Cardan transfer

General information about cardan transmissions:

Intermediate transmission on cars on tractors, transfers torque if the intermediate transmission is placed between the units, rigidly connected to the frame or body body, the angle between the axes of their shafts at the skew frames should be no more than 2-3 degrees. If when driving vehicle One or both of the units connected along with wheels (bridges), the angle between the axes of the shafts of these aggregates increases, reaching from 15 to 20 degrees, and in high-passable cars, the limit reaches from 30 to 45 degrees. Intermediate connections or transmissions include:

Cardagne transmission of equal and non-equal angular velocities

These presented the following requirements:

Transferring torque without creating additional bends and twisting moments

Vibration and axial loads

Ensuring the equality of angular velocities

Silent work

Intermediate transmissions for assignment, that is, the transmission of torque is divided into:

Elastic connections

Cardania

Hinges of equal angular velocities

Cardagne transmission of cars and tractors consist of the following main parts:

Elastic connections (Soft Cardanins)

Elastic compounds are installed between the elements of the transmission in order to reduce the dynamic loads with a sharp increase in its increase, quenching vibrations and tweeted oscillations, that is, for damping the load oscillations. As an elastic element, rubber pillows or sleeves are most often used. The most common elastic connections of two types are:

With elastic disk

With rubberometallic sleeve

With a elastic disk, it works satisfactorily at an angle from 2 to 5 degrees.

With rubberometallic bushings of the numbers of which are chosen from 4 to 8 degrees depending on the value of the transmitted torque and depending on the type road coat from operating conditions, etc. Permissible corner There are up to 12 degrees between the shafts in the rubberometallic bushing of Kardan. The physico-mechanical properties of rubber used in rubberometallic sleeves are as follows:

The gap strength should provide from 150 kPa

Relative elongation of at least 350%

Asynchronous cardans.

Cardanne programs consist of one or two cardan hinges. The hinge is the part in the form of a plug connected by crissists and serves to connect the input and output shafts as well as for transmitting torque.

Working conditions cardan Transmission Determined by the angle between the axes of their shafts: the greater the angle of the heavier operating conditions. The efficiency decreases sharply depending on external factors. When the shafts are rotated at an angle, the crosspieces swings on spikes within the angle that causes non-uniformity of the shaft rotation, with a uniform rotation of the input shaft. For any position of the shafts, equality is performed:

![]()

Where are the angles the turn of the lead and the slave. The internal plugs of the joints are located on the shaft in the same plane, noting the label. If the angles are the same, that is, A1 \u003d A2, it is ensured by the synchronization of the rotation of the entire system. The cardan transmission is a combination of cardan hinges and cardiac shafts that is intended or used to connect the transmission units, the axes of which do not coincide as well as for transmitting torque. Each hinge consists of forks, crossmen, needle bearings whose glasses are fixed with covers and bolts. In the cross, it is sometimes involved in the oilbox, in the bearing injected long-term lubricant. Axial move cardan shafts It is carried out due to the use of a moving compound, moving connections can be rolling with friction. Their working elements are that there are balls or rollers have a cylindrical or spherical surface shape and move in the grooves of the corresponding profile.

In the designs of cardan gears, moving connections with friction slip are most often used. In this case, the shafts are performed with a slotted eusolvent or rectangular profile. To increase the wear resistance, the slots are covered with antifriction polymeric materials, with rotation or when the torque transmission is transmitted to a large distance, two cardan shafts are used with three hinges and with an intermediate support of one of the shafts (suspended bearing).

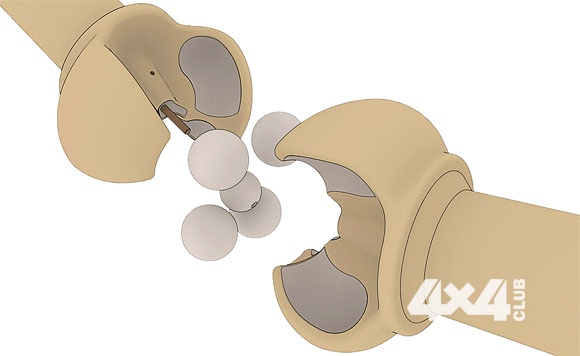

Hinges of equal angular spells - hinges use a community when transmitting the moment on the drive-driven wheels. In this case, uniform rotation of the wheels is ensured at high changing angles between the shafts. When installing the Sls, the angular velocities of the shafts connected by them will be the same with any of their corner moving. Sls, (synchronous hinges) distinguish with the type of working elements, dual cardan hinges with crosses and needle bearings, balls with 4, 6th balls, disc. On high patency cars, ball screws with dividing grooves and a dividing lever are widely used.

Hinges of equal angular spells - hinges use a community when transmitting the moment on the drive-driven wheels. In this case, uniform rotation of the wheels is ensured at high changing angles between the shafts. When installing the Sls, the angular velocities of the shafts connected by them will be the same with any of their corner moving. Sls, (synchronous hinges) distinguish with the type of working elements, dual cardan hinges with crosses and needle bearings, balls with 4, 6th balls, disc. On high patency cars, ball screws with dividing grooves and a dividing lever are widely used.

Federal Agency for Education

Siberian State Automobile and Road Academy (Sibadi)

Department of "Cars and Tractors"

Cardan transfer

Methodical instructions for the implementation of laboratory work on the discipline "Construction of cars and tractors" for students of the specialty 190100

Compilences: A.M. Zarekov

THEM. Knyazev

I.V. Hamov

Publisher - Sibadi

Reviewer Dokt. those. Sciences, prof. V.V. Evstifeev

The work is approved by the scientific and methodological advice of the specialty "Cars and Automotive" as methodical instructions To fulfillment laboratory work Under the discipline "Design of cars and tractors" for students of the specialty 190100.

Cardan transmission: Methodical instructions for the implementation of laboratory work on the discipline "Construction of cars and tractors" for students of the specialty 190100 / Sost: A.M. Zaroshnikov, I.M. Knyazev, I.V. Hamov - Omsk: Publishing House Sibadi, 2013.- 18 p.

Cancellation options for car drives, their work. and calculation elements.

Il. 15. Bibliogr.: 3 Names.

© Compilebooks: A.M. Zaroshnikov, I.M. Knyazev, I.V. Hamov

2013

1. Basic provisions .......................................... ... ... 4

1.1. Classification of cardan gears .. ... .. .............................. ... 4

1.2. Kinematics of asynchronous cardan hinge thick ................9

1.3. Critical frequency of rotation of the cardan transmission (CCV) ......... 13

2. The order of work .................................... ... 15

3. Control questions ................................................ 15

Bibliographic list ............................................. ..... 16

The purpose of the work: to study the device and the operation of the automotive cardan transmission.

Equipment: stand with a cardan transmission layout based on an asynchronous hammer hinge.

Basic provisions

1.1. Classification of cardan gears

The cardan transmission serves to transmit the power flow between the transmission nodes, the mutual linear and the angular position of which changes during the operation.

Cardan Transmission Requirements

Provide a synchronous connection of angular velocities of rotation of the leading and slave links.

To allow the corners of the deviation between the axes of the shafts exceeding the maximum possible during operation.

Critical speeds should exceed the maximum possible operation of the entire period of operation.

Provide partial damping of dynamic transmission loads.

Do not allow noise and vibrations throughout the operating speeds interval.

Classification:

1. By kinematics:

Hinge of equal angular velocities (Sls).

Hinges of unequal angular velocities.

2. By design:

With simple cardan hinges (Fig. 1. Hollow Hug). These are hinges of unequal angular velocities (asynchronous).

Hinge of equal angular velocities (cutting) with a divisory lever of type "Rapting" (Fig. 2.).

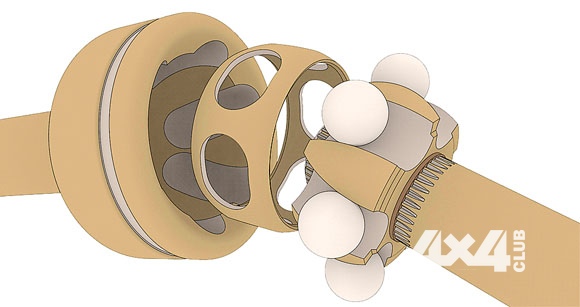

Ball hinges of equal angular velocities with divided lever or divided grooves (Fig. 3).

Fig. 1. Asynchronous Cardan Hinge Thick

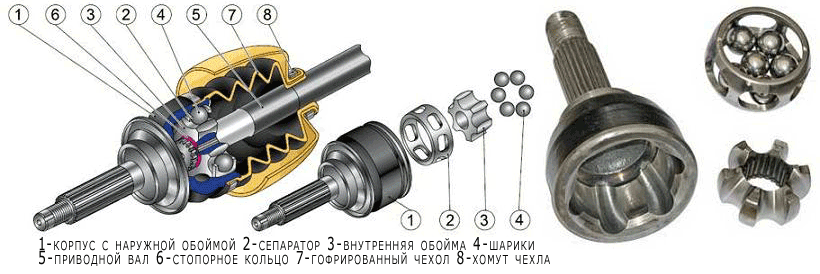

Fig. 2. Hinge of equal angular velocities with a divided lever:

1 - slave shaft; 2 - dividing lever; 3 - spherical cup (part of the slave shaft); 4 - spherical fist (on the slots of the leading shaft); 5 - presenter; 6 - spherical separator balls; 7 - Compression Spring For Reflauding Installation Level

Spells with dividing grooves received the greatest distribution. On modern domestic cars, the front-wheel drive is carried out using just such hinges. Outside (near the wheel), a six-wing hinge type "Birfield" is usually installed. It allows you to rotate the controlled wheel up to 45 0.

In fig. 3A shows the drawing of the hinge, and in fig. 3B Scheme of the hinge and placement of the ball 2 in the housing 1 and fist 4. Under the number 3, a spherical separator is shown, which simultaneously conjugates with the spherical surface of the case 1 by radius R. 2 and spherical fist surface 4 by radius R. one . Shaft 5 through the internal hinge connects main TransferAnd on the shaft, which comes from the case 1 is attached to the drive wheel of the car.

Fig. 3. Hinge of equal angular velocities with dividing grooves

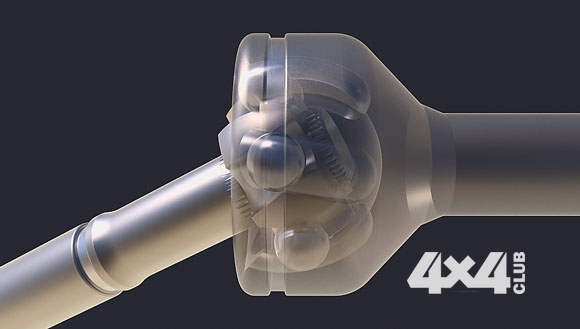

Internal hinge (Fig. 4), also equal angular velocities, still allows you to change the length of the drive to compensate for the suspension move, moving the longitudinally. Therefore, it is called universal.

Fig. 4. Internal Universal Slus

In it, the separator 4 has different centers of the external and internal sphere. In addition, the separator sphere, which conjugates with the housing 1 passes in a narrow part in general in the conical surface. Grooves in housing 1 and fist 3 longitudinal, so the ball is not only rolling, but also slip during the longitudinal movement of the shaft with a fist 4. Maximum corner The inclination of such a hinge, due to the above, does not exceed 20 0.

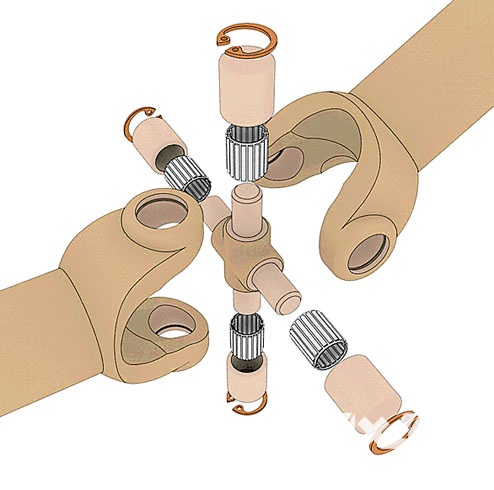

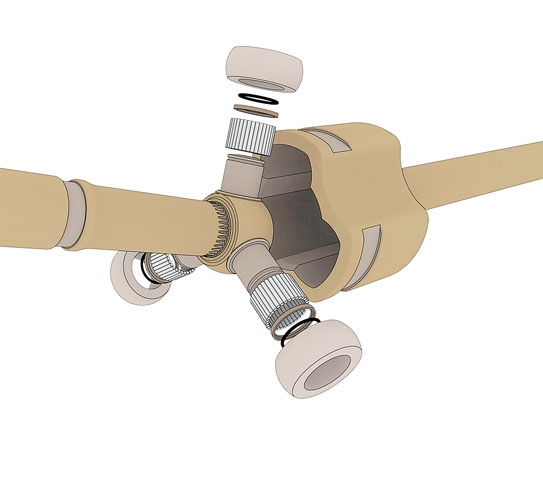

Three-hand drive hinge of equal angular velocities (Fig. 5):

Fig. 5. Tricky Schlus

a) rigid (only changes the angle between the shafts, therefore it is outside (Fig. 5);

b) The universal hinge of the same type allows you to have longitudinal movement drive to compensate for moving from suspension.

Three spikes 2 are rollers 3, which are rolled through forks 4. In addition, it is possible to move the roller along the spike 2.

Shruses of this type got a slight distribution due to greater loading of parts.

Cam (Fig. 6.) and disk (Fig. 7.) Shruses.

Fig. 6. Cutting shrus

Fig. 7. Disk shrus

3. By tough stiffness:

With rigid hinges.

With elastic (elastic) hinges.

4. At the limit corner of the deviation:

With full cardanes (deflection angle of more than 40 0). These hinges are discussed above.

With half-dressed hinges (the angles do not exceed 1.5 ... 2.0 0, Fig. 8).

Fig. 8. Polianardian hinge

The middle shaft in fig. 8. In terms of edges, gear wheels are engaged with toothed couplings, and those, in turn, overlap with their teeth of the gear of the presenter (left) and the slave (right) shafts. In each gear, a slightly distortion is possible, which allows to obtain a small angular deviation of the slave shaft relative to the lead. But, since the gear pairs are with a breakdown, they wear them quickly and unevenly.

Elastic couplings also include half-dressed hinges.

The four-wheel drive implies that a torque is connected to each wheel. And so that the wheel can move and rotate relative to the body

Actually, rotates the wheel drive. When on the screen dashboard Your SUV arises an animated picture of the distribution of thrust on axes and wheels, it immediately repeats the real system of trees under his bottom. These shafts are thick metal rods or pipes with hinges at the ends. The hinge allows you to transmit rotation at an angle: the wheels along with the suspension go up and down, and the front is also rotated for a decent angle.

First shackles

First in the world of the drives reigned leather belts, the same as used in the machines. At the then low speeds and the funny power of the motors, it was still suitable, but as soon as the speeds rose, roller chains with moving links became popular, like motorcycles. The transmission in the back of the car ended with the usual bridge, rigidly fixed on the frame. Instead of wheels, driving stars were mounted to its ends, and the wheels suspended on the springs were driven. On a couple rear wheels There were two bridges - a leading and suspension, and the free sagging chains provided some mobility of the latter. About the drive with their help the front rotary wheels could not be speech.

From this scheme quickly refused due to cumbersomeness and unreliability and began to invent more advanced.

Where does jums from?

Under unequal angular speed, the rotation is understood when the wheel is continuously accelerated and slows down each quarter of its turnover. In addition to unpleasant impacts on steering and suspension (jerking), work with unequal angular velocity is fraught with rapid wear of the entire transmission. The non-uniformity of the rotation of the cardan transmission is the greater the greater the angle between the axes of its shafts. In this case, the leading part of the hinge rotates uniformly.

Kardano and Leonardo

To think only, the principle of the cardan transmission was described in detail by Jirolamo Cardano in the XVI century, and for the first time he mentioned Leonardo da Vinci! But one thing to come up with, and completely different - to embody in the metal.

First cardan shafts Settled on cars already in the first decade of the twentieth century. Of all the mobile transmission applicable today, the cardanna is the simplest. Four needle bearings and crosses. Its simplicity is compensated by one important drawback: small operating angles. Up to 12 degrees, it still spins more or less smoothly. Above - with jerks. Few people know that even without an angular difference, Kardan is harmful to work: the fixed needles bearings are done in the supporting fingers of the grooves, damping mobility. Therefore, it is usually a small (1.5-2 °) working angle.

Cardan is suitable for actuating rear wheel drive, but what about the front, where is the corners of the turn often approach 30 degrees?

IN front bridge All well-known Jeep lived dual cardan crosses lived for many years. Brilliant Solution - divided the working angle in half between two hinges - has two notable drawbacks: the bulky structures and all the same jets with the highest steering. It was necessary to come up with something radically new.

Parryrals do not agree

In conventional drive shafts of the bridge drive, two crossmen are used, the ears of which on the same shaft are located in the same plane. The shafts themselves are located if possible so that the axes of the output shaft of the dispensing box (or gearbox) and the axis of the master shaft rear gearman were parallel. The same, but multidirectional corners of the tilt cross cardanian Vala contribute to compensation of angular pulsations. One of the reasons for the appearance of independent rear suspension The fact that their gearbox is almost never moved relative to the rest of the transmission. Corners cardanic hinges In this case, unchanged and minimal.

Union of needles. No hinge simply cross Cardana.

But a terrific constructive entails operating subtleties.

Four needle bearings need lubricant -

laid at the factory or periodically replenished during driving

Side by side. Double Cross allows you to share a harmful corner

equally between half of the hinge.

The rough decision "in the forehead" came out efficient and

quite budget, but bulky

World of sliding balls

For the first time to transmit rotation with equal angular speed and replace cardan bearings The gentle balls guessed the German inventor Karl Weiss in the early 1920s. His invention, the very first shrus, was two forks at the ends of two shafts, in the paired grooves of which four balls were rolled. The fifth ball in the center served as a hinge relative to which the shafts bent. Some time later, Waissa's patent bought the company of the American inventor and the industrialist Vincent Gogo Bendix, and so far, Bendix - Weiss, we can see, for example, in the front bridge of the UAZ.

This design is well suited for the gear of a solid moment in heavy off-road machines, but still has a low resource and noticeable losses at large angles due to the small total touch surface (only two balls are operating at the same time). Path of improvement corner joints became obvious: an increase in the number of contacting parts.

Familiar Bendix. The design of the hinge, well-known owners

Uzaz and good half of other SUVs.

Easy, technological and inexpensive. One trouble - only two balls

simultaneously transmit rotation, which is mala the work surface

More - better

In 1936, the inventor Alfred Tsyu managed to achieve unprecedented uniformity angular speed shafts. Successional Success - six balls instead of four, spherical shape of a hinge and long guide grooves. Most often, it is this hinge today today we call the screen - hinge of equal angular velocities. Strictly speaking, and in the hinge of the mouth there is barely noticeable jerks, but they are so small that even with a huge driven driven drives at 40 degrees can be neglected. However, these hinges won the world pretty slowly: the manufacture of complex spatial parts - internal and external subsidiaries, separator with holes, accurate spherical conjugations - required the accurate equipment and high-quality materials. But it is the shruches of "Rapppa" and their diverse descendants ("Birfields" and GKN) today rule the ball in systems full drive. The usual "pomegranate" in the drive is she, the Rating six-haired coupling.

Curse Kardana

The problem of unequal angular speed is familiar owners Lada. 4 × 4 and Chevrolet Niva.. Cardan monitance between the gearbox and dispensing box The old version of the transmission is associated with the effects of two car drive drives - the source of the most unpleasant vibration of the SUV. One of the good recipes against vibrations is a rigid fastening of transmission units to each other - ignored in Niva, having received a indestructible source of various transmission jerks. Less technological, but the next "golden rule" of UAZ received a monoblock transmission without intermediate cardanov and calm, without ripples, transmission.

Sphere in the field. The mains of the invention of the drug -

sliding spherical surfaces in each other.

For their manufacture, it is necessary very accurate equipment.

Aside and backward

But not only the Sls of the "Rappa" turns the wheels on off-road technique. The design with openwork details of high precision wins in compactness, but has limit on the magnitude of the torque. Speaking easier, it is well suited for SUVs and crossovers, but too expensive and unreliable for use in heavy military and special machines. Easy and low cost is important for them, and jerks in the transmission are a minor matter.

Manufacturers of front-wheel drive vehicles, not wanting to pay the owners of the owners of the patents of Bendix-Weiss and the "Raptpa" money, developed simplified designs. For example, the "tract" hinge is a combination of cams and sleeves connected by sliding parts with large grinded surfaces. A similar device has a domestic cam-glass joint, which is successfully used on all-wheel drive Kamaz, Krazakh and Urals. Large dimensions And the huge surface of friction such hinges is not scary on a large technique with a high torque of the motor, and the limited resource of parts is compensated by their cheap and simplicity of replacement.

Sly Thomson. Placing one cross in the other,

tomson won the engineer in size, but lost in strength.

Pay attention to the complex system of divisory levers.

Another Erzatz-hinge is the tricky name "Tripod". Everything is simple here: the three axis sticking in different directions at the end of the drive carry on the roller with a spherical surface. Rollers are included in three cuts of the exterior rope. The system is simple and reliable, but badly gets around with large corners. Nevertheless, the tripods are often used as inner hinges in front. The reason is still the same - relative simplicity and low cost.

Tripod. Non-flat design with rollers and grooves in the external clip.

Not afraid of gaps, but does not like big corners.

Often works as an internal front wheel drive hinge