Page 1 of 3

The basic repair work for a five-speed gearbox is similar to repairing a four-speed gearbox. Disassembly and assembly of the four-stage box is described in the article - "Gearbox repair".

For five-speed gearboxes, since 1992, the washer is not installed on the output shaft and the configuration of the output shaft and the hub of the V-gear synchronizer clutch has been changed. On the secondary shaft, the hub diameter was 28, became 25 mm; the width of the landing part of the hub has become larger and the landing diameter has been reduced from 28 to 25 mm.

These parts are not interchangeable with previously produced ones, therefore, when repairing a gearbox of an "old" design, we observe the following rules:

If the washer changes, then we put the output shaft and the hub of the "old" design;

If, instead of the secondary shaft or the hub, parts of the same name of a "new" design are installed, then we change them completely, that is, when replacing the hub, we also replace the secondary shaft and vice versa. In this case, we do not install the washer.

|

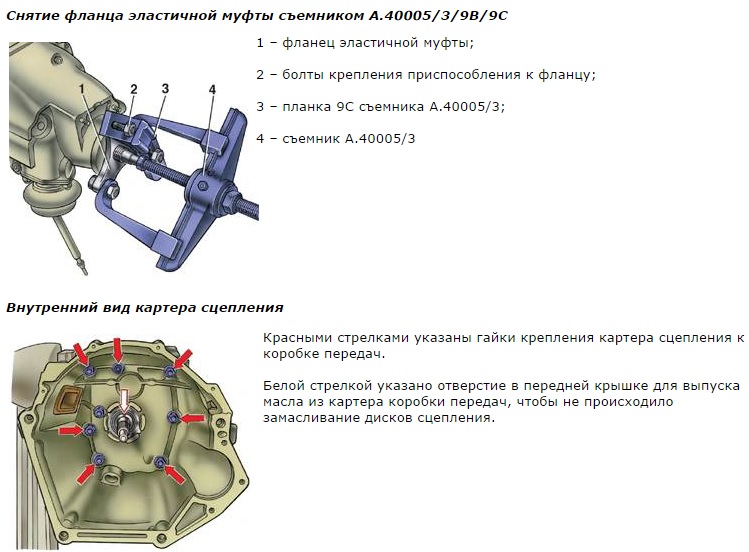

1.To facilitate removal and subsequent installation elastic coupling, tightly wrap it with tape. |

The flexible coupling can be clamped with a large band clamp |

|

We remove the flange of the elastic coupling, the gearbox support, the speedometer drive. |

|

|

|

|

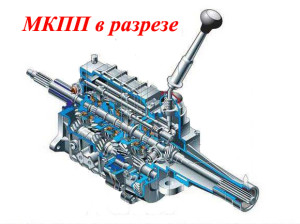

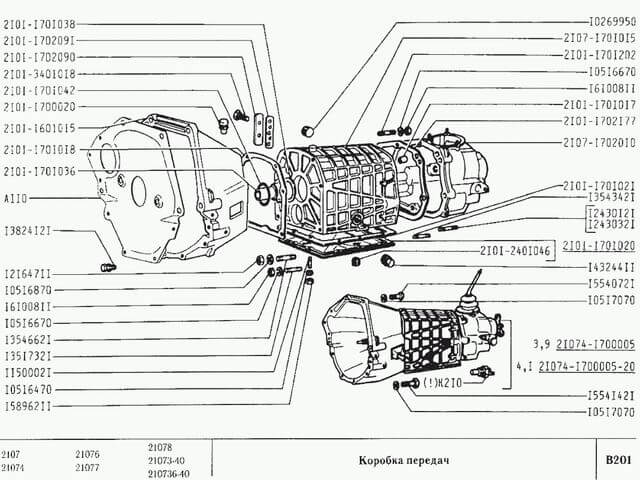

The domestic car VAZ-2107, popular among drivers, is equipped with a four- or five-speed manual gearbox. But the four-speed gearbox can only be seen on cars of the first production. Subsequently, the VAZ-2107 of all modifications was equipped with a five-speed manual three-shaft gearbox with a two-shaft cardan transmission that transmits engine torque from the gearbox to the driving rear axle.

Gearbox vaz 2107 5 mortar scheme

The five-speed gearbox is designed to improve engine performance, increase its economy and expand the speed range. This view the box is made on the basis of a four-speed, but due to the appearance of the fifth gear, some structural changes were made to the rear end of the secondary shaft and the rear end intermediate shaft... The gear ratios of the first four gears are identical to the four-speed gearbox. The fourth gear is also direct, and the fifth gear with a minimum engine torque allows maximum speed movement. Its gear ratio is 0.82.

The device of a five-speed gearbox in the VAZ-2107.

A car's manual gearbox is a rather complex device. In general, it consists of three main parts - shafts. Each of them has its own purpose:

- - primary (driving) shaft, on which drive gears and synchronizers equalizing their speed are mounted;

- - intermediate shaft

- - secondary (driven) shaft, also equipped with gears.

These mechanisms and assemblies are protected by a common body on three sides, and the handle of the gear control lever is located on top.

To represent the principle of operation of a five-speed gearbox, you should consider its structure in detail.

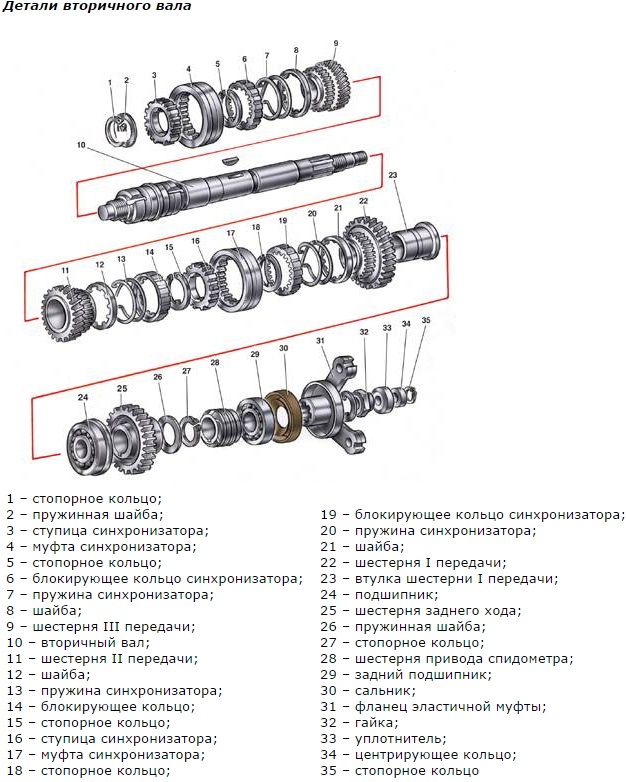

Primary shaft - a structure equipped with gears. It is mounted on a bearing located in the cavity of the gearbox housing.

Secondary shaft of manual transmission continues the driving shaft. The gears of the first three gears are fixed there. They all have different diameters, and it is due to this that the difference in gear ratios is achieved.

Table: values \u200b\u200bof gear ratios of a five-speed gearbox

| broadcast | value |

| the first | 3,67 |

| second | 2,10 |

| third | 2,0 |

| fourth | 1,0 |

| fifth | 0,82 |

The rotation of the secondary shaft is carried out not by one, but by three bearings, one of which is installed directly in the drive shaft, and the other two - inside the crankcase and directly in the rear housing cover.

Intermediate shaft also rotates on three ball bearings, and the gears form a single whole with it. This unit transmits the torque of a given value from the drive shaft to the driven shaft.

The reverse gear is mounted on a separate small shaft connected to the driven transmission shaft by means of several splines.

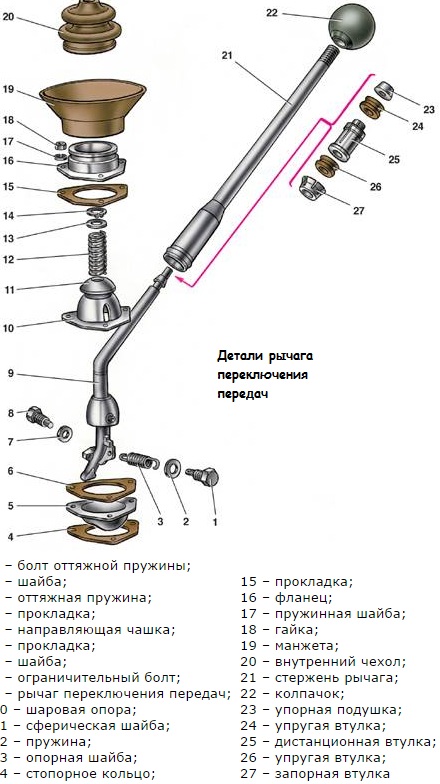

The driver is shifting gears by means of the so-called forks, driven by a lever, which is located inside the passenger compartment, to the right of the driver. When you change the position of the lever, its hinge engages with a recess of a certain rod, which is fixed with a fork on the other side. The fork itself is in the groove of the corresponding gear. When the shift lever is moved, the fork also moves, whereby the desired gear of the driven shaft meshes with a specific gear of the intermediate. Consequently, the rotation of the driven shaft of the box acquires the speed that corresponds to gear ratio connected gears.

When shifting to reverse, the fork makes contact with the reverse idler. To turn it on, you need to drown the gearshift lever down.

Filling hole for transmission oil in the box of the VAZ-2107 car is located on the left in the body and closed with a sealed stopper. To avoid oil leakage from the manual transmission pan, all bearings are protected by oil seals.

A mechanical five-speed three-shaft gearbox is a complex mechanism, so its disassembly and repair should not be done with your own hands and at home.

The gearbox is one of the most important units in the device of any mechanical vehicle, which makes it possible for the engine and the wheelbase to interact, as a result of which movement occurs. When the box for one reason or another becomes unusable, further full operation of the car is no longer possible. Domestic cars are no exception.

Russian automotive industry although it succeeds in selling cars budget class, but it cannot be called successful. FROM bunch, which has no equal in the number of claims against itself, frequent visits to the station maintenance, rapid corrosion of body elements, poor and unsightly interior - these eternal companions do not leave Lada from the moment of its production to this day.

The only advantage of the so-called "TAZ" among the people is the relatively low price, both for the cars themselves and for service. But in fairness, it must be said that when it comes to the powertrain, there are the least complaints from users. In particular, gearbox VAZ 2107it is famous, oddly enough, for its durability and the relatively small number of problems arising in terms of service.

At the same time, it would be unfair to say that repair of the gearbox VAZ 2107 - something out of the ordinary, and her work goes on flawlessly.

Of course, the technology of 6 or more gear shifting steps, and even more so with automatic selection, hardly made it to the VAZ 2107 - the engineers laid the good old mechanical five-stage transmission. However, it is unlikely that the rear-wheel drive old-timer of the auto world needs something more.

He does not claim to be sporting laurels, since the number of horses under the hood is only good for moving the car and maintaining a safe speed for the driver and passengers up to 120-130 km / h. The torque, although it is also quite small, but "5-s stupid»Perfectly recycles and transfers it to the wheelbase.

Simplicity is the key to success, as you know, and at least in this sense, designers automobile plant "VAZ" made the right decision with the "seven" box. In comparison with similar mechanisms in foreign cars, the box of the seven has no frills and focuses on a time-tested device. As practice shows, regular oil changeat Checkpointand neglect of fun such as sudden acceleration from a standstill can extend the life of the transmission up to several hundred thousand kilometers.

Of the obvious shortcomings of the box, we can note the noise it makes during operation. Its level cannot be reduced by any manipulation. And given the poor sound insulation of the VAZ 2107 interior, this can cause significant discomfort to everyone who is in it. However, if you use the car solely as a "workhorse" to get from point "A" to point "B", you can simply ignore it.

DEVICE

The entire transmission of the "seven Lada" is enclosed in a block that is closed on both sides with covers. The gear selector is located at the top. The work of the box is based on three shafts:

- primary;

- intermediate;

- secondary.

The primary actually protrudes with gears that rotate on a bearing in the crankcase, one piece. The secondary is its continuation: it has gears of the first, second and third speeds. They move along a given trajectory and thus interact with the gears of the intermediate shaft.

The magnitude of the torque directly depends on the diameter of the gears, which for various shafts in the gearbox for VAZ 2107 slightly different. The rotation of the output shaft takes place on bearings, one of which - roller - is located in front, and the rest - on the rear cover and in the crankcase.

The function of the intermediate shaft is the transfer of torque in the required amount between the secondary and primary, from the first of the named to the second, respectively. As with the primary, the countershaft itself and the gears form a single mechanism. The rotation is carried out on ball bearings. Blocks responsible for the fifth and reverse gearare located here.

On the left side of the box body there is a hole through which topping up and oil change transmissions. Airtight gaskets are located between the covers and the unit to minimize the risk of smudges working fluid.

IMPORTANT: the minimum amount of oil required for normal operation manual transmission for VAZ 2107 - 1.5 liters. Some car owners, in order to simplify the procedure, carry out filling directly at the junction of the selector with the box body. Of course, this is much easier than topping up the working fluid through the hole in the sump.

The shifting process itself is carried out using forks, which are activated by a lever. As soon as it changes its position, the hinge engages one end with a notch on the axle, and the other with the fork. Since the lever is responsible for moving the fork, this process causes the gears of the secondary and intermediate shaft... The transmission shifts when its torque circuit closes - then the secondary axle begins to move at a speed corresponding to the gear ratio.

REPAIRS

On VAZ 2107 5-step box, which, despite the comparative simplicity of its device, may become unusable for reasons classic for manual transmissions:

- wear due to natural reasons: high mileage, irregular operation and resource development constituent parts, inconsistency of weather conditions with the desired ones, and as a result - a decrease in the resource, etc .;

- non-compliance of the working fluid with the standards suitable for normal work transmissions;

- non-original spare parts included in the box;

- damage to the gearbox housing mechanical impact;

When it comes to the gearbox, even if it's a Zhiguli, the best option will commission diagnostics and servicespecialists at the service station. Good, renovate it will not cost too much, except in rare cases that require complete replacement the whole mechanism, when it will be more expedient to purchase the same new car.

SPECIFICATIONS

The car was produced from 1982 to 2013. The configuration of the VAZ 2107 provides for the presence of engines of small volume and power, from 1.3 to 1.7 liters. Minimal amount horse power - 64, maximum - 135.

All variations are equipped with five-speed mechanics, without exception. Acceleration time to 100 kilometers per hour varies from 13 to 17 seconds, depending on the internal combustion engine. Although the maximum permissible speed auto - 180 kilometers per hour, even the engineers themselves do not recommend exceeding the mark of 140. The danger is due to the lowest score on automotive standards safety (not the best location of the engine, fragile body materials, etc.), a high probability of skidding due to the low weight - 1040 kilograms - and rear-wheel drive.

Dismantling the gearbox from the car VAZ 2106, 2107.

Dismantling work, disassembly of the gearbox and renovation work - complex and time-consuming work that requires the necessary conditions, instrument and knowledge.

The vehicle should be installed on inspection pit, disconnect the wires from the storage battery.

The list of works includes the following actions:

- withdrawing the locking sleeve from the plane of the assembly by inserting a screwdriver into the locking hole of the sleeve;

- dismantling the lever rod; dismantling the damper sleeve; kickback of the cover fixing bolts, which are located on the bottom of the car and remove the lever with a seal;

- disconnect the pipe from the exhaust system;

- dismantling the starter and phased disconnection of the lamp wire (reverse);

- dismantling cardan transmission and flexible shaft;

- kickback of the clutch housing bolts using a socket wrench;

- disconnecting the clutch from the block;

- neatly removing the PP box.

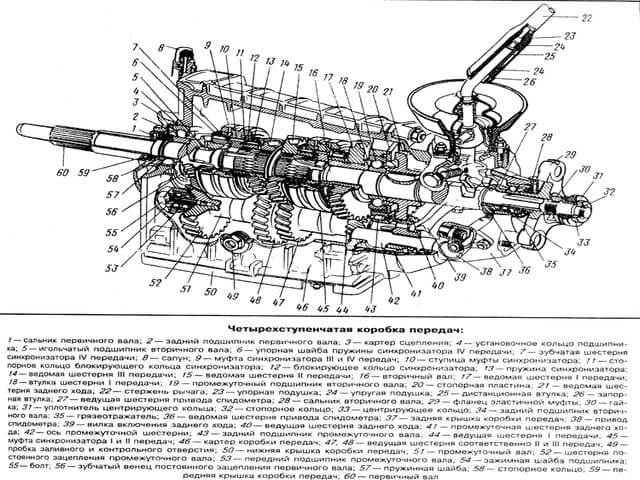

Disassembly of the box occurs in a strictly defined sequence.

Stages of disassembly and assembly of the box VAZ 2107, 2106:

- preparation of the workplace for disassembling the box, tool, container for small parts and fasteners;

- cleaning the four-stage box unit from adhered dirt and oil drips using a brush and kerosene or solvent;

- tool preparation (impact screwdriver, torque wrench, three-grip puller, fixing glue, shaft seals, gaskets and rags);

- removal of the release bearing clutch and the clutch fork (disengagement);

- disconnecting the propeller shaft and output shafts and removing the flange;

- disconnection of the engine mountings drive;

- removing the ball joint cuff on the shift lever;

- return of the nut of the receiving tube bracket using a 13 key (end);

- removing the bracket;

- unscrewing the nuts of the lower box cover (Key # 10);

- detaching and removing the back cover;

- carefully removing the cover to avoid damage and subsequent replacement of the inner gasket;

- a recess from the back cover of the V gear plastic plug;

- removing the thrust ring from the flow channel of the cover using tweezers, removing the bearings of the rear and fifth gear.

At the final stage of disassembling the gearbox, the auto vaz 2106 and vaz 2107 remain only:

- remove the shaft seal (secondary);

- press out the rear bearing;

- remove the secondary shaft ring.

Dismantling the transmission finished... You can start revising the unit for wear and tear, malfunctions - gears of the first and second gears, synchronizers, cracks and crunches, clutches of the gearbox signaling device, the condition of the clutch teeth, the gaps between them, reverse gears, forks with a stem, checking the state of spraying.

The assembly of the VAZ 2106 and VAZ 2107 gearbox is performed in the reverse order after the unit has been identified and worn out and replaced.

Repairs

Repair of the five-speed gearbox of cars VAZ 2106, 2107 is carried out in cases of observation of increased noise, heavy, fuzzy gear shifting. These factors signal that the box needs repair work.

There are many reasons for the incorrect operation of the checkpoint:

- wear of the hinge of the shift lever and its holes, manifests itself by spontaneous disengagement of the gear, and difficult shifting;

- wear on bearings, gear teeth or synchronizers;

absence or insufficient amount lubricant manifested by increased volume in operation and the presence of extraneous noise;

various types of deformation of parts; - loose crankcase fasteners, covers, wear on oil seals and gaskets lead to transmission oil leakage, which can lead to significant damage to the transmission.

To identify the causes, it is required complete disassembly of the checkpoint. After diagnosing and determining the cause of the breakdown of the gearbox, it is necessary to replace inoperative units and parts. Also, it will not hurt to replace the still working, but with a high level of wear of the gearbox assemblies.

We examine: clutch, crankcases, cover for cracks, surface roughness, holes, dents, etc.

Minor chips can be removed with sandpaper. Severe damage indicates replacement of defective parts. It is recommended to check the bearing fit for wear and mechanical damage... In case of damage, it is recommended to replace the crankcases.

Check the forks and shift rods, oil seals, bearings of the box VAZ 2108 VAZ 2109. If dents, roughness, holes under the clamps are observed, it is recommended to replace the rods. Check the condition of the gear shift forks. Concave forks, worn out, must be replaced.

Oil leakage through the oil seals, wear of the working edge indicates the need for urgent replacement of the unit. Appearance bearings of VAZ 2106, shells of treadmills and rolling bodies of the VAZ 2107 box, traces of pressure of rolling bodies, damage to bearing cages - is characterized as a defect and it is recommended to replace all units, as well as jammed gaskets with damage.

Transmission

The gearbox of the VAZ 2106 model is in constant motion, the elements of which it consists are continuously heated. To stop their rapid wear, gear oil is poured into the gearbox.

The required volume of oil for the normal functioning of the box is 1.35 liters. The mechanism must be regularly inspected for oil leaks. Checking the fluid level is carried out, depending on the service life or mileage - once a year, or once every 15,000 km of run. Replacement lubricating fluid, held at leastthan once every 5 years, or once every 50,000 kilometers.

The mechanisms connecting the engine to the driving wheels are called transmission mechanisms. Gearbox, clutch, power take-off, transfer case, drive axle, differential and cardan shafts are part of the vehicle's transmission system.

The gearbox is responsible for the torque, speed and direction of the vehicle.

The clutch provides a smooth transition of gear shifting in the box due to the short-term disconnection of the engine from the box.

Cardan and main gear boxes transmit torque to the wheels of the car.

The differential ensures the distribution of torque between the wheels.

Car transmissions are divided into the following types:

Mechanical... The simplest type of transmission, with a manual gearbox containing only gear and friction devices. The transmission type is distinguished by high reliability, ease of operation and maintenance, small dimensions and high efficiency.

Electromechanical... Converts mechanical energy into electrical energy and vice versa. Provides automatic changes in torque and traction force over a wider range. Cons - heavy weight, dimensions and high cost.

Hydromechanical transmission automatically changes the torque, equipped with an automatic transmission. The disadvantages include low efficiency, the presence of a special cooling system and large dimensions.

Hydraulic the transmission provides shockless gear shifting using a special fluid coupling. The disadvantage is the presence of a separate fluid coupling.

Transmission

The gearbox (five-speed, four-speed) is one of the units in the vehicle design, with the help of which the transmission of power from the engine to the drive wheels in the form of torque is regulated. One of essential functions Gearbox - disconnect the transmission of torque from the transmission, which allows the engine to operate on idlingwithout driving the vehicle.

AT mechanical box This function is driven by the clutch. Powered by mechanical action (manually). This type of gear shifting is considered the most reliable. It is easy to operate and has a fairly high power. The disadvantages are the loss of the efficiency of the four-speed box due to the friction of the gear, constant manual switching lever, pressing the clutch - a mechanism for connecting or disconnecting the engine to (from) the transmission system (mechanical box).

Automatic five-speed gearbox, gear shifting is carried out automatically, depending on the selected driving mode. The driver sets the direction of movement with a lever (forward or backward). They do not differ in increased power.

The "Robot" checkpoint is developed on the basis of "mechanics", but the control here is mechanical. Vehicle equipped robotic box gear, adaptable to any driving style. In the "robot" the efficiency is increased, since two shafts were used during the development. The manual transmission is distinguished by its compactness and high level of reliability.

Cars equipped with a variator have seen the world recently. Smooth speed switching is available. The car is easy to drive. The CVT is not yet available for trucks and miniature vehicles.

"Transmission" is carried out by a set of gears, which, working in sync at the same time, regulate the ratio of engine speed to wheel speed. The term describes each transmission speed. AT automatic box the electrical part automatically selects the correct shaft with gears to optimize the transmission of torque. In a manual transmission, the driver independently selects the required speed. Gear ratio: This is an indicator of the ratio of the driven shaft speed to the driving speed.

Converting a four-speed gearbox to a five-speed one

How to convert a four-speed gearbox to a five-speed gearbox in VAZ 2106,2107 cars?

The primary shaft of the four (mortar) VAZ 2106 has 17 teeth on the main gear, each shaft corresponds to an intermediate one. The intermediate shaft is characterized by 28 teeth and modulus.

The shaft of the five (mortar) VAZ 2107 does not differ in the configuration of the gears. The only difference is a threaded hole, used to attach the additional gear unit. It can be purchased separately. Details are versatile.

Converting a gearbox from a 4-speed to a 5-speed is quite realistic. The principle of operation and the main details in the boxes of the VAZ 2106, 2107 do not have significant differences. Mechanisms, gear change sequence, crankcase, input and output shafts and their fasteners are identical.

In order to add a fifth gear to a 4-mortar, it is recommended to prepare the following parts in advance:

- intermediate and secondary shafts;

- a block of gears for the fifth gear (includes - hubs, couplings, synchronizer gears, fifth gears, reverse gears, oil washers);

- set of rods;

- fifth gear and reverse gear fork;

- mechanism for selecting the "transfer" position.

- The axis of the intermediate reverse gear in the four is equipped with two supports, one of which is located in the crankcase of the box, the second is on the rear cover. In the top five, there is no support on the lid. We leave the gear as our own - the axial guide is replaced.

The cover of the four must be replaced, because the fifth gear into it does not fit. - The drive unit for gear shifting requires replacement,

- the support of the power unit is modernized,

- gear block bearing,

- reverse signal connection sensor.

The VAZ 2107 gearbox is one of the main parts of the vehicle. If the checkpoint is faulty, then you should not leave the track, as this can lead to emergency... Due to the fact that the device of the VAZ 2107 gearbox is quite simple, it will not be difficult for people who understand at least a little about cars to fix it on their own.

Generally speaking, the gearbox repair conditionally consists of two stages:

- The checkpoint is removed from the car;

- Directly start of the renovation;

Each phase has its own sequence of actions. We will consider them for each stage separately.

On a note. The process of repairing a conventional gearbox and repairing a gearbox 5 VAZ 2107 is the same.

The main problems of the VAZ 2107 gearbox

There can be many gearbox faults, but the most frequent ones are:

- Noise at the checkpoint. The reason may be wear of bearings, lack of oil in the gearbox;

- Changing gears is difficult. A common reason there may be a breakdown of the lever, which is responsible for changing speeds;

- Leakage of oil. Reasons: worn oil seals, loose crankcase covers.

Of course, these are far from all the problems that may arise with the gearbox.

First step. Removing the gearbox from the car

- the starter is removed;

- the "cross" is removed;

- the support cross member of the power device is disconnected;

- it is necessary to remove the flexible shaft, which is attached to the speedometer drive;

- the hydraulic cylinder must be separated from the crankcase. Important! The hose connected to it does not need to be touched;

- remove the bolts that secure the clutch housing cover using a ten key;

- it is necessary to install a support under the checkpoint;

- it is necessary to take an extension cord and put it on a key 19, end type;

- using a key and a "cross" hinge, you need to unscrew the bolts securing the cylinder block with the clutch;

- using a screwdriver that was inserted into the gap, it is necessary to squeeze the clutch from the cylinder;

- remove the starter from the direction bushings;

- gearbox input shaft vaz 2107 it is necessary to remove from the hub of the driven disk;

- we displace the primary type shaft from inside the bearing ring, which is in the crankshaft;

- and finally, remove the gearbox from the car.

Second phase. Disassembly and direct repair

Before starting the repair, it is necessary to clean the outer part of the gearbox using a brush and rinse it with kerosene. Now you can start. The plug is removed from the checkpoint, disengaging the clutch and release bearing in the sleeve. Separate the secondary shaft from the EF cardan shaft and disconnect the EF edge from the secondary shaft. Then we detach the whole block power unit... We carry out the extraction of the speedometer drive.

- It is necessary to remove the cuff from the ball joint;

- Unscrew the three fastening nuts that secure the shift lever to the rear housing;

- The sealing gasket is removed from the stud;

- Using a socket-type wrench, the nuts that secure the supports (bracket) of the intake pipe are loosened;

- This support is removed and the bolt that is between them is removed;

- The nuts that fasten the cover at the back must be unscrewed with a thirteen key;

- Using a 10 socket wrench, unscrew 10 nuts securing the bottom cover of the box;

- Then the lid is removed and the gasket is removed from under it;

If the nuts are turned out at the same time as the studs, then it would be wise to use fixing glue. Before applying it to the thread holes and studs, it is necessary to pre-wash all of them with a solvent. After completing this procedure, you need to take a 30 wrench and unscrew the nut that secures the back cover. You can see it inside the crankcase itself.

Then you need to remove the back cover. Important! It is necessary to put the second gear. We take out the plug, made of plastic, which is located on the back of the lid, using tweezers or tweezers, you need to get the thrust ring. And finally, we take out the secondary shaft ring, which is located inside.

Sometimes it becomes necessary to replace bearings. So, the replacement of the gearbox bearings of the VAZ 2107 will be carried out according to the following algorithm:

- The retaining type ring is removed from the cage located outside;

- Using a puller, the ring is removed;

- Then we take out the old bearing and insert a new one, after which we put the retaining type ring in place.

This completes the disassembly of the vaz2107 gearbox. All unusable parts can now be replaced.

2. Having unscrewed three nuts with two “19” keys and removed three bolts, remove the coupling.

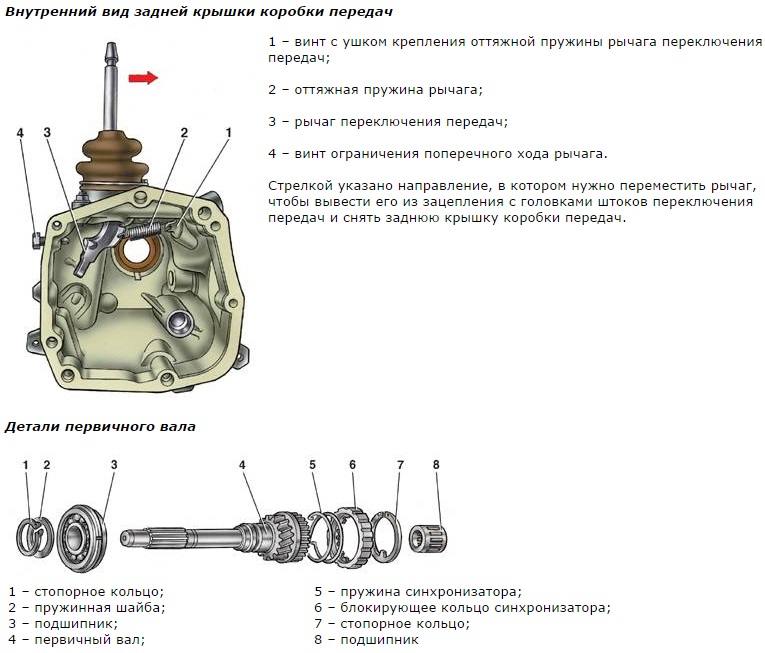

2. Having unscrewed three nuts with two “19” keys and removed three bolts, remove the coupling. 3. Using the "10" wrench, unscrew the three nuts securing the ball joint of the gear lever and ...

3. Using the "10" wrench, unscrew the three nuts securing the ball joint of the gear lever and ... 4 ... remove the lever from the studs of the rear cover of the gearbox.

4 ... remove the lever from the studs of the rear cover of the gearbox. 5. Using the "27" key, turn off the light switch

5. Using the "27" key, turn off the light switch