A speedometer is an important part of a vehicle that measures and displays the instantaneous speed of movement, and also calculates the distance traveled by the car. This data is shown by a special sensor that is located on the instrument panel. If a this device defective, the life of passengers and the driver himself is at risk, as to follow the rules road traffic and the set speed mode will be difficult for a motorist. This is why every driver should look after technical condition speedometer and be able to timely and independently identify the cause of the malfunction and eliminate it.

If the odometer or speedometer systems in your car break down for one reason or another, you need to get the speedometer repaired before you can continue to drive safely. A broken speedometer makes driving safely very difficult as you don't know how fast you are going. It also makes you more prone to driving too fast, which can lead to expensive accidents and travel tickets... Before consulting a mechanic and looking into buying a new one electric speedometer for your vehicle, consider if you can repair the speedometer instead.

The presence of a speedometer is considered mandatory for every vehicle, since it not only helps to determine the speed of the car, but also shows the distance that the car has traveled during its entire operation. The latest information is shown by the counting unit, which is included in the speedometer package, and is called the odometer. With its help, the driver can determine exactly when it is necessary to change the oil or, for example, filters. In addition, when purchasing a used car, such data are far from the latest. Also, thanks to the odometer, you can find out intermediate information about the distance traveled. With this function, a car enthusiast can calculate fuel consumption or measure the distance, for example, from home to work.

This option is usually easy and almost always quite cheaper than the alternative. The first thing you need to do to accurately repair your speedometer system is to determine what the problem is. The odometer and speedometer are connected by a system called a speedometer gauge that exists below the line of the car. To access this, you will have to first disconnect the negative end of the car battery cable from the battery in order to short-circuit the electrical systems in the car. Then use a flat head screwdriver to pry the cover gasket out of the speedometer.

The correct determination of the speed depends on the main working elements - the flexible shaft and the drive cable. With their help, the rotational movement is transmitted directly from the transmission to the device, in other words, they permeate the entire vehicle system, connecting the instrument panel and the gearbox.

Be careful not to break the gasket or cover. Remove the gasket and set it aside. Next, you will need to remove the gauge that holds the speedometer section in place in the speedometer and odometer system. It connects behind the odometer in most cars. Grasp the odometer and feel the wire connection, then carefully remove the wires from the back of the odometer. It should come out cleanly in your hands.

Check the speedometer for signs of faulty gears. The most common cause of damage to a speedometer is a faulty gear mechanism in the back of the face. If so, you need to replace it with an appropriate mechanism mechanism. They are available at the dealership that specializes in your vehicle or at various vending machines. Or you can also purchase one from the Internet.

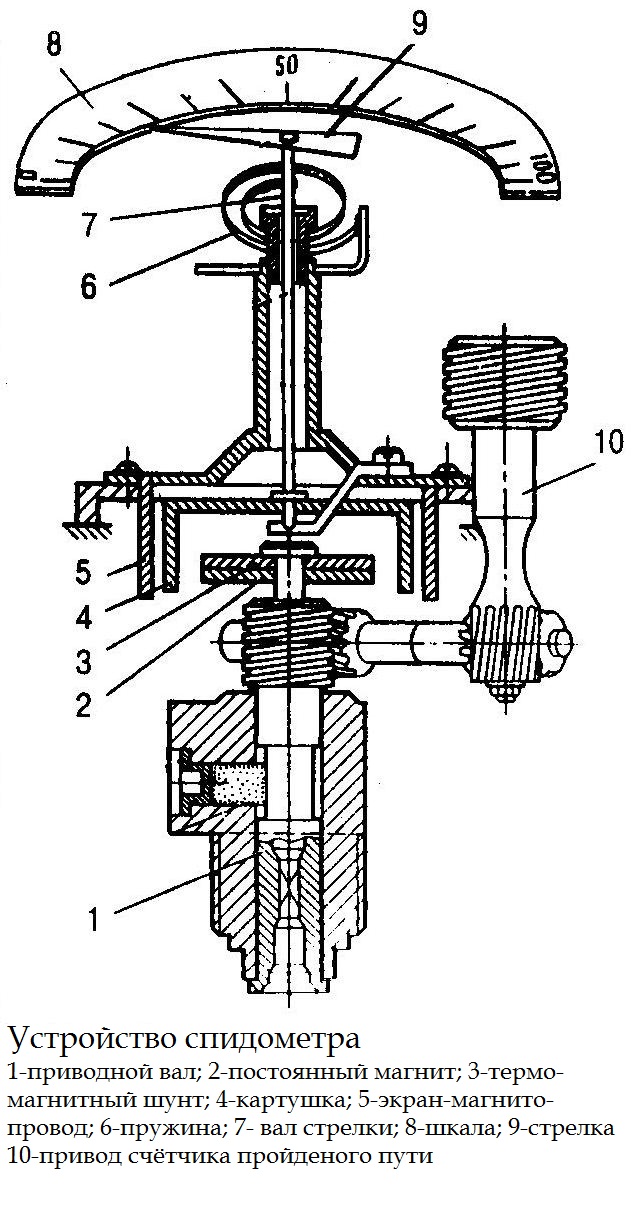

The principle of operation of the speedometer has not actually changed over a century. For such a long time, changes have occurred only in the mechanism of the indicator.

Today, there are two types of speedometers - electronic and mechanical.

The first of them are equipped with an electronic indicator, like numbers on the display, and the second - a mechanical one, in the form of an arrow. The magnetic induction speedometer is the most popular among mechanical instruments. It is equipped with two mechanisms - counting and high-speed. As for the electronic speedometer, outwardly it is no different from the mechanical version, there are only some differences in their work.

If there is another component that is damaged, you may need to replace it. Alternatively, if you can't see anything with the speedometer, see a specialist for a second opinion. In the worst case, you will have to purchase a completely new speedometer surface and system, after which you can reconnect to the odometer sensor and reinstall the vehicle. However, it is cheaper than buying a brand new speedometer gauge from the start.

Why does the speedometer break down

The dashboard gauges in your car tell a complex story about everything from your current speed level, to the condition and health of your engine, and even whether things like headlights are on. Different vehicles have different sensors and some dashboards are much more complex than others. But when the sensors in your car stop working, that's not a situation you can safely ignore.

In modern cars, mechanical speedometers are practically not used. In particular, due to the fact that their error is significantly greater - 15%, when for electronic ones - only 5%. In addition, the mechanical drive and the elements of such a speedometer can wear out over time and have to be changed, which is a rather complicated and time-consuming operation, since you need to lay the cable straight, without a single bend.

When one gauge stops working, the problem could be the gauge itself or the bad gauge, while all gauges cutting out at the same time often indicate a faulty or instrument cluster. The most common causes of sensors in a non-working machine can be broken down into three scenarios.

If none of the sensors are working at all, the problem could be a blown fuse or a defective instrument cluster. If the sensor readings are considered low or unstable, there may be a problem with the voltage regulator that supplies the instrument cluster. If the sensors are tied to the highest possible reading, there may be a connection problem or a poor instrument voltage regulator. None of the sensors are working. ... Individual calibration does not work.

Speed \u200b\u200bsensor does not work, reasons

The most obvious sign of a speedometer failure is when the movement of its arrow is absent while the vehicle is moving. In addition, the needle may twitch, but the device will still not show adequate speed. There are a number of reasons that can cause problems with the speedometer:

Sensors in the car don't work at all

If oil, coolant, charge, or gas pressure is not working or is unstable, the problem is with the gauge, wiring, or gauge. Speedometers are unique in that some of them use physical cables instead of sensors, so a speedometer not working can also indicate a broken cable or a stripped transmission. If one or more of the warning lights do not come on when the key is first turned on, this usually indicates a blown lamp. If none of the lights come on at all, first check the fuses and wiring on the dashboard. If lights up signal lamp and stays on when the engine is running, this usually indicates a problem with that particular system. One or more of the dashboard warning lights are not working. ... There are many different types of instrument cluster designs and configurations, but when all the sensors in a car stop working immediately, the problem is usually a fuse or wiring problem.

1.If the nut has come off, with which the speedometer shaft is attached to the flexible shaft. This is the most common and commonplace reason why a speedometer can fail. The situation can be easily corrected by simply tightening the nut and tightening the mount securely. However, if this procedure did not give the desired result, one should look further.

The first step in diagnosing this type of problem is to identify the fuse associated with the instrument cluster or sensors. The fuse must be powered on both sides when the ignition key is turned to the on position. You can check it with help or take your car from a mechanic if you don't have necessary tools or it is not convenient for you to delve into such diagnostics.

If the fuse is good, the next thing you or your mechanic will want to do is test the wattage on individual sensors. This usually requires removing the instrument cluster, which can be quite difficult and time consuming in some vehicles.

2. If the flexible shaft breaks during operation. This often happens during long-term operation of the car, the part can simply wear out and burst. In this case, troubleshooting will be much more difficult, but nothing is possible. The situation is solved by replacing the torn element.

3. If the speedometer mechanism itself is broken, which is located on the dashboard. You can eliminate such a breakdown by replacing the mechanism.

At the minimum, you may have to remove some trim pieces and twist off the cluster to free it up. The difficulty level is usually at the same level, so if you are comfortable with the job, you can probably handle it.

What if the indicator and backlight don't work?

If your gauges aren't working and your lights and lights don't light up as well, that's a clue that a serious problem could arise. This assumes that you have already checked the sensor fuses and determined that it is in good working order.

4. If the shaft-cable is dry. In such a situation, it is necessary to lubricate the semi-collapsible shaft, which is the main component of the device. It is located in a special shell, which is placed in a PVC tube. It prevents moisture and grease from entering the mechanism, which is very important for accurate and continuous operation of the flexible shaft. If the liquid is dry, the needle of the device will twitch, and the motorist will hear a typical rustling.

The problem with electronic instrument clusters

In some cases, you may find that the entire dashboard is bad. For example, if you have an electronic instrument cluster that does not have separate sensors that receive independent inputs from individual senders, a common failure of all sensors often requires replacing the entire cluster.

What if only one sensor fails?

When one gauge stops working, the problem is either the gauge, the wiring, or the sending device. If you are comfortable with finding and removing transmitting devices and sensors, you can diagnose this type of problem yourself. Otherwise, you have to go to a mechanic.

5. In addition, incorrect installation of the speedometer or its elements can cause such problems.

6. If the arrow of the speedometer goes off scale, but does not change its position either during stopping or while the vehicle is moving, this indicates a break in the opposing spring.

As an example, using a coolant temperature sensor, the diagnostic procedure involves finding and disabling the sender. With the ignition on, the sensor should register cold. If you connect the wire of the transmitting device to ground, the sensor should switch to hot.

If the sensor moves as expected, you may suspect a bad sending device. If the sensor doesn't move when you ground the sensor wire, you might suspect a bad sensor. Similar tests can be performed on all measuring instruments in your instrumentation, although specific procedures may differ from one application to the next.

The speedometer cable has dried up, how to lubricate, the course of work in stages

In order to lubricate the cable, you will need the following materials and tools:

1.Special grease.

2. Wrenches.

3. Screwdriver.

Getting started:

1.First, you need to open the hood and pull the cable out of the box - this will greatly facilitate the operations with the dashboard. The socket is located in the center of the engine compartment.

When it doesn't work Speedometer

While all gauges can be analog or digital, speedometers are unique in that they can have either mechanical or electrical inputs. All others instrument indicators connect to sensors or send devices over wires while your speedometer can use.

Sensor operating principle

In cars that use cables, the speedometer is physically connected to the transmission over the cable. The cable is usually square at both ends, or square at one end and cut at the other. When the cable breaks, the sensor may not move at all, or it may twitch slightly.

3. We take out the element and unscrew a few more screws.

4. Now we take out of the niche directly dashboard.

5. Disconnect the device, for which it is necessary to unscrew the union nuts on both sides.

6. Pull out the flexible shaft towards the drive, separate the ends of the support washer and remove it.

The fix for this issue is to simply replace the speedometer cable, which involved disconnecting it from the gearbox, disconnecting it from the instrument cluster, and then swiping it through the firewall. In many cases, this also requires the removal of the instrument cluster itself.

Defective speedometers and speed sensors

Some cars even have a speed sensor and cable, in which case the cable usually drives the speedometer when the speed sensor or wheel sensor tells the computer how fast the car is going. The only way to know for sure what you have is to either look at your make, model and year, or physically check the back of the instrument. If there is no cable on the back of the cluster, then your vehicle has a speed sensor.

7. The part from the shell must be pulled out in stages.

8. Using kerosene, remove the old grease, after which the parts must be dried.

9. From the drive side, grease the element 2/3 of its length.

10 We insert it into the shell, close it with a locking washer and mount it back.

11. Tighten the pressure nuts tightly.

12. The dashboard should also be refitted.

Since cruise control also uses a speed sensor, it will not work properly or at all if the sensor is bad. If you find that your cruise control is working, but your speedometer is not working, you should suspect a bad speedometer. The converse is also true, so if your speedometer and cruise control are both malfunctioning, you may suspect a bad speed sensor or a wiring problem.

What if these are dashboard warning lights not working?

In less common cases the electronic unit controls may also not work properly. Using specialized test equipment, they can also actually test the speed sensor. While many vehicles have sensors that show specific information about everything from the state of the charging system to the temperature of the coolant, some cars and trucks have warning lights.

Replacing the speedometer, the progress of work in stages

To replace the speedometer, it is necessary to unscrew and remove the dashboard in the order described above, and then the speedometer itself. In fact, self replacement speedometer is a rather laborious process, but it is quite possible to carry it out at home. In fact, to replace the speedometer, you just need to disconnect the electrical connectors from the old device and connect them to the new device. To do this, unscrew the cable nut with pliers and connect it to a new speedometer. In some cars, in particular the VAZ 2109, the speedometer cable is first unscrewed from the gearbox. This connection is located near the gearbox, under the bottom of the vehicle.

We unscrew the cable nut using the example of the VAZ 2109:

1. We tie a strong thread or soft wire to a special eye of the nut.

2. From the side of the gearbox from under the bottom, pull the cable towards ourselves so that the end of the wire remains in the vehicle interior.

3. We untie the thread from the old rope and tie it to the new one.

4. Then, you need to pull it into the salon and connect.

Sometimes, there is no eyelet on non-original cables. In this case, we use the nut directly instead. To make the locking washer easier to insert, it should be lubricated with lithol.

In any case, the failure of the speedometer is a rather serious breakdown, which should not be allowed. It is important to know that if in vehicle one mechanism is not functioning properly, this can soon lead to a malfunction of the other. Not to mention the usual rules of the road, which not everyone can follow without a speedometer. By following the above instructions, you can easily find the cause of the malfunction and eliminate it without asking for help from specialists. However, it is worth considering the fact that for each car model there are peculiarities of both dismantling and mounting of this device.

The speedometer is installed on any modern car, he can be different types - liquid crystal, pointer, indicator. If the device stops working, it becomes more difficult for the driver to navigate by speed, it is easier to break speed mode.

In this article we will look at why the VAZ-2110 speedometer does not work: the reasons for the failure, troubleshooting methods, typical malfunctions.

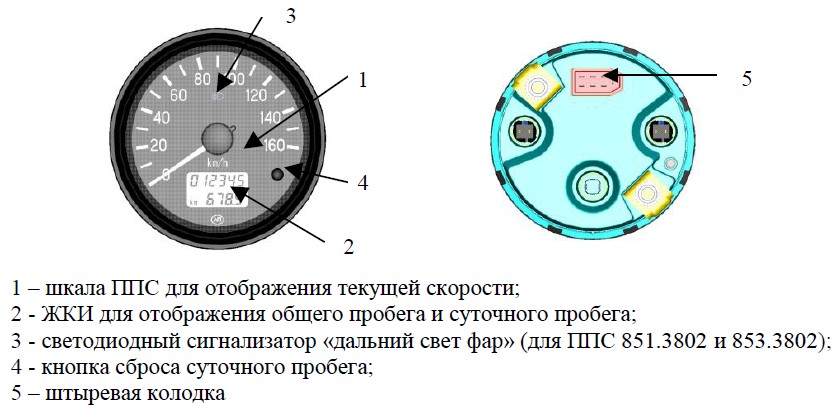

Types of speedometers VAZ-2110

On the VAZ-2110 car, speedometers are with electronic and mechanical drive, devices of the second type were installed on cars of the first years of production from carburetor engines (8 valves). Later, the top ten began to use electronic speedometers, the torque from the gearbox to the dashboard is transmitted through the speed sensor.

All devices on the VAZ top ten, showing the speed of the car, dial, and signs of a malfunctioning state are determined by deviations from the norm of the speedometer needle. If the speedometer is faulty, the arrow when the vehicle is moving:

There are other signs of a malfunctioning speedometer, for example, on a cold engine, the device works, and its readings are normal. As the engine warms up completely, the arrow freezes and stops moving.

The main reason why the speedometer on the VAZ-2110 injector does not work is contamination (oiling) of the speed sensor (DS), especially often a failure occurs if the DS gets oil from the gearbox or engine (for example, there is a leak from valve cover ICE). There are also other reasons:

Before you start changing anything, you need to find out why the device does not show the speed. First of all, they start checking with the speed sensor, since most often all failures in work are associated with it. We examine the DS for contamination, see if there is a break in the wires.

If the electrical part of the sensor is faulty, the Check Engine lamp on the instrument panel comes on. During the computer diagnostics at faulty sensor the scanner displays the error code P-0501, P-0501 or P-0503. Another error is determined on-board computerinstalled on the car.

There are also other signs of a faulty DS:

- on idling The internal combustion engine is unstable, and the engine can also stall at low speeds;

- increased fuel consumption.

Verify electrical circuit from the DS to the speedometer on a VAZ-2110 car, the injector is quite difficult, so here it is better to resort to the help of specialists.

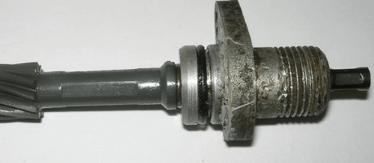

The gears of the DS drive, which are in the gearbox, can also break. It is easy to check the drive itself - you need to unscrew the two bolts of its fastening with a 10th key, make a visual inspection of this mechanism.

If the plastic gear has broken teeth, chances are good that the gear is also broken in the gearbox. To replace the drive gear, you will have to remove and disassemble the gearbox.

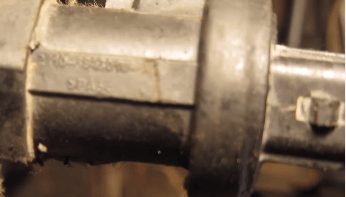

On cars of the first 2110 editions with a carburetor, the speedometer needle is driven from the gearbox by a mechanical cable, and it is much easier to determine the cause of the malfunction here than in electronic circuit... It is simple to check the serviceability of the speedometer cable (TC): it must be disconnected from the checkpoint - if at its end the tetrahedron is intact, then everything is in order in this connection.

Then we grasp the end of the cable with our fingers and try to twist it, if there are no cable breaks, the arrow of the speedometer should begin to move (rise). If the vehicle rotates too freely with your fingers, the cable is most likely broken. To check the mechanical speedometer "tens" itself, it is necessary to remove the instrument cluster.

On the VAZ-2110 with an injector, a separate device showing the speed of the car is not sold, and the instrument cluster for 2110-11-12 changes in assembly. If it turns out that the cause of the malfunction lies in dashboard, it needs to be changed. We remove the instrument cluster (old model) as follows:

The main cause of speedometer malfunctions is the failure of the speed sensor, and if the DS is faulty, it must be changed. It is not difficult to replace the sensor on the "top ten" VAZ, almost any driver can do this work independently. The operation is especially easy on a machine with an 8-valve engine. Let's start replacing:

When installing, we put the connector in place, it should snap into place with a click, this work can be considered finished. With sufficient dexterity, such an operation is performed in 5-10 minutes.

Often, car owners encounter a problem when, after replacing the sensor, the speedometer arrow starts to "lie" - to show the wrong speed. It should be noted that for VAZ "dozens" several types of DS have been developed, and they have different catalog numbers. When buying, you should pay attention to the number of the failed sensor, and you need to purchase new part only with the same marking.

- The search for the cause of the inoperability of the speedometer should begin with an external inspection of the DS and the wires going to it. It is not uncommon for the wires to break in the immediate vicinity of the plug.

- If the speed sensor is covered with a layer of dirt or oily, it is necessary to remove it, wipe it, reinstall it and check the speedometer readings again. Perhaps, after that, the instrument arrow will start to show the speed normally again.

- If you cannot deal with the malfunction yourself, you should contact the car service to an electrician.