Heading

The main task brake system consists in changing the speed of movement of vehicles, at the command of the driver or electronic system manuals. The second purpose of the braking system is to keep the car in stationary in relation to the road, at the time of parking.

In today's article, we will discuss in more detail the malfunctions of the brake system, namely, we will answer the following questions:

This allows us to create added value for you: through product differentiation, advanced technology and service you can trust wherever you are. Anyone with a vacuum in the car may experience a confrontation that is either depletion of air from the surrounding area or a crack in the penis. Combat affects engine performance, especially cold and reinforcing effects.

In the case of a hacked element, the amplifier does not work. We will spread power so that we take one half and turn the other. It is quite tough and requires a lot of power. It is advisable to help with the loophole, which we will take for the emerging screws. The force is raining because there is spring. You now have two halves of the booster, a buckle attached to a plastic blade, and a spring with a spatula. If you have a broken penis, remove it from the blade. It can be broken the most, but it doesn't have to.

- What is the braking system?

- Brake system device;

- How many types of braking systems are there?

- What is the principle of action?

- How many pitfalls and faults are there?

- Diagnostics of the brake system at the stand;

- Replacing the brake fluid at the stand.

basic information

The main function of braking is considered to control the speed of the car, to stop it, as well as to keep it in one position with the help of the braking force between the road and the wheels of the car. Braking force can be generated car engine, a mechanism for braking the wheels of a car, an electronic or hydraulic retarding brake, which is located in the transmission. For the functioning of all of the above functions, the vehicle is installed Various types brake systems.

The disadvantage arises from a bulging notch clamped in the bottom of the amplifier. The collar can be a round spring. In order not to recede again, it is easy to apply silicone to the cord after applying the spring. If the whole gefero is bad, it needs to be replaced. The mountain support is a small body in the lower body. This is again the best way to change for new or new.

Damaged or damaged vacuum valve must be replaced by another. The entire ball can be simply removed. When the pedal is off, the system sounds. Can't escape the air around the trap attached to the pedal? Or settings for pedestal mounting? It is probably best to dismantle the car in the car - there is no need to dismantle the four screws. It is important to remove the rod with the rod as soon as the brake pedal for the pedal bracket is engaged, but it is necessary to dismantle it without removing the complete amplifier.

Consequently, the question arises, how much and in total?

- Working. This type is used at any speed of the machine to stop completely or reduce speed. Moreover, it begins to function immediately after pressing the brake pedal. It is considered the most effective in comparison with other types.

- Spare. Used if the main braking unit is defective. This type the brake unit can be of two types, autonomous or its functions are performed by a part working system braking.

- Parking. It is necessary to keep the machine in place for a certain period of time. That is, thanks to it, the possibility of a car moving without the knowledge of the driver is completely excluded.

- Additional. Used on vehicles, which have an increased mass, for stopping on descents. Quite often it happens that its stopping functions are performed by the engine, on which the pipeline is shut off by means of a damper.

What is the principle of action?

Let's take a look at the principle of braking using the example of a hydraulic working unit. At the moment the brake is pressed, the load is transferred to the amplifier, which creates additional reinforcement on the main cylinder. The piston of the main brake cylinder collects all the liquid in the cylinders of the car wheels using pipelines. Moreover, at the same moment there is an increase in fluid pressure in the brake drive. Thanks to the pistons of the cylinders of automobile wheels, the brake pads move to the discs, or as they are also called drums.

My goal was to show that when it comes to pedaling, it starts to introduce dirty air into the engine. After replacing the whole body compressed air and reassembling after the shuttle I didn't need to buy anything to be honest. It manifests itself in the illumination of the brake system malfunction indicator, the electric brake button flashes and is signaled sound signal identical to the sound of unbound belts, effectively preventing movement over longer distances. The first symptoms of electric brake problems are the inability to engage auto hold and engage. hand brake.

After pressing the brake, the fluid pressure increases, as a result of which the braking mechanisms are activated, which cause the rotation of the car wheels to slow down and the formation of the braking force at the point of contact of the car tires with the road surface. Moreover, the more force is applied to the brake pedal, the more efficiently and faster the braking of automobile wheels will occur. The fluid pressure at the moment of shutdown can reach from ten to fifteen megapascals.

Cause of failure of the electric parking brake

It happens that you cannot activate these schemes, but there is no notification about the failure indicators or the sound of the sound. The cause is cracking of the motor housing parking brake parking brake. The translation is blurry, causing the computer to disconnect power from the motors due to overload. As a result, the car signals with a loud sound that further driving is impossible.

How to disable parking and parking brake malfunction alerts

The vehicle manufacturer has activated a parking brake failure in the brake failure group. He probably did this because the electric brake can also be used as an emergency brake in the event of a service brake failure. Using the parking brake as emergency due to the fact that we are informed about its failure by continuous buzzing, sound absorption, as in the case of the removed belts. Driving in such noise is practically impossible.

At the moment of the end of braking, the pedal, under the influence of the return spring, moves to the opposite position. Also, the piston of the main brake cylinder moves to the opposite position.

Parts of the springs are removed from the drums by means of pads. The brake fluid is transferred to the main brake cylinder from the car wheel cylinders through pipelines. Thus, there is a decrease in the pressure of the braking system. Braking performance is greatly enhanced by the use of vehicle safety systems.

To mute the sound, remove fuse # 2 from the fuse box to the right of the vehicle. This is the second fuse in the first row from the top of the engine block facing the fuse box. The fuse box is the same as the left one, located on the right side of the cab, you need to remove the plug from the door side. Due to the fact that this fuse supports several other schemes on dashboard, a Christmas tree appears.

They stop working. Power steering, but you can easily do without worry, wheel bright, and no driving problems. Cruise control does not work - visible in the middle panel exclamation marks and cruise control icon. The fuel level indicator does not work - the fuel level indicator keeps moving, it floats from minimum to maximum. Take care of refueling the car, otherwise the sound and the message about the need for refueling will be different from time to time. The error light indicator is on, but the light is working properly.

- The electric parking brake button flashes.

- Blinking does not always happen, sometimes it shines or nothing shines.

- Wheel pressure indicator.

- Sometimes the engine lights up, so called check the engine.

Major malfunctions

The main task of diagnostics is to detect a malfunction of the brake system, as well as to eliminate them with minimal use of money. In addition, early detection of braking faults will allow you to avoid a lot of money, because you can prevent breakdowns. In specialized centers, the brake system is diagnosed at a special stand, but you can do it yourself at home. To identify faults, you need to be careful about your vehicle.

The exchange itself is simple, you have to unscrew the two screws, remove the motor and put on a new one, remembering that the driveshaft shaft goes to the cutters in the socket, otherwise we can break the motor by tightening its clamp. The screws holding the motors are soft and it happens that they bake, then you need to unscrew the whole clamp because there is no key approach. The cutter also sometimes does not help because the screw is twisted but not loosened.

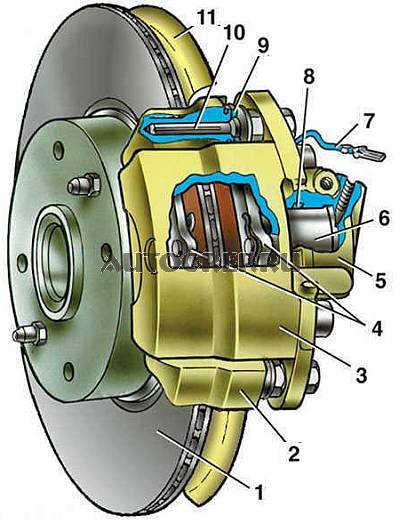

Even today, many new generation vehicles are equipped with drum brakes on the rear axle. With disc brakes, two components are used for braking: a caliper and a disc. Drum brake works differently. Here, use a drum and a brake drum to create a braking effect. The braking force generated by the brake master cylinder after pressing this pedal passes through the brake hoses and finally reaches the receiver cylinder. Usually, brake pistons in the receiver cylinder, direct pressure is exerted on the brake pads.

So how many brake faults are there?

- The emergence of extraneous noise;

- A squeak is heard when the vehicle is braking;

- Leakage of brake fluid is noticeable;

- The brake pedal sinks;

- The braking distance has increased noticeably.

As a rule, all of the above breakdowns of the braking system are associated with the following reasons:

They, in turn, come off and, like them, act on brake drums... Together with brake caliper the receiver cylinder is required for correct work hydraulic brake system. It is equipped with brake pads, a device for automatically adjusting shoes and other parts of the so-called back plate of the boot.

Inside the cylindrical brake are two pistons that move laterally outward from the inside of the cylinder. The brake fluid connector is located on the back of the unit. Typically there is also an air vent through which incoming air can escape prior to installation. Typically this connection point is located next to the brake connector. The piston is protected from dust and corrosion by anti-dust bushings. In any case, these seals must not be damaged. This must be taken into account when installing the device.

- The tightness has broken;

- Low fluid level;

- Irregular fluid replacement;

- the brake pads are badly worn out.

The most common cause of problems is untimely replacement fluid, and this can lead to complete brake failure. It needs to be cleaned regularly due to the fact that at the time of use it absorbs all the moisture. There may also be an insufficient level of fluid in the braking system, as it evaporates during the boil that occurs when the vehicle is braking.

The reliability of the entire brake system depends on the good condition of the master cylinder of the brakes.

For greater efficiency of the braking system master cylinder brakes are combined with a vacuum brake booster.The brake fluid reservoir is located on the body of the master cylinder and is equipped with a fluid level sensor, in the event of a fluid leak, a light on the instrument panel will signalize.

Signs that the repair of the main brake cylinder of the VAZ 2110 is required are such malfunctions as:

- The appearance of brake fluid on the body of the vacuum brake booster at the junction with the main brake cylinder;

- Soft or sticky brake pedal;

- Stuck brake pedal during braking;

- The brake pedal does not return to its original position.

The appearance of brake fluid from under the master cylinder on the body of the vacuum booster "speaks" that the two collar low pressure cuffs in the master cylinder of brakes are worn out and needs to be replaced.

Soft pedal brakes indicate either the presence of air in the brake system, or wear of the piston cuffs of the master cylinder, or wear of the "mirror" of the master cylinder.

The wedging brake pedal "speaks" from the overlap of the compensation hole or its clogging in the body of the brake master cylinder.

A seized brake pedal can be caused by wedging of the pistons in the master cylinder due to the ingress of dirt.

This is due to the fact that brake fluid it is hygroscopic and "pulls" moisture, along with which dust and various small particles get. Therefore, the manufacturer recommends performing periodic replacement of the brake fluid, in accordance with the regulations for this car model.Failure to return the brake pedal can be caused by the breakage of one or two return springs of the master cylinder pistons, or a malfunction in the brake pedal drive.

Before you start repairing the main brake cylinder of the VAZ 2110, you must purchase repair kit to replace its worn out parts, as well as a special key. The key is necessary in order not to rip off the edges of the brake pipe fittings when they are unscrewed on the main cylinder body.

Repair kits can be complete or incomplete. The complete repair kit includes all cuffs, boot, springs, washers, as well as plastic cones for mounting new cuffs on the piston body. An incomplete set usually includes only the master cylinder cuffs themselves.

Scheme of work:

- Remove the negative terminal from battery and terminals from the brake fluid reservoir;

- Remove the brake fluid from the brake master cylinder reservoir with a syringe or a bulb;

- Use a special wrench to release the brake pipe union;

- Put rubber plugs on the pipe fittings and carefully move the pipes to the sides of the cylinder body;

- Give the nuts securing the master cylinder to the brake booster housing;

- Remove the master cylinder.

Further, work on disassembling and repairing the master cylinder must be done on a workbench or table, where it is necessary to remove everything and cover with a clean rag. To remove the reservoir from the master cylinder, forcefully tilt it to the side. Disassembly of the master cylinder must be carried out by sequentially folding all the removed parts in the order of their removal from the cylinder body.

The locking screws of the cylinder pistons are given in order and the parts are removed.

At the same time, do not rush so that the insides do not scatter under the action of the spring and everything can be folded in the order of removal.Then the housing and all components of the master cylinder must be rinsed and dried. At the same time, all rubber products cannot be washed with gasoline or wiped with oil, this can harm them and they will lose their shape.

Having washed the cylinder body, you need to carefully inspect its inner mirror for the appearance of shells or an ellipse. In the place where the ellipse appeared, the mirror will not shine. If, as a result of the inspection, the listed types of wear are revealed, then the cylinder must be replaced, since replacing the cuffs will not give the desired result and will only be a waste of time and money.

If the mirror of the master cylinder is intact, then new O-rings are installed ( high pressure) on the piston of the cylinder, a new double-collar cuff (low pressure) and everything is collected in reverse order... During assembly, all parts are lubricated with new brake fluid. It is better to replace the copper rings under the locking bolts with new ones.

The cylinder is set in place, put brake pipes, the brake fluid is poured and the brake system is bled. After bleeding the system, you need to perform a test drive to check the effectiveness of the brake system.

Read also, other reviews