Withdrawal. Disconnect the wires from battery and remove the cover of the signal switch.

Take off steering wheel... Remove both halves of the steering shaft shell.

NOTE

If it is necessary to remove only the steering box housing, unscrew the bracket bolts and the bolt securing the steering shaft to the worm shaft, and then slightly slide the steering shaft with the bracket inside the saloya and place a support under the shaft so that it does not hang on the wires.

Remove the instrument panel and disconnect the turn signal and headlamp switch plugs from the wiring harness plugs.

Disconnect the wires from the ignition switch terminals and, after unscrewing the fastening screws and drowning the lock latch, remove the ignition switch.

Loosen the clamp of fastening of the pipe of the upper support of the steering shaft and remove it together with the switch of direction indicators and headlights, having previously unlocked the steering shaft from the anti-theft device.

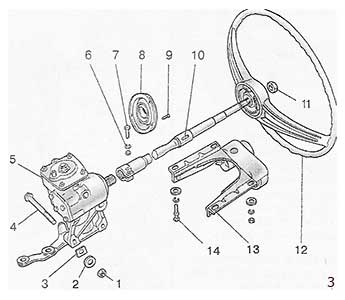

Figure: 6.3. Steering parts: 1 - steering box; 2 - bolt of fastening of the steering box to the body; 3 - an adjusting washer; 4 - flat washer; 5 - nut; 6 - spring washer; 7 - bolt of fastening of the tip of the steering shaft on the worm shaft; 8 - shaft seal; 9 - bolt for fastening the rubber seal to the body; 10 - steering shaft; 11 - bolt of fastening of the steering shaft bracket; 12 - steering shaft bracket; 13 - steering wheel; 14 - steering wheel mounting nut

Remove the bracket 12 (Fig. 6.3) securing the steering shaft. Remove the seal 8 of the steering shaft.

Having unscrewed the bolt 7 securing the steering shaft to the worm shaft, remove the steering shaft into the body interior.

Using the A.47035 puller, press out the ball pins of the steering rods from the hole in the bipod.

Remove the steering box housing.

NOTE

When removing the steering housing, note the number and placement of washers 3 between the side member and the crankcase in order to refit them when installing the crankcase. This is to maintain the alignment of the steering shaft and the worm shaft.

Figure: 6.4. Installing the steering gear on the car: 1 - bolts for fastening the steering box to the body; 2 - bolt of fastening of the steering shaft to the worm shaft; 3 - bolts of fastening of the steering shaft bracket to the body; 4 - plastic sleeve; 5 - steering shaft mounting bracket; 6 - adjusting washers to ensure the alignment of the worm shaft and the steering shaft

Installation of the steering gear carry out in the reverse order of removal. In this case, before finally tightening bolts 1 and 3 (Fig. 6.4) fastening the steering housing and the steering shaft bracket, temporarily put the steering wheel on the shaft, turn the shaft two or three times to the left and right. In this case, the shaft and other parts take correct position (self-aligning) thanks to oval holes on the crankcase and on the bracket.

NOTE

It is possible to separately assemble the steering shaft with seal, bracket, ignition switch, turn signal and headlight switch, steering wheel and install this unit on the vehicle.

Opening and sideways steering mechanism

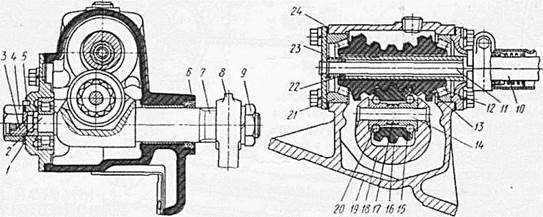

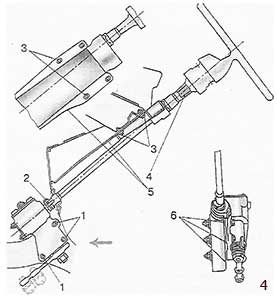

Disassembly. Drain the oil from the steering box. Fix the crankcase on the bracket A.74076 / R with the support A.74076 / 1.

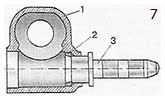

Figure: 6.5. Removing the bipod: 1 - puller А.47043; 2 - steering bipod shaft; 3 - bipod; 4 - bracket A.74076 / R

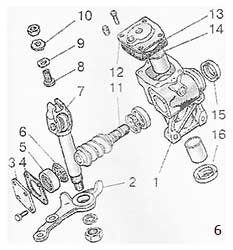

Figure: 6.6. Steering gearbox parts: 1 - crankcase; 2 - bipod; 3 - lower crankcase cover; 4 - shims; 5 - outer ring of the worm shaft bearing; 6 - separator with balls; 7 - bipod shaft; 8 - an adjusting screw; 9 - adjusting plate; 10-lock washer; 11-shaft of the worm; 12 - upper crankcase cover; 13 - sealing gasket; 14 - bipod shaft sleeve; 15 - worm shaft oil seal; 16 - bipod shaft oil seal

Having unscrewed the nut securing the steering arm 3 and removing spring washer remove the bipod using the A.47043 puller (Fig. 6.5). Having unscrewed the fastening bolts, remove the cover 12 (Fig. 6.6) of the steering box housing together with the adjusting screw 8, adjusting plate 9, lock washer 10 and locknut. Remove from the crankcase 1 shaft 7 of the bipod assembly with the roller.

Having unscrewed the mounting bolts, remove the cover 3 of the worm shaft thrust bearing together with the shims 4.

With the worm shaft 11, push the outer ring 5 of the bearing out of the crankcase and take out the shaft together with the bearing separators b. Sleep

Press the oil seal 15 of the worm shaft and the oil seal 16 of the bipod shaft.

Figure: 6.7. Removing the outer ring of the upper worm bearing: 1 - crankcase mechanism; 2 - outer ring of the worm's upper bearing; 3 - mandrel 67.7853.9541

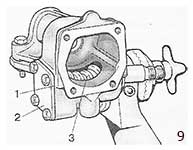

Using a mandrel 67.7853.9541, press out the outer ring of the upper bearing (Fig. 6.7).

Assembly of the steering gear carry out on the bracket A.74076 / R in the reverse order of disassembly. Press the outer ring of the upper bearing of the worm with a mandrel 67.7853.9541, rearranging the nozzle on the mandrel handle with the reverse side.

Figure: 6.8. Installing the steering worm: 1 - bearing cover; 2 - shims; 3 - worm

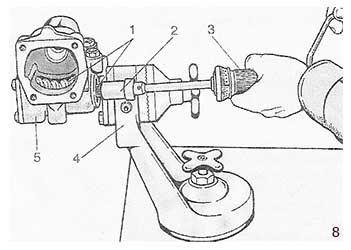

Figure: 6.9. Control of the friction torque of the worm with a dynamometer: 1 - worm; 2 - head A.95697 / 5; 3-dynamometer 02.7812.9501; 4 - stand bracket for repairing the steering gear housing; 5 - steering gear housing

After installing the worm in the steering gear housing and securing the bottom cover, check with the dynamometer 02.7812.9501 and the head A.95697 / 5 (Fig. 6.9) the friction moment of the worm shaft; it should be within 19.6-49 N * cm (2-5 kgf * cm). If the torque is less than the specified, reduce the thickness of the shims 2 (Fig. 6.8) and if more, increase.

After installing the bipod shaft, check that there is no play or engagement of the roller with the worm in the positions of the worm shaft turned to the right and left by 30 ° from the neutral position of the bipod. Eliminate any gap in the engagement with the adjusting screw 2 (Fig.6.2) and tighten the lock nut 3.

After adjusting the gap in the engagement of the roller and the worm, check the friction moment of the worm shaft with a dynamometer, which should be equal to 88.2-117.6 N * cm (9-12 kgf * cm) when the worm shaft is turned by 30 ° both to the left and to the right from the middle position and should decrease smoothly to 68.6 N * cm (7 kgf * cm) when turning from an angle of 30 ° to the stop.

At the end of the assembly, check the angles of rotation of the bipod from the neutral position, which should be 32 ° 10 "± 1" both to the left and to the right until the bipod stops in the bolt heads, pour 0.215 liters of TAD-17i transmission oil into the steering gear housing.

Inspection and repair

Carefully inspect for any signs of wear, binding, dents or marks on the running surfaces of the roller and worm. Replace worn and damaged parts.

Check the clearance between the bushings and the bipod shaft, which should not exceed 0.10 mm. If the clearance is greater than the specified, replace the bushings using a mandrel A.74105.

There are spiral grooves on the inner surface of the bipod shaft bushings, which extend only to one side of the bipod. When pressing the bushings, position them so that their ends with groove exit are inside the crankcase bore, and the groove outlets are opposite each other. The ends of the bushings should sink into the crankcase hole by 1.5 mm.

Lubricate new bushings before pressing transmission oil.

After pressing into the crankcase, finish the bushings with a reamer A.90336 to a size of 28.698-28.720 mm. Mounting clearance between the bipod shaft and the bushings should be within 0.008-0.051 mm.

Check the ease of rotation of the bipod shaft roller.

The worm and roller bearings should rotate freely, without jamming, and there should be no wear or damage on the surface of the rings and balls.

Check the runout of the steering shaft journal relative to the average spline diameter of the shaft end. To check, the lower end of the shaft is put on a special mandrel, which is installed on the prism. When turning the mandrel on the prism, the runout of the bearing journal of the shaft should not exceed 3 mm. If the shaft is deformed, then straighten it on a hand press.

Check the axial clearance between the head of the adjusting screw 8 (Fig. Bb) and the groove of the bipod shaft 7. The clearance should not exceed 0.05 mm. If it is larger, replace the shim 9 with a thicker one.

NOTE

Spare parts are supplied in eleven sizes of shims, from 1.95 to 2.20 mm; the increase in each dimension is 0.025 mm.

The steering mechanism consists of a steering wheel, a shaft enclosed in a steering column, and a steering gear associated with the steering gear. The steering mechanism allows you to reduce the force applied by the driver to the steering wheel to overcome the resistance that occurs when turning the steering wheels of the machine due to friction between the tires and the road, as well as deformation of the soil when driving on dirt roads.

The steering gear is mechanical transmission (for example, toothed), installed in the housing (crankcase) and having gear ratio 15 - 30. The steering mechanism reduces the force applied by the driver to the steering wheel, connected by means of a shaft to the gearbox, by so many times. The greater the gear ratio of the steering gear, the easier it is for the driver to turn the steered wheels. However, with an increase in the gear ratio of the steering gear for turning at a certain angle of the controlled wheel, connected through the drive parts with the output shaft of the gearbox, the driver needs to turn the steering wheel at a greater angle than with a small gear ratio. When the vehicle is moving with high speed it is more difficult to make sharp turns at a high angle, because the driver does not have time to turn the steering wheel.

Steering gear ratio:

Up \u003d (ap / ac) \u003d (pc / pp)

where ap and ac are the angles of rotation of the steering wheel and the output shaft of the gearbox, respectively; Pp, Pc - the effort applied by the driver to the steering wheel and the effort on the output link of the steering mechanism (bipod).

So, to turn the bipod by 25 ° with the steering gear ratio equal to 30, the steering wheel must be turned by 750 °, and with Up \u003d 15 - by 375 °. With an effort on the steering wheel of 200 N and a gear ratio Up \u003d 30, the driver creates a force of 6 kN at the output link of the gearbox, and with Up \u003d 15 - 2 times less. It is advisable to have a variable steering gear ratio.

At small angles of rotation of the steering wheel (no more than 120 °), a large gear ratio is preferable, providing easy and precise control of the vehicle when driving at high speed. When low speeds a small gear ratio allows, at small steering wheel turning angles, to obtain significant steering angles, which ensures high vehicle maneuverability.

When choosing the gear ratio of the steering mechanism, it is assumed that the steered wheels should turn from the neutral position to maximum angle (35 ... 45 °) not more than 2.5 turns of the steering wheel.

Steering mechanisms can be of several types. The most common of these are "worm-three-ridged roller", "worm-gear" and "screw-ball nut-rack-pinion". The gear in the steering mechanism is made in the form of a sector.

The steering mechanism converts the rotational movement of the steering wheel into angular movement of the steering arm mounted on the output shaft of the steering gear. When driving a fully laden vehicle, the steering gear, as a rule, should provide a force on the steering wheel rim of no more than 150 N.

The angle of free rotation of the steering wheel (play) for trucksmobile vehicles should normally not exceed 25 ° (which corresponds to a shower length of 120 mm measured at the rim of the steering wheel) when driving in a straight line. For other types of vehicles, the steering wheel play is different. Backlash occurs due to wear in the operation of steering parts and misalignment of the steering mechanism and drive. To reduce friction losses and protect parts of the steering gear from corrosion, special gear oil is poured into its crankcase, mounted on the machine frame.

When operating the vehicle, it is necessary to adjust the steering mechanism. The steering gear adjusting devices are designed to eliminate, firstly, the axial play of the steering shaft or the driving element of the gearbox, and secondly, the backlash between the driving and driven elements.

Consider the design of the "globoidal worm-three-ridge roller" steering mechanism.

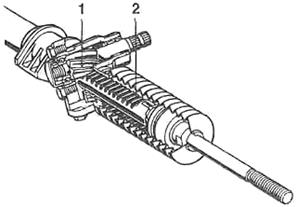

Figure: The steering gear of the "globoidal worm-three-ridge roller" type:

1 - steering gear housing; 2 - head, steering arm ral; 3 - three ridge roller; 4 - shims; 5 - worm; 6 - steering shaft; 7 - axis; 8 - bipod shaft bearing; 9 - lock washer; 10 - cap nut; 11 - adjusting screw; 12 - bipod shaft; 13 - oil seal; 14 - steering bipod; 15 - nut; 16 - bronze bushing; h - adjustable depth of engagement of the roller with the worm

Globoidal worm 5 is installed in the crankcase 1 of the steering gear on two tapered roller bearings, which take well the axial forces arising from the interaction of the worm with the three-ridge roller 3. The worm pressed onto the splines at the end of the steering shaft 6 provides, with a limited length, good engagement of the roller ridges with a worm cut. Due to the fact that the action of the load is dispersed over several ridges as a result of their contact with the worm, as well as the replacement of sliding friction in engagement with much lower rolling friction, high wear resistance of the mechanism and a sufficiently high efficiency are achieved.

The roller axis is fixed in the head 2 of the shaft 12 of the steering arm 14, and the roller itself is mounted on needle bearings, which reduce losses during the rotation of the roller relative to the axis 7. The bearings of the steering arm shaft are, on the one hand, a roller bearing, and on the other - a bronze bushing 76. The bipod is connected to the shaft by means of small splines and secured with a washer and a nut 15. To seal the bipod shaft the oil seal is used 13.

The engagement of the worm with the ridges is carried out in such a way that, in a position corresponding to the rectilinear movement of the machine, free run there is practically no steering wheel, and as the steering angle increases, it increases.

Adjustment of the steering shaft bearings tightening is carried out by changing the number of gaskets installed under the crankcase cover, with its plane resting on the end face of the extreme tapered roller bearing. The adjustment of the engagement of the worm with the roller is carried out by displacing the steering arm shaft in the axial direction using an adjusting screw 11. This screw is installed in the side cover of the crankcase, closed from the outside with a cap nut 10 and fixed with a lock washer 9.

On heavy-duty vehicles, steering mechanisms of the "worm-side sector (gear)" or "screw-ball nut-rack-pinion" type are used, which have a large contact area of \u200b\u200bthe elements and, as a result, low pressure between the surfaces of the gearbox working pairs.

The steering gear of the "worm-side sector" type, the simplest in design, is used on some cars. Meshing with the worm 2 enters the lateral sector 3 in the form of a part of a gear with spiral teeth. The lateral sector is made as a whole with the bipod shaft 1. The bipod is located on a shaft mounted on needle bearings.

The gap in engagement between the worm and the sector is not constant. The smallest clearance corresponds to the center position of the steering wheel. The engagement gap is adjusted by changing the thickness of the washer located between the side surface of the sector and the cover of the steering gear housing.

The design of the "screw-ball-nut-rail-sector" steering mechanism is shown in the figure. Steering wheel shaft by cardan transmission connected to a screw 4 interacting with a ball nut 5, fixed by a locking screw 15 in the piston-rail 3. The thread of the screw and nut is made in the form of semicircular grooves filled with balls 7 circulating along the thread when the screw rotates. The extreme threads of the nut are connected by a groove 6 with an outer tube that circulates the balls. The rolling friction of these balls on the thread during the rotation of the screw is negligible, which leads to a high efficiency of such a mechanism.

Figure: Steering gear of the "worm-side sector" type:

1 - bipod shaft; 2 - worm; 3 - lateral sector

![]()

Figure: Steering gear type "screw-ball nut-rail-sector":

1 - cylinder cover; 2 - crankcase; 3 - piston rack; 4 - screw; 5 - ball nut; 6 - gutter; 7 - balls; 8 - intermediate cover; 9 - spool; 10 - control valve body; 11 - nut; 12 - top cover; 13 - plunger spring; 14 - plunger; 15 - locking screw; 16 - toothed sector (gear); 17 - shaft; 18- bipod; 19 - side cover; 20 - retaining ring; 21 - adjusting screw; 22 - ball pin

One of the main systems that ensure the safety of movement in a car is steering. The purpose of the car's steering is the ability to change the direction of travel, make turns and maneuvers when avoiding obstacles or overtaking. This component is as important as brake system... Proof of this is the prescription of traffic rules, the operation of a car with faulty specified mechanisms is strictly prohibited.

Features of the unit and design

On cars, a kinematic method of changing the direction of travel is used, which implies that the rotation is carried out by changing the position of the steered wheels. Usually the front axle is steered, although there are cars with the so-called steering system. The peculiarity of working in such cars is that the wheels of the rear axle also turn when changing direction, albeit at a smaller angle. But so far this system has not become widespread.

In addition to the kinematic method, power is also used on technology. Its peculiarity lies in the fact that to make a turn, the wheels of one side are braked, while on the other side they continue to move at the same speed. And although this way of changing direction is passenger cars did not receive distribution, on them it is still used, but in a slightly different capacity - as a system of exchange rate stability.

This vehicle assembly consists of three main elements:

- steering column;

- steering gear;

- drive (system of rods and levers);

Steering knot

Each component has its own task.

Steering column

Transfers the rotational force that the driver generates to change direction. It consists of a steering wheel located in the cabin (the driver acts on it, rotating it). It is rigidly mounted on the column shaft. In the device of this part of the steering, a shaft is very often used, divided into several parts, interconnected by cardan joints.

This design was made for a reason. Firstly, it allows you to change the angle of the steering wheel relative to the mechanism, to shift it in a certain direction, which is often necessary when assembling component parts auto. In addition, this design improves the comfort of the cabin - the driver can change the position of the steering wheel in reach and tilt, providing the most comfortable position.

Secondly, the composite steering column tends to "break" in accident casereducing the likelihood of injury to the driver. The bottom line is that in a frontal impact, the engine can move back and push the steering gear. If the column shaft were solid, a change in the position of the mechanism would lead to the exit of the shaft with the steering wheel into the passenger compartment. In the case of a composite column, the movement of the mechanism will only be accompanied by a change in the angle of one component of the shaft relative to the second, while the column itself remains stationary.

Steering gear

Designed to convert the rotation of the steering column shaft into translational movements of the drive elements.

The most widespread mechanisms in passenger cars are gear-toothed-rack mechanisms. Previously, another type was used - the "roller worm", which is now mainly used on trucks. Another option for trucks is “screw”.

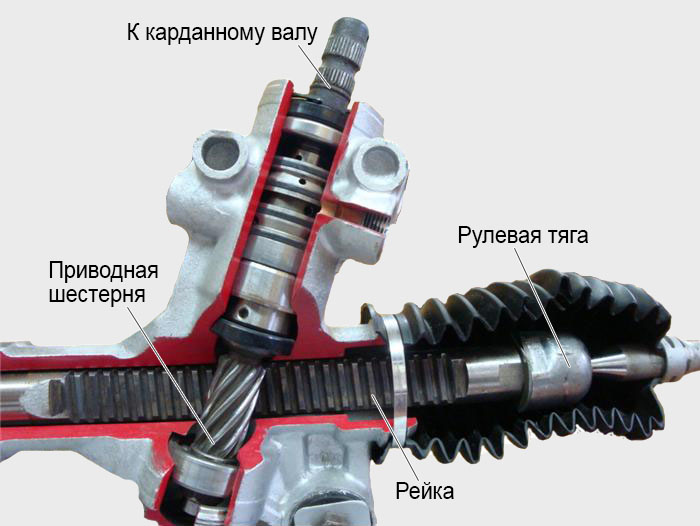

"Gear-rack"

The "gear-rack" type became widespread due to the relatively simple device steering gear. This structural unit consists of three main elements - a housing in which a gear is located and a rack perpendicular to it. There is a permanent gearing between the last two elements.

This type of mechanism works like this: the gear is rigidly connected to the steering column, so it rotates with the shaft. Due to the toothed connection, rotation is transmitted to the rail, which, with this effect, shifts inside the housing to one side or the other. If the driver turns the steering wheel to the left, the interaction of the gear with the rack causes the latter to move to the right.

Often on a car, gear-rack mechanisms with a fixed gear ratio are used, that is, the range of rotation of the steering wheel to change the angle of the wheels is the same for all their positions. For example, suppose that to turn the wheels at an angle of 15 °, you need to make 1 full turn steering wheel. So, no matter what position the steered wheels are in (extreme, straight-line), to turn by the specified angle, you will have to make 1 revolution.

But some automakers install mechanisms with variable gear ratios on their cars. Moreover, this is achieved quite simply - by changing the angle of the position of the teeth on the rail in certain zones. The effect of this modification of the mechanism is as follows: if the wheels are straight, then it takes 1 revolution to change their position by the same 15 ° (example). But if they are in the extreme position, then due to the changed gear ratio, the wheels will turn through the specified angle after half a turn. As a result, the end-to-end steering range of the steering wheel is significantly less than with a fixed gear ratio.

Variable Rack

In addition to the simplicity of the device, the "gear-rack" type is also used because in such a design it is possible to implement the actuators of the hydraulic booster (GUR) and the electric booster (EUR), as well as the electro-hydraulic (EGUR).

"Worm-roller"

The next type, the "roller worm", is less common and is now practically not used on passenger cars, although it can be found on VAZ cars of the classic family.

This mechanism is based on a worm gear. Represents a worm screw with a thread of a special profile. This screw is located on a shaft connected to the steering column.

A roller connected to the shaft on which the bipod is seated is in contact with the thread of this worm - a lever that interacts with the drive elements.

Worm gear steering

The essence of the mechanism is as follows: when the shaft rotates, the screw rotates, which leads to a longitudinal movement of the roller along its thread. And since the roller is mounted on the shaft, this displacement is accompanied by the rotation of the latter around its axis. This in turn leads to a semicircular movement of the bipod, which acts on the drive.

The mechanism of the "worm-roller" type on passenger cars was abandoned in favor of the "gear-rack" due to the impossibility of integrating a hydraulic booster into it (it was still available on trucks, but the actuator was removed), as well as a rather complex drive design.

Screw type

The design of the screw mechanism is even more complicated. It also has a threaded screw, but it is not in contact with the roller, but with a special nut, on the outside of which a toothed sector is applied, interacting with the same one, but made on the bipod shaft. There are also mechanisms with intermediate rollers between the nut and the toothed sector. The principle of operation of such a mechanism is almost identical to the worm - as a result of interaction, the shaft turns and pulls the bipod, and that, in turn, the drive.

Helical steering gear

A hydraulic booster can be installed on the screw mechanism (the nut acts as a piston), but it is not used on passenger cars due to the massive structure, therefore it is used only on trucks.

Drive unit

The drive in the steering structure is used to transfer the movement of the rack or bipod to the steered wheels. Moreover, the task of this component is to change the position of the wheels by different angles... This is due to the fact that the wheels when turning move along different radii. Therefore, the wheel with inside when changing the trajectory of movement, it must turn at a greater angle than the outer one.

The design of the drive depends on the mechanism used. So, if a "gear-rack" is used on a car, then the drive consists of only two rods connected to a steering knuckle (the role of which is played by a shock absorber) by means of a ball tip.

These rods can be attached to the rail in two ways. Less common is their rigid fixation with a bolted connection (in some cases, the connection is made through a silent block). For such a connection, a longitudinal window is made in the body of the mechanism.

The more common method of connecting rods is a rigid but flexible connection to the ends of the rail. To ensure such a connection, a ball tip is made at the end of both rods. This ball is pressed against the rail by means of a nut. When the latter moves, the rod changes its position, which provides the existing connection.

![]()

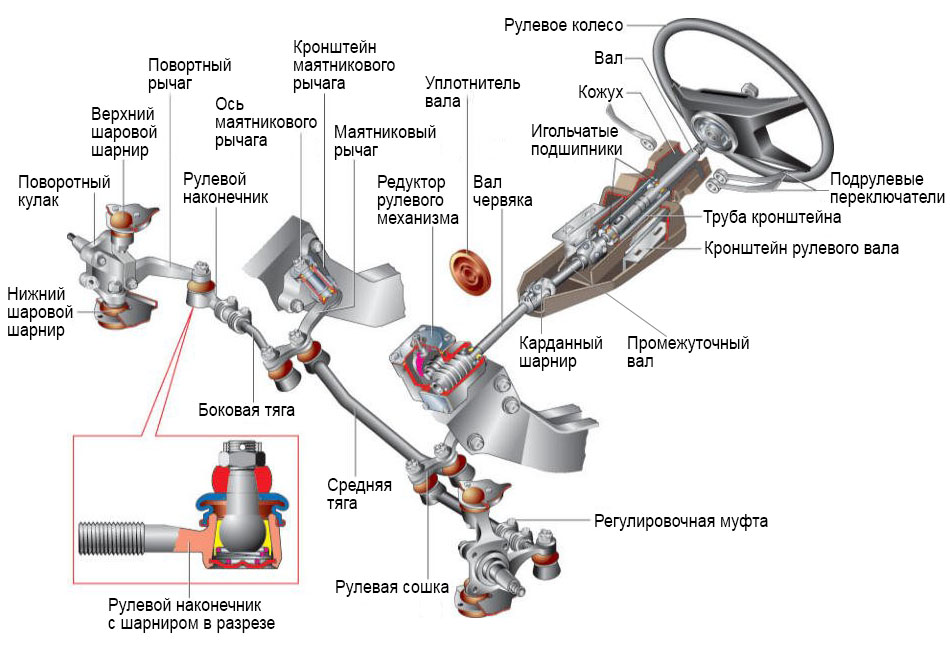

In drives where the worm-roller mechanism is used, the design is much more complicated and is a whole system of levers and rods, called the steering linkage. So, for example, on the VAZ-2101, the drive consists of two side rods, one middle, pendulum arm and steering knuckles with levers. At the same time, to ensure the possibility of changing the angle of the wheel position, the steering knuckle is attached to the suspension arms using two ball bearings (upper and lower).

The large number of components, as well as the connections between them, makes this type of drive more susceptible to wear and the occurrence of backlash. This fact is another reason for abandoning the worm gear in favor of the rack and pinion.

"Feedback"

It should be noted that in the steering mechanism there is also the so-called " feedback". The driver not only acts on the wheels, but through it also receives information about the features of the movement of the wheels on the road. This manifests itself in the form of vibrations, jerks, the creation of definitely directed efforts on the steering wheel. This information is considered very important for the correct assessment of the behavior of the car. Proof of this is the fact that in cars equipped with power steering and power steering, the designers have retained "feedback".

Advanced developments

This unit continues to be improved, so the most recent achievements are systems:

- Active (dynamic) steering. It allows you to change the gear ratio of the mechanism depending on the speed of the vehicle. Also performs and additional function - Correction of the angle of the front wheels when cornering and when braking on slippery roads.

- Adaptive steering (wire-guided). This is the newest and most promising system. There is no direct connection between the steering wheel and the wheels; everything works due to sensors and actuators (servo drives). The system has not yet become widespread due to psychological and economic factors.

Rudder-by-wire system

Conclusion

In general, the mechanism is a fairly reliable unit that does not require any maintenance. But at the same time, the operation of the car's steering implies timely diagnostics to identify malfunctions.

The construction of this unit consists of many elements with movable joints. And where there are such connections, over time, due to wear of the contacting elements, backlashes appear in them, which can significantly affect the car's handling.

The difficulty of steering diagnostics depends on its structural performance... So in nodes with a gear-rack mechanism there are not so many connections that need to be checked: tips, gear engagement with the rack, steering column cardans.

But with a worm gear, due to the complex design of the drive, there are much more diagnostic points.

Concerning renovation works in case of malfunction of the unit, then the tips are simply replaced with severe wear. In the steering gear, at the initial stage, the backlash can be removed by adjusting the engagement, and if this does not help, by rebuilding the assembly using repair kits. The column gimbals, like the tips, are simply replaceable.

The task of the steering gear is to change the direction of movement of the vehicle. In most cars, you can only change the direction of the front wheels, but there are modern models, which are controlled by changing the direction of all four wheels.

The steering system of a passenger car consists of a steering device and a drive. As a result of the rotation of the steering wheel, the engine begins to move forward. Then the steer wheels turn and the car changes direction.

During this process, the initial movement of the driver is amplified several times. The steering gear diagram shows which parts and mechanisms are involved in the process of driving a car. On modern cars and trucks, intended for the transportation of large loads, are additionally installed hydraulic boosters. The hydraulic boosters make driving easier and increase driving safety.

a) the traditional scheme; b) rack and pinion steering;

1 - lever steering knuckleand; 2 - lateral steering rod; 3 - pendulum arm; 4 - transverse steering rod or gear rack; 5 - steering wheel; 6 - steering shaft; 7 - steering gear housing; 8 - steering bipod.

Figure 3.7 - Steering diagram

Worm type steering gear

Figure 3.8 - Worm type steering gear

This is the oldest type of steering. The system consists of a crankcase with a built-in screw called "worm". The "worm" is directly connected to the steering shaft. In addition to the screw, the system has one more shaft with a roller sector. The rotation of the steering wheel leads to the rotation of the "worm" and the subsequent rotation of the roller sector. A steering arm is attached to the sector roller, connected by means of a hinged control with a linkage system.

As a result of the operation of this linkage system, the steered wheels turn and the vehicle changes direction. The worm-type steering mechanism has several disadvantages. First is big loss energy due to high friction inside the mechanism.

Secondly, there is no rigid connection between the wheels and the steering wheel. Thirdly, in order to change the direction of movement, you need to turn the steering wheel several times, which not only looks out of date, but also does not meet the existing management standards in the world.

Steering gear with three-ridge roller and globoid worm

The steering mechanism can be worm, screw, crank, gear transmission or a combination of such transmissions. Greater distribution among passenger cars received steering mechanisms in the form of a worm gear with a globoid worm and gears - racks (rack type). Let's consider these steering mechanisms in more detail.

1-lock washer; 2-bipod shaft shank; 3-screw; 4.9 nuts; 5-pin; 6.22-cuff; 7-shaft bipod; 8-bipod; 10-shaft; 11-tube; 12,15,20,21-bearing; 13-globoid worm; 14-axis roller; 16-roller; 17-spacer sleeve; 18-crank; 19-crankcase; 23-spring; 24-gasket.

Figure 3.9 - roller worm

The steering wheel is attached to the upper end of the shaft 10. At the opposite end of the shaft, a globoid worm 13 is pressed onto the splines, which rests on tapered roller bearings 12 and 21. In engagement with the worm is a three-ridge roller 16, seated on two ball bearings 15 and 20, between which a spacer 17 is placed. The roller axis 14 is fixed in the forked crank 18 of the bipod shaft 7. The shaft 7 of the bipod is sealed with a collar 6. The bipod on the tapered splines of the shaft is reinforced with a nut 9. The shaft has double splines that ensure correct installation of the bipod at the required angle. On the cartel of the steering mechanism, protrusions are made that serve as stops for the roller when turning the bipod from the middle position to the extreme at an angle.

The axial clearance of bearings 12 and 21 is adjusted by changing the number of spacers 24 under the crankcase cover. The engagement of the worm and the roller is adjusted, without disassembling the mechanism, with a screw 3, into the groove of which the shank 2 of the bipod shaft enters. The axes of the roller and the worm lie in different planes, therefore, to reduce the clearance in the engagement, it is enough to move the bipod shaft towards the worm by screwing in screw 3. To fix the adjusting screw, use a lock washer, pin 5 and a nut screwed onto the screw. Many Russian passenger cars have a similar steering mechanism.

The worm gear consists of:

- globoid worm (variable diameter worm);

- steering shaft;

- video.

Figure 3.10 - worm and roller mechanism

A lever (bipod) is installed on the roller shaft behind the steering gear housing, which is connected to the steering rods.

The worm gear is less sensitive to shock loads, allowing larger steering angles, resulting in better vehicle maneuverability. But the worm gear is difficult to manufacture and its cost is high. This mechanism requires periodic adjustment due to the large number of connections.

Worm gear used on machines high cross-country ability with dependent suspension steering wheels and light trucks.

Principle of operation:

1.With the rotation of the steering wheel, the roller moves along the worm (roll-in), the bipod swing.

2. There is a movement of the steering linkage, due to which the wheels turn.

Helical type steering gear

Figure 3.11- Screw type of steering mechanism

1-steering gear; 2-seal; 3-cardan joint; 4-steering shaft; 5-steering column tube; 6-contact ring; 7-nut; 8-steering wheel;

9-bearing; 10-steering bipod; 11-hinge of the side rod end; 12-pivot arm; 13-tie clamp; 14-adjusting tube; 15-hinge of the bipod rod; 16-side rod; 17-side rod hinge; 18- bipod thrust; 19-tie rod end; 20-swingarm hinge; 21-swingarm; 22-swingarm bracket; 23-threaded plug; 24-conical spring; 25-support heel; 26-rod eye; 27-hinge housing ;

28-plastic spacer sleeve; 29-rubber seal of the side link hinge; 30-eye of the swing arm or bipod link; 31-ball pin; 32-joint pin nut; 33-cotter pin of the threaded plug; 34-plastic cracker; 35-rubber seal of the hinge bipod rods; 36-metal spacer sleeve; 37-pendulum arm pin; 38-pendulum arm pin nut; 39-bushing; 40-rubber protective sleeve; 41-rubber protective sleeve.

The screw mechanism is also called "ball screw nut". While developing this system, the designers replaced the "worm" with a special screw with a ball nut attached to it. On the outer side of the nut there are teeth, which come into contact with the same sector roller as in the previous system.

In order to reduce friction, the developers proposed to place ball channels between the sector roller and the nut. Thanks to this solution, it was possible to significantly reduce friction, increase recoil and facilitate handling. However, the presence of the same complex system of rods, large dimensions and inconvenient shape of the screw mechanism led to the fact that the screw system was also recognized as unadapted to modern conditions.

However, some well-known car manufacturers still use the screw-ball nut mechanism in the manufacture of cars with longitudinal motor... Such mechanisms have nissan cars Patrol, Mitsubishi pajero other.

Rack type steering gear

![]()

Figure 3.12 - Rack and pinion steering mechanism

1-tip of the steering rod; 2-ball joint of the tip; 3-pivot arm; 4-locknut; 5-rod; 6-inner tips of the steering rods; 7-bolts of fastening the steering rods to the rack; 8-inner tips of the steering rods; 9- steering gear mounting bracket; 10-steering gear support; 11-protective cover; 12-connecting plate; 13-locking plate; 14-silent block; 15-damping ring; 16-support bushing of the rack; 17-rail; 18-steering gear housing ; 19-clamping bolt of the coupling; 20-lower flange of the elastic coupling; 21-upper part of the cladding casing; 22-damper; 23-steering wheel; 24-ball bearing; 25-steering shaft; 26-lower part of the cladding casing; 27- steering shaft mounting bracket; 28-protective cap; 29-roller bearing; 30-drive gear; 31-ball bearing; 32-retaining ring; 33-protective washer; 34-sealing ring; 35-bearing nut; 36-boot; 37-stop o-ring; 38-stop ring of the stop nut; 39-rack stop; 40-spring; 41-stop nut; 42-ball pin hinge; 43-protective cap; 44-ball pin insert; A. mark on the boot; B. mark on the steering box; C. surface of the ball joint; D. the surface of the swing arm.

Rack and pinion is the most common steering device. The strength of this design lies in its simplicity. This simple and progressive mechanism is used in the production of 90% of cars. The steering rack device is based on the main element - the shaft-rack. The rack-shaft is equipped with transverse teeth. A gear is located on the steering shaft, which engages the teeth of the steering shaft and moves the rack.

By using this system, it has been possible to achieve a minimum number of pivot joints and significant energy conservation. Each wheel is "supposed" to have two hinges and one rod. For comparison: in the "screw-ball nut" system, the wheel corresponds to three rods, in the "worm" mechanism - five rods.

Steering rack provided an almost direct connection between the steering wheel and the wheels, which means that it several times increased the ease of driving. Such steering gear car made it possible to change the direction of travel with a minimum number of turns of the steering wheel.

Another advantage of the rack and pinion design is the size and shape of the crankcase. With its small size and elongated shape, the crankcase can fit anywhere in the car. Automakers place the crankcase above the engine, below the engine, in front or behind, depending on the car model.

The rack and pinion mechanism made it possible to achieve almost instant reaction of the wheels to the steering wheel turn. This system made it possible to create high-speed cars with a modern, improved control system.

1 - gear: 2 - toothed rack

Figure 3.13 - Rack and pinion steering gear

Figure: 1. Steering:

1 - side thrust:

2 - bipod;

3 - medium thrust;

4 - pendulum lever;

5 - adjusting clutch;

6 — lower ball joint of the personal suspension;

7 - right steering fist;

8 - the upper ball joint of the front suspension;

9 - the right lever of the steering knuckle,

10 - pendulum arm bracket;

11 - the right side member of the body;

12 - oil filler plug;

13 - steering gear housing;

14 - steering shaft;

15 - facing casing of the steering shaft;

16 - steering wheel;

17 - pipe of the upper support of the steering shaft;

18 - steering shaft bracket;

19 - left side member of the body;

20 - clamping clamps of the adjusting clutch;

21 left steering knuckle.

Possible malfunctions steering BA3-2106, their causes and methods of elimination:

...

INSPECTION, INSPECTION AND STEERING ADJUSTMENT

In the event of malfunctions in the steering (knocking, increased free play of the steering wheel or, conversely, its tight rotation, etc.), inspect the steering parts. Inspect in next order... Clean the steering gear parts and the steering box from contamination. Set the wheels to the straight ahead position.

By turning the steering wheel to both sides, make sure that:

Free play of the steering wheel does not exceed 5 ° (when measured along the wheel rim, no more than 18-20 mm);

- no knocking occurs in the joints, joints and steering mechanism;

The steering housing and swingarm bracket are firmly attached (tighten if necessary threaded connections);

There is no free play in the ball joints of the rods and in the pendulum arm bracket, and the worm shaft does not move in the axial direction;

The effort to turn the steering wheel (when installing the front wheels on a smooth plate) does not exceed 245 N (25 kgf).

Turning the adjusting couplings of the side links, make sure that their clamps are tightened securely.

Check the condition of the ball joints and rubber protective caps as follows.

BALL JOINT CHECK. STEERING RODS

First of all, check the movement of the rod ends along the axis of the fingers. To do this, using the lever and support, move the tip parallel to the axis of the finger.

The axial movement of the tip relative to the pin should be 1-1.5 mm. This movement indicates that. that the liner of the pin is not jammed in the socket of the rod end and will mix with the pin, compressing the spring. Replace the joint with a jammed insert.

Swinging the steering wheel in both directions, check the lack of free play in the steering link joints by touch. If free play is felt in the ball joint, replace the rod end or steering rod assembled.

Check the condition of the protective rubber caps on the ball joints of the steering rods. The cap must be replaced if it cracks, breaks or peels off the rubber from the bezel, or if grease seeps out when squeezed by hand.

If the protective caps are in good condition and ensure cleanliness inside the hinges, the service life of the latter is practically unlimited. If moisture, dust, etc. enter the hinge. premature wear of its parts occurs.

CHECKING AND ADJUSTING THE CLEARANCE IN THE BEARINGS OF THE STEERING GEAR WORM

Set the front wheels to position straight motion and turning the steering wheel in one direction or the other, check if the distance between the end of the housing 7 (Fig. 2) of the steering mechanism and the tip of the steering shaft changes. Change in distance: This is an indication of clearance in the worm bearings.

Figure: 2. Section of the steering gear housing:

Figure: 2. Section of the steering gear housing:

1 - plate of the bipod shaft adjusting screw;

2 - adjusting screw of the bipod shaft;

3 - nut of the adjusting screw;

4 - oil filler plug;

5 - steering gear housing cover;

6 - worm;

7 - steering gear housing;

8 - bipod;

9 - nut for fastening the bipod to the shaft;

10 - spring washer nuts for fastening the bipod;

11- bipod shaft oil seal,

12 - bronze bipod shaft sleeve;

13 - bipod shaft;

14 - bipod shaft roller;

15 - worm shaft;

16 - top ball bearing;

17 - lower ball bearing;

18 - shims;

19 - bottom cover of the worm bearing;

20 - roller axis;

21 - needle bearing;

22 - worm shaft oil seal.

To adjust the clearance in the worm bearings, turning the steering wheel to the left by 1-1.5 turns, unscrew the bolts securing the bottom cover 19 and drain the oil from the steering box housing. Remove the bottom cover remove one of the shims 18 or replace it with a thinner one.

NOTE. The shims are available as spare parts with a thickness of 0.10 and 0.15 mm. After securing the bottom cover, check again for axial movement of the worm in the bearings. If there is no movement, fill the steering box with 0.215 L of transmission oil. Check the steering effort by placing the front wheels on a smooth plate. It should not exceed 245 N (25 kgf).

CHECKING AND ADJUSTMENT OF THE CLEARANCE IN THE ENGAGING OF THE ROLLER WITH THE WORM

After making sure that there is no axial displacement of the worm in the bearings, press out the pins of the ball joints from the holes in the bipod with a puller А.47035 and disconnect the rods from the bipod, while maintaining the straight position of the front wheels.

Shaking the bipod by the head, check. whether there is a gap in the engagement of the roller and the worm. There should be no perceptible free play of the bipod within the 30 ° steering wheel rotation to either side of the neutral position. If you feel free movement of the bipod, loosen the nut 3 (Fig. 5-2) of the adjusting screw and, lifting the lock washer, tighten the adjusting screw 2 until the gap is eliminated. Do not over-tighten the adjusting screw. Then, while holding the adjusting screw with a screwdriver, tighten the nut 3.

After making sure that the bipod does not move, connect the ball pins to it. Check the steering effort. If it exceeds 245 N (25 kgf), then loosen the adjusting screw 2.

STEERING GEAR BA3-2106

REMOVAL AND INSTALLATION

Withdrawal. Disconnect the wires from the battery and remove the signal switch cover. Remove the steering wheel. Remove both halves of the steering shaft shell. Remove the instrument panel and disconnect the turn signal and headlamp switch plugs from the wiring harness plugs.

Disconnect the wires from the ignition switch terminals and, after unscrewing the fastening screws and drowning the lock latch, remove the ignition switch.

NOTE

If it is necessary to remove only the crankcase of the ruble mechanism, then unscrew the bracket mounting bolts and the bolt securing the steering shaft to the worm shaft, and then slightly slide the steering shaft with the bracket into the interior and place a support under the shaft so that it does not hang on the wires.

Loosen the clamp of fastening of the pipe of the upper support of the steering shaft and remove it together with the switch of direction indicators and headlights, having previously unlocked the steering shaft from the anti-theft device.

Remove the bracket 13 (Fig. 3) fastening the steering shaft. Remove the seal 8 of the steering shaft. Having unscrewed the bolt 7 securing the steering shaft to the worm shaft, remove the steering shaft into the body interior.

Figure: 3. Steering parts:

Figure: 3. Steering parts:

1 - nut;

2 - flat washer;

3 - an adjusting washer;

4 - bolt for painting the steering box housing to the body;

5 - steering gear housing;

6 - spring washer;

7 - bolt of fastening of the tip of the steering shaft on the worm shaft;

8 - shaft seal:

9 - bolt for fastening the rubber seal to the body;

10 - steering shaft;

11 - steering wheel fastening nut;

12 - steering wheel;

13 - steering shaft bracket;

14 - bolt of fastening of the steering shaft bracket.

Using the A.47035 puller, press out the ball pins of the steering rods from the hole in the bipod.

Remove the steering box housing.

NOTE. While removing the steering box housing, note the number and location of shims 3 between the side member and the crankcase in order to refit them when installing the crankcase. This is necessary to maintain the alignment of the steering shaft and the worm shaft.

Install the steering mechanism in the reverse order to removal. In this case, before finally tightening bolts 1 and 3 (Fig. 4) fastening the steering housing and the steering shaft bracket, temporarily put the steering wheel on the shaft, turn the shaft two or three times to the left and right.

Install the steering mechanism in the reverse order to removal. In this case, before finally tightening bolts 1 and 3 (Fig. 4) fastening the steering housing and the steering shaft bracket, temporarily put the steering wheel on the shaft, turn the shaft two or three times to the left and right.

In this case, the shaft and other parts take the correct position (self-aligning) thanks to the oval holes in the crankcase and on the bracket.

NOTE. It is possible to separately assemble the steering shaft with seal, bracket, ignition switch, turn signal and headlight switch, steering wheel and install this unit on the vehicle.

Figure: 4. Installing the steering gear on the car:

1 - bolts of fastening of the steering box to the body;

2 - bolt of fastening of the steering shaft to the worm shaft;

3 - bolts of fastening of the steering shaft bracket to the body;

4 - plastic sleeve;

5 - steering shaft mounting bracket

6 - adjusting washers to ensure the alignment of the worm shaft and the steering shaft.

DISASSEMBLY AND ASSEMBLY OF THE STEERING GEAR

Disassembly. Drain the oil from the steering box. Fix the crankcase on the bracket A.74076 / R with the support A.74076 / 1.

Disassembly. Drain the oil from the steering box. Fix the crankcase on the bracket A.74076 / R with the support A.74076 / 1.

Having unscrewed the nut securing the steering arm 3 (Fig. 5) and having removed the spring washer, remove the bipod with the A.47043 puller. Having unscrewed the fastening bolts, remove the cover 12 (Fig. 6) of the steering box housing together with the adjusting screw 8, the adjusting plate 9. the lock washer 10 and the locknut. Remove from the crankcase 1 shaft 7 of the bipod assembly with the roller.

Having unscrewed the mounting bolts, remove the cover 3 of the worm shaft thrust bearing together with the shims 4.

Figure: 5. Removing the bipod:

1 - puller А.47043;

2 - bipod shaft of steering etching;

3 - bipod;

4 - bracket A. 74076 / R

Figure: 6. Steering gear reducer details:

Figure: 6. Steering gear reducer details:

1 - crankcase;

2 - bipod;

3 - lower crankcase cover;

4 - shims;

5 - outer ring of the worm shaft bearing;

6 - separator with balls;

7 - bipod shaft;

8 - an adjusting screw;

9 - adjusting plate;

10 - lock washer.

11 - worm shaft,

12 - upper crankcase cover;

13 - sealing gasket;

14 - bipod shaft sleeve:

15 - worm shaft oil seal;

16 - bipod shaft oil seal.

With the worm shaft 11, push the outer ring 5 of the bearing out of the crankcase and take out the shaft together with the cages 6 of the bearings. Remove the worm shaft oil seal 15 and the bipod shaft oil seal 16.

Using a mandrel 67.7853.9541, press out the outer ring of the upper bearing (fig. 7).

Figure: 7. Removing the outer ring of the upper worm bearing:

Figure: 7. Removing the outer ring of the upper worm bearing:

1 - steering gear housing;

2 - outer ring of the worm's upper bearing;

3-amendment 6 7.7853.9541

Assemble the steering mechanism on the bracket A.74076 / R in the reverse order to disassembly. Press the outer ring of the upper bearing of the worm with a mandrel 67.7853.9541, rearranging the nozzle on the mandrel handle with the reverse side.

After adjusting the gap in the engagement of the roller and the worm, check with a dynamometer the friction torque of the worm shaft, which should be equal to 88.2-117.6 Ncm (9-12 kgf.cm) when turning the worm shaft by 30 ° both to the left and to the right from the middle position and should decrease smoothly to 68.6 Ncm (7 kgfcm) when turning from an angle of 30 ° to the stop.

After installing the worm in the steering gear housing and securing the bottom cover, check the friction torque of the worm shaft using a dynamometer 02.7812.9501 (Fig. 8) and head A.95697 / 5; it should be within 19.6-49 Ncm (2-5 kgf.cm).

After installing the worm in the steering gear housing and securing the bottom cover, check the friction torque of the worm shaft using a dynamometer 02.7812.9501 (Fig. 8) and head A.95697 / 5; it should be within 19.6-49 Ncm (2-5 kgf.cm).

If the torque turns out to be less than the specified one, reduce the thickness of the shims 2 (Fig. 9) and if more, increase it.

After installing the bipod shaft, check that there is no play in the engagement of the roller with the worm in the positions of the worm shaft turned to the right and left by 30 ° from the neutral position of the bipod.

Remove any gap in the engagement with the adjusting screw 2 (see Fig. 2) and tighten the lock nut 3.

At the end of the assembly, check the angles of rotation of the bipod from the neutral position, which should be 32 ° 10 "± 1 both to the left and to the right to the stop of the bipod in the bolt heads, pour 0.215 liters of transmission oil into the housing of the steering mechanism.

INSPECTION AND REPAIR OF THE STEERING GEAR

Carefully inspect for any signs of wear, binding, dents or marks on the running surfaces of the roller and worm. Replace worn and damaged parts. Check the gap between the bushings and the bipod shaft, which should not exceed 0.1 mm. If the clearance is greater than the specified one, replace the bushings using the A.74105 mandrel.

There are spiral grooves on the inner surface of the bipod shaft bushings, which extend only to one side of the bipod. When pressing the bushings, position them so that their ends with groove exit are inside the crankcase bore, and the groove outlets are opposite each other. The ends of the bushings should sink into the crankcase hole by 1.5 mm.

Lubricate new bushings with transmission oil before pressing. After pressing into the crankcase, finish the bushings with a reamer A.90336 to a size of 28.698-28.72 mm. The mounting clearance between the bipod shaft and the bushings should be within 0.008-0.051 mm. Check the ease of rotation of the bipod shaft roller.

The worm and roller bearings must rotate freely, without jamming; there should be no wear or damage on the surface of the rings and balls.

Check the runout of the steering gear shaft journal relative to the average spline diameter of the shaft end. To check, the lower end of the shaft is put on a special mandrel, which is installed on the prism. When turning the mandrel on the prism, the runout of the bearing journal of the shaft should not exceed 3 mm. If the shaft is deformed, then straighten it on a hand press. Check the axial clearance between the head of the adjusting screw 8 (see Fig. 6) and the groove of the bipod shaft 7. The clearance should not exceed 0.05 mm. If it is larger, then replace the shim 9 with a thicker one.

NOTE. Spare parts are supplied in eleven sizes of shims, from 1.95 mm to 2.20 mm; the increase in each dimension is 0.025mm.

STEERING RODS AND BALL JOINTS BA3-2106

REMOVAL AND INSTALLATION

Unscrew and remove the nuts holding the side link ball pins to the pivot arms. Using the A.47052 puller (Fig. 10), remove the ball pins from the tapered seats on the levers.

Unscrew and remove the nuts holding the side link ball pins to the pivot arms. Using the A.47052 puller (Fig. 10), remove the ball pins from the tapered seats on the levers.

Unscrew and unscrew the nuts securing the ball pins of the middle and side links to the bipod and to the swing arm. Using the A.47035 puller, remove the fingers from the corresponding sockets on the levers and remove the rods.

Install the steering linkage in the reverse order of removal. Tighten all nuts of the ball pins with a torque wrench followed by a split pin. If the cut of the nut does not coincide with the hole for the cotter pin, then turn the nut at an angle less than 60 ° to ensure the cotter pin. After installing the links, adjust the toe-in of the front wheels.

INSPECTION AND REPAIR

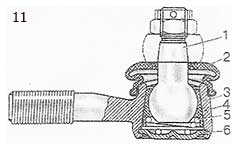

Check the condition of the protective caps 2 (fig. 11) as described above (see “Inspection, check and adjustment of the steering control”), if damaged, replace.

Check the condition of the protective caps 2 (fig. 11) as described above (see “Inspection, check and adjustment of the steering control”), if damaged, replace.

Figure: 11. Section of the ball joint of the steering link:

1 - ball pin;

2 - antisplash cap,

3 - hinge body;

4 - insert;

5 -spring;

6 - plug.

Check the condition of the ball joints of the rods by the radial and axial clearance. If you feel free play in the ball joint, as well as when dirt, sand gets into the joint, corrosion appears on the ball pin, and full use travel of the bearing pad - replace the hinge with the rod end.

PENDULUM ARM BRACKET

REMOVAL AND DISASSEMBLY

To remove the pendulum arm bracket, separate the pendulum arm from the ball pins of the middle and lateral right rods by undoing and unscrewing the nuts first and removing the ball pins from the lever sockets with a puller A. 47035. Then unscrew the bolts securing the bracket to the side member and remove the bracket.

Fasten the bracket in a vise, expand and unscrew nut 4 (Fig. 12), then remove washers 3 and 6 and pendulum arm 1 assembled with axis 9, washer 10 and self-locking nut 11, remove seals 7 and you press bushings 8 ...

Figure: 12. Sectional view of the pendulum arm bracket:

Figure: 12. Sectional view of the pendulum arm bracket:

1 - pendulum arm;

2 - bracket body;

3 - washer;

4 - adjusting nut;

5 - cotter pin;

6 - upper washer;

7 - sealant;

8 - sleeve:

9 - lever axis;

10 - lower washer;

11 - self-locking nut.

CHECK

Check the condition of the pendulum arm axle bushings: if you find ovality or inadmissible clearance between them and the axle, replace the bushings with new ones. Check axle for ovality and damage, if necessary replace it with a new one. Make sure the pendulum arm is free of deformation: otherwise replace it with a new one.

ASSEMBLY AND INSTALLATION

Before assembly, grease the pendulum arm axle bushings and fill the space between them with LITOL-24 grease. Assemble the pendulum arm bracket in the reverse order of disassembly.

If the axle 9 has been replaced (see Fig. 12), then tighten the self-locking nut 11 of the lever fastening with a torque wrench. Washer 6 is installed by pushing up. After tightening the nut 4, the lever in the horizontal position should not rotate under its own weight. It must rotate under the action of a force of 9.8-19.6 N (1-2 kgf) applied at its end.

If the adjusting nut 4 is over-tightened, unscrew it. lift washer 6 and tighten again. Secure the bracket to the side member with two self-locking nuts and flat washers and tighten the nuts with a torque wrench. Connect the ball pins to the pendulum arm.