VAZ cars, especially of the "classic" family, are famous for their simple design, so that repairs can be done by hand. And this applies to any details. Comes to the point that garage conditions "Capitalize" the engine. And it turns out at a high level. The car continues to drive and delight the car owner. But sometimes it happens that the machine malfunctions. This is due to the ignition system. How to install ignition on a VAZ-2109 (injector, 8 valves)? In today's article we will look at how to perform this operation on modern and classic AvtoVAZ models.

Signs of an incorrectly set ignition

How do you know if your car needs tuning? This can be seen from the way the engine operates. Characteristic metallic sounds (very sonorous) appear in the area of \u200b\u200bthe cylinders. Vehicle power decreases, fuel consumption increases. On idling the unit is unstable. Turnovers are falling. If it is late ignition, the engine overheats quickly. Carbon deposits form on the spark plugs and in the cylinders. With such symptoms, it is urgent to expose desired angle... Otherwise, the motor will operate under heavy load, which significantly reduces its resource.

Why is it necessary to adjust the ignition timing?

The need for this setting arises when the factory settings disappear. This happens when dismantling the distributor. After its replacement or repair, the ignition distributor malfunctions. It comes to the point that the car cannot start normally with a good battery charge and new candles. Why are the factory settings getting lost? It's all about the timing marks. When dismantling the distributor, they automatically go astray. As a result, the question arises "how to install the ignition on a VAZ-2109 - an injector, 8 valves - by tags". Of course, you can contact the service, but if this domestic car, even a beginner can understand this issue. If you want to properly adjust the ignition (VAZ-2107 is no exception), you need to find and set gas distribution marks. To do this, rotate the pulley crankshaft... If it is going tight, you can put the car in second or third gear and push it forward a little. The position of the shaft should change. The marks on the pulley and pin must match. Next, the ignition distributor is installed in place. It is important to remember the current position of the so-called slider. Experts do not advise turning the crankshaft pulley with the distributor removed. This does not work to adjust the ignition valve. This will break the settings and break the labels. We'll have to start all over again.

We expose by tags

How to adjust the ignition on a VAZ-2109 (carburetor) using the marks with your own hands? Experts recommend using a stroboscope. But the problem is that not every driver has one in their garage. Moreover, not everyone has a garage at all. Therefore, below we will consider how to adjust the ignition on a VAZ-2109 (carburetor) without a stroboscope. For this we need a candle and open-end wrench for 13 and a control 12-volt lamp. So where do you get started? We begin to set the ignition on the engine by disconnecting the negative terminal. Next, it is necessary to set the piston of the first cylinder to the top dead position. To do this, unscrew the spark plug with a special 6-sided wrench and turn the crankshaft until the piston comes into contact with this hole. There must be a gap between the spark plug and the piston head. How to determine exactly where it is located? To do this, you can use a screwdriver (a long drill is suitable as an analogue). It is placed with one end inside the combustion chamber, and by the handle you will determine its upper position. As the pulley turns, the screwdriver moves up and down. Its upper position will be the very point that we need. It is important to keep the inside of the combustion chamber clean - the screwdriver should be as clean as possible. Otherwise, the debris will remain inside the cylinder. It is not good. So, how to adjust the ignition on the VAZ-2109 (including the injector) further? The next step is to align the pulley marks. One of them is located on the cover of the timing mechanism drive.  The one in the middle means that the lead angle is 5 degrees.

The one in the middle means that the lead angle is 5 degrees.

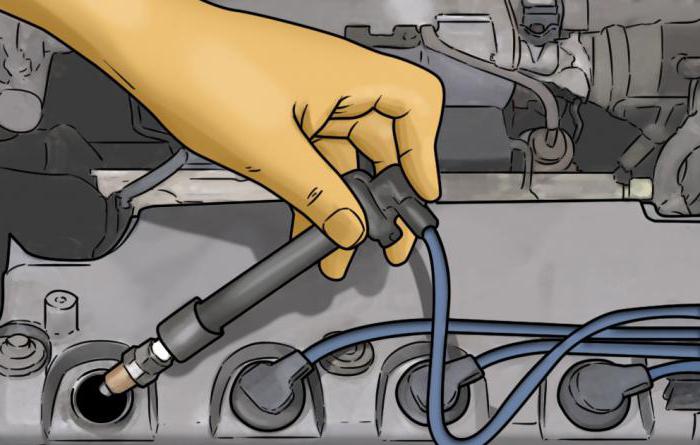

What if you didn't find the tag?

It must be there, just sometimes covered with a layer of dirt or oil film. Thoroughly degrease the surface with petrol or white spirit. Try not to get the solution on rubber surfaces, especially on the timing belt. After setting the marks, take out the screwdriver back, tighten the candle with a key and connect the high-voltage wire. By the way, it must be removed very carefully - it often breaks off at the junction with the end of the candle.  If the wire "does not go", under no circumstances pull it by force. Rotate it clockwise and counterclockwise. This usually helps to remove the stuck wire to the outside. But tugging is simply pointless - you will get a torn part.

If the wire "does not go", under no circumstances pull it by force. Rotate it clockwise and counterclockwise. This usually helps to remove the stuck wire to the outside. But tugging is simply pointless - you will get a torn part.

Determine the ignition moment

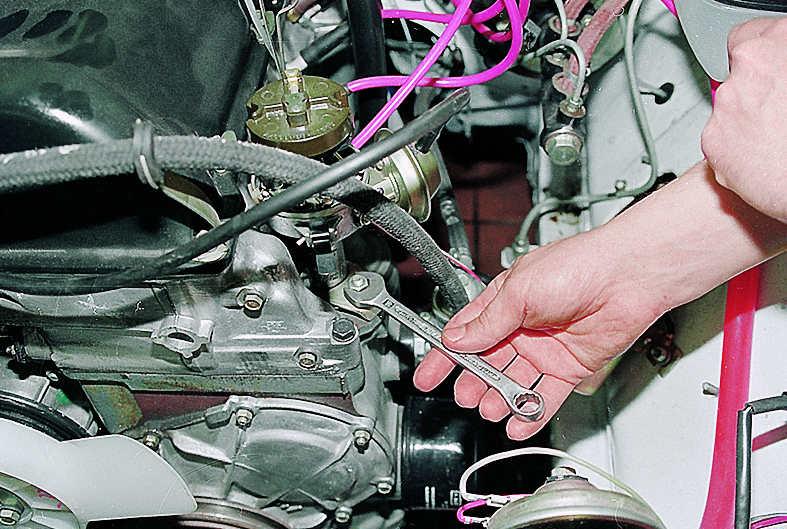

Considering the question "how to adjust the ignition", it is important to correctly determine the moment. To do this, connect the battery terminal back and, with a 13 key, partially unscrew the nut that secures the distributor. Then we take a control light in our hands. We connect it to ground at one end, and to the coil with the other. Next, turn the ignition key to the third position and carefully scroll the distributor housing clockwise. How to adjust the ignition further? We continue to rotate until the light starts to go out. The same goes for the rotor. We turn it counterclockwise.  We twist until the contacts open. Simply put, we rotate until the lamp lights up again. After that, we tighten the fastening nut with a key and check the behavior of the machine on the move.

We twist until the contacts open. Simply put, we rotate until the lamp lights up again. After that, we tighten the fastening nut with a key and check the behavior of the machine on the move.

How to check the correctness of the work?

To do this, the engine must be well warmed up. The check is carried out at a speed of 20-50 kilometers per hour. When the speedometer needle reaches 40, we turn on the fourth gear and move in a straight line without acceleration. After a few seconds, press the gas pedal. Detonation will be heard. This is normal. When the speedometer needle leaves the mark at 45 kilometers per hour, the sound of detonation and ringing of "fingers" will disappear. If this is the case, then you have adjusted the ignition correctly. But if the ringing continues at 50 kilometers per hour, the marks are set incorrectly. Additional adjustment of the distributor is required.

We bring the lead angle to mind

So how do you adjust the ignition if the car detonates? In this case, it is necessary to set the angle of the distributor.  We rotate the distributor clockwise by 1 degree. After that, it goes back to the test. If the detonation disappears after 45 kilometers per hour, then you did everything right. But if it does not exist at all, you have too early a lead angle. How to adjust the ignition in this case? It is required to scroll the distributor 1-2 degrees counterclockwise. When accelerating, the knock should disappear after one and a half seconds, that is, when the car starts to pick up the desired speed.

We rotate the distributor clockwise by 1 degree. After that, it goes back to the test. If the detonation disappears after 45 kilometers per hour, then you did everything right. But if it does not exist at all, you have too early a lead angle. How to adjust the ignition in this case? It is required to scroll the distributor 1-2 degrees counterclockwise. When accelerating, the knock should disappear after one and a half seconds, that is, when the car starts to pick up the desired speed.

What if the distributor was removed before?

If you have done repairs or replacement of the ignition distributor, you need to know how to properly reinstall it. In fact, there is nothing difficult here. To do this, we set the first cylinder to the top dead position (determined with the same screwdriver as before) and look for the location of the marks on the crankshaft pulley. They need to be combined. We turn the shaft clockwise. When the middle mark on the timing belt coincides with the one on the protective casing, proceed to disassemble the distributor cover. It is often attached with small screws. You may need a 6.7 or 8mm wrench. Then we take out the lid and see a slider in front of us. It looks like the photo below.  It may differ in color, but its shape is the same. How do I expose it? We twist the element until it is directed directly to the contact of the cover of the first cylinder. Then we install the housing back and check the correctness of the ignition on the go. This is done according to the same principle - 4th gear, speed 40 kilometers per hour.

It may differ in color, but its shape is the same. How do I expose it? We twist the element until it is directed directly to the contact of the cover of the first cylinder. Then we install the housing back and check the correctness of the ignition on the go. This is done according to the same principle - 4th gear, speed 40 kilometers per hour.

Setting the advance angle on the injector

The latest models of "nines" have been going since injection engines... The tuning process of those practically does not differ from the carburetor ones, even when compared with the classic VAZ models. First you need to inspect the degree of opening throttle... We take a tester in our hands and check the voltage of the DMRV sensor. The normal reading should be between 0.4 and 0.55 volts. If the voltage is lower or absent altogether, the element must be replaced.

Perhaps, after such an operation, you will not need to adjust the advance angle at all - the motor will work properly, without knocking and floating speed.

To set the angle, we do all the operations as before. The slider is set to the desired position and turns crankshaft until the labels match. After that, we take a test lamp in our hands and connect one of its wires to the coil. The second, as usual, goes to "ground" - this is any bare part of the body. For greater accuracy, you can take the negative terminal of the battery.

What's next?

We turn the slider counterclockwise until the light goes out. Then we fix the fastening bolts and put the cover in place. At this stage, the operation "how to adjust the ignition with your own hands" has been successfully completed. It remains only to check the car for detonation.

Conclusion

So, we figured out how to properly set the ignition. As you can see, this operation can be done by hand due to the simplicity of the design of the car itself. But this only applies to 8-valve engines. On 16-valve, ignition is arranged differently, and in some cases the hand of a professional is required. When performing this operation, remember the main thing: do not tear off the high-voltage wires from the candles and do not allow the combustion chamber to become dirty. When dismantling the distributor, remember that all marks automatically "fly off", and further installation without adjustment is simply meaningless.

Modern automotive world full of new systems and technologies. But the lovers of Togliatti classics, who enjoy "digging", have not yet died out. These cars are attracted by the fact that they can independently adjust, tune and fine-tune the engine, as well as other units. For experienced car owners Togliatti creations will not be problematic to solve the question of how to set the ignition on a VAZ-2107 or some other model.

Why the ignition is adjusted

If the car is set correctly, then this only positively affects a large number of engine performance. It so happens that some drivers drive for a long time with the ignition knocked off, not knowing about it. And this is the reason for an increase in fuel consumption, a decrease in the dynamics of the iron horse. Therefore, conversations about the quality and durability of Fiat engines are becoming more frequent, which are outdated in all respects and cannot work normally. Naturally, this does not reflect reality in all cases.

Of course using contactless ignition in a car is much more reliable and more accurate, and current cars designed in such a way that they need minimal adjustments. And if they will be produced, it will be only with the help of a computer. That is why today not everyone can cope with such a very simple process as ignition adjustment.

How does the distributor work?

To carry out the correct ignition adjustment, you need to have a certain set of tools:

- flat screwdriver;

- open-end wrench 12 to 13;

- set of adjusting probes;

- curve starter;

- candle wrench.

If you do everything sensibly, then it will take no more than fifteen to twenty minutes. The whole point of adjustment is to change the spark overshoot time. This should be done not when the piston "stands" at the dead top point and the resulting spark does not give the desired result, but a few moments earlier. Of course, this figurative meaning in "a few moments" each owner of the "swallow" has its own and it is determined according to the factory parameters. For 2016 models, the lead angle is set at one degree, and for VAZ-2101 - three degrees. It is with such settings that fuel mixture and its complete combustion.

To make adjustments, each cylinder uses an ignition distributor (distributor) that sparks the spark plugs in the order in which the cylinders are fired. You need to know exactly how the cylinders are triggered - this is one, three, four, two. The main working elements of the distributor are the slider and contacts. The slider distributes the voltage by means of the cover over the cylinders, and with the help of the contacts, at the moment of their opening and closing, the moment of the spark is determined.

What needs to be foreseen in order to make the correct adjustment

You can do it once for a long time, for example, a year or two, but you can do it monthly, and in some cases more often. It all depends on whether the conditions that are necessary for the successful completion of the undertaken are met:

- Before starting the adjustment, you need to make sure that the entire set of spark plugs is in working order.

- Clean the breaker contacts, check its condition and clearances.

- Must be in good condition BB wires. They should not be damaged, the plug caps, ignition coils and contacts with the distributor should be in perfect order.

- The vacuum ignition drive must be connected, it must have free play.

Adjustments can only be made if all of these instructions are followed.

Adjusting the lead angle

- First you need to determine the compression stroke on the fourth cylinder. In the block head we overlap with a finger or something else and turn the crankshaft with a curved starter. When the fixing object pops out, then the compression moment of the fourth cylinder will be reached.

- Next, you need to combine the marks that are applied to the engine cover and on.

- Next, you need to install the distributor so that the cylinder head is located perpendicular to the slider. This is followed by a very important manipulation - you need to slightly raise the distributor body and throw the slider with the shaft clockwise by one tooth. Then you need to set the ignition angle for the spark. To do this, insert the ignition element into the cover, ensuring a tight ground contact. Then turn the crankshaft one quarter counterclockwise. Then, with the ignition on, crank the crankshaft until a spark is formed. It is also advisable to check the position of the pulley. If it is located according to the marks, everything is fine, there is a slight discrepancy - perform a simple adjustment by adjusting the position of the distributor to the position of the middle mark.

Instructions

Adjust the angle of the closed state of the distributor contacts (UZSK). To do this, remove the cover of the breaker-distributor and clean the contacts with a file with a file, removing all the formed oxide bumps. After cleaning, make sure that the contacts are flat against each other. Correct if necessary by slightly bending the stationary contact.

Turn the crankshaft until the distance between the distributor contacts is greatest. Remove the screw that secures the contact block to the bearing plate and insert a 0.4 mm feeler gauge between the contacts. Pick a position contact groupforce, and fix it by tightening the screw. Check the clearance with the 0.35 and 0.45 mm feeler gauges.

Use the special key to rotate the crankshaft. If it is not there, rotate it slowly, gently pushing the car in fourth or fifth gear. Do not use a starter for this purpose. Having established the required clearance, the required value of the UZSK is automatically set, but only in new distributors assembled without violating the technology and dimensions. Therefore, make additional adjustments.

Remove the central high-voltage wire from the breaker cover and place it against the ground. Connect a light bulb to the wire from the distributor to the ignition coil. Turn on ignition: the lamp will be on when the breaker contacts open and go out when they are closed. Begin to slowly turn the engine crankshaft clockwise.

As soon as the light goes out, mark the position of the slider on the distributor body. Also note the position of the slider when the light comes on. Measure the length of the circular arc along the body of the breaker. To calculate UZSK, multiply pi (3.14) by 360 and by the diameter of the distributor body, and then divide by the measured arc length between the marks. The result will be the angle in degrees and minutes. Compare it with the recommended values \u200b\u200bin the instruction manual.

To adjust the ignition timing (UOZ), turn the crankshaft so that the mark on its pulley coincides with the mark on the timing cover (see the operating instructions). In this case, the distributor slider should stand opposite the high-voltage wire of 1 cylinder. Connect the bulb with one wire to the wire from the distributor to the ignition coil, the other to ground. Remove the center wire from the breaker cover and lean against the ground. Loosen the bolt fixing the distributor housing. Turn on ignition.

Begin to turn the distributor housing clockwise until the light goes out. Then slowly spin it in back side until the light is turned on. As soon as the light comes on, fix the breaker housing with the bolt in this position. After making all adjustments, check the result while driving.

Warm up the engine, accelerate to 40-50 km / h in 4th gear. When hard pressing the gas pedal should show characteristic knocking knocks and a steady set of speed should begin. If there is no audible detonation, turn the distributor counterclockwise 1 division on the scale at the base of the case. If knock knocks last more than 1-2 seconds, turn the distributor clockwise by the indicated amount. Repeat the procedure until you get a detonation, lasting 1-2 seconds.

Absolutely any owner of a carburetor rear-wheel drive car will sooner or later face such a problem as ignition adjustment. Experienced drivers know perfectly well that a properly adjusted ignition is a guarantee correct work engine. Let's try to figure out what the ignition moment is, what is it for and what methods of ignition adjustment are used for a VAZ 2106 car?

What is ignition timing and how does it affect a car engine?

Before you figure out how to adjust the ignition, you need to know how this system works. It is designed to ignite a mixture of gasoline and air in the combustion chamber of an engine at a certain point in time. This moment should occur when the piston has not yet reached the top point of the cylinder, but only begins to move upward. This moment is just a moment or.

If the spark at the ends of the plug passes too soon or too late, the mixture will ignite at the wrong time and the pistons will receive little energy. As a result, the crankshaft will receive low torque and the engine will not develop the required power. In addition, reduced engine efficiency significantly affects not only vehicle speed but also fuel consumption. After all, it may increase, and the engine will become unstable to work on idle... An incorrect lead angle increases the chance of engine overheating. And this is dangerous for both cylinder head gaskets, and for the engine itself. After all, overheating can lead to engine seizure. All this brings a lot of inconvenience to the driver.

It turns out that the point of appearance of a spark should occur at the moment when the piston begins to move to the top point of the cylinder. The value of this important parameter depends on many factors: the number of revolutions of the crankshaft, the composition of the combustible mixture, in particular its quality.

In injection vehicles, the process of setting the ignition timing is carried out using special sensors, which, analyzing certain information about the crankshaft revolutions and determining the first signs of detonation, shift the advance angle, thereby performing this process automatically. This function is controlled by computer technology.

Concerning carburetor cars, then the angle is constantly shifting in a certain direction, regardless of the level of vehicle operation. That is why, you have to manually set the ignition on the VAZ. This can be done in different ways.

Methods for adjusting the ignition on a VAZ 2106

This method is the easiest and simplest. To do this, you need to have a special car strobe.

Procedure:

- First, connect a stroboscope to your on-board network... Remove and plug the octane-corrector hose from the distributor.

- Start the car engine and warm up to the rated temperature. The most important condition when making adjustments is that the engine runs smoothly. Otherwise, the result of adjustments may be severely distorted.

- Unscrew the bolt for attaching the distributor. The light received from the stroboscope should be directed towards the crankshaft pulley.

- The distributor must be turned so that the number 1 mark on the pulley is opposite the number 2 mark, which is located on the timing cover. After this happens, tighten the distributor housing bolt.

Also, the correctness of the adjustment is checked by increasing the speed. Pull back the gas pedal actuator on the carburetor and note the angle. If it moves, then the adjustment is correct.

Don't forget to put on the octane corrector hose.

Adjusting the advance angle using a lamp

For use this method you will need two items - this is a 12 volt lamp and a wrench with which you can turn the crankshaft.

Procedure:

- Turn with a special key until its mark is opposite the division of the 0 degree mark. At the same time, the distributor slider must be installed on the side of the first cylinder.

- One of the lamp contacts must be connected to a wire that goes to the ignition coil. The second is connected to the "ground" of the car. To do this, you can use any part that has a connection to the car body. The central wire located on the distributor is disconnected and also connected to ground.

- Remove the bolt that secures the distributor housing and turn the key in the ignition lock. The distributor must be turned clockwise. This action is carried out until the lamp goes out. After this happens, turn the distributor again, but in the opposite direction, until it lights up again. After that, tighten the fixing bolt.

Video - How to set the ignition on a VAZ 2106 in 3 minutes

How to check the ignition control while driving?

There is a way by which you can check the setting of the lead angle while driving. To do this, do the following:

- Warm up the car engine to the rated temperature.

- Find a flat stretch of road and pick up a speed of 40 kilometers per hour. Shift into 4th gear and step on the gas pedal as quickly as possible. With a normal lead angle, the engine will start making appropriate sounds within 1-2 seconds, which indicate fuel detonation. After that, the car starts to pick up speed. If this was not the case, then the distributor is weakened and rotated one division counterclockwise. These divisions are located on the body at the base of the distributor.

- If the sounds of detonation continue for a long enough time, then the distributor must be turned one division, but in the opposite direction.

If after the adjustments you still have not achieved positive results, then the distributor is faulty and needs to be replaced. In addition, it may indicate the composition air-fuel mixturewhich is out of order.

There is another way to adjust the lead angle. Experienced auto mechanics use it. For this, the car engine is started and warmed up to operating temperature. After that, you need to open the hood of the car and unscrew the nut that secures the distributor housing. By rotating the distributor in different directions, the optimal engine operation with the correct ignition timing is determined by ear.

This completes the adjustment of the ignition timing of the VAZ 2106. As you can see, this is not difficult to do and spending a lot of money on auto repair services is not at all necessary. Almost any car enthusiast is able to cope with this task.

To adjust or set the ignition, we will consider it the same. While.

Usually the “problem” is seen like this. In order not to invent any abstract stories, let's take the first one that already exists. History from the site Azlk-team.ru.

This is not even a story, but a simple question.

Further in the topic there will be my answers, I will try to explain how I see this lesson in installing the ignition myself. To understand that there will be many answers to the question and they may be different, we will give one of them.

There seems to be an answer, but it adds a few more new questions. Everyone finds for himself a convenient way to set the initial ignition moment based on what he himself knows on this topic. I will write a little on my own. It is worth highlighting separately. This is the ignition setting when the engine is running at idle... That is, we set the ignition correctly and select the “idle and no more” speed mode for this. This is always the case.

The record will not be short and it will not be compiled at once.

First, I kind of answered the questions myself. But this, too, will not be a complete answer. It's easier to start point by point and then the rest.

………….

1. The vakkumnik does not need to be removed while the ignition is on (to remove means to remove the tube from it and exclude its operation).

But. It is necessary to first check at idle whether it changes the engine speed or not. If it does not change, then it is possible and necessary to regulate the ignition with it, and this is correct.

If the RPM changes (i.e. if we pick up the phone - the RPM falls, we put the pipe back on - the RPM increases), then alas, there is a problem. The problem will be called "wrong vacuum cleaner, you need to replace it."

We will expose the ignition with the vacuum cleaner already connected, knowing that this is already wrong. But there is no other way out yet.

2. Using a stroboscope.

I'll tell you a terrible thing, but it is not necessary to set the initial ignition moment. You can do without it and without lamps. But with him it is easier and faster. Why is it optional ...

We will still shift it to the side with a 90% probability after the “precise setting of the ignition by the stroboscope”. Which way - it will show only driving. More often - towards the earlier.if the car dulls on the move. But sometimes in the direction of the late - when the "fingers" tinkle on the go.

3. "Instruction and especially for contactless ...".

No difference - contact ignition or contactless - principle one.

The instruction can be, but it is better if it comes with preliminary explanations.

Next is the main text. So far, nothing concrete has been written.

- How to expose "by ear"

- How to set by light bulb (contact ignition system only)

- How to expose without a light bulb, on a "spark"

- How to correct “on the fly”. This is not exactly the case of "fourth gear and recessed gas pedal". Although this, too, will not make a big mistake.

Further, the answer is possible why none of the methods helps and the stroboscope does not help.

Let's go on the second round.

1.The vacuum cleaner at idle speed should not start working, so let it remain connected. What to do if it works (changes speed when it is connected). You just need to prepare to change it, it is problematic. There is a too soft spring in it and the minimum vacuum at idle speed already forces it to compress and pull the ignition displacement with it. It is also worth considering whether the second end of the tube going from the vacuum cleaner to the caruretor is connected there. It only goes to the minimum hole in the carburetor chamber. Now (at idle speed) this hole from the inside of the carburetor well is closed (without details) by the end of the throttle valve or this valve is still lower and closed (there is no large vacuum). When the position of the damper changes (the gas pedal is pressed) then the first strong vacuum appears, acting through the tube on the spring of the vacuum regulator.

2.

Let's try to do without a stroboscope when installing the ignition.

- on contact system you can use a "light bulb". That is, hang one end of the car carrier on the terminal on the side of the distributor, and the other on the ground. Remove the cover from contact distributor, turn on the ignition, by hand to the right (clockwise) removes the play of the slider and turn the distributor clockwise until our light comes on.

In the literature it is written this way (so that no one can be mistaken)

… Turn the valve body counterclockwise until the breaker contacts are closed. Wherein control lamp should go out. Grasping the slider with your fingers, apply a slight force to it in the clockwise direction (to eliminate gaps in the drive mechanism) and gently turn the distributor housing in the same direction until the warning lamp comes on ...

In general, the instruction in the literature is the same, but I haven't done it for so long, so I check it on the original source.

The check is just that. This will be the moment to fix the distributor. The distributor is fixed, click on the contacts of the contact group. The light should go out with each press, release - it lights up. So everything was done according to the book, put on the cover, start the engine.

The method is "universal", but I didn't have to use my contactless one. My car starts up.

I used to do that.

We unscrew the first candle (or just take a new one) and put it on the high-voltage wire of the first cylinder. We put the connected plug on the valve cover. We turn on the ignition and, in twilight (or complete silence), turn the engine ratchet with a crank or a large key. When the ignition mark is close, we turn it slower and wait for the moment when a barely noticeable spark passes through or we hear its faint click.

We stop and look at the position of our mark on the pulley. She reached her place (opposite the pin) or did not reach. If it did not reach, then the spark slipped too early and we need to turn the distributor counterclockwise, that is, towards the ignition delay. And vice versa….

You can turn the distributor slightly and repeat almost two turns. Then the spark will slip through again.

As it happened, it happened. On my third test attempt, I usually lacked the spark power. I started the engine for a couple of minutes, accumulated the power of the spark and then again continued “searching”.

Exactly the same, if you just keep the tip of the spark plug wire at a minimum distance from the ground (body or valve lid). But this is not convenient, although the spark is more noticeable (and all the more very sensitive to the hands).

As without a light bulb, by sensation or by ear. We put the distributor at approximately correct position and start the engine. If it does not start immediately, turn the distributor clockwise by 5mm (see everything from above). Let's start again. Started up immediately - good. Turn off the engine and make a mark on the body (with a fine chisel or screwdriver, or make a scratch on the distributor body and into parts seat, into which the distributor is inserted). Now we know that in this position our engine will always start.

Shift the distributor by 3-5 mm another clockwise (this is done even earlier ignition). Trying to start. It is necessary to try to define “our limit” in the regulations. If now we start and the engine periodically as if it is “bumping into something”, it means that right now the ignition is too early. An early spark pushes the pistons back, although they have not yet reached their top position. This is not permissible, we just mark the new position of the distributor for ourselves and remember it in this position, we will never leave it like that.

We are looking for the optimum between “never will” and “the engine starts right away”.

Further, you always need to check and refine the ignition on the go. What matters is the rotation of the position of the distributor every 2 mm. Therefore, we need a good mark of the position of the distributor - with a chisel or screwdriver.

We check the ignition on a fully warmed up car. It is not necessary to look for the ringing of "fingers" from the pressed pedal in fourth gear at a speed of 40 km / h. This is more about the violence of technology, although it is, of course, metal and will withstand everything. Long or short ringing is not the main thing. Our distributor is already approximately correct, it remains to correct its position by 2-3mm. You yourself will understand when it pulls better and does not ring. And when, on the contrary, the traction is slightly worse and the car dulls a little.

Along the way, you can note the operation of the engine by ear.

If we spin the engine and switch to the next gear, then at this moment we have two extreme “wrong” manifestations of sound.

a) The engine does not want to slow down quickly. We are not accelerating, and he has not yet reacted to the reset, the turns are kept for some time. Means too late ignition.

b) The engine instantly loses speed when the gas pedal is released, plus a tinkling sound during acceleration - this means that it costs a little early ignition.

But this last “by ear” is more for “our knowledge”, for convincing ourselves that we were not mistaken before.

Now we check the whole "theory" in practice and

…

enriched with knowledge, then we try to understand. Why in some cases none of these methods helps. And even a master with a strobe does not help.

This is a must, but a little later.

Added December 11 Not ready in detail yet. The main position is

- there are distributors that do not allow the ignition to be set. so that everything suits... At the same time - easy start, traction at the bottom, no “ringing”, excellent dynamics at maximum speed.

Therefore, they try to turn the distributor to the right and left, without results.

There are only two ways out:

1. Buy another distributor.

2. Adjust (or tune) the distributor. This second concept is more complicated. Many do not believe in him.

….

Also, for winter it is worth adding that sometimes it makes sense to do the ignition a little later, with the loss of dynamics.

But this is when very coldy and the battery is weak, it is difficult for him to overcome the minimum "sticking" when starting up.

There are no related posts yet