt

- upper support to the body

Shock absorbers, together with springs, enable the rear wheels to move up and down when driving over irregularities, and also dampen body vibrations that are inevitably formed in this case.

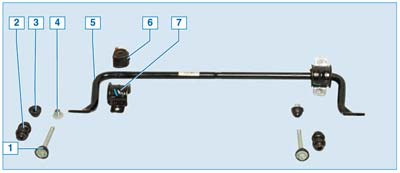

The anti-roll bar consists of:

The steering rack, which turns the wheels, is mounted on a subframe, which in turn is mounted on the car body through these bushings. As for the more obvious parts of the suspension, such as the springs and dampers, both have been reinforced. The front spring rate is about 30 percent stiffer, but that's not all it needs for a sporty chassis because the 0-liter turbo engine and its plumbing, and the six-speed gearbox provide a little extra pound for support.

The A-pillars share the same body, but the inner damper is significantly different, resulting in more damping in corners that are dominated by low internal piston velocities associated with body roll rather than high velocity shock impacts. "Lower speed damping" is a phrase that refers to the speed at which the suspension is suspended, not the speed vehicle on the road.

- bottom cushion with bolt

- buffers

- top cushion

- nuts with washer

- barbells

- pillows

- staples

It is designed to make the car roll as little as possible when cornering, and also to increase the overall lateral stability of the car.

Menu 1.Operating manual 2.Engine 3.Clutch 4.Gearbox 5.Front wheel drive 6.Front suspension 7. Rear suspension 8.Steering 9.Brake system 10.Electrical equipment 11.Body 12.Heating, ventilation and air conditioning 13.Applications Forum Technical assistance "FORD"

Here we can see that the brakes themselves are single-piston calipers, but the internal piston bore and pad size are increased to accommodate larger rotors. It uses the so-called "Ford" blade with a trailing arm. The heavy lower link carries the spring and most of the lateral pivot loads with the shorter lower leg in front of it. There is a single decoupling line at the top that holds the top of the wheel to the desired camber angle.

Front hub bearing replacement diagram

We also get another glimpse of the sock link and the main footer link. If these numbers don't make sense in your head, you may have missed the engineering class where the professor explained that the torsional stiffness of a stabilizer is proportional to its diameter raised to the fourth degree.

Rear suspension: 1- trailing arm; 2 - shock absorber; 3 - stretcher; 4 5 6 - lower rear arm; 7 - spring; 8 - brake shield; 9 - upper arm; 10 - lower front arm; 11 - silent block of the trailing arm

And, as we saw the front, its inner guts were altered to provide more low speed damping to aid in cornering. This is a pretty neat package too, with the top end of the spring acting directly on the strongest part of the unity. A solid rubber rack and landing pad sit right behind the reels.

This bottom view shows the new routing of the stabilizer bar at a new angle. It's a long way from the swivel hub to the new end, which is a new source of inefficiency because the rod is likely to bend a little rather than wriggle exclusively.

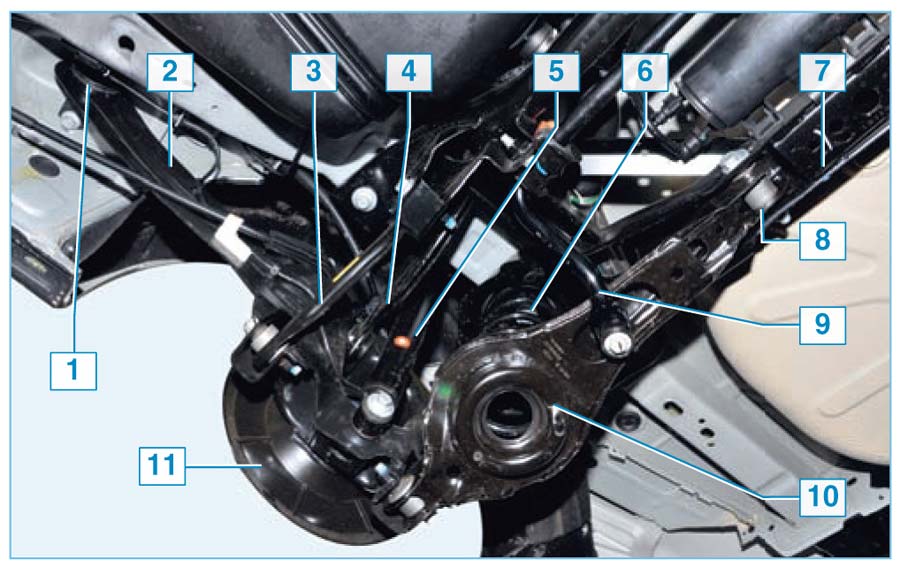

Rear suspension elements on the car: 1- silent block of the trailing arm; 2 - trailing arm; 3 - lower front arm; 4 - upper arm; 5 - shock absorber; 6 - spring; 7 - stretcher; 8 — adjusting bolt (the bolt securing the rear lower arm to the subframe); 9 - anti-roll bar; 10 - lower rear arm; 11 - brake shield

You will want a spare kit of something else if you live where there is snow. Assembled together, they weigh 8 pounds - close to the factory average of 16 or 17, but on the cardinal point for factory 18-inch tires and wheels of this size and in this price range.

We haven't seen just acres of aluminum or gimmicky adaptive hanging bits that will surely drive the price up. Experience rear wheels proves how much you can get from a few subtly redesigned chassis parts and a well-done suspension recalibration.

Titanium: A mineral from which a light, durable, glossy and corrosion-resistant metal is made that does not deform to a certain extent when exposed to high temperatures and has widespread use in the manufacture of missiles, commercial aircraft, military and spacecraft. Thus, while confirming the correct designation of the vehicle, it is curious to indicate that some Brazilians "nave" or "plane" are more attentive to the movement of the streets.

The rear suspension is independent, multi-link, with coil springs and double-acting hydraulic shock absorbers.

The main supporting elements of the suspension are stamped trailing arms, each of which is connected to a subframe by three wishbones through silent blocks.

The braking forces when the car is moving are perceived by the trailing arms, and the forces in the direction perpendicular to the longitudinal axis of the car are perceived by the wishbones.

His trump card: the car, which has always been distinguished by excellence in interior decoration, pleasant handling, safe and precise, now wants to win hearts and minds with an extensive package of standard items, as well as technological and electronic options... The car can have, among other things, a programmable key with a presence sensor, multimedia systemwhich allows the driver to control various functions of the vehicle with a voice command in Portuguese and a second generation automatic parking module that helps to park in parallel and perpendicular waves.

Trailing arm

A silent block is installed in the front of the trailing arm, through which the arm is fixed with two bolts to the body. The rear wheel hub assembly is attached to the rear of the arm with four screws.

And the elect could not be different. Walter Arada and Jose Estanislau Germano. At 49, the repairman is another with fat in his veins: he has been playing with cars since he was 11. An Italian from the Salerno province of southern Italy, Martino has been in Brazil for 35 years, where he came to work in the workshop of his uncle's company. He arrived here accredited with a degree in industrial mechanics from the Technical Institute of Salerno and with a familiar experience that included, at the age of 5, dismantling and installing the engine of his grandfather's old Fiat Balilla, who served as his first foreman.

Rear wheel hub assembly: 1 - rear wheel hub; 2 - wheel speed sensor

The hub unit is a non-separable unit with a bearing and a master element for the wheel speed sensor of the anti-lock braking system.

Lower rear arm

In Brazil, he met Dona Lourdes, with whom he had two daughters, and made him return to Botha just for a walk. But it's good not to get carried away by the strong accent of the repairman: judging by the line of customers waiting for service, Guglielmo works well, with anything imported and national that moves on four wheels.

Pedro Demeter and Dirceu Junior. It's a partnership that worked, says Junior, who already has 26 years of renovation experience. At first it makes a good impression, it is beautiful. Easy access to controls and readout system on on-board computer simple and highly visible, says Walter. “The car is comfortable, although the rear seats are not designed for very tall people,” says Herman. His appearance and the completion says that we will have a good thing.

Spring support cups are made in the lower rear levers. The upper ends of the springs abut against the subframe cups. The cups are fitted with rubber pads.

The lower shock absorber eye is bolted to the trailing arm, and the upper shock absorber mount is bolted to the body.

Shock absorbers and rear suspension springs allow the rear wheels to move up and down when driving over bumps and at the same time dampen body vibrations.

Suspension monitoring

The machine is triggered and has no sedan unclean air. It's hard for me to get into the car and feel good the first time, like now. Everything is adjusted: seat height, steering wheel size and steering position. The car impressed the repairmen with its convenience, comfort and performance. Nothing is lost due to the filling and turning of the engine, which is reasonable, not to mention that in the corners the car exhibits stability and sticks on the track. We note that 175 horses, when the engine is fueled by gasoline, as is the case, are under the hood, says Herman. Between throttle control and the throttle there is no gap.

Anti-roll bar parts: 1 - bottom cushion with a bolt; 2 - buffer; 3 - top pillow; 4 - nut with washer; 5 - barbell; 6 - pillow; 7 - bracket

To increase lateral stability and reduce the roll angles of the car, an anti-roll bar is installed. The stabilizer bar in its middle part is attached with two brackets through rubber split pads to the subframe. The ends of the stabilizer bar are connected to the rear lower arms through struts with rubber-metal hinges.

The car does not require much turning to reach high speed and speeds up acceleration a little. Many of these qualities are undoubtedly the result of this system. direct injectiondesigned by Ford. Congratulations to the engineers, - comments Walter Arada. When he tested the Focus Focus on Nazare Avenue, not far from the Ipiranga Museum, Guglielmo Martino from Carbello could not resist and resorted to the term from the old Bota: "Beautiful!" According to him, the agility of the car makes the driver who cultivates the pleasure of driving, forgetting about life. “It's a shame that the movement of our cities, Brazilian fuel and conditions on the streets and roads of the country are not helping,” he complains.

Upper arm

Lower front arm

The toe angles of the rear wheels are adjusted by rotating the bolts securing the lower rear arms to the subframe (adjusting bolts).

We have to go forward, not backward, ”he says. Driven by a thin cable, it does not appear to provide an alternative to open in the event of a failure, which is typical of small forward collisions. “If this cable comes out of the black workshop, it will suffer to open,” Herman warns. Of course, direct injection is all about performance. The quick and strong reactions that the engine presents are associated with the direct injection system. Its nozzles are located inside the combustion chambers and work under high pressureare no longer exposed in the manifold.

The adjusting bolt has an eccentric head and a washer. When the bolt with the washer rotates, its position in the subframe hole changes: when the bolt is displaced to the longitudinal axis of the car, the outreach of the lower rear arm decreases and, therefore, the wheel toe angle decreases; when the bolt is displaced from the axis, the angle increases.