other services

Flushing the injector (s)

Very often we have to answer the following questions:

What is the best way to flush the injector with liquid or ultrasound?

Is it true that ultrasound kills injectors?

And if you flush the nozzles with liquid, which one is better?

Do they need to be washed at all?

Will flushing surely solve all my problems?

In this article, we decided to disclose in detail all the issues related to this topic, describe the methods of flushing, review equipment, flushing fluids, describe all their advantages and disadvantages! And also to help you avoid unnecessary costs.

Flushing the injector

Nozzle is simple solenoid valvedesigned for the most accurate dosage of fuel delivery and atomization.

The main stages of injector clogging.

1. Stage clogging: the difference in the performance of the nozzles is 5-7%. With little blockage, there are no special problems with the engine. Usually, there is an increase in fuel consumption by 1-3 liters per 100 km. On bad gasoline detonation may occur.

2. Stage clogging: the difference in the performance of the nozzles is about 10-15%. On idling the engine "podtraits" (starts to work unevenly). The exhaust also becomes uneven, with chaotic popping. Fuel consumption increases noticeably and acceleration dynamics deteriorates. Detonation appears, acrid smell from the exhaust pipe.

3. Stage clogging: the difference in the performance of the nozzles reaches 20-50%. The engine is trying to "jump" out of the hood. One or more cylinders may not idle at all. Upon attempt hard pressing on the gas pedal in the housing air filter claps are heard. All the symptoms of the first two stages are also present in a more vivid form.

There are currently 2 main ways to clean injectors:

Flushing the injector with liquid (performed without removing the injectors from the engine).

The procedure is carried out by connecting a flushing unit with flushing liquid to the fuel supply system to the injectors, while standard system The fuel supply is turned off so that the flushing liquid does not get into the gas tank under any circumstances. If you pour flushing fluid directly into the gas tank, it will dissolve deposits on the walls of the fuel tank, which will clog the intake screen of the gas pump and fuel filter, which threatens to replace the fuel pump and ultrasonic flushing of the injector. There are quite a few types of washing installations, but the installation does not affect the quality of washing. Its task is simply to supply the flushing fluid to the nozzles. The quality of the procedure depends only on the liquid used and the time of work with this liquid.

What liquid should I use to flush the injector?

At the moment, there are a lot of manufacturers of liquid for flushing the injector. But we will only consider the most common brands.

1. Wynn "s (Vince), perhaps one of the most famous manufacturers of flushing fluids. Very strong, completely kills spark plugs, but perfectly removes carbon deposits from combustion chambers and valves. Indispensable for flushing injectors on cars older than 2002. On many cars it is highly undesirable to use it.For newer nozzles, it is better to use a different fluid.

2. LIQUI MOLY (Likvi Moli) more gentle washing, spark plugs after it can not be changed. She rinses the nozzles quite well, but practically does not remove carbon deposits from the valves. Its advantage lies in the fact that you can flush the injectors on any cars without fear of killing the injectors. We recommend it for flushing systems with direct injection fuel (Mitsubishi GDI, Nissan neoDI, Toyota D4, WV Audi FSI).

3. Laurel - flushing by its nature is very similar to Wynn "s, but it is not justifiably expensive. For this reason, it is little used in car services.

4. Carbon Clean wash with moderate character, golden mean between Wynn "s and LIQUI MOLY.

Can the nozzles be damaged by liquid flushing?

In fact, you can only harm the wrong choice of flushing fluid.

But if you know what liquid to wash this car, then you will not have unexpected costs for the purchase of new injectors. For example, flushing with Vince on a Nissan with neoDI injection, one hundred percent leads to injector failure. And the cost of a set of nozzles for it is about 45,000 rubles.

The advantages of liquid flushing are that the procedure is useful not only for the injector, but also for the engine itself; carbon deposits are removed from the valves and the combustion chamber.

The procedure is recommended to be carried out once every 30,000 km. mileage.

Ultrasonic flushing injector.

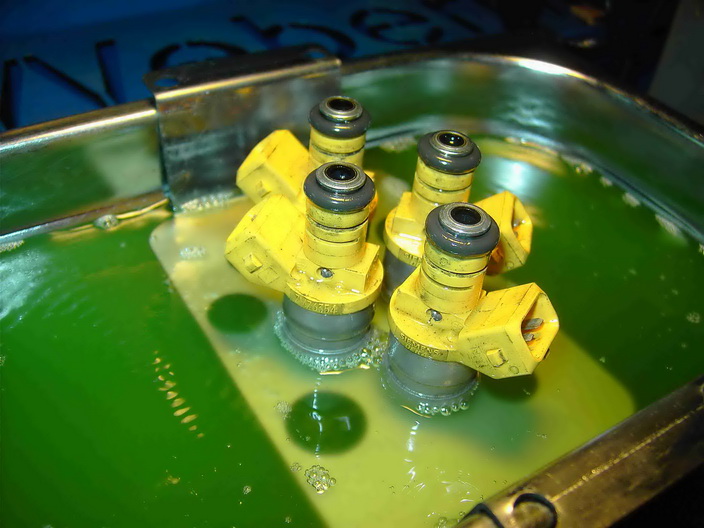

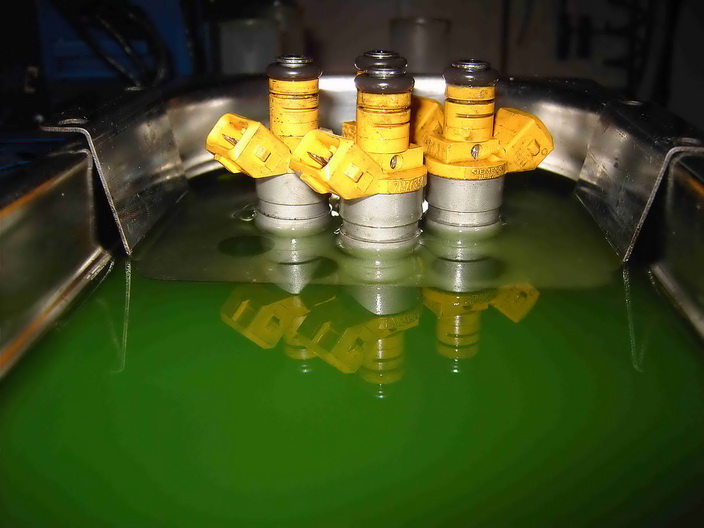

During ultrasonic washing, the nozzles are removed from the engine and placed in an ultrasonic bath, where they are washed using the cavitation effect.

As a rule, we start the first rinsing cycle at low power in a gentle mode. The nozzles are then installed in a test bench where the spray pattern and performance are checked.

![]()

This procedure is repeated until the difference in performance between the nozzles is less than 1-3%.

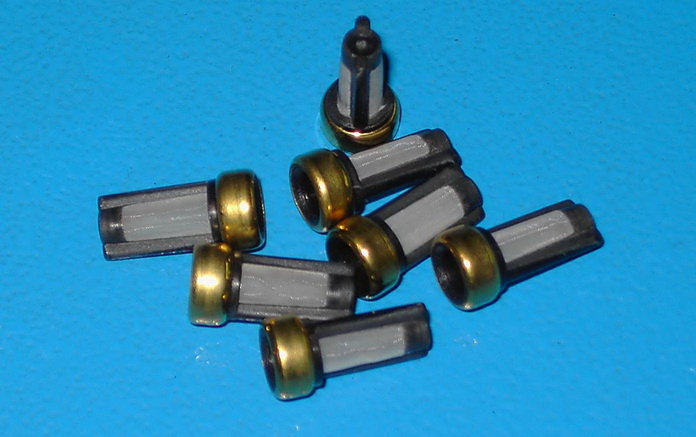

Then, if necessary, new filters and O-rings are placed on the nozzles.

In the overwhelming majority of cases, even the most neglected nozzles can be flushed out. We managed to wash these. Liquid cleaning of the injector in such a case would be useless.

Of course, there are cases that the nozzles cannot be flushed (as a rule, after water gets into the gas tank and the car is parked for a long time). In such a situation, the money is taken from the client only for checking the injectors in the stand and a verdict is issued in full or partial replacement nozzles. But in any case (as opposed to liquid flushing) it becomes clear whether the problem is in the nozzles or not.

Can the nozzles be damaged by ultrasonic flushing?

Of course yes! You can break everything! On old cars, the injectors are very strong and in 30 minutes they only begin to rinse, unlike injectors from fresh cars, which during the same time can completely crumble. Ultrasound should be handled with care. Typically, a wash stand has many wash modes and it is possible to start the wash with a gentle, gentle wash. It should be understood that the main value of ultrasonic washing is not in the ultrasound itself, but in the fact that the nozzles are checked in the stand! And you can evaluate the performance of the nozzles both before and after flushing.

What affects the quality of ultrasonic cleaning?

Equipment can be different, more expensive, as a rule, more convenient to use, looks more beautiful, has touch control. There are also a lot of liquids for ultrasonic baths, but they all have approximately the same composition. IN in general terms So it turns out that the quality of ultrasonic washing depends only on the human factor.

Which injector flushing is best done by ultrasonic or liquid?

If you don't have any special problems with the car, the engine idles smoothly, then of course it is better to do liquid injector cleaning... The procedure is useful not only for the injectors themselves, but also for the engine (removes carbon deposits from the valves and the combustion chamber). Liquid cleaning can easily handle the first stage of nozzle clogging! It is advisable to guess the procedure for changing the oil, filters and spark plugs. Liquid cleaning is a preventive procedure and its main disadvantage is that it is done “blindly”.

If there are visible problems in the operation of the car engine, then it is definitely necessary to do DIAGNOSTICS and not just reading error codes, but real comprehensive diagnostics with checking the ignition system, checking the fuel pressure, checking the catalyst backpressure, etc. According to statistics, only 5% of all cars that turned to our car service for diagnostics really needed to flush the nozzles. The remaining 95% had completely different problems: (sensor malfunction, air leakage, malfunction of high-voltage wires, ignition coils, fuel pump, clogged catalyst, etc.)

In the case when everything has already been checked and there is a real suspicion that the nozzles are clogged, it is necessary to remove the nozzles, put them in a test stand, check the spray and performance. According to the result, it will be clear what to do: either wash them, or put them in their place and look for the problem elsewhere.

Not sure what is best for YOUR car or did not find the information you are interested in? Call us:

>>>Even a well-groomed car sometimes wants to "play up" - fuel consumption becomes incredibly high, the car refuses to accelerate with its former agility, and when pressed, the gas pedal falls through unpleasantly. The reason is simple - the fuel system is clogged and needs cleaning.

| Cleaning the Tsi and Fsi system nozzles 1-piece. (excluding the dismantling of the injectors) | 300 RUR |

| Khimichki injector flushing (engine capacity up to 2.0 l.) | 1800 RUR |

| Chemical flushing of the injector (engine capacity from 2.5 to 3.5 l.) | 2500 RUR |

| Chemical flushing of the injector (engine capacity from 4.0 l.) | 3500 RUR |

| Removing the injectors | 1500 rub. * |

| Diagnostics of injectors at the stand | 400 RUR |

| The cost of removing the injectors may vary depending on the complexity of removing the injectors. * |

Why injectors are clogged

Many drivers tend to consider low-quality gasoline with mechanical impurities as a source of trouble, but this statement is only partly true. Fuel filters reliably trap all particles with parameters exceeding 10-20 microns. However, during operation, the inevitable deposition of heavy gasoline fractions occurs, the process begins immediately after the engine stops. At this moment, the temperature of the nozzle body rises, as a result of which the light components of the fuel evaporate, and the heavier ones settle as a strong resinous lacquer deposit along the entire length of the fuel line. Gradually, the fuel is atomized more and more poorly, and sometimes, with a significant narrowing of the section of the calibrated channel, it is injected with a jet. Hence the unpleasant changes in engine performance. Thus, heavy oily and resinous fractions contained in low-octane and low-quality fuel - the main reason for the accelerated clogging of injectors.

Fuel system problems - when you need specialist help

The main signs that an injector needs to be flushed are:

- fuel consumption increased;

- problems with starting the engine;

- loss of auto power and deterioration of acceleration;

- at idle speed, the engine is unstable;

- an increase in the toxicity of exhaust gases;

- gas pedal failures.

How to clean the fuel system

Even if your car does not bother with the problems listed above, experts advise you to pay close attention to the regularity of cleaning the power systems of diesel and gasoline cars. It is recommended for routine maintenance and at least every 20-30 thousand kilometers.

Even if your car does not bother with the problems listed above, experts advise you to pay close attention to the regularity of cleaning the power systems of diesel and gasoline cars. It is recommended for routine maintenance and at least every 20-30 thousand kilometers.

Attention! For diesel engines that run on diesel fuel domestic production from oil containing up to 2% sulfur, it is recommended to flush the injector every 10,000 km!

Flushing the injector is a complex and responsible process, therefore, it is better to entrust the intervention in the fuel system to experienced professionals. Regardless of which brand of car you own, experts use two main methods to clean the formed deposits:

1. Ultrasonic flushing of the injector with dismantling of the nozzles

An effective, but quite expensive way. Its disadvantage is that only nozzles are subjected to the cleaning procedure, which are dismantled for this and immersed in a container with a special solution. Under the influence of ultrasound, they are cleaned and, before installation, are checked at the stand.

2. Liquid flushing of the injector under pressure

The most popular method for successfully cleaning the fuel system in the complex. With this flushing of the injector, the nozzles remain in place, which is a strong argument in favor of choosing this method. Stationary installations supply a special solution (solvent) under pressure, which contributes to the uniform circulation of the chemical composition throughout the entire injection system and helps to flush all the components with high quality, including the injector. Such cleaning is especially effective on a warm engine. The technology is applicable for diesel and gasoline engine, the difference lies only in the choice of fluid.

The most popular method for successfully cleaning the fuel system in the complex. With this flushing of the injector, the nozzles remain in place, which is a strong argument in favor of choosing this method. Stationary installations supply a special solution (solvent) under pressure, which contributes to the uniform circulation of the chemical composition throughout the entire injection system and helps to flush all the components with high quality, including the injector. Such cleaning is especially effective on a warm engine. The technology is applicable for diesel and gasoline engine, the difference lies only in the choice of fluid.

Our company uses high-quality auto chemicals from well-known manufacturers, which have important advantages - the absence of aggression towards the hoses and the requirement for an obligatory replacement of oil and spark plugs in such cases. Some motorists consider it sufficient to self-rinse by pouring a chemical composition into fuel tank... The method is only good for prophylaxis, since commercially available fluids often do not cope with severe contamination. For high-quality flushing of the injector on gasoline and diesel engines we recommend using the services of our company, the cost of which is quite affordable.

How and how to flush the injector nozzles?

Most modern cars a fuel injection system is used, which assumes the presence of an injector. In fact, this part itself is much simpler when compared to a conventional carburetor. However, due to the presence of sophisticated electronics that regulate the quantity and quality fuel mixture... there can be much more problems with injectors.

But what to do if this detail clogged? How to flush an injector? Of course, the best option there will be an appeal to a car service, where all work will be carried out by professionals at a specialized stand using ultrasonic technology.

Should I drive to a car service?

However, the cost of such a service may be too high, or the location of the given car service may be too distant. Therefore, you can try to determine the need for flushing using self-diagnosis. injection system ... So, it would be appropriate to try to cope with such problems yourself, especially if you have one of the most popular chinese cars in our country - Lifan. These machines are distinguished by their unpretentiousness and good capabilities, both for service and for self-service.

Contacting a service center would be ideal

Signs of the need to flush the injector

It must be remembered that a car is a complex mechanism in which there are many electronic components.

So, there can be many real reasons for problem driving.

Nevertheless, it is necessary to exclude the most obvious options, such as a plugged injector.

This applies to those cases when the car starts to work with reduced power or with increased fuel consumption, or starts to triple and stall. Also, the option with a sharp "failure" of the accelerator pedal or with unstable operation is also possible power unit... And in the case of exhausts, their smokiness can be increased.

Check the quality of the exhaust

The most "harmless" option will be a simple decrease in dynamic performance. The car, as it were, will stop "pulling".

If the problem is simply ignored, then the car may have more serious problems. The point is that the injector will be clogged to such an extent that it will have to be completely replaced. And this, depending on the car model, can result in expenses up to several hundred US dollars.

But, it can be very difficult to do this, since the quality of the fuel can vary, even within the same filling station.

Injector prevention standards

Prevention of the injector should be carried out at least once every five thousand kilometers, if we talk about the water binder in gasoline; or at least once every ten thousand kilometers, in the case of a complete cleaning of the injector. Even if the injector has no “symptoms” of problems, this does not mean at all that they will not be there in the future.

How to flush an injector

Now the time has come to take immediate action, which consists in self-service your car. If you are wondering how to clean the injector yourself, then the following information will be very useful to you.

To begin with, you need to decide what is the best way to flush the injector. Most often, we are talking about a special fluid that is sold in car stores.

If you don't have it at hand, you can also use a carburetor flushing fluid.

Its chemical composition practically does not differ, since this substance does the same - it removes extraneous elements from the fuel movement channels. Now you will no longer have to worry about which liquid to flush the injector. Thus, we can say that we just have to chase special liquid through the nozzle to achieve complete cleaning.

There is no fundamental difference in the fluid for flushing the carburetor or injector

In order to clean the injector with your own hands, you need to reduce the pressure in the fuel line. This is done in the working condition of the motor. We need to remove the fuse, which is responsible for the operation of the engine. Now we wait a few minutes before the motor is completely stopped.

We remove the rail with nozzles

After that, it is necessary to disconnect the injector terminals, as well as several other elements, including the injection and reversible fuel line hoses, as well as a rail with injectors, which must be unscrewed and completely removed.

Check all accompanying items

And only after that, it is time to remove the nozzle rings.

It is important to consider the rings here. If they become black or too hard, then they must be replaced.

Flushing process

Rinsing the injector yourself is quite simple. To do this, it is necessary, as we have already noted, simply to drive the corresponding liquid through the injector. Each nozzle will have to be flushed separately. To do this, we will need wires with terminals or other reliable contacts to connect to a power source operating in the range of 9 to 12 volts. It is necessary to check that the contact with the push-button switch is as reliable as possible.

A regular syringe will do

It is now important to ensure a snug fit of the fluid passage in the nozzle. To do this, you can use a five-gram syringe, which is attached to the nozzle from its wide side.

However, the syringe can be replaced with another item, if necessary.

Take care of the power supply

Now we connect the prepared terminals to the power source. Thus, we begin the process of simulating the operation of the valve, by pressing and releasing the switch button. We need to pass the liquid through the nozzle under high pressure... By doing this, we can clean the valve seats, as well as the fuel channels.

Once the liquid has been passed through the nozzle several times, it must be left for a while before the oxidation process takes place. After that, the procedure is repeated again. If everything is done correctly, the injector will start functioning again as it did from the very beginning.

The assembly of all elements of the injector is carried out in the reverse order.

It is important to pay attention to whether there is a leak at the base of the nozzle.

It will be quite easy to check this - to set the pressure in the line using a gas pump for this. So, we will need to start the engine a couple of times without starting it.

You can put everything in its place

After these simple procedures, you need to check if the car is working properly. If all is well, then the only problem was the injector malfunctioning. Otherwise, it is necessary to look for other shortcomings in the functioning of the power unit.

about cleaning nozzles at home

If, after cleaning the injectors, your car is still "dull", then you need to check the pressure in the fuel rail. the problem may be in some of its elements.

http://lifanovod.ru

The main symptoms of contamination of fuel injectors are:

- loss of power

- increased fuel consumption

- jerking or "failures" when accelerating the car

- on idle unstable work, "Tripping" of the engine

We do the same adaptation throttle, cleaning the throttle valve, replacement of the throttle valve, throttle valve adjustment, checking petrol injectors, cleaning of nozzles with ultrasound, replacement nozzles, injector cleaning cost.

Injector contamination mainly occurs for two reasons. The first and most common is the use of low quality fuel. The second reason is long-term or complete neglect of preventive cleaning fuel system and cleaning the nozzles. All this can lead to injector leaks, destruction of the "seat" and, ultimately, to improper formation of the jet or injection cloud and, as a result, negatively affect the fuel combustion process.

We clean the nozzles in two ways:

- Cleaning without removing the nozzles.

- Cleaning with removal of nozzles.

In this case, not only the injectors themselves are cleaned, but also the fuel rail of the injection system, as well as partially the valves and the combustion chamber.

This cleaning of the nozzles is carried out using a special flushing agent, for example renowned manufacturer autochemistry "Winn's", at an automated stand.

The effectiveness of the procedure is average. Has a drawback - possibly a negative effect on catalytic converter exhaust gases, after the procedure, it is necessary to replace the spark plugs and it does not allow visual diagnostics of the injectors' performance.

injector flushing price

The duration of the procedure is about 1.5 hours.

The cost of work:

ICE up to 2.0L - 1900 rubles.

Internal combustion engine from 2.0l to 3.0l - 2500 rubles.

ICE from 3.0 l - 3500 rubles.

Cleaning liquid 1 liter - 850 rub

The injectors are removed from the fuel rail of the internal combustion engine injection system. With the help of our special diagnostic equipment it is possible to determine the degree of contamination of each individual nozzle and their subsequent fault detection. After diagnostics, the nozzles, if necessary, are placed in an ultrasonic bath, where in a special chemical solution, the process of cleaning from deposits takes place. Further, at the stand, the cleaning results are re-analyzed. The cost of flushing the nozzles. Injector cleaning price.

We always offer the client to be present during the process of diagnostics and analysis of the injector performance, because it is possible to visually see the operation of the injectors in various modes that simulate the process of fuel injection into the engine combustion chamber. Injector flushing in Moscow.

The effectiveness of such diagnostics and cleaning is high, and in some cases, according to its results, the replacement of a faulty nozzle is required.

The duration of the procedure is about 2 hours.

The cost of work:

ICE 4-cylinder - from 2500 rubles.

Internal combustion engine V6 cylinder - from 5000 rubles

Checking and Ultrasonic cleaning of removed gasoline injectors - 400r for 1pc.

Our address: Ogorodny pr-d, 8s1... The nearest metro stations are Timiryazevskaya, Dmitrovskaya, Maryina Roshcha, Butyrskaya, VDNKh, Telecenter, Otradnoye, Vladykino, Botanichesky Sad, Altufevo, Bibirevo.

Opening hours of the car service "Avtonavtika" - 9:00-21:00

Despite the fact that the engine power supply system from the carburetor is a thing of the past, and its place has been confidently taken by the injector, the old problems remained "due to" the quality of the fuel. Only now it is necessary to clean the nozzles of dirt, not the jets. If you go to a car repair shop, then you will be charged decent money for the ultrasonic cleaning procedure along with disassembling the unit. To save on this service, you need to figure out how to flush the nozzles with your own hands directly on the car in your own garage, without using expensive equipment.

Flushing frequency

Sprayer for direct fuel injection into the cylinder - the device is quite reliable and when used quality gasoline it reliably serves about 100-120 thousand km of run. But since there have always been problems with the quality of fuel in the post-Soviet space, signs of contamination of small holes in the nozzles appear much earlier:

- Due to insufficient amount of supplied air-fuel mixture the engine loses power.

- The controller, seeing the lack of fuel from the signals of the lambda probe, increases its supply, which increases the total fuel consumption. And the car's behavior is not getting better.

- Pops can be heard in the receiver of the injector or in exhaust pipe, from where black smoke periodically falls.

- The motor is unstable.

These are clear signs that it is time to urgently clean the nozzles due to the high degree of contamination. But flushing after a long interval (more than 50 thousand km) can lead to a negative result and the replacement of these parts, for which you need to be prepared.

Premature wear of the spray nozzles occurs as follows: due to dirt that has been stuffed under the valve for a long time, a depletion is formed in its parts. After removing this dirt, which plays the role of a kind of seal, the injectors lose their tightness and begin to leak when the engine is off, although they behave well on the move. Because of this, the engine starts up hard (especially in hot weather), and the oil in the crankcase is diluted by the gasoline flowing down there, that is, one "disease" is replaced by another. There is only one way out - to change the nozzles.

You will be protected from getting into a similar situation by the preventive flushing of the injector, carried out once every 5-20 thousand km of run. But when the above signs appear, be sure to go through diagnostics at the station maintenance... You should make sure that it is the injectors that are floundering, and that some sensor is not out of order.

Cleaning methods

There are several options for cleaning the injector:

- removal of impurities in an ultrasonic bath, which requires disassembling the injector and removing the nebulizers;

- periodic flushing with special additives into gasoline;

- use of flushing fluid instead of fuel.

The last two methods are well suited for flushing the injectors with your own hands, since for their implementation you do not need to disassemble and remove the elements that supply fuel to the cylinders from the engine. Another thing is that these methods are not as effective as ultrasonic treatment, and therefore are considered preventive.

Hence the conclusion: such procedures should be done more often.... The optimal interval for the use of a cleaning additive in fuel is 5-10 thousand km. A more efficient flushing of the injectors without removing them from the engine, where a liquid is used - a substitute fuel, can be done 1 time in 15-20 thousand km of run.

Do not use to service the injector folk methods, providing for the addition of kerosene, pouring a solvent or the use of other exotic compositions.

Instead of saving money, you may end up with large fuel system repair costs.

Gasoline additive application

This procedure is best timed to coincide with the replacement of fuel filters and here's why. The detergent additive is poured into the tank, so the cleaning effect extends to the entire fuel supply system.

Any foreign deposits that have been washed away rush into the filter screens and quickly clog them. If you do not change the filter elements, then it will not be possible to clean the nozzles normally, because dirt will get to them. So, to perform the operation you will need:

- liquid - fuel additive;

- mesh filters for fine and coarse cleaning.

The method of use is simple: the chemical composition from the bottle must be poured into the tank and the vehicle must be continued to operate. Replace the filter elements after 200-300 km. An important point: the amount of cleaner in the container is designed for a certain volume of gasoline, their ratio is always indicated on the product packaging. In order not to get a negative result and not to harm the motor, observe the prescribed dose of the composition.

Most often, motorists use liquid for flushing the injector from the following manufacturers:

- Hi-Gear;

- Kerry KR-315;

- Liqui Moly;

- concentrate Injector Cleaner from the American brand STP.

Do not use this cleaning method after a long run (over 15 thousand km), when a sufficient amount of deposits has accumulated in the system.

When washed, they will not only clog all filters, but also damage the fuel pressure regulator.

Using cleaning liquid

The best way to flush the injectors without removing them from the engine ramp is to connect the container with the flushing compound directly to the fuel line of the power unit. The procedure will not affect other elements of the system - filters, pump and pressure regulator. But you will need to make a simple device from the following parts:

- automobile gasoline hose 1 m long;

- cheap fuel filter with paper element;

- hose clamps;

- 2 valves for tubeless rubber equipped with spools;

- plastic bottle with a volume of 2 liters;

- manual or electric pump with pressure gauge.

It is necessary to make holes in the bottom and cork of the bottle, choosing the diameter of the drill to match the size of the valves. Then, into the hole made in the plug, you need to cut a valve without a spool and attach a hose to it with a clamp. After that, the hose is cut in half and a fuel filter is placed in the gap, observing the direction of flow (from the bottle). A valve with a spool is inserted into the second hole, where the pump is connected. For convenience, it is advisable to hang the bottle to open hood neck down. The device is ready.

Before you flush the injector directly on the car, you need to connect the homemade system to the fuel rail, for which you will have to relieve pressure in it. Find a process connection with a spool built into the end of the ramp, place a plastic cup under it and press a sharp object against the valve. Excess fuel will pour into the glass and the pressure will drop. Then follow this algorithm:

- Disconnect the main fuel line from the rail and connect the hose from the bottle in its place.

- Disconnect the car fuel pumpby removing the corresponding fuse. Another option is to place a gas canister under the disconnected line.

- Pour all of the flush liquid from the bottle into the bottle.

- Connect the pump and pump a pressure of 3 bar into the container (no more!).

- Start the engine at idle speed. Now it does not run on gasoline, but on washing liquid.

- Flushing continues until the motor has used up all the fluid. In the process, you need to monitor the pressure in plastic bottle and maintain it with a pump at 2.7-3 bar.

The cleaning procedure is performed with a warm engine, therefore it must be brought to operating temperature before connecting the flushing attachment.

Using the described technology, it is quite simple to clean the injector yourself, and it will take a little time. It is desirable to combine the procedure with the replacement engine oil, since during flushing, part of the liquid that has not burned in the cylinders can enter the crankcase. The mileage between lubricant changes in the engine approximately corresponds to the periodicity of preventive cleaning of the injectors.