Optics on any machine is primarily an element of the traffic safety system. To personalize their car, many drivers improve their own lighting system. There is a headlight with your own hands. Each of them does not require highly specialized equipment, expensive materials or special skills.

The main options for modifying optics

Beautiful headlights give the car a more spectacular, exclusive and expensive look

There are several inexpensive and simple headlight modifications:

- cilia;

- color film;

- toning;

- "Angel eyes";

- lED strips.

Cilia

Without significant financial investments, you can use special pads on the optics - cilia. Visually, they seem to be a continuation of the hood, as they overlap the upper part of the headlights. This gives the car a more dynamic and aggressive look. In this case, the linings can have any shape - it all depends on the preferences of the owner of the car.

Cilia are sold in almost every parts store, so every motorist can do their own headlight tuning. Select the desired plastic profile and cut the appropriate component. Before installation, the resulting parts are usually painted in a suitable color. Then, using double-sided tape, the pads are installed on the optics.

There is a method that will allow you to make more spectacular eyelashes. For this you will need:

- fiberglass;

- epoxy adhesive;

- sandpaper;

- primer;

- masking and double-sided tape;

- paint;

- fiberglass scissors;

- a set of keys for removing and installing optics;

- marker.

The first thing to do is remove the headlights. Then, using adhesive tape, block the glazing zones. Strips of fiberglass of the desired width are glued on top, which are impregnated with "epoxy". When they are dry, another tape and glue is applied. This must be repeated until four uniform layers are obtained.

Then masking tape is glued on top. Pressure is applied to it so that the workpiece takes the shape, like the glazing profile. Depending on the manufacturer, epoxy glue dries from eight hours to a day. With the help of a marker, markings are applied for the cut, along which you need to walk with scissors. After that, the workpiece is processed with sandpaper, primer and paint are applied. After drying, the finished products are glued to the headlights with double-sided tape.

This method allows you to create different designs of cilia. Many people even recommend making several options, and then just choosing the most attractive one.

This method has its advantages:

- ease of creation;

- the gap between the hood and optics is overlapped;

- stylish tuning look;

- no problem when replacing.

Color film

This method enables headlights quickly and inexpensively. To do this, you need to have:

- colored tint film;

- detergent and napkin;

- soap solution;

- sharp knife;

- rubber squeegee;

- a set of keys for mounting headlights;

- marker.

In order to facilitate the gluing procedure, the optics must first be removed. Glass is wetted detergent and wiped dry with a napkin.

After that, it is necessary to attach a tint film to the headlight and mark it with a marker. Cut out the required part. Then the protective layer on the film is removed and moistened with soapy water, like the optics itself. Then the surfaces are connected.

When heating the film with a hairdryer, you need to slowly smooth it out with a rubber squeegee, which allows you to remove air bubbles. Then the optics is set to its original position.

Tinting

Do-it-yourself headlight tuning, like many others, is not difficult. You need to allocate a few hours of free time and purchase necessary materials... In particular, in order to give the optics a new shade of glow using tinting, you need:

- a bottle of professional paint, which is designed specifically for headlights;

- paper tape;

- degreaser;

- polishing napkins;

- keys set.

The headlights are removed, cleaned of dirt and dust. Areas that will not be tinted are covered with tape. The required segments are degreased.

Before applying the paint, it is better to place the balloon in hot water for five minutes - this will make the varnish more plastic. You need to spray at a distance of 30 centimeters from the surface of the headlights. After creating the first layer, you need to wait a while, as indicated in the instructions, for everything to dry. Then the action is repeated.

IMPORTANT! If the process is accelerated, streaks may appear. Then everything must be removed with a solvent that will not damage the optics, and the whole process must be repeated. The surface will shine with a special polishing cloth.

"Angel Eyes"

At first glance, Angel Eyes LED headlight tuning is something impossible. But if you look at it in detail, the whole process is simple and short-lived. To do this, you need to prepare the following materials and tools:

- lEDs of the desired color - usually blue or white;

- two 220 ohm resistors;

- wire;

- pliers;

- soldering iron;

- file;

- sandpaper;

- transparent plastic tubes;

- stationery knife;

- insulating tape;

- construction hair dryer;

- nine volt battery;

- a stencil around which plastic can be bent.

The transparent tube heats up and bends around the stencil. It is better to use pliers for this. With the help of a knife, the excess is cut off, the edges are sanded. It turns out a ring that exactly matches the size of the glazing. After cooling, the rings have a small gap of two to five centimeters. Around the entire circumference at a distance of half a centimeter from each other with the help of a knife, recesses of several millimeters are made and "brought to mind" with the help of a file.

After that, a wire is soldered to the LED on one leg, and a wire and a resistor are soldered to the other. After that, you need to connect the battery to check the functionality. All contacts are wrapped with electrical tape. The second LED is made in the same way.

After that, both are connected to each other. The resulting light structure is mounted in a break in the plastic circle so that the diodes are placed at different ends of the tube. Then the system is again checked for operability. If everything functions normally, the system is mounted in the designated places.

LED strips

To complement the image of "angel eyes", LED headlights are often tuned using special tapes. Not much is needed for this:

- lED Strip Light;

- wires for connection;

- soldering iron;

- transparent glue;

- degreaser.

First you need to measure the required length of the light strip in each headlamp. After that, wires are soldered to the connectors for connection.

Before gluing, be sure to degrease the surface. The tapes are installed directly on transparent glass. After that, the headlights turn into pronounced "eyes", which gives the car an aggressive character.

Any tuning of the optics system will immediately distinguish the owner of the vehicle from the rest. In addition, after such an improvement, the car instantly begins to look "more expensive". At the same time, to create the desired effect, you need only a few hours of free time, as well as purchase the necessary components.

Decorating the taillights

Often a lot of attention is paid to the headlights, but the rear ones are usually forgotten, but in vain, they can also be quickly and easily decorated by installing an LED strip in them.

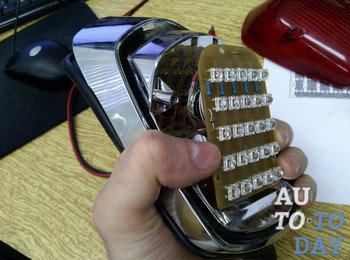

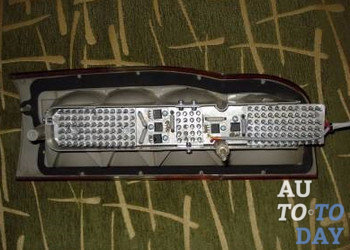

You will need a tape for 120 light elements, dismantle the headlight and remove the glass; to do this, you need to remove the sealant (using heat and using a knife). Glass with inside we glue it with masking tape.

It is important to isolate the remaining surface from drops of paint, and paint the inside silver color... When the paint is completely dry, remove the tape and a relief pattern will remain on the headlight. Glue the required size on it led strip using superglue or double-sided tape and connect the wires.

The coloring was carried out to ensure a uniform glow of the dimensions. During such tuning, there is no need to turn off the headlamp incandescent lamp, it is enough to insulate the dimensions contacts.

How to illuminate the car from the inside

Do-it-yourself internal light tuning of a car can be done in two ways: with a strip of LEDs and neon lamps.

Neon salon

You will need:

- Nylon clamps.

- Aluminum corner.

- Neon lamps.

- Self-tapping screws.

It is more correct to start tuning by installing neons at the bottom of the cabin.

Most often, neon lamps are made with a cigarette lighter socket, it must be cut off, and then the ends are cleaned. Then we saw off an angle corresponding to the size of the lamp, and screw it under the torpedo in the cabin. We fix the lamp on the corner with nylon clamps. The same is done in the rest of the cabin, except rear seats, where the corner is fastened upside down to protect the lamp from damage.

We stretch the ends of the wires under the rugs to the dashboard near the driver's seat and isolate them at the joints. Then we connect them to the door sensor, the interior light switch and the battery. It is also important not to forget to connect one of the wires to the sensor. throttleso that in the future he notifies about the available lighting during the ECU flashing, this is necessary so that the neon lamps do not burn out.

The result will be a triggered lighting during door opening, which will amaze with its unusualness not only you, but also the passages passing by.

LED salon

Connecting the backlight using LEDs is similar to neon, the only thing you need to correctly position the tape (you may have to cut off individual pieces), and then strip the ends and solder to each other, bushings are put on the joints for safety reasons and warmed up with a hair dryer.

Luminous bottom

We immediately warn you that tuning the light for the underside of the car is illegal, since the changes are not provided for by the manufacturing plants and machine designs. But this does not stop many motorists, so it's up to you to make such an upgrade or not.

Previously, the "lower" tuning was done using neons, but it was quite unprofitable and the tuners switched to LED backlighting, which is much easier to install and consumes much less electricity.

You will need:

- Waterproof LED strip.

- Soldering iron and everything needed for soldering.

We measure the size of the bottom and cut the tape to the desired size. It's good if you get 4 pieces. Then contacts are soldered to each piece. Then we install them on the bottom of the car with clamps, so it will hold much stronger than if you glue it on.

Pass the wiring through the holes, connect to the dimensions, or make a separate power button.

The bottom lighting procedure, like the others, does not require special knowledge, even a novice car enthusiast can handle it. The main thing is that with such a tuning, the traffic police officer does not catch the eye.

In conclusion, we note that light tuning is one of the inexpensive and effective ways to distinguish yourself. It can be implemented on your car in a short time, so do not be afraid to experiment, and the result will be great.

Probably, every car owner would like his car to look as stylish as possible, and everyone around him envied him. This result can be achieved with a mass different ways - the modern market offers many effective paints and varnishes, polishes, vinyl stickers and other materials for tuning. But many, putting in order the glass, the body, wheel disks, often forget about They, although they are not considered the main element of the car, but when the right approach will attract the glances of other motorists in the stream, as well as passers-by. Therefore, along with tuning the body, toning the taillights will not be superfluous at all if you need to give the exterior a few exclusive details.

Headlight tinting and the law

Before deciding on such an operation, you need to remember that if you violate the standards (that is, darken the lights incorrectly), then the traffic police will issue a fine for this. Its amount is almost the same as for tinting, which is not done according to GOST. Therefore, many are afraid to do something with the headlights, so as not to break the law and not pay extra fines.

Application methods

Refusing to decorate a car in this way just because of fines is not entirely the right decision. You just need to find out what is allowed and allowed, and what is prohibited, and then you can safely modify the car. Tinting the rear lights will not only give the car a modern appearance, but will also protect the glass or plastic of the headlight from various scratches and dusts. The surface will become as even as possible if the application process is carried out using a special film.

There are two methods to darken the headlights. This is the use of paint and tinting the taillights with foil. Which of these two ways should you choose? Each driver will decide for himself. Both tuning methods have their pros and cons, differ in cost, labor input and time.

Paint tinting: features

This method of painting headlights is as economical as possible. However, it is quite laborious. It is necessary to thoroughly clean the surface, sand the plastic or glass, and only after that you can proceed directly to painting. The darkening process takes a long time. And the results are not always the way we would like. Such tinted taillights are suitable for those who do not want to invest large sums in tuning their cars.

Vinyl wrap: features

This method will take much less time than the previous option. Also, this method is less laborious than in the case of staining. But there is one point with which there can be certain difficulties. It is necessary to stick the film so that there are no folds on the surface. Among the benefits of using this method you can highlight the ability to quickly remove the film at any time. There are many shades. There are all colors (for example, the red tinted taillights look great). The shade can be matched to a specific vehicle.

Paint tinting: how to apply varnish or paint

If a decision is made to darken using paint, the first step is to purchase a special preparation. It is best to choose tinting varnishes. They are much more convenient to apply and use. The cost of these paints and varnishes can be quite high. But the result is worth it. To process two lanterns, just one can is enough. It is recommended to carry out work related to painting headlights in well-ventilated rooms. It is best to do this outdoors. Choose a clear but not too sunny day.  Do-it-yourself tinting of the taillights using paints or varnishes is carried out in several stages. The first step is to dismantle the headlights. This will allow the varnish to lie on the surface as evenly as possible. Please note that then the lights will need to be installed back. This requires skills.

Do-it-yourself tinting of the taillights using paints or varnishes is carried out in several stages. The first step is to dismantle the headlights. This will allow the varnish to lie on the surface as evenly as possible. Please note that then the lights will need to be installed back. This requires skills.  Further, the surface of the glass or plastic of the lantern must be degreased. To do this, you can use traditional alcohol or use special products. After the end of the process, the headlamp is allowed to dry. Shake the can before spraying the paint and varnish composition. Further, the paint is applied as thin and even layer as possible. Then the headlamp is allowed to dry out a little. It is necessary to lay it in such a place that small debris and dust do not fall on the painted surface. Next, another (or more) layer of paint is applied - while painting it is necessary until then, so as not to exceed the norms of light transmission of the headlight. When the lanterns are completely dry, they should be polished to a mirror finish. Then the optics can be put back on the car and enjoy the result.

Further, the surface of the glass or plastic of the lantern must be degreased. To do this, you can use traditional alcohol or use special products. After the end of the process, the headlamp is allowed to dry. Shake the can before spraying the paint and varnish composition. Further, the paint is applied as thin and even layer as possible. Then the headlamp is allowed to dry out a little. It is necessary to lay it in such a place that small debris and dust do not fall on the painted surface. Next, another (or more) layer of paint is applied - while painting it is necessary until then, so as not to exceed the norms of light transmission of the headlight. When the lanterns are completely dry, they should be polished to a mirror finish. Then the optics can be put back on the car and enjoy the result.

Tinting with film: instructions

The following tools will be needed for work: a building hair dryer, a fairly sharp knife, an alcohol solution and an ordinary spatula. The first step is to tint the rear lights to thoroughly clean the surface. The headlights are first cleaned by removing moisture from them. This can be done conveniently and effectively with a microfiber cloth. Also, experts recommend using special cleaning products. Then an alcohol solution is sprayed on the surface of the film and on the headlight. This is done in order to simplify the tinting process.

Stretch the vinyl in order to lay flat and take the shape of the taillights. This is done by hand or using a hair dryer. The material needs to be heated, and then the film will become flexible. It is important not to overheat the vinyl. Otherwise, wrinkles will appear.

What's next

Now we have the most important stage of work. It is necessary to stretch the material with a spatula and stick the film on the headlights. If something goes over the edges, it is cut off with a knife. Reviews say that tinting the rear lights with foil with your hands should be done very carefully. It is possible to damage the flashlight and hands in the process. This completes the process, and you can enjoy the result.

Headlight tinting and fines

As all car owners know, the country has introduced a ban on too strong car glass tinting. This is done to improve safety, as visibility is reduced and the driver may not notice the brake light or turn signal.  At all, taillights the review of the road situation is not affected in any way, however, if the toning is done incorrectly, then the car owner faces not only a fine, the amount of which is similar to the fine for tinted glass, but also the obstruction of the movement of other cars from behind. Driver reviews repeatedly confirm this.

At all, taillights the review of the road situation is not affected in any way, however, if the toning is done incorrectly, then the car owner faces not only a fine, the amount of which is similar to the fine for tinted glass, but also the obstruction of the movement of other cars from behind. Driver reviews repeatedly confirm this.

The law allows you to drive a car, the taillights of which have white color... Others are also allowed lighting devices yellow, red and orange. Tinted taillights (Priora is no exception) can significantly change the shades of the lamp's radiation. Therefore, work should be done very carefully and carefully. Otherwise, you will have to pay a fine of 500 rubles. Inspectors often interpret this tuning as a vehicle malfunction. In the worst case, you can lose driving license for 6-12 months under clause 13 of Art. 12.5 of the Code of Administrative Offenses.

When using black taillights, an accident can occur, and in this case the driver who drives with toning will be to blame. Then you will have to pay not only the fine, but also the repair of the damaged car.

When using black taillights, an accident can occur, and in this case the driver who drives with toning will be to blame. Then you will have to pay not only the fine, but also the repair of the damaged car.

There is an option when you can protect yourself from fines and still drive a beautiful and spectacular car. Reviews of car owners say that for this you need to do blackout in a specialized salon. How much does the taillight tinting cost? The price in large cities of Russia is from one and a half thousand rubles, depending on the car model and the geometry of the headlight itself. This is a relatively small amount. But by paying it, you can protect yourself from traffic police inspectors and protocols. In practice, most often no one will fine anyone, especially if the headlights are tinted correctly and skillfully. In this case, the brightness of the glow practically does not decrease. If the inspector sees a gross violation, he can ask to fix the problem on the spot. Reviews say that it is easiest to do this with film.

Conclusion

As you can see, this tuning method can be performed independently with certain skills. If you do everything correctly and follow the instructions, then this will not be considered a violation.

As a rule, the design and design of standard taillights in passenger cars quite satisfied with their owners. However, in some cases, these lighting devices require certain modifications, for example, increasing the brightness of the lamps or changing the shape and size of individual sections (brake lights, direction indicators or side lights).

This is especially true for "older" cars domestic production, where the taillights initially do not differ in particular expressiveness and brightness, and over time they even require replacement or serious revision.

Tuning options for the rear lights

There are several options for homemade lantern tuning. In the simplest case, the standard lamps are replaced with more powerful ones, and the lamp diffuser is darkened by pasting with a tint film. Of course, such "tuning" flatters the owner's pride, however electrical wiring such a car works with overload, and the lights themselves shine too dimly and are practically invisible in the daytime.

Gluing shiny stripes over the diffuser along the edges of the lantern sections is intended to make them more elegant. At least, such a harmless modification does not affect the operation of the light signaling in any way and has a right to life.

Tuning taillights with LED installation

A much more competent option for tuning the rear lights is to install modern LEDs in them. The advantages of this refinement are:

- Compared to traditional incandescent bulbs, LEDs consume much less power;

- Minimum response time (lighting up) of LEDs;

- High brightness and large viewing angles make it possible to abandon the use of reflectors in the design of the lantern and, if desired, make its diffuser colorless;

- The compact size of the LEDs allows them to be positioned and grouped in any order, that is, as the owner wants (of course, all this must be done within the technical standards, as well as the available space on the rear panel of the car).

To upgrade the taillights, we need to buy a certain number of LEDs with an operating voltage of 12-16 volts. In the case of using a standard rear light diffuser (with already painted signal sections), the LEDs should be white or as close to it as possible. If it is planned to make a colorless (transparent) diffuser, then we need red LEDs for brake and side lightsorange for turn signals and white for lights reverse.

The number of LEDs for each section is selected based on the available free space in each section. A plate made of a thin and durable dielectric or foil-clad getinax is best suited for attaching the LEDs legs. In the first case, the installation of LEDs is carried out using pieces of thin wire, and when using a getinax, you can etch the required number of current-carrying paths on it to supply power to "+" and "-". Of course, the 2nd option is somewhat more laborious, but this design looks more accurate and is less afraid of vibrations.

In order for all LEDs to shine equally brightly, they are connected in parallel. When buying, it is best to use such LEDs that already come with a resistor (it is needed to limit the current flowing through the diode). Otherwise, you will have to select this resistor yourself. The resistors must be fastened in such a way that they do not touch adjacent wires and do not damage them.

All connections of the supply wires are carefully insulated with a plastic cambric or a thin heat shrink tube. In those places where the wire can be damaged by sharp edges, it is additionally protected with a dense cambric.

Some relays that set the flashing frequency of the turns are very sensitive to the load. That is, at the factory they are calculated to power four lamps with a capacity of about 50W (21 + 21 + 4 + control lamp in dashboard). In the case of using diodes with a lower power consumption, the flashing frequency of the lamps may change, so this fact should be borne in mind.

- Like any other part, diodes can fail over time. Therefore, it makes sense to buy them with a small margin, so that, if necessary, you do not go shopping in search of diodes with the characteristics you need;

- Diodes also do not like excessive vibration and shaking. In this regard, the diode bodies are inserted into the board body with some interference, and all connections are made by soldering.

It is probably very difficult to imagine how in modern world you can drive and not use reverse gear, since by and large such a situation simply cannot arise. In addition, movement only during the daytime is not always possible, and therefore you must always have additional function good overview and visibility. That is why it is necessary to ensure maximum comfort in movement to the maximum, both in the evening and at night, and during the day when there is fog in the yard, it is raining or there are other vagaries of the weather that do not in the best manner affect directly the visibility on the road to all road users.

Based on the foregoing, the main function of this kind of lighting devices will be to illuminate the road when driving backward. In addition, it is these devices that will warn all road users that the motorist intends to reverse, thereby performing an informative function. Nevertheless, unfortunately, sometimes the motorist will need to install an additional device. This is directly related to the fact that the device of a standard flashlight will not be able to fully fulfill all the tasks at the required high level.

1. How to properly install LEDs in the rear lights.

It is important to note that this kind of operation is quite easy, although you need to be very careful when performing all the necessary procedures indicated below. First, you need to dismantle the rear lights with a utility knife and a candle. After that, you will need to remove the glass from the headlight. It is important to note that this will require a high level of care to avoid damaging the plastic or glass. After that, it is necessary to completely remove everything from the headlight itself, and pour the mounting foam inside, which in the future will serve as the basis for attaching the LED strip.

It is important to note that this kind of operation is quite easy, although you need to be very careful when performing all the necessary procedures indicated below. First, you need to dismantle the rear lights with a utility knife and a candle. After that, you will need to remove the glass from the headlight. It is important to note that this will require a high level of care to avoid damaging the plastic or glass. After that, it is necessary to completely remove everything from the headlight itself, and pour the mounting foam inside, which in the future will serve as the basis for attaching the LED strip.

After the polyurethane foam has completely dried, the motorist will need to endow it with the desired shape.In order to provide the desired level of rigidity, the surface of the foam must be reinforced with an overlay, which is made of fiberglass. The fabric itself will need to be impregnated with epoxy resin, after which it will be necessary to wait for a certain period of time until it dries.

Then all the light elements must be soldered together, connected, after which it will be necessary to check the operation of the entire established structure. After the headlight glass is applied, the motorist will see the remaining particles of foam, which in best case can be disguised. You can also paint it, but it is important to note that you will first need to cover all the LEDs with squares. In addition, it is important to remember that all headlights must be correctly connected to the entire automotive system and networks.

Power will be supplied to all dimensions, the voltage will be 6 volts, while the brake light devices will be 12 volts. Such a headlamp is quite spectacular and beautiful. However, a certain problem arises, since the brightness of such headlights in the daytime is quite low. To solve the problem, you should install a higher power LED strip. Sometimes, due to the installation of LEDs, an error may occur in the readings of the corresponding device. In order to prevent this, it is necessary to install the "trick".

Power will be supplied to all dimensions, the voltage will be 6 volts, while the brake light devices will be 12 volts. Such a headlamp is quite spectacular and beautiful. However, a certain problem arises, since the brightness of such headlights in the daytime is quite low. To solve the problem, you should install a higher power LED strip. Sometimes, due to the installation of LEDs, an error may occur in the readings of the corresponding device. In order to prevent this, it is necessary to install the "trick".

Now it is necessary to dwell in sufficient detail on the procedure for installing the diode tape or LEDs directly into the reflector. First you need to dismantle the reflector and taillights. The headlight itself will need to be disassembled. In order to glue flexible plastic, you need to use a heat gun or high-quality glue. If diodes are to be used, then they must be soldered together. The structure itself needs to be connected before direct painting, and also to check its performance. This is directly related to the fact that the defective diodes will not light at all, or they will go out a few minutes after switching on. It is important to note right away that the device of one reflector will require about 5 meters of LED strip.

Nevertheless, the task can be somewhat simplified, since the reversing device can be installed halogen lampswhich will replace the standard lamps. Such devices will have great power, sometimes even doubled. The bulb itself is disassembled, and all the insides are neatly removed with tweezers. Further, the halogen holder-base is inserted directly into the device and the wire is soldered. In order to securely fix the cartridge from the "halogen" itself, it is necessary to fill its metal base with silicone sealant.

Using the simplest syringe without a needle, all the gaps between the ceramic cartridge and the metal base should be evenly filled with sealant. It is important with all this not to forget the fact that halogen type lamps will heat up much more than conventional incandescent lamps. Due to this nature, it is necessary to install a ceramic cartridge device instead of conventional soldering. All characteristics of the silicone sealant will be maintained when heated to a sufficient temperature.

Using the simplest syringe without a needle, all the gaps between the ceramic cartridge and the metal base should be evenly filled with sealant. It is important with all this not to forget the fact that halogen type lamps will heat up much more than conventional incandescent lamps. Due to this nature, it is necessary to install a ceramic cartridge device instead of conventional soldering. All characteristics of the silicone sealant will be maintained when heated to a sufficient temperature.

2. What is needed to install LEDs in the taillights.

All lights that have LEDs are efficient enough, visually stylish and beautiful. In order to install such kind of light elements in reflectors, it will be necessary to drill holes in which 120 LEDs will be installed. All rows of holes must be straight. Among other things, the on-board power supply of the car does not provide for the operation of diodes, in connection with which it will be necessary to purchase 120 suitable resistors. It is necessary to install diodes directly into plastic in accordance with certain instructions... The plane of the plastic itself will be heated by a stream of air, into which the LED will be pressed. After direct cooling of the plastic, the diode will be sufficiently fixed.

You can also use LEDs with a diameter of five millimeters. In this case, it will be necessary to change the taillights, which will occur due to the expansion of the area of \u200b\u200b\\ u200b \\ u200bthe dimensions and brake lights. The board itself must be clamped and fixed by the internal shape of the headlight. When using a special LED strip, installation and installation should be an order of magnitude faster, since there will be no need to install each element separately.

You can also use LEDs with a diameter of five millimeters. In this case, it will be necessary to change the taillights, which will occur due to the expansion of the area of \u200b\u200b\\ u200b \\ u200bthe dimensions and brake lights. The board itself must be clamped and fixed by the internal shape of the headlight. When using a special LED strip, installation and installation should be an order of magnitude faster, since there will be no need to install each element separately.

3. Pros and cons of LEDs in the taillights.

The biggest light problem for motorists will be the constant lack of lighting. It is because of this that the question of supplementing or replacing the already built-in and existing standard lamps will arise. This replacement focuses on LED lights. In addition, it is important to note that all LED lights will save a lot of money and time for a motorist to choose and purchase batteries that will drain 80% less than directly using traditional and conservative light sources.

Based on these considerations, many motorists only dream of replacing standard lamps with expensive LED devices. That is why LEDs are becoming more and more popular in the modern automotive community.

The biggest plus in using LEDs is that they have a sufficiently high coefficient of light output, which will make them an order of magnitude brighter than an ordinary light bulb. It is important to note that this kind of improvement will occur at the same current consumption. It should be noted that not every motorist considers it convenient to push his car in the morning, because of the unplugged music in the car, dimensions and as a result of the "death" of the battery. The most positive thing about led lights that they can be done without any effort by any motorist and novice who wishes to improve their vehicle in moving backward.

The biggest plus in using LEDs is that they have a sufficiently high coefficient of light output, which will make them an order of magnitude brighter than an ordinary light bulb. It is important to note that this kind of improvement will occur at the same current consumption. It should be noted that not every motorist considers it convenient to push his car in the morning, because of the unplugged music in the car, dimensions and as a result of the "death" of the battery. The most positive thing about led lights that they can be done without any effort by any motorist and novice who wishes to improve their vehicle in moving backward.

Thus, LEDs in the taillights are the best way out of a situation when standard lights exhaust themselves with weak and unpleasant light. The use of LEDs will increase the brightness of the glowing rear parts, since they have a completely different design and principle of operation, and therefore exceed by an order of magnitude all their standard factory (and not only) counterparts.

Subscribe to our feeds in